Used KLA / TENCOR 2135 #9249042 for sale

URL successfully copied!

Tap to zoom

ID: 9249042

Wafer Size: 8"

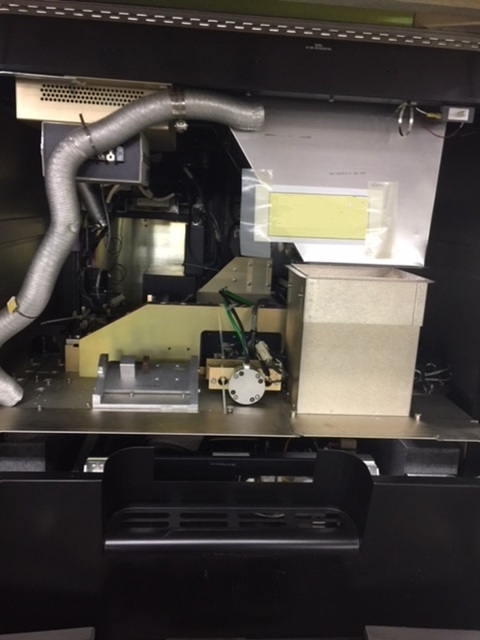

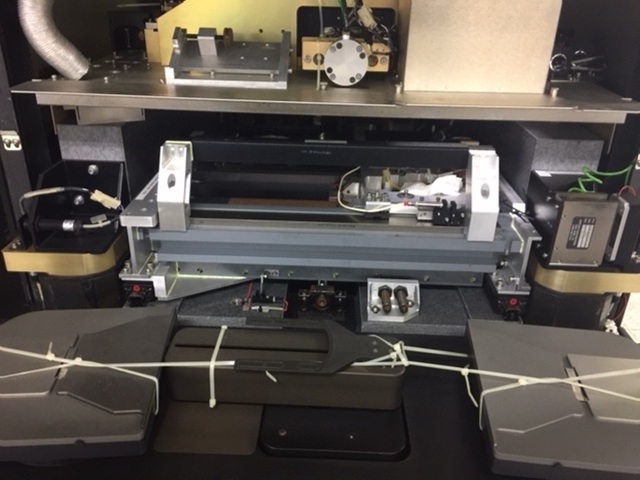

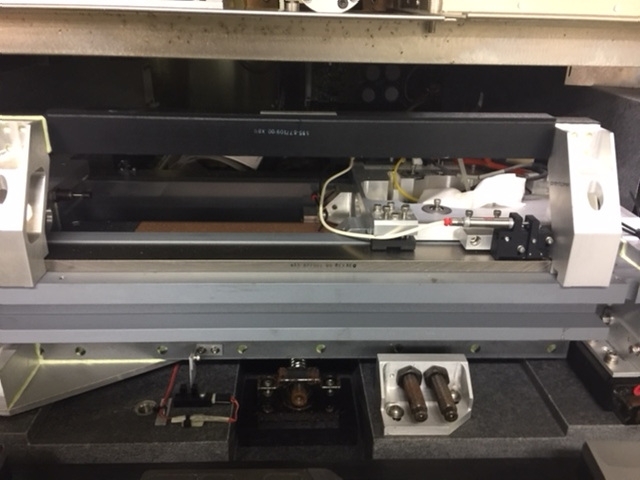

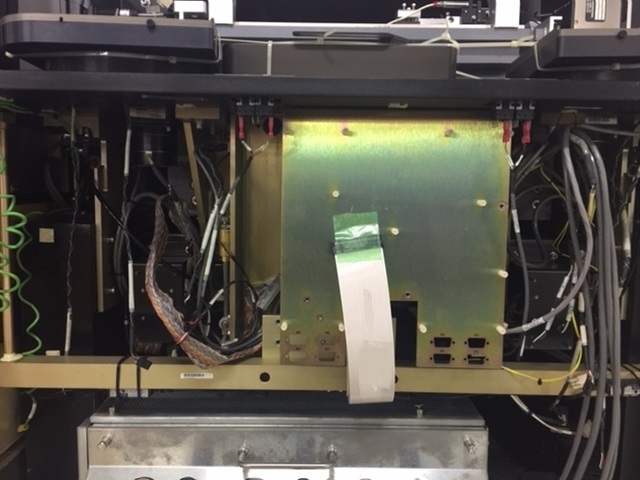

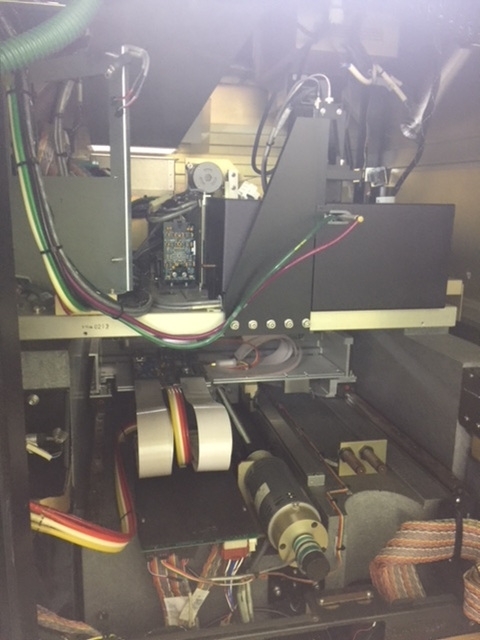

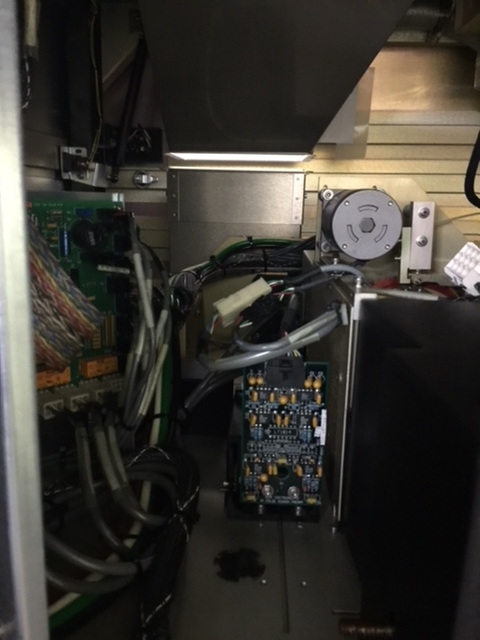

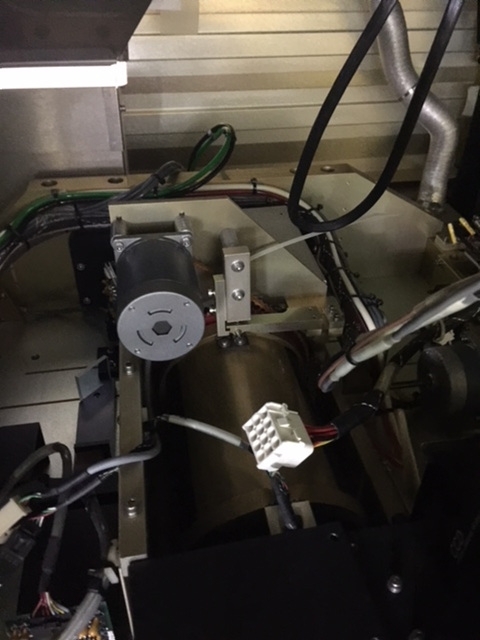

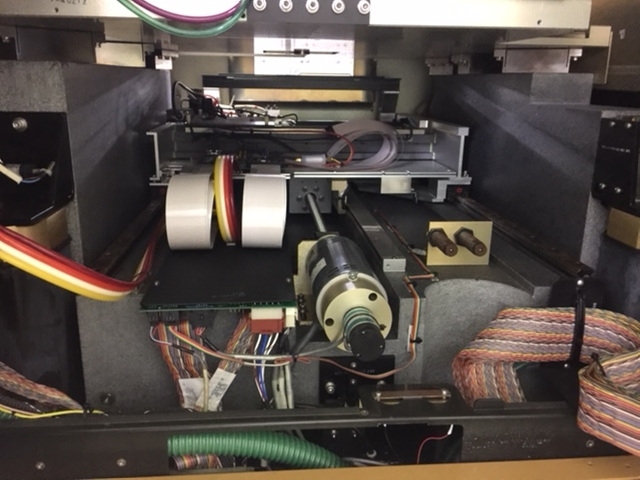

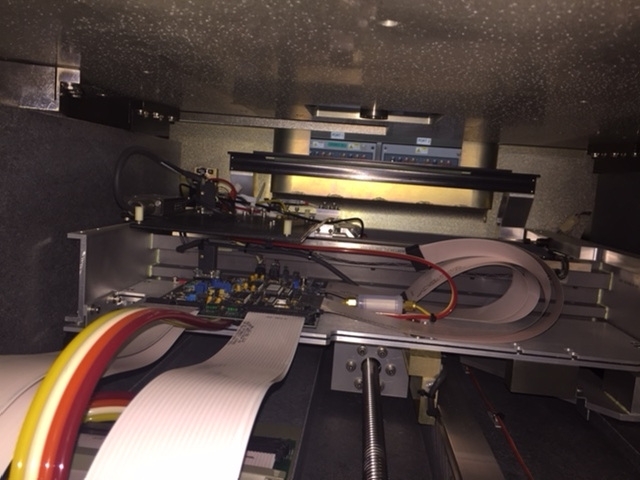

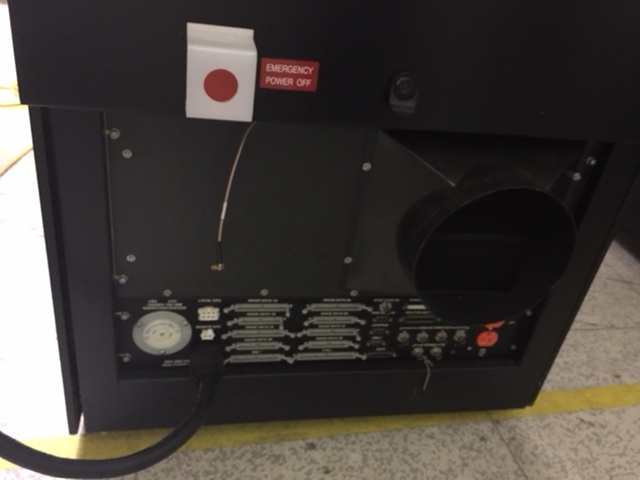

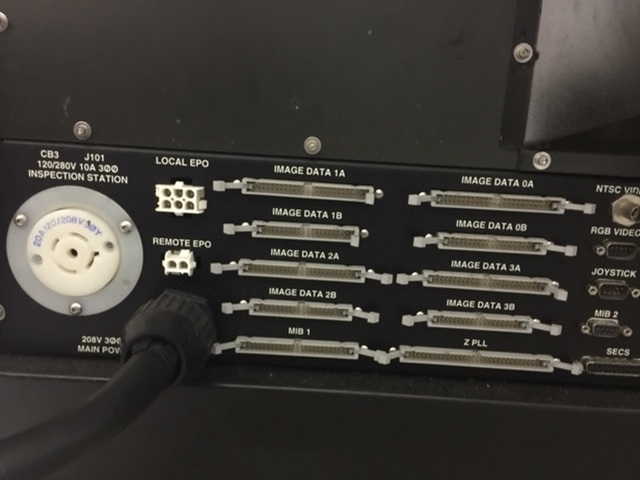

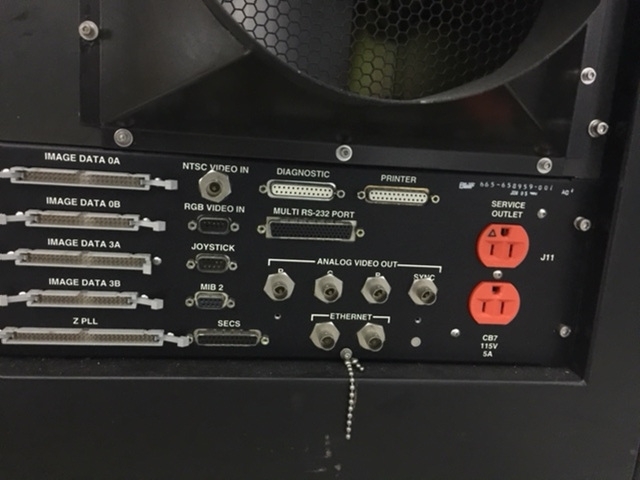

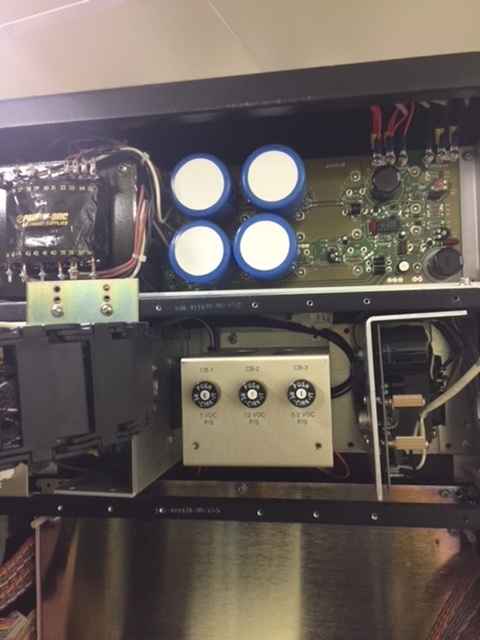

Wafer inspection system, parts machine, 8"

Missing TDI module and PLLAD module.

KLA / TENCOR 2135 Mask and Wafer Inspection Equipment is an advanced metrology solution dedicated to the metrology needs of modern semiconductor manufacturing. Its proprietary technology enables it to quickly and accurately measure the critical patterns contained within lithographic masks or wafers used in the production of semiconductor devices. KLA 2135 is capable of detecting extremely small defects and feature variations on a device scale with a high degree of accuracy and repeatability. TENCOR 2135 system is built on a modular platform that can be configured for various applications on an as-needed basis. This enables users to easily adapt the tool for different lithographic applications as needed. These applications can range from die-to-die defect inspection to feature profile qualification to clock jitter analysis. To facilitate high accuracy measurement and analysis, the tool incorporates proprietary hardware and software. A unique combination of high definition optics, confocal laser scanning, interference optics, and advanced detectors measure and analyze features with micron-level resolution. Additionally, the inspection unit's defect detection algorithms are precisely calibrated to detect even the tiniest variations in a feature's dimensions and shape. Equally important is 2135 machine's ability to rapidly process and analyze large quantities of data in an efficient manner. The tool can process hundreds of gigabytes of data in a single hour thanks to its on-board image archiving and retrieval capabilities. Furthermore, KLA / TENCOR 2135 asset can automatically recognize, classify, and measure device characteristics with virtually no human intervention required. This ensures that the tool can consistently deliver high quality results without the need for tedious manual inspection processes. Overall, KLA 2135 Mask and Wafer Inspection Model is a robust and reliable solution for the metrology needs of modern semiconductor manufacturing. Its combination of advanced hardware, software, and analysis processes allow it to reliably identify defects on lithographic masks and wafers, allowing for greater quality control and production yields. With its ability to reduce human labor during inspection processes, the tool is an ideal choice for any modern lithographic application.

There are no reviews yet