Used KLA / TENCOR 2132 #9159041 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9159041

Wafer Size: 6"

Vintage: 1996

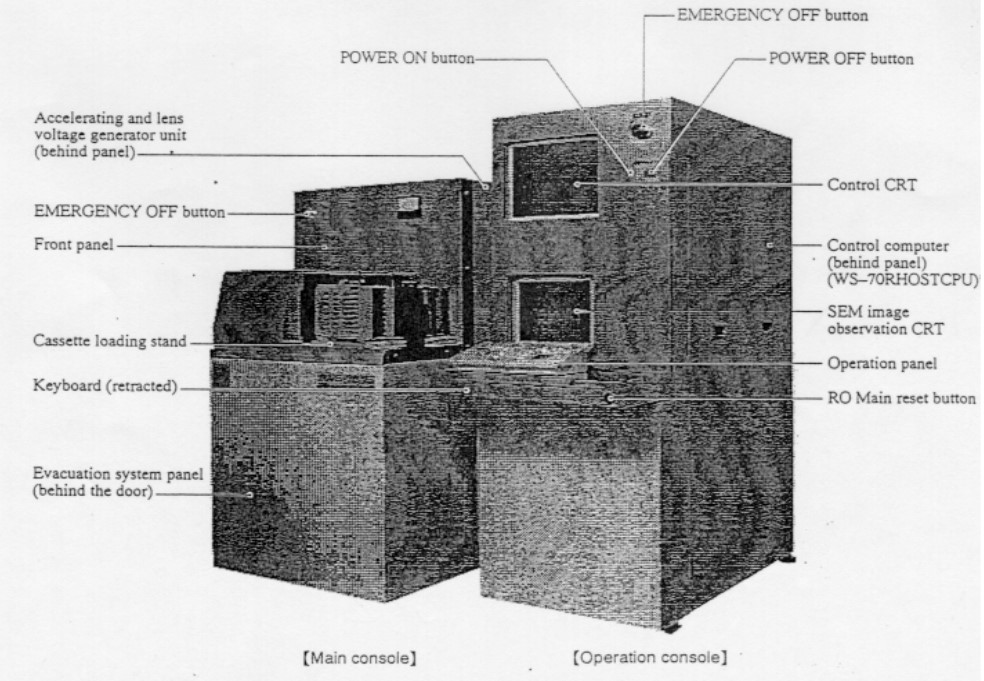

Wafer inspection system, 6"

Scan machine:

A mechanical arm

Two cassette holder

The main operating machine:

Two monitor

Keyboard, mouse

Stage operating lever

1996 vintage.

KLA / TENCOR 2132 is an optical inspection equipment specifically designed for mask and wafer inspection. Combining advanced light-based imaging technologies and software, it provides a comprehensive and high-precision analysis of the mask and wafer surfaces. The system consists of a number of individual components. A high-resolution camera module is used to collect image data of the masks and wafers. The camera module is then connected to a precision frame scanning unit which moves the camera and sample in predetermined pattern in order to acquire multiple images from different angles or orientations. A high-precision laser spot positioning machine is used to acquire and analyze sample features in both the x and y axis. The laser spot features are then automatically registered and aligned with the imaging tool for greater accuracy. Once the data has been acquired, the information is transferred to an analysis computer. This analysis computer processes the data and performs a variety of different inspections including particle detection, texture measurements, voltage contrast, spectral selection, mask inspection, and wafer inspection. It can detect extremely small features, flaws and defects, and identify ANY type of problems that are specific to the masks and wafers. KLA 2132 provides industry-leading speeds and resolutions and offers class-leading repeatability. It is capable of measuring minimum clearances of 5 microns and can detect particles as small as 1 micron. It can also accurately measure pin-to-pin clearances of 3 microns. Furthermore, the asset is also equipped with a range of advanced features, such as automatic alignment, automated zone inspection, automated die and lot identification, automated defect recognition, and in-depth data analysis capabilities. All this ensures that every piece of data is thoroughly inspected and analyzed, and that defects can be rapidly identified, catalogued and reported. TENCOR 2132 is a truly advanced model that can provide reliable inspection capabilities for mask and wafer inspection. It is the equipment of choice for a wide range of industries, with its superior speed and accuracy providing assurance that any mask or wafer inspected by it will be to the highest possible standards. In short, 2132 is the ideal solution for mask and wafer inspection.

There are no reviews yet