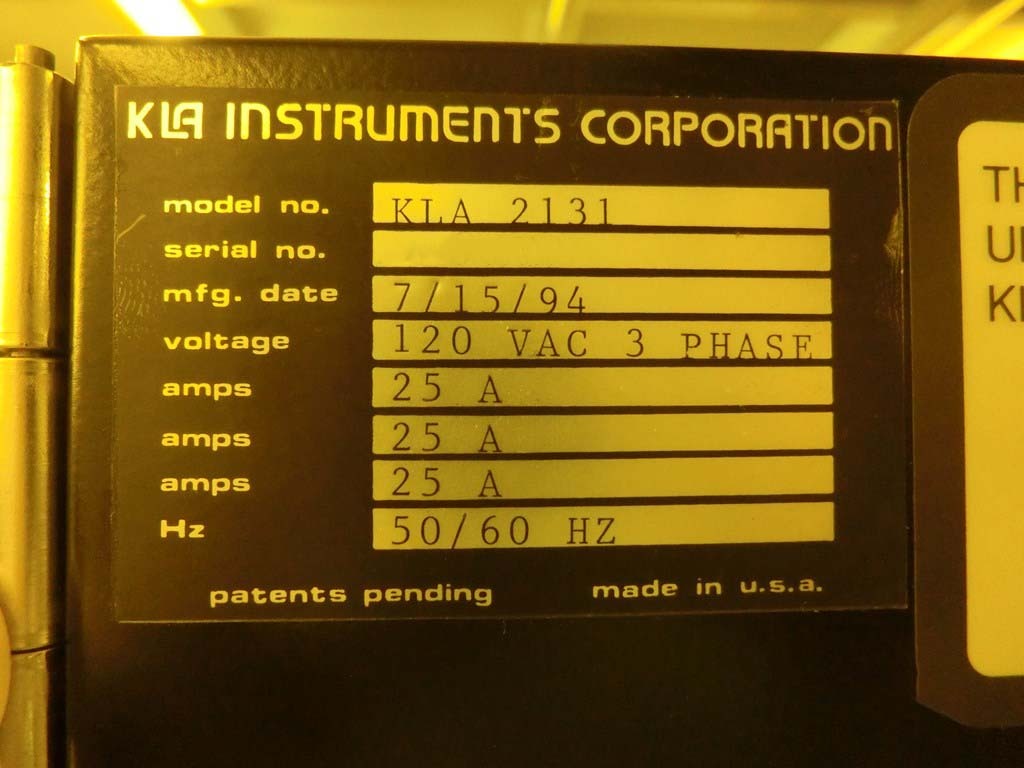

Used KLA / TENCOR 2131 #293587951 for sale

URL successfully copied!

Tap to zoom

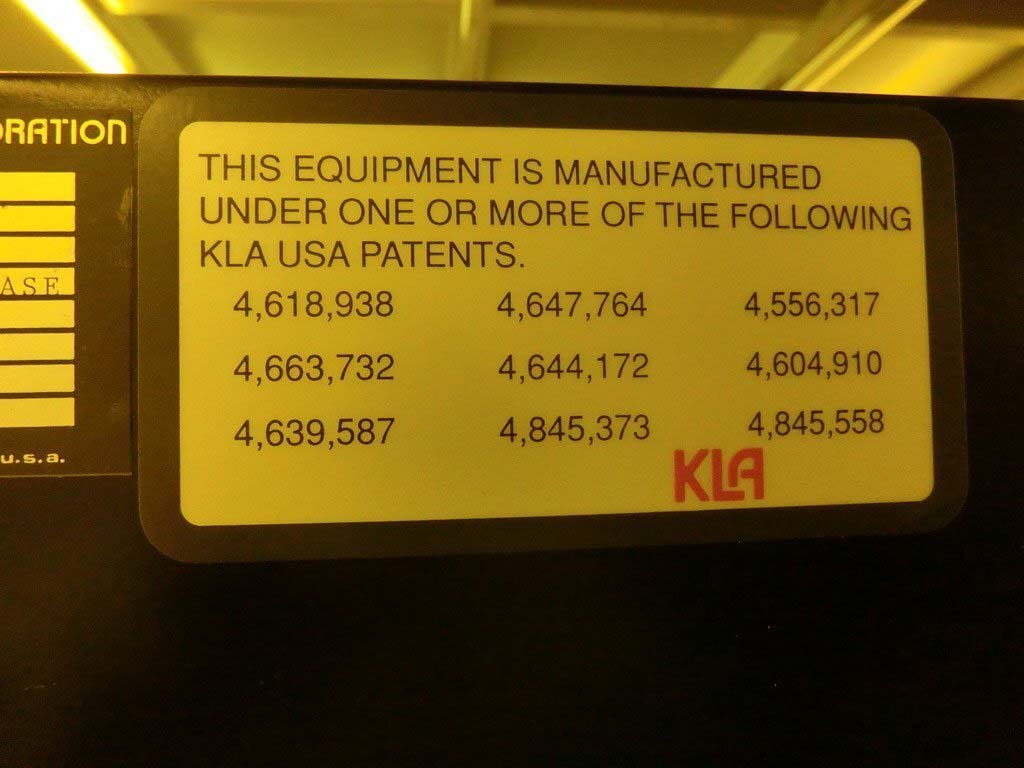

KLA / TENCOR 2131 mask & wafer inspection equipment is a multi-functional system designed for the inspection of IC (integrated circuit) masks and wafers. The unit combines a top-notch optical imaging station and advanced defect detection algorithms to provide a fast, accurate and high-resolution inspection of masks and wafers. The machine features a state-of-the-art optical imaging station that is equipped with multiple DCI-LX cameras and advanced illumination sources. The cameras are used to capture high-resolution images of the masks and wafers. The illumination sources can be used to collect scattered light from the samples to detect the presence of opaque defects on the wafer surface. The tool's advanced defect detection algorithms can be used to detect missing polysilicon lines, eroded vias and opens on the IC masks and wafers. KLA 2131 asset also features advanced data analysis capabilities. The model can automatically process images taken of the IC masks and wafers to identify patterns, detect anomalies, and extract statistical information. This information can be used to assess the quality of the IC masks and wafers and to eliminate potential defects. The equipment can also be used to measure the critical dimensions of IC circuits on the masks and wafers. The system is also capable of automated wafer defect classification. This feature allows the unit to automatically classify defects as either isolated, clustered, linear or extended. This information can be used to determine the severity of the defects and to prioritize corrective actions. TENCOR 2131 machine is designed for use in a production environment and is capable of operating at a high throughput rate. It can be connected to a factory's production control tool, which allows it to control the production line in real time. The asset also features an extendable defect repository, which can be used to compare current results against historical results. This feature allows for a more comprehensive understanding of the defects on the IC masks and wafers. 2131 mask & wafer inspection model is an advanced and powerful solution for the inspection of IC masks and wafers. It combines a top-of-the-line optical imaging station, advanced defect detection algorithms and automated wafer defect classification to provide fast and accurate results. The equipment also features a extendable defect repository and can be connected to a production control system, allowing it to operate at a high throughput rate.

There are no reviews yet