Used KLA / TENCOR 2132 #139716 for sale

URL successfully copied!

Tap to zoom

ID: 139716

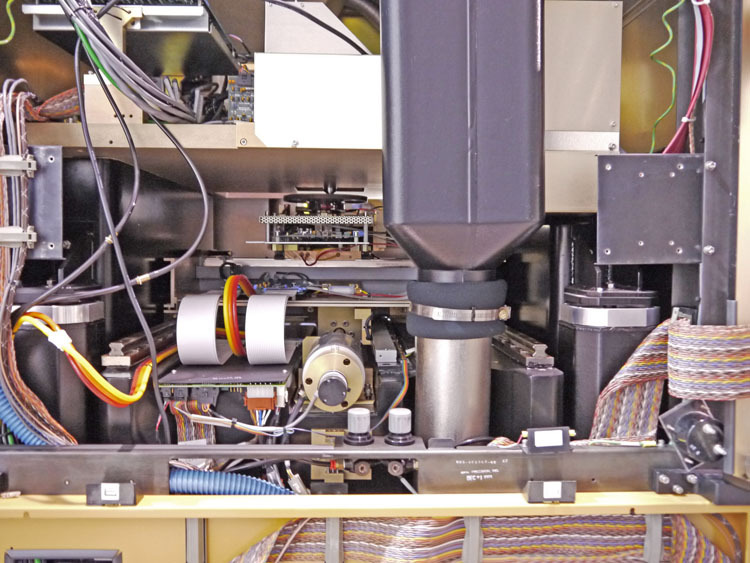

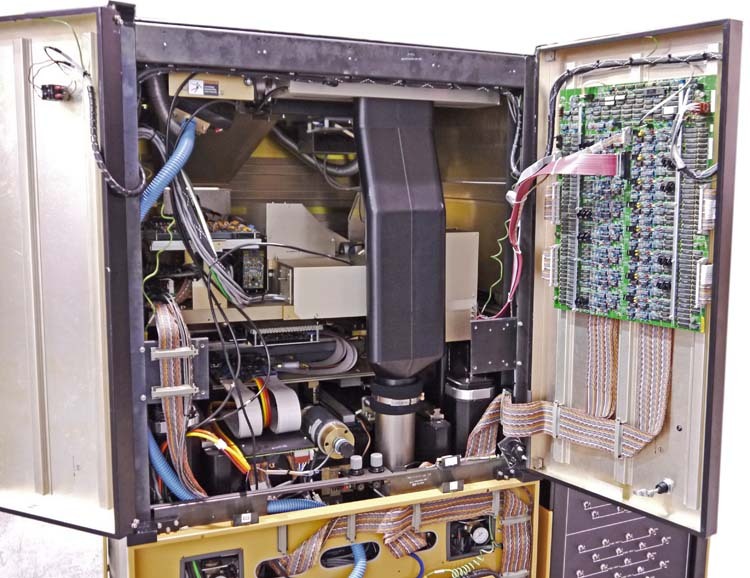

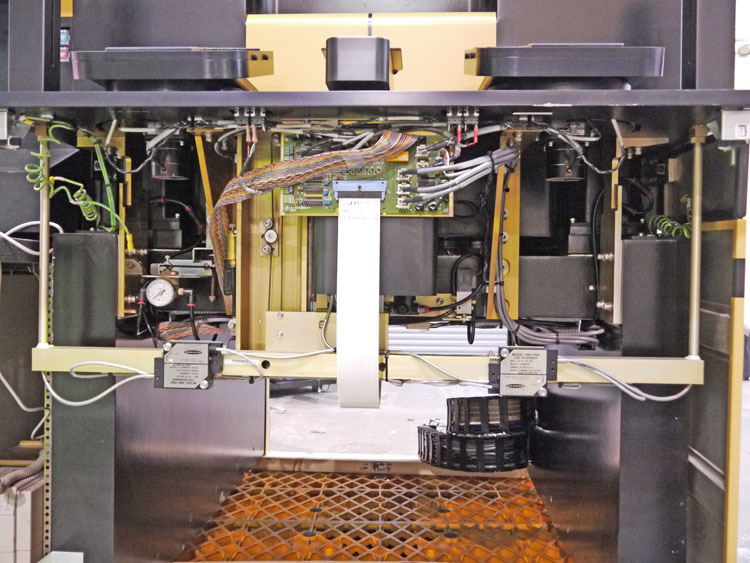

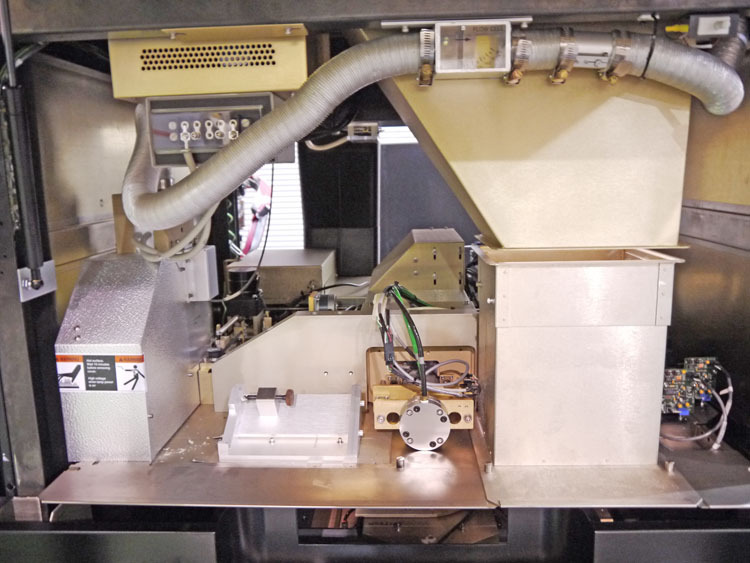

Wafer defect inspection system

Includes:

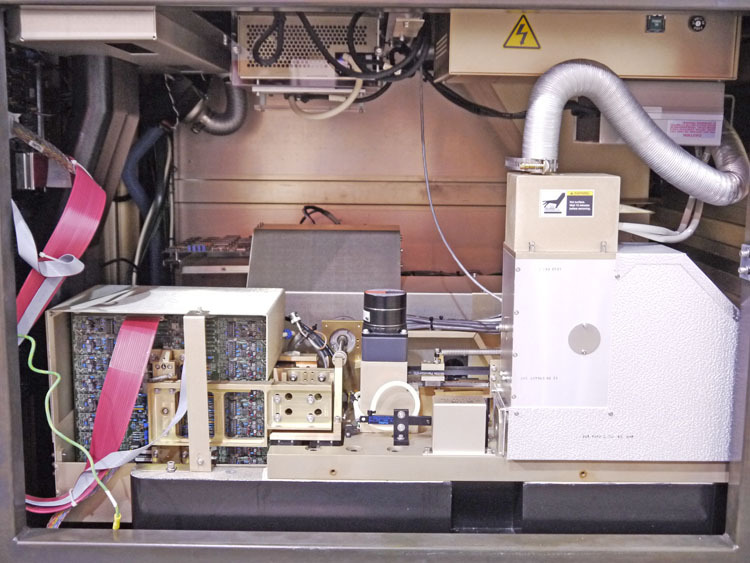

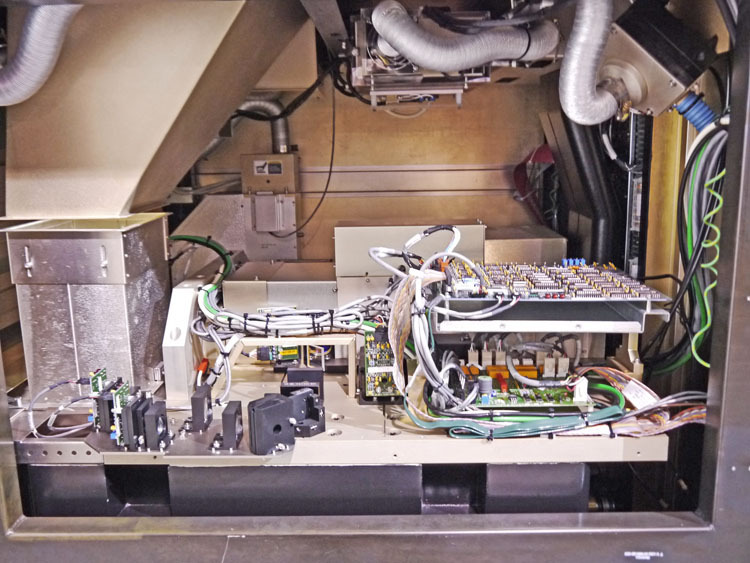

KLA / TENCOR 2132 wafer inspection unit (primary)

KLA / TENCOR 2132 wafer inspection unit (secondary)

KLA / TENCOR 2552 data analysis station

KLA / TENCOR 2132 power line conditioner

Specifications:

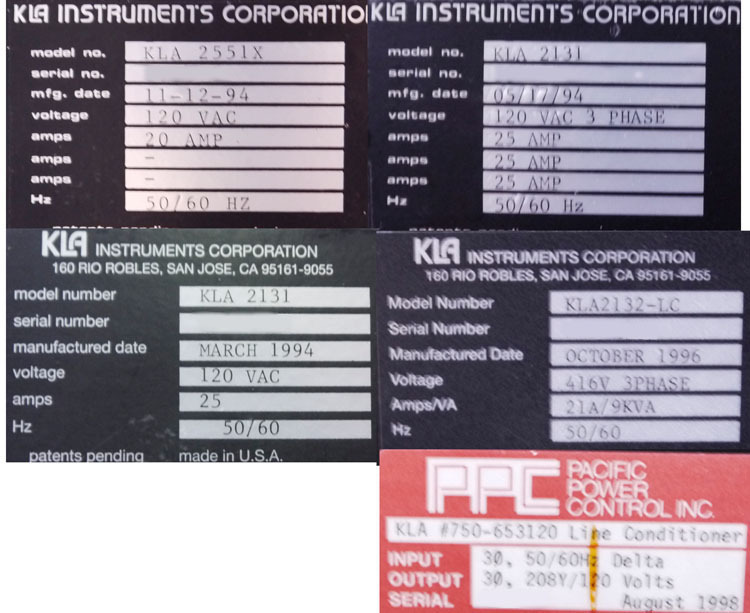

KLA / TENCOR 2132 wafer inspection unit (primary):

Label model: KLA-2131, front panel reads "2132"

Chuck installed: 8"

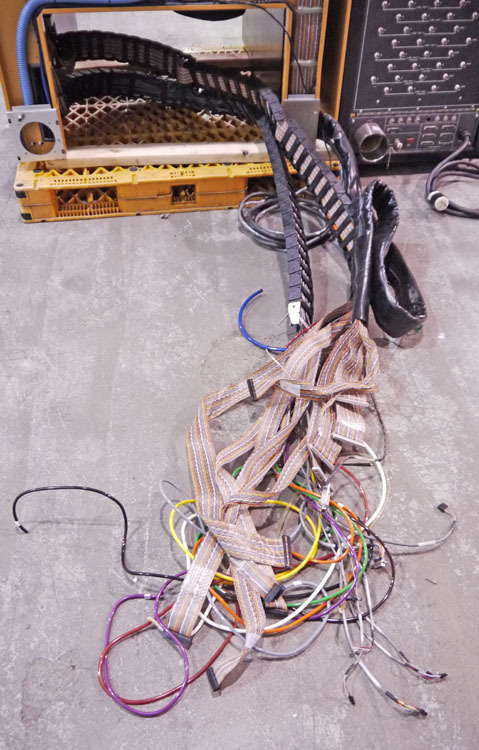

Power cable intact, all other cables cut

Front upper panel cover shocks / struts are worn

Missing: PC, 1-2 body panels

Power rating: 120VAC, 25A, 50/60Hz

1994 vintage

KLA / TENCOR 2132 wafer inspection unit (secondary):

Label model: KLA-2131, front panel reads "2132"

Body panel does not fully mount

Power rating: 120VAC, 3-phase, 25A, 50/60Hz

1994 vintage

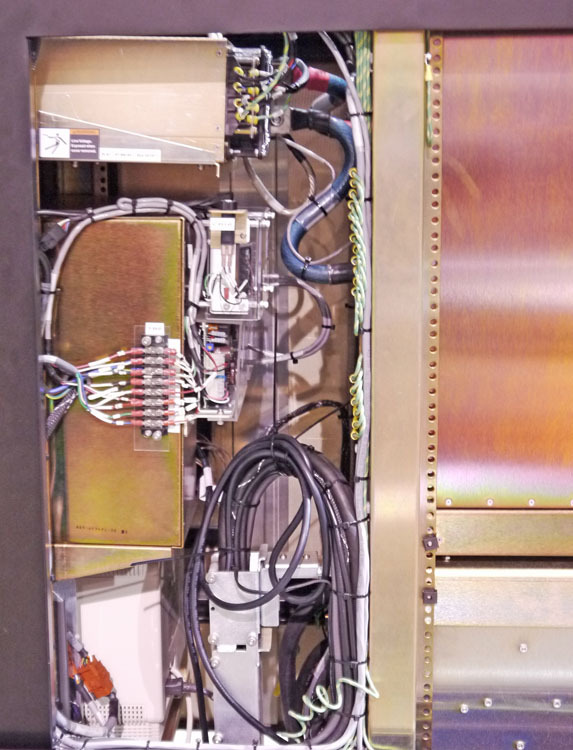

Components:

KLA PC/IF 486/66 PC system, p/n 750-660859-00

Dual monitors

Keyboard

Trackball

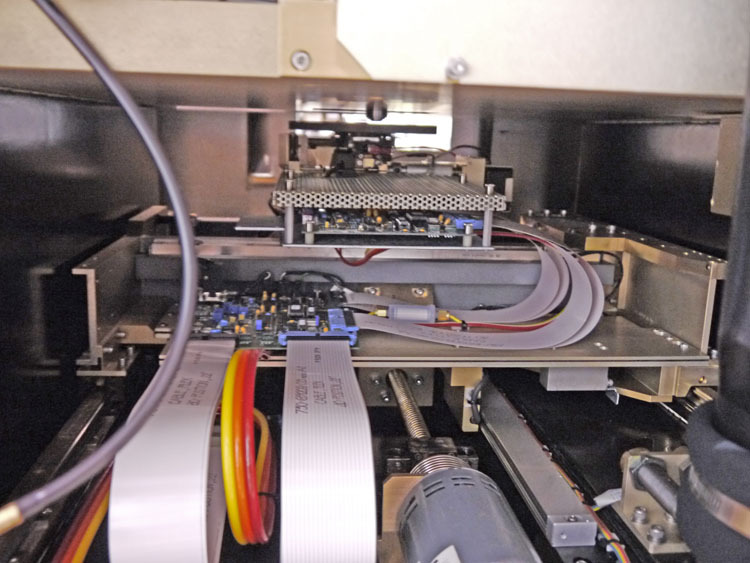

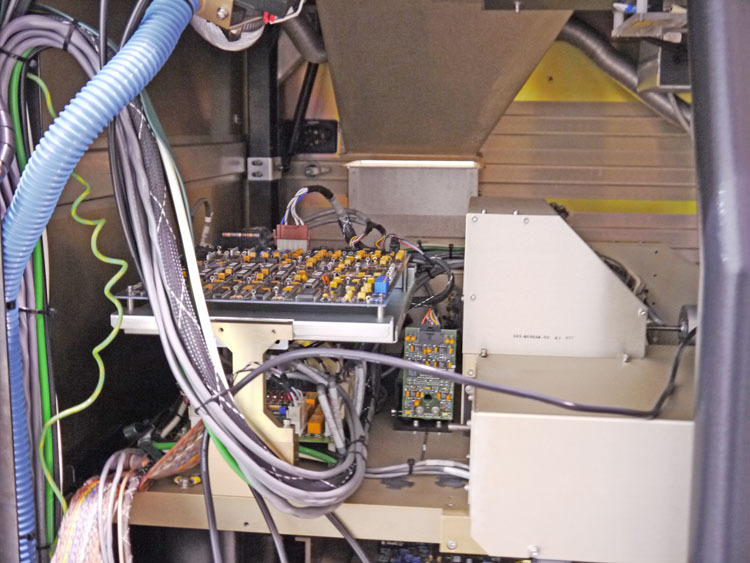

Modules installed:

KLA PC/IF 486/66 PC system, p/n 750-660859-00

KLA Memory Controller Phase 3, p/n 710-658232-20

FAB, p/n 710-658085-00

(2) Mass Memory 2 Phase, p/n 710-658051-20

(2) KLA CornerTurn 3, p/n 710-655651-20

(2) Y-Interpolator, p/n 710-658172-20

(2) X-Interpolator, p/n 710-658177-20

UNIQUENESS Processor, p/n 073-658045-00

Alignment Processor Phase 3, p/n 710-658041-20

Alignment Processor (AP1), p/n 710-65803620

Defect Filter (H.R.), p/n 710-659724-00

Defect Processor Phase 3, p/n 710-658075-20

KLA DP, p/n 710-650099-20

KLA DD, p/n 710-650044-20

KLA DF FAB PH3073, p/n 073-65836-00

IB Module

RIF Module

KLA / TENCOR 2552 data analysis station:

Label model: KLA-2551X, front panel reads "2552"

Power rating: 120VAC, 20A, 50/60Hz

1994 vintage

Components:

INTEL XBASE8TE8F-C PC computer tower

APC BackUPS

Dual monitors

Keyboard

Trackball

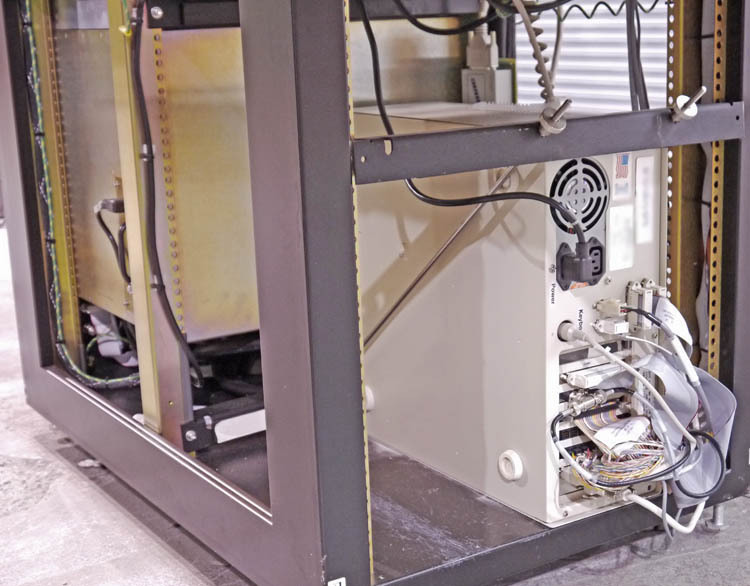

KLA / TENCOR 2132-LC power line conditioner:

P/N: 750-653120

Power rating: 9kVA, 416V, 21A, 3-phase, 50/60Hz

Input: 3-phase, 50/60Hz

Output: 3-phase, 208V/120V

1996 vintage

System currently de-installed.

KLA / TENCOR 2132 is a full-featured, automated mask and wafer inspection equipment. It features advanced, high-performance sensors and advanced imaging technology for high-precision, accurate inspections. The system utilizes bright lines, bright defects, and dark defects imaging sensors with regions of interest, improved defect sorting and classifying, and high-speed automated defect review and defect disposition. The unit provides unsurpassed defect identification and accurate defect disposition for up to 60 wafers per hour. It is a non-contact, non-destructive machine, which ensures wafer-to-substrate integrity throughout the inspection process. With its sophisticated sensor technology, the tool is capable of analyzing a variety of substrates, including silicon, photoresist, glass and ceramics, with a size up to 300mm. The advanced imaging technology of the asset incorporates a variety of imaging modes, enabling the inspection of any grade of semiconductor wafer. High-resolution images of the wafer surface are captured through a variety of lenses and optical presets, enabling a comprehensive overview of the wafer quickly and easily. Three types of imaging modes are available for task-specific inspections: high magnification images, planar images, 3D images. The model also offers improved defect sorting and classifying capabilities. By combining bright line, bright defect, and dark defect images with light from different angles, the equipment can characterize defects with a high degree of accuracy. Defects are classified automatically in real-time and sorted into groups based on the severity of their nature. With the advanced 3D defect analysis module, a detailed 3D map of wafer surface defects can be created. KLA 2132 is an invaluable tool for detecting and disposing of defects with increased precision and accuracy. With its robust features, it helps to boost yield and reduce wafer scrap for a variety of wafer inspection needs.

There are no reviews yet