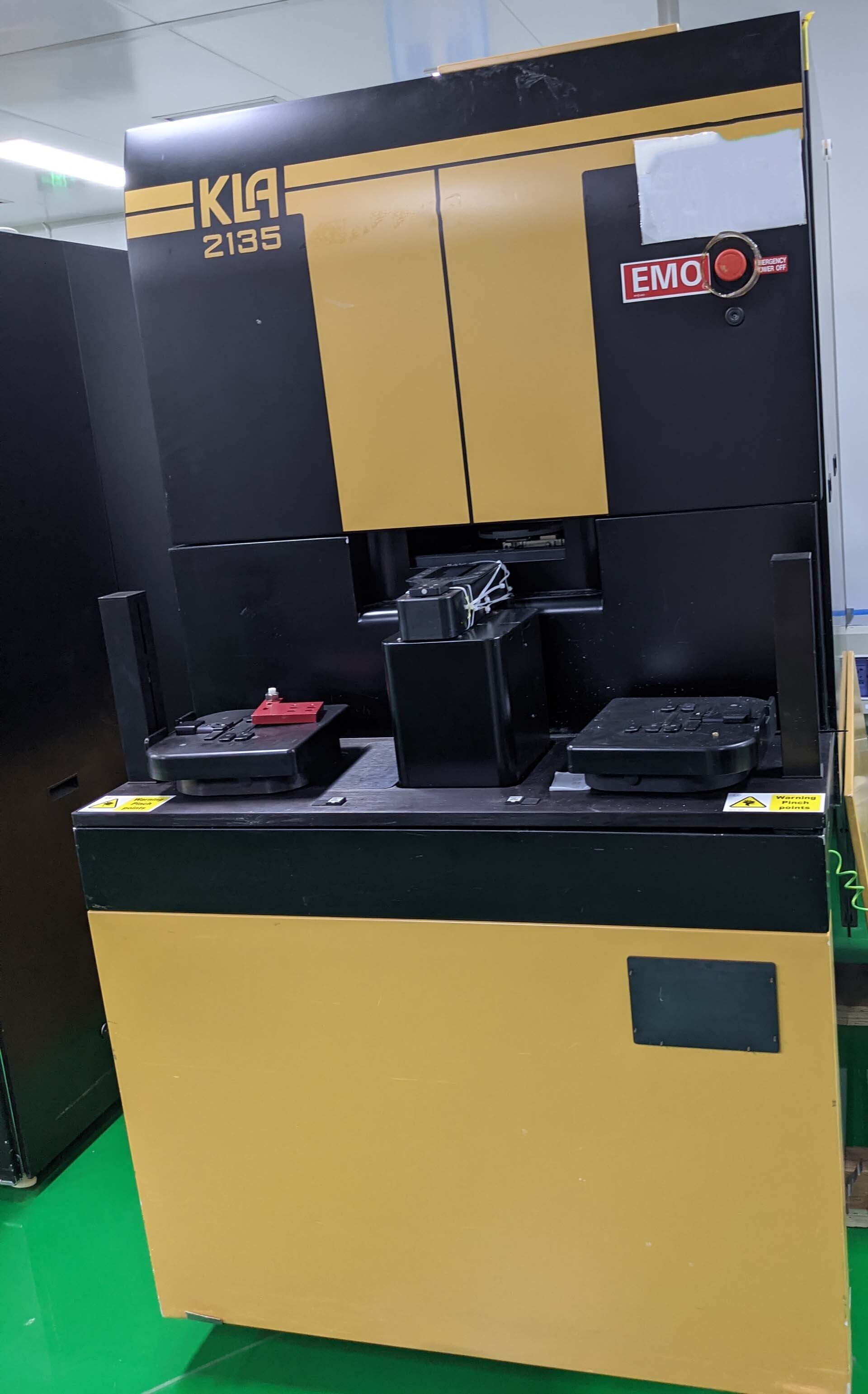

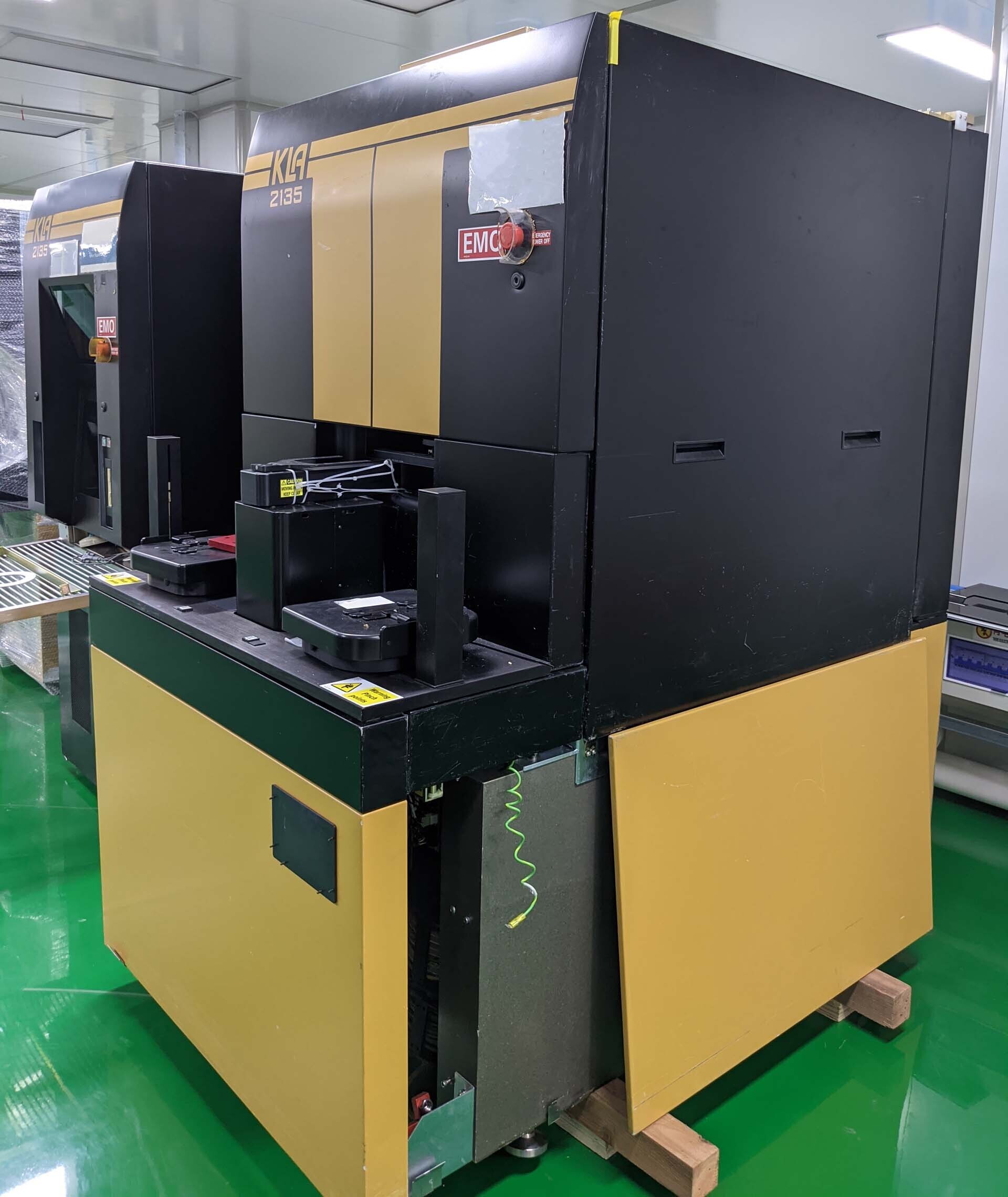

Used KLA / TENCOR 2135 #293610038 for sale

URL successfully copied!

Tap to zoom

KLA / TENCOR 2135 is a mask and wafer inspection equipment used in the production of advanced semiconductor devices. It is a tool specifically designed to inspect a substrate before, during, and after the actual production process. The system uses charge-coupled device (CCD) cameras to detect any anomalies or defects on the surface of mask and/or wafers. It provides a comprehensive set of tools and algorithms to automatically detect, quantify, measure, and classify each defect. KLA 2135 utilizes state-of-the-art ultraviolet (UV) imaging for non-contact, defect detection. It is equipped with pixel-precise pattern-matching and can be used for both static and dynamic tasks. The machine integrates with other software and is capable of interfacing with automated probe and metrology systems. It can also be used to calibrate and measure equipment in the lithography process. The unit consists of a high-speed pattern-matching engine, multiple CCD cameras, and a flexible software environment for defect parameter optimization. The pattern-matching engine can detect and analyze any size of defect within a 3D area of interest. The CCD cameras can identify hundreds of defects in a fraction of a second and provide precise 3D mapping of each defect. The software can be used to customize the parameters used in the pattern-matching engine, as well as the thresholds used in defect classification. Data collected can be stored by the software in a database, allowing for quick and easy retrieval of information. Data can also be used to generate reports and prepare analyses, which can be printed or sent electronically to other personnel in charge of the manipulation and optimization of the process. The machine can be integrated with existing metrology and test systems, significantly improving process times, reducing costs, and streamlining processes. Overall, TENCOR 2135 is a reliable, high-performance mask and wafer inspection tool designed to ensure production accuracy and quality control for semiconductor devices. It is a asset that helps ensure the accuracy of manufactured parts on a nanoscale. It is a cost-effective, efficient solution for inspecting for a variety of defects, both during and after the production process.

There are no reviews yet