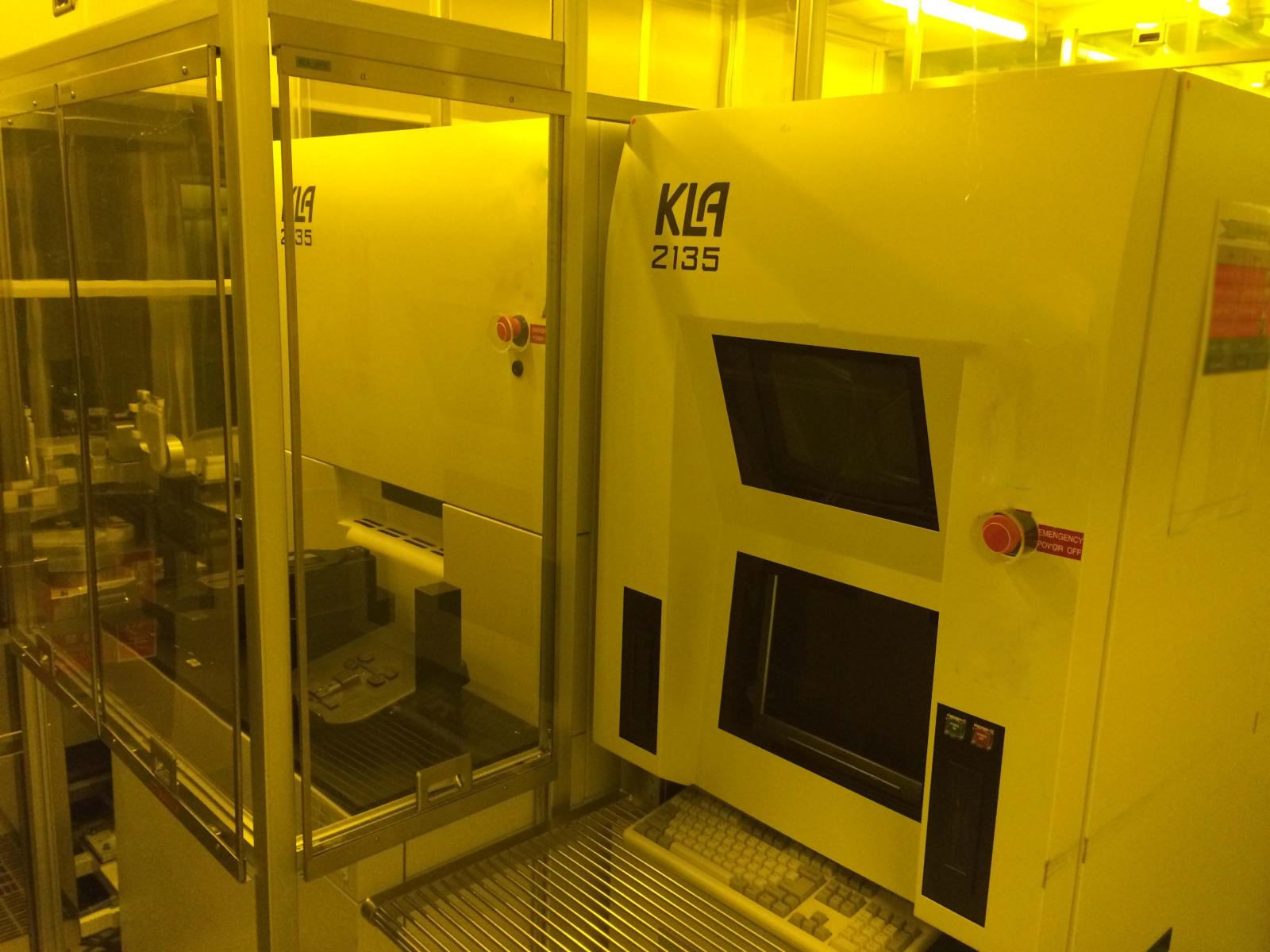

Used KLA / TENCOR 2135 #9189621 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

KLA / TENCOR 2135 is an advanced mask & wafer inspection equipment. The system provides high-speed automated wafer inspection with superior defect detection accuracy and sensitivity, allowing for reliable spot-checking of wafers. The unit uses advanced optics and imaging technology such as high-resolution CCD cameras and optical systems to achieve a high degree of accuracy and reliability. It consists of three main components: the image acquisition, image processing, and defect detection subsystems. The image acquisition subsystem captures the images of the wafers at high resolution. This component is comprised of multiple cameras and depending on the desired inspection resolution, may include different camera types such as CCD and CMOS cameras. This machine also incorporates laser-based height compensation systems to adjust for variations in the wafer surface. The image processing subsystem performs a number of complex operations to convert the raw images into a form suitable for defect detection. This includes image analysis, image cleaning, image stitching, image alignment, image registration, image segmentation, and image registration. The image processing subsystem is also capable of recognizing different types of defects, such as pits and voids, cracks and scratches. The defect detection subsystem is responsible for automatically detecting and localizing defects on the wafers. This is accomplished through a combination of optical and defect detection algorithms, such as pixel-level analysis, color histograms and linewise scans. The tool is also capable of classifying the detected defects into various defect types. KLA 2135 is an advanced mask & wafer inspection asset capable of providing reliable quality assurance services. The high-precision optics and imaging technologies incorporated in the model allow it to accurately and sensitively detect, classify and localize even the smallest defects at high speed. This makes it ideal for applications such as defect assessment, quality assurance and semiconductor fabrication.

There are no reviews yet