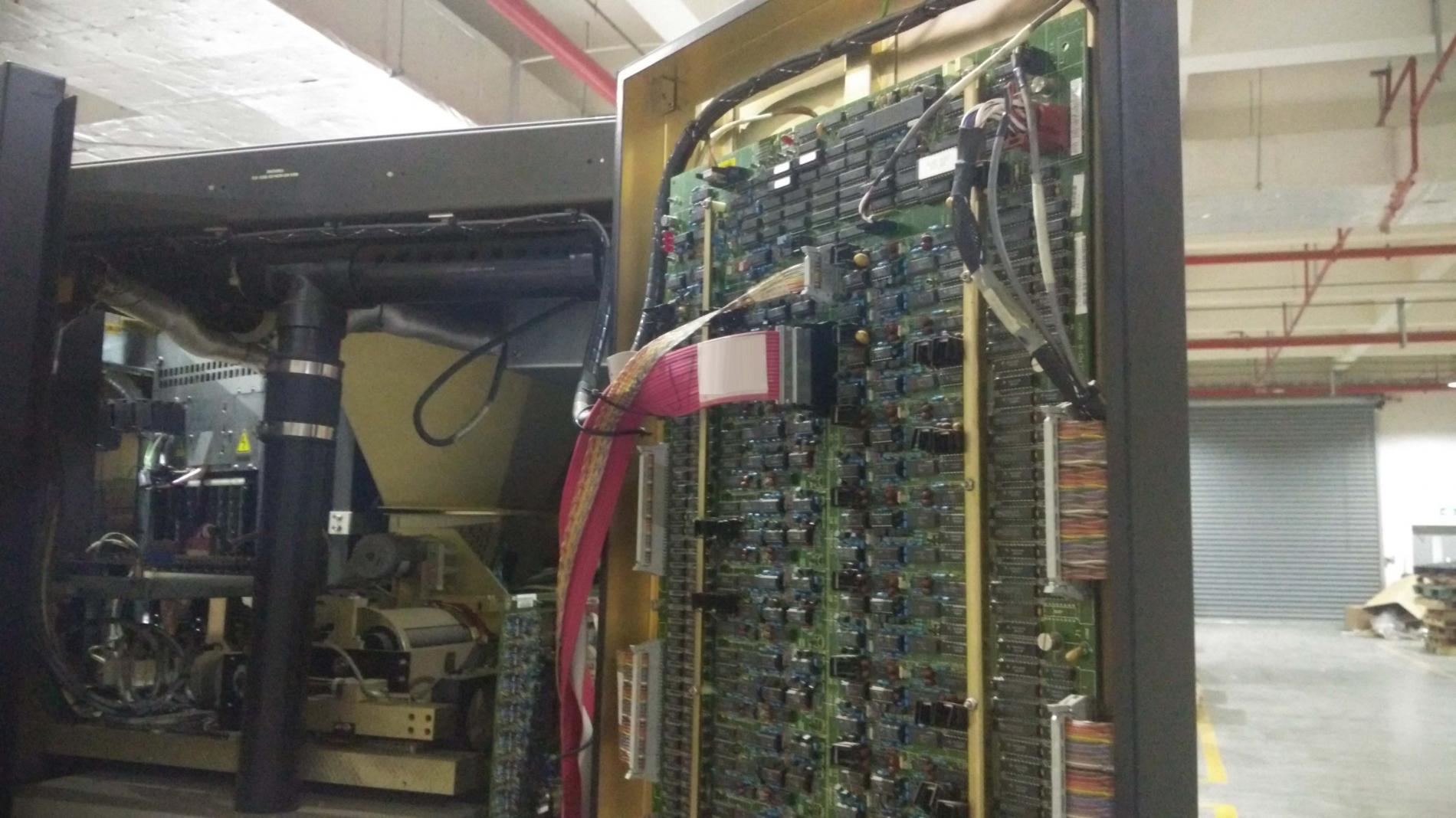

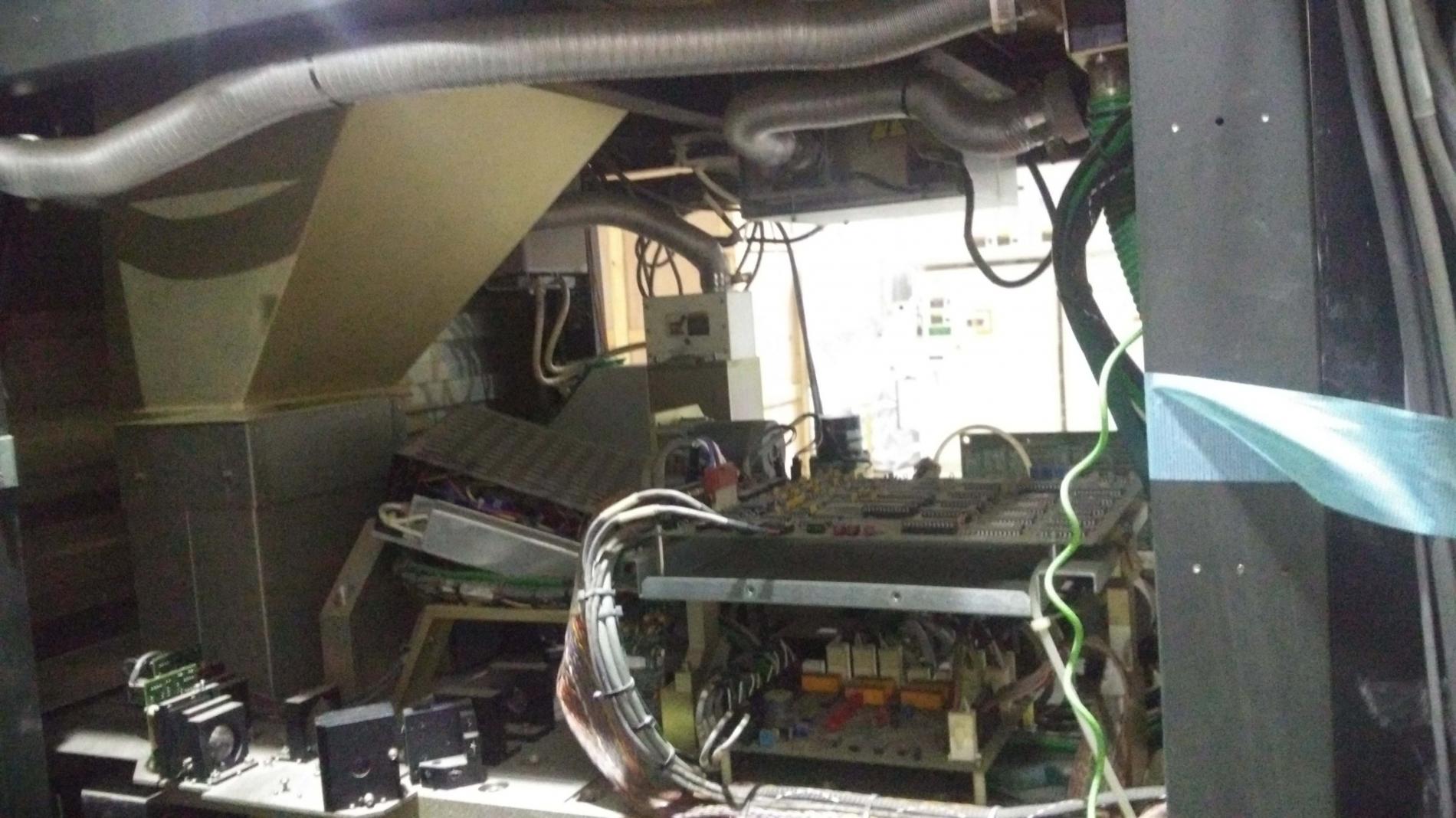

Used KLA / TENCOR 2131 #9186639 for sale

URL successfully copied!

Tap to zoom

KLA / TENCOR 2131 is a mask and wafer inspection equipment. It is an automated, computer-controlled device which provides ultra high-resolution imaging for both mask and wafer defect inspection with advanced high-speed measurement, optical and statistical analysis software. Advanced optical technologies provide superior image detail and image recognition capabilities for semiconductor masks and wafers. The optics employs a laser illumination system with a high-resolution CCD (charge-coupled device) camera, providing clear defect images. It includes a low-noise linear diode array and a high-resolution air-spaced zoom lens. The camera unit can magnify the inspected item up to a factor of 256X and has a maximum line and space measurement of 0.12 microns, providing sufficient resolution and sensitivity to perform small feature critical defect detection. KLA 2131 has a multiple sample stage that can be isolated in order to provide a clean and dust-free environment. Its automated vision machine provides automatic detection and identification of defects that go beyond traditional imaging. It can also analyze weak defects, such as bridging, by continuing to scan after a defect is detected. The tool combines an array of advanced software applications to provide comprehensive image analysis and defect classification. It includes a comprehensive suite of advanced optical tools for defect characterization, such as defect classification, edge detection, and polarity analysis. It also includes a variety of statistical and visualization tools that provide useful measures of defect distribution. TENCOR 2131 inspection asset offers high productivity and precision, with rapid defect identification and defect classification to classify and report defects accurately. Its advanced software is designed for ease of use, with a graphical user interface that enables users to quickly and easily monitor, analyze and review data. Overall, 2131 is a powerful mask and wafer inspection model, providing high-resolution imaging, advanced image analysis and defect classification capabilities, and superior software capabilities. Its combination of advanced optical and software technologies makes it a reliable and cost-effective solution for semiconductor inspection.

There are no reviews yet