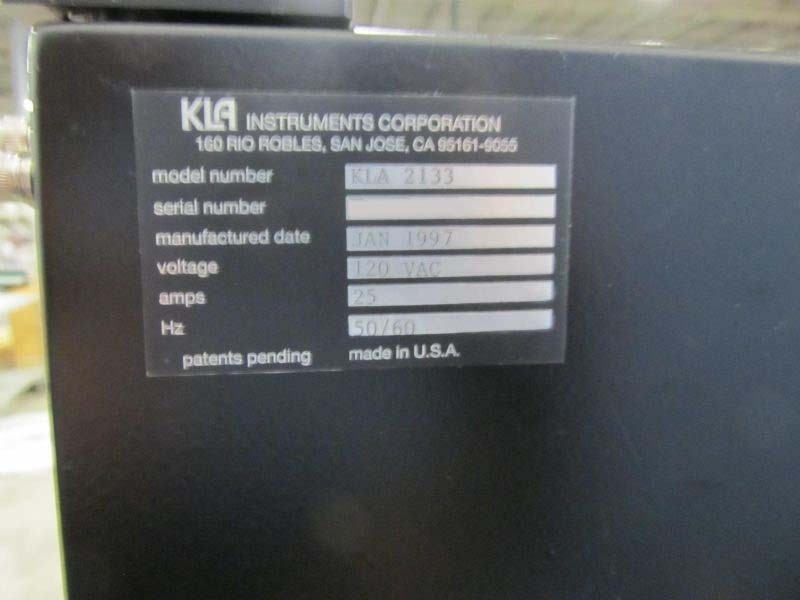

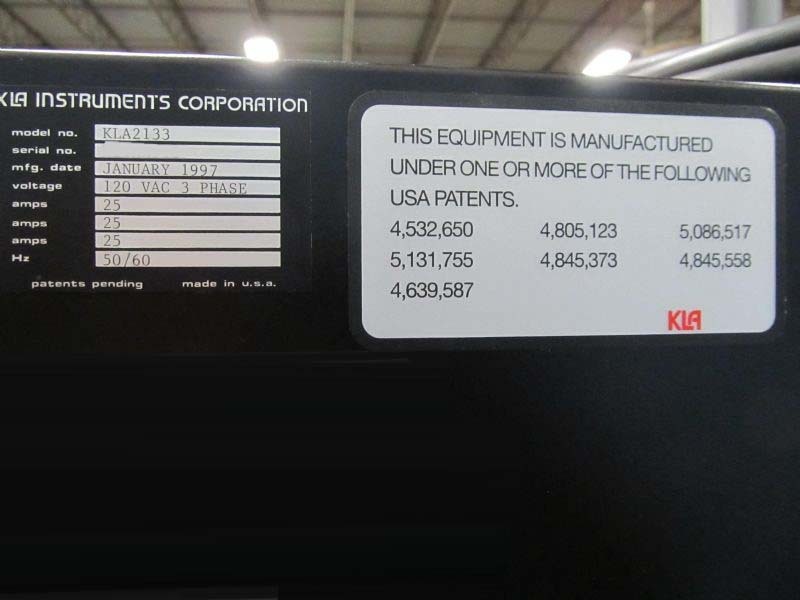

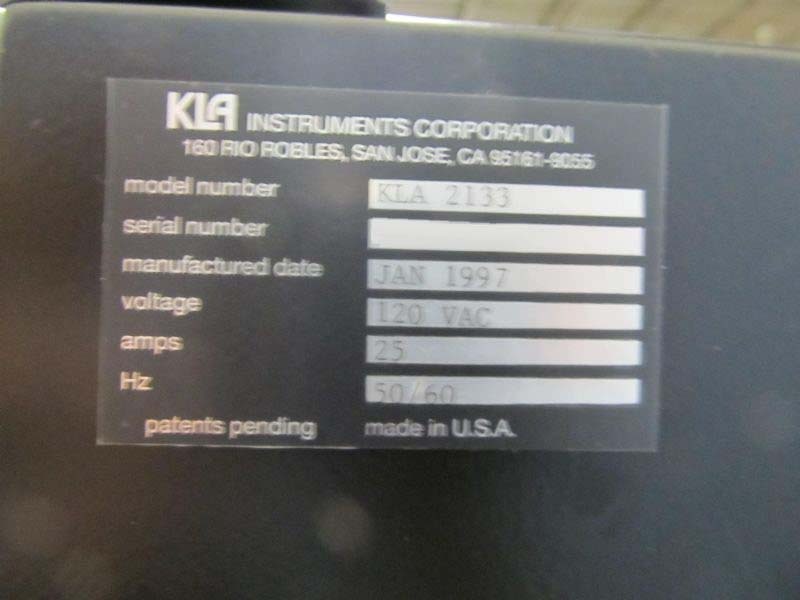

Used KLA / TENCOR 2133 #9150400 for sale

URL successfully copied!

Tap to zoom

ID: 9150400

Vintage: 1997

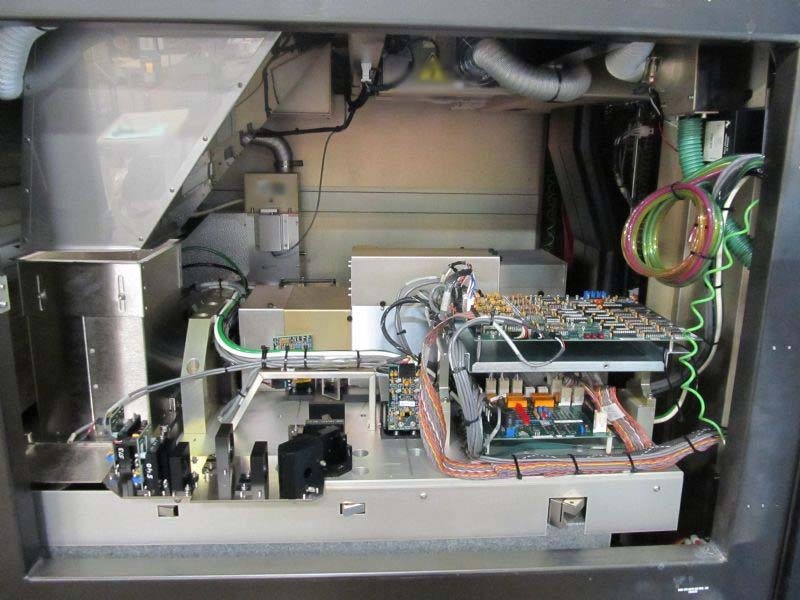

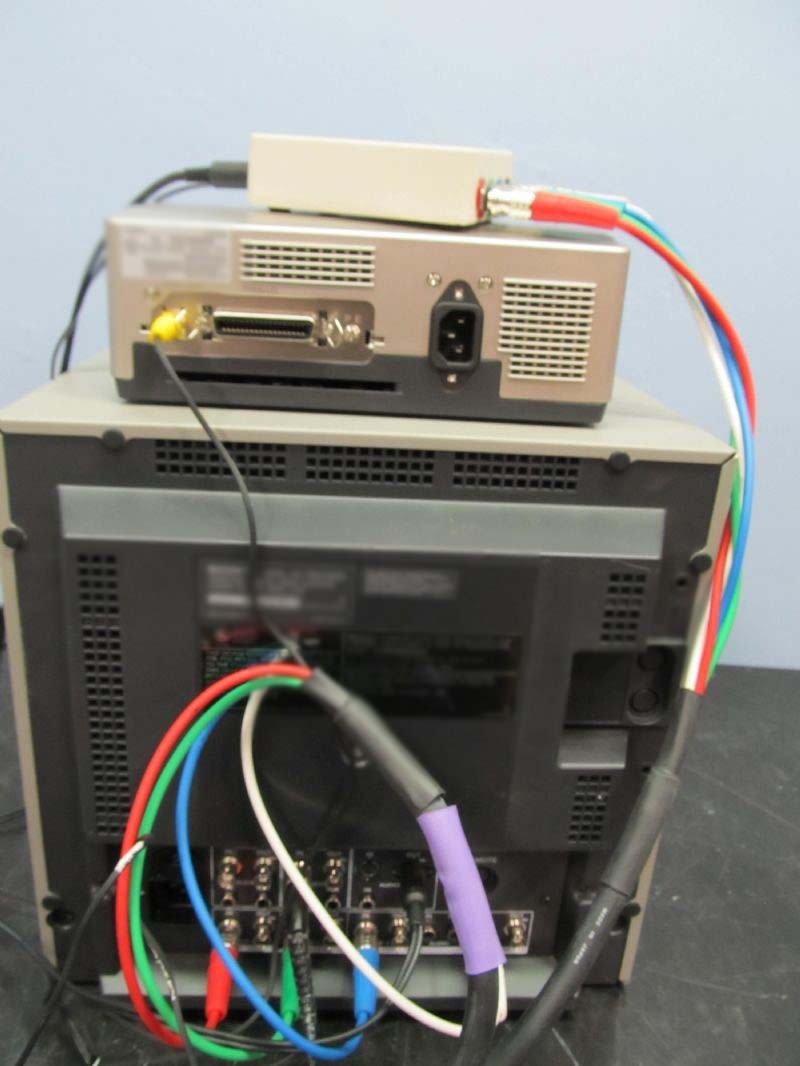

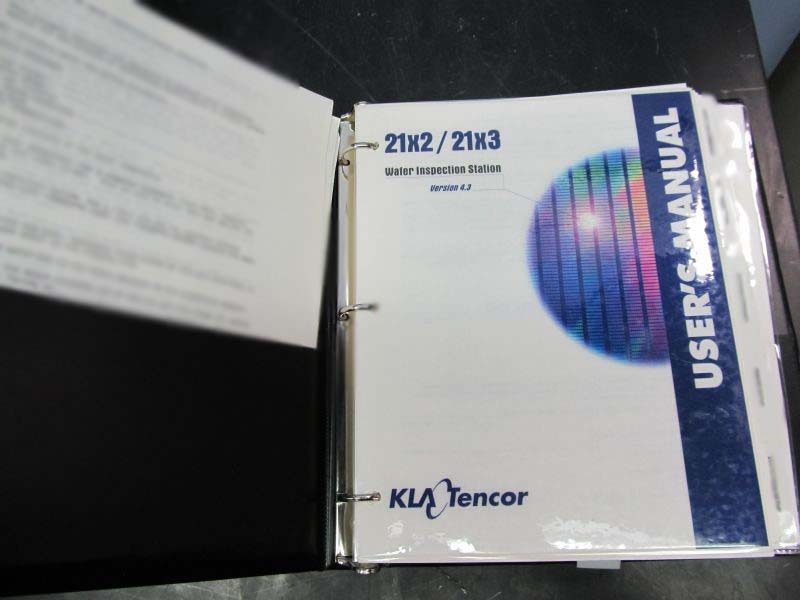

Wafer inspection system

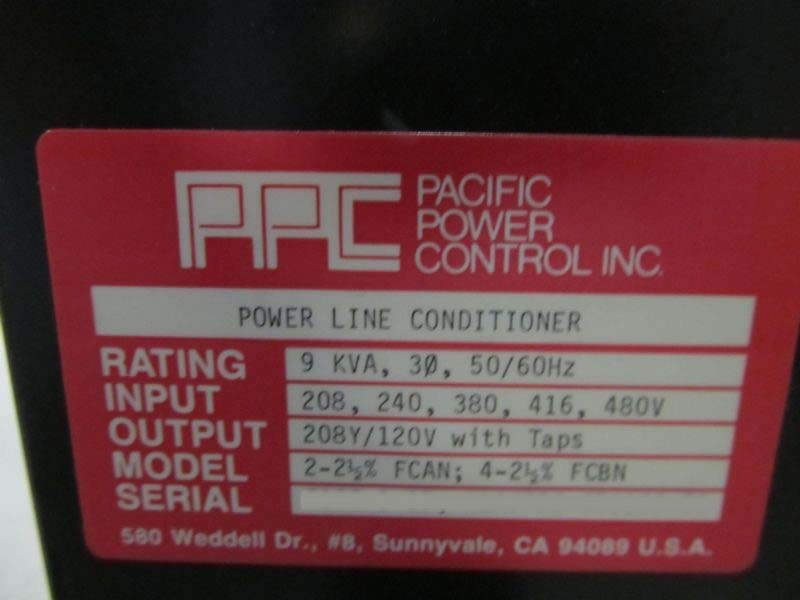

Equipment specifications:

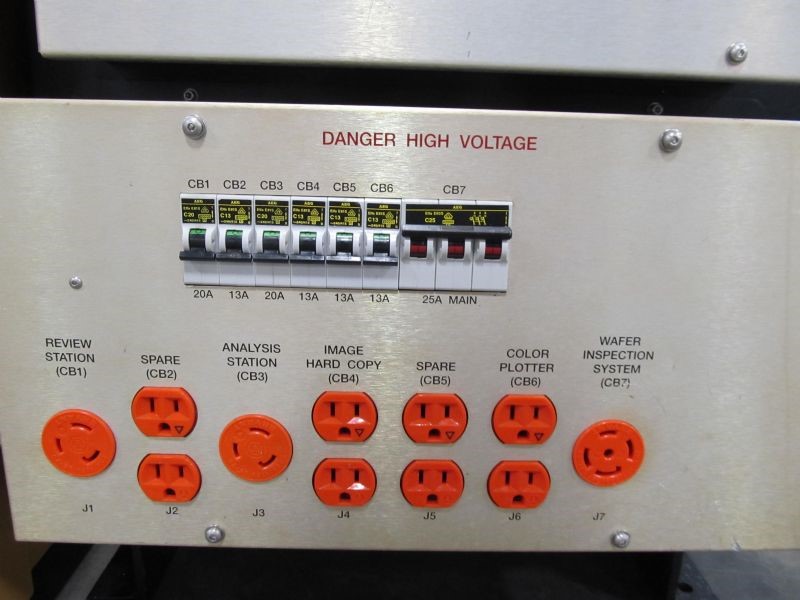

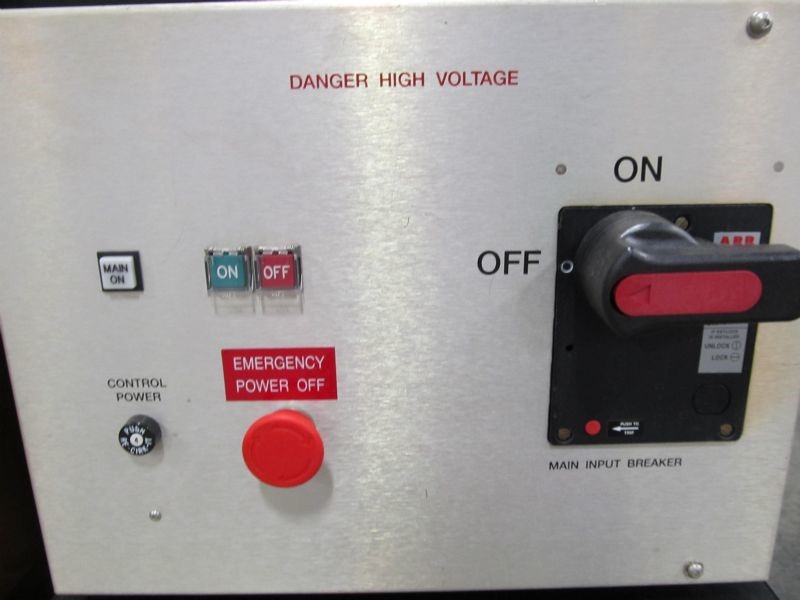

Voltage: 120 Volts

Frequency: 50/60 HERTZ

(3) Phase

Current: 25 AMPS

(2) Wafer cassette loading platforms

Independent load / Unload control per station

Robotic wafer handler

1997 vintage.

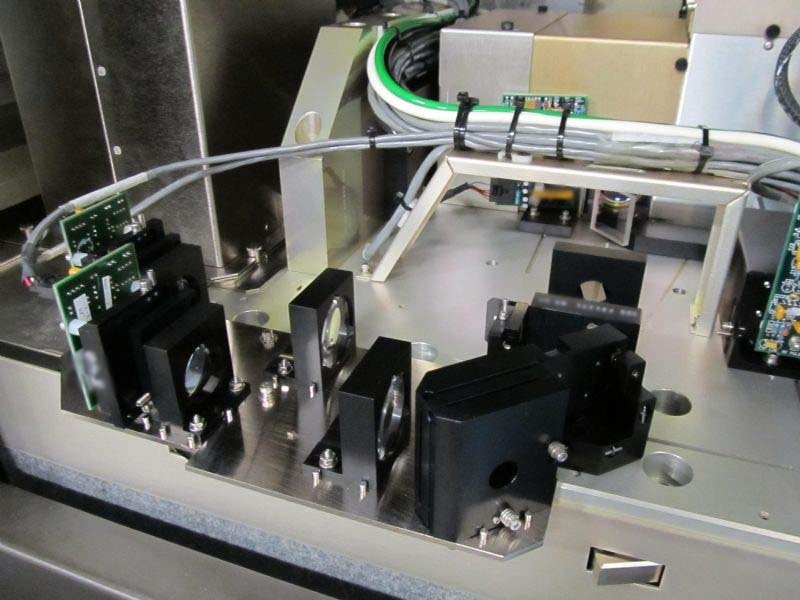

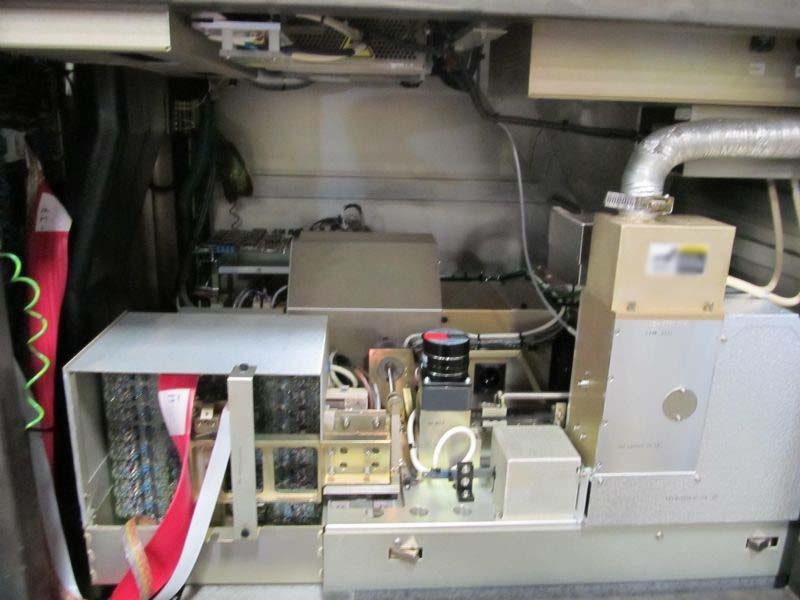

KLA / TENCOR 2133 Mask & Wafer Inspection Equipment is a comprehensive, highly-accurate, automated inspection system designed for the detection and identification of defects in photo masks and semiconductor wafers. The unit operates by using an advanced automated microscope to scan the area for microscopic particles, contaminants, irregularities, or defects. It then compares the images produced by the microscope to established standards and determines if the pattern is acceptable or needs to be fixed. KLA 2133 Mask & Wafer Inspection Machine has an advanced optical path that ensures the highest level of defect detection and accuracy. The tool includes an advanced auto-focus mechanism for automatic and manual image optimization, advanced illumination techniques for improved contrast and clearness of patterns, and a suite of unique defect detection algorithms that provide exceptionally precise defect identification. Also included in the asset is a suite of versatile inspection, verification, and analysis functions that allow for quick and easy defect monitoring and performance analysis. TENCOR 2133 Mask & Wafer Inspection Model is optimized for use with complex defect structures such as those found in logic and memory products. The equipment can accurately detect critical defects from 0.5 to 5 microns in size, and can also detect sub-micron structures. Additionally, the system provides an integrated defect analysis package to allow for detailed investigation and defect diagnosis. The unit also offers full traceability of defect results, allowing for improved defect visibility and process control. 2133 Mask & Wafer Inspection Machine also offers a variety of functions such as automated image generation, defect data logging, user-friendly software, intuitive reports, and user-programmable functions. In addition, the tool provides an integrated calibration asset and enhanced 3-D capabilities for enhanced defect monitoring. Overall, KLA / TENCOR 2133 Mask & Wafer Inspection Model is a robust, highly-accurate, automated inspection equipment designed for the detection and identification of defects in photo masks and semiconductor wafers. With features such as advanced optics, defect detection algorithms, and sophisticated analysis capabilities, the system provides an ideal solution for ensuring the quality and reliability of electronic products.

There are no reviews yet