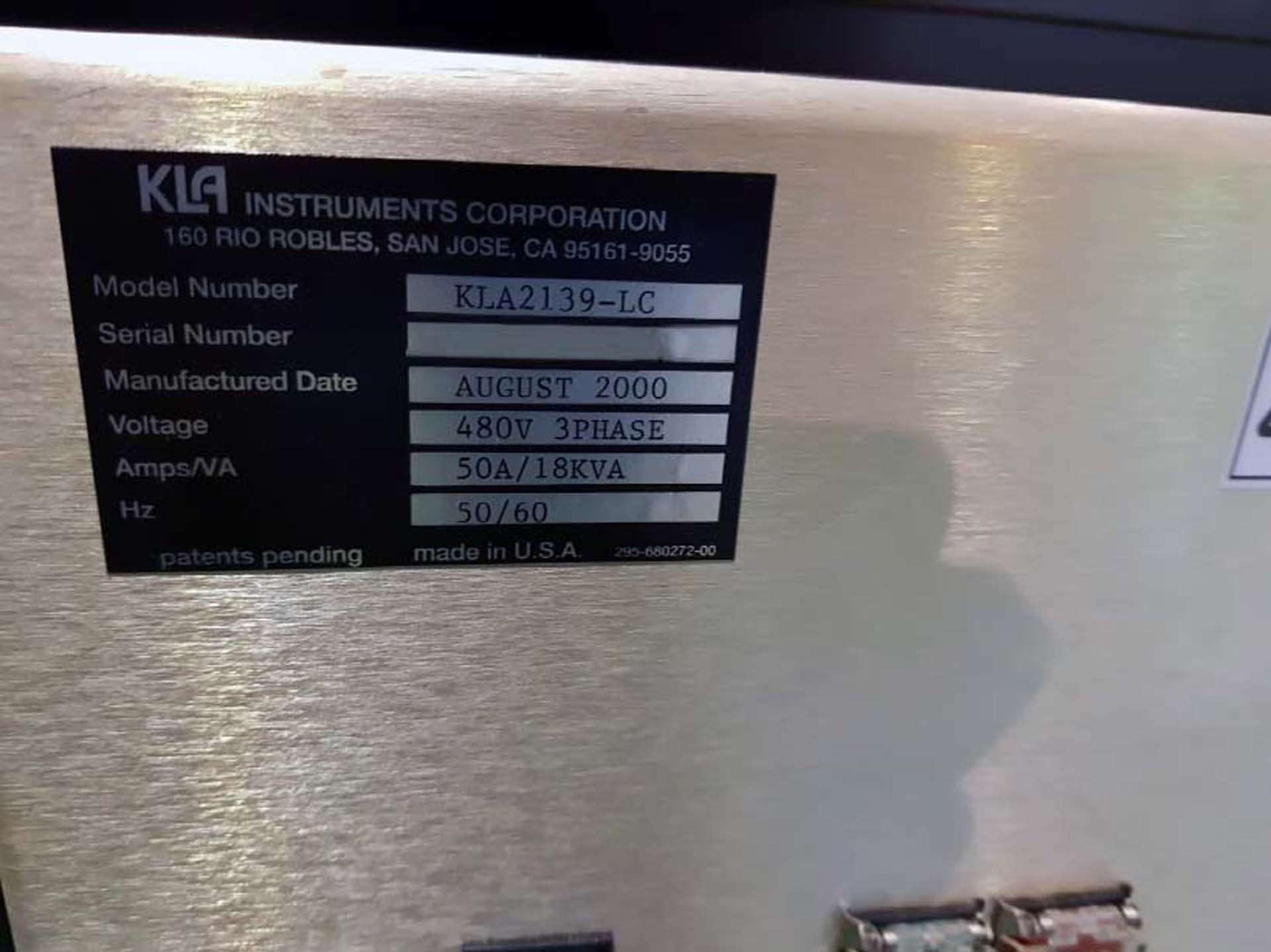

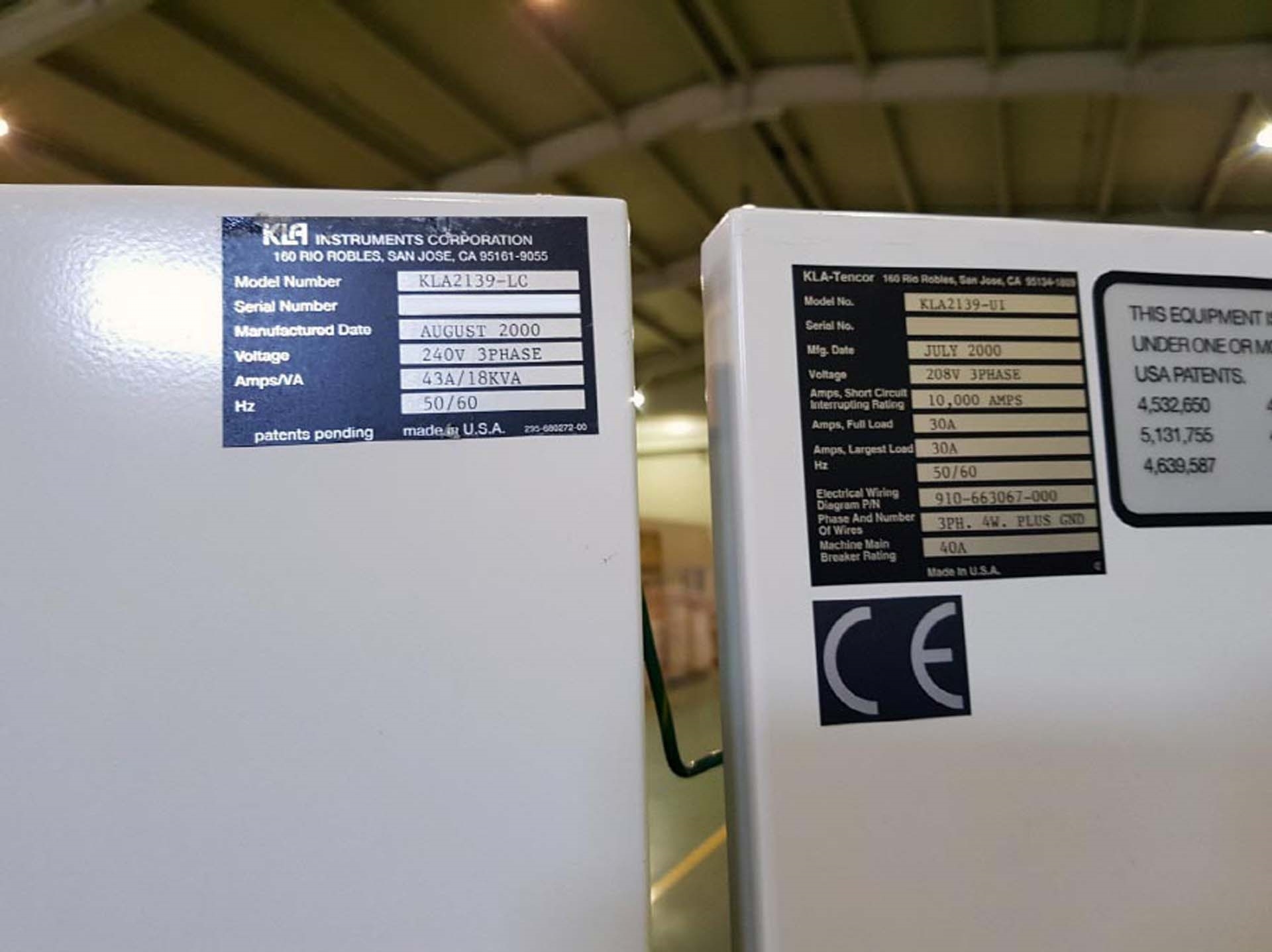

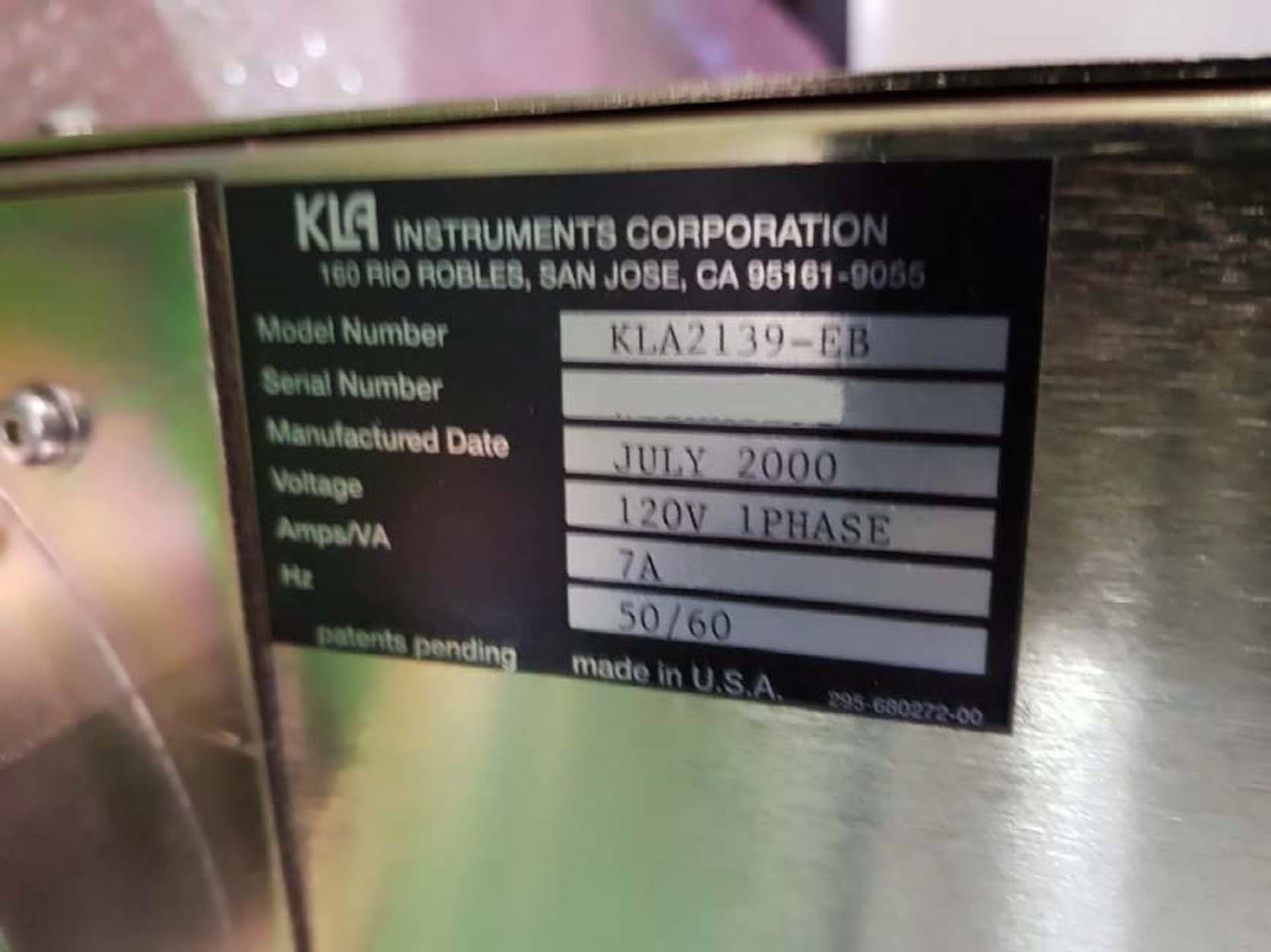

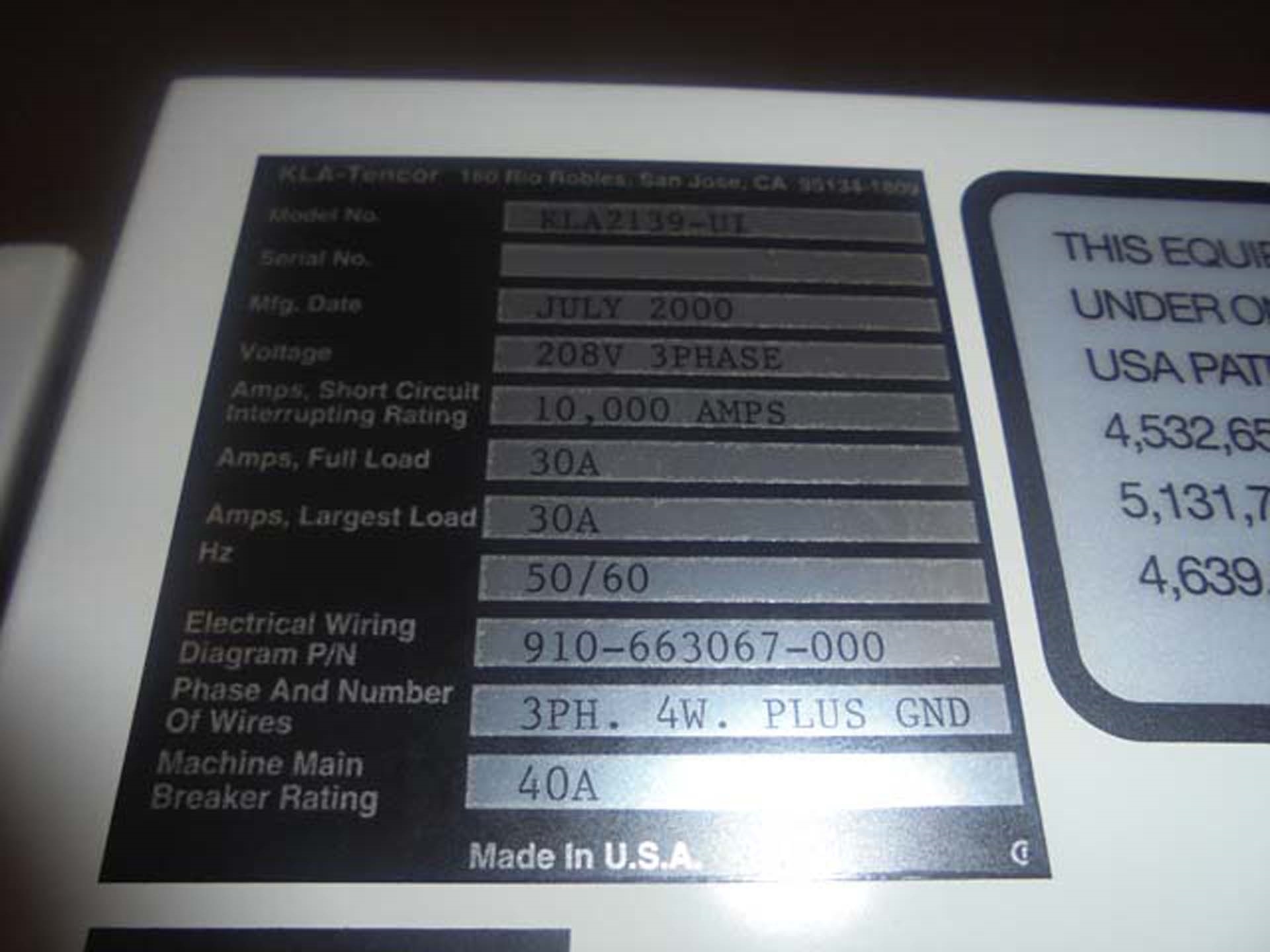

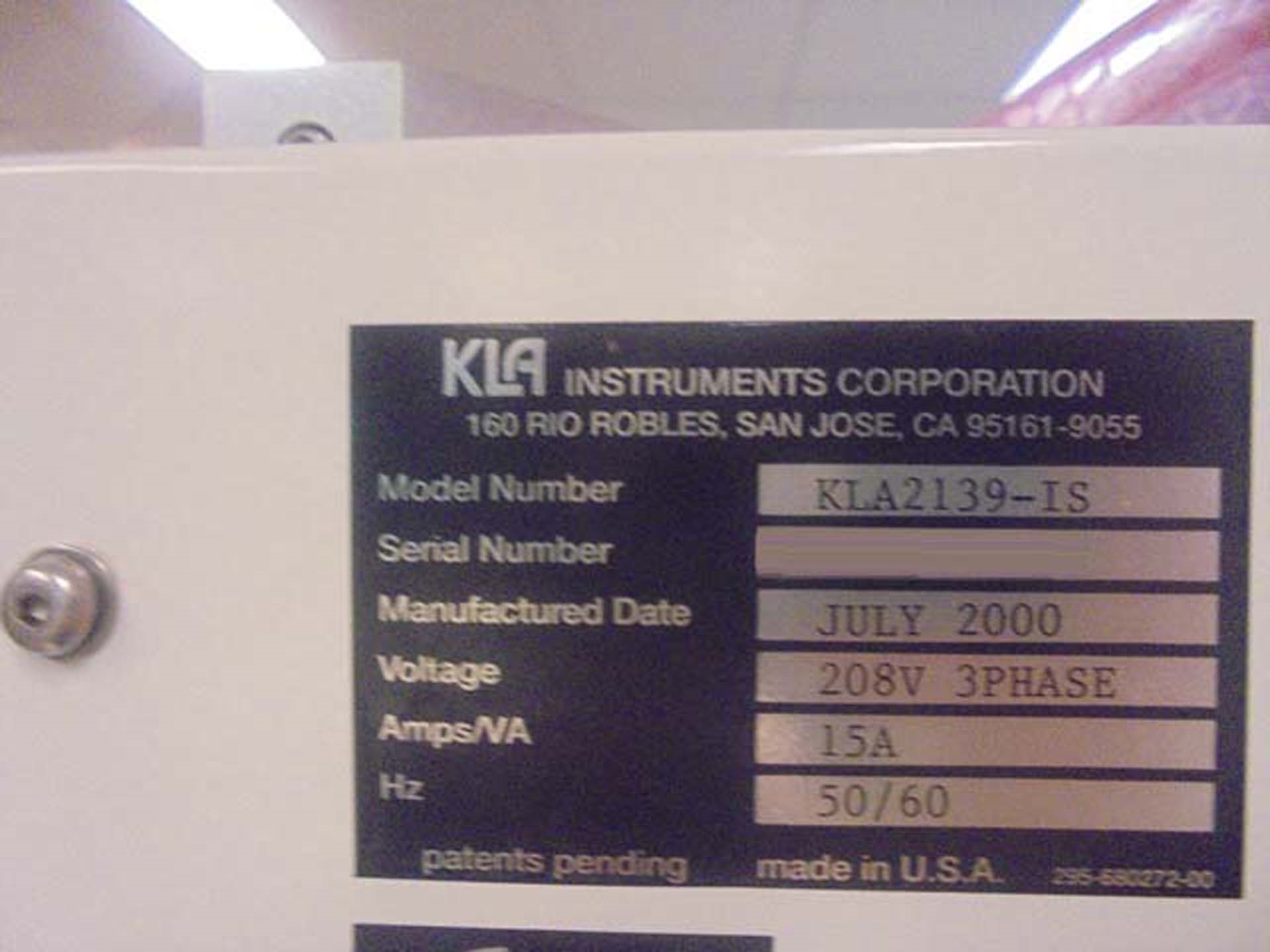

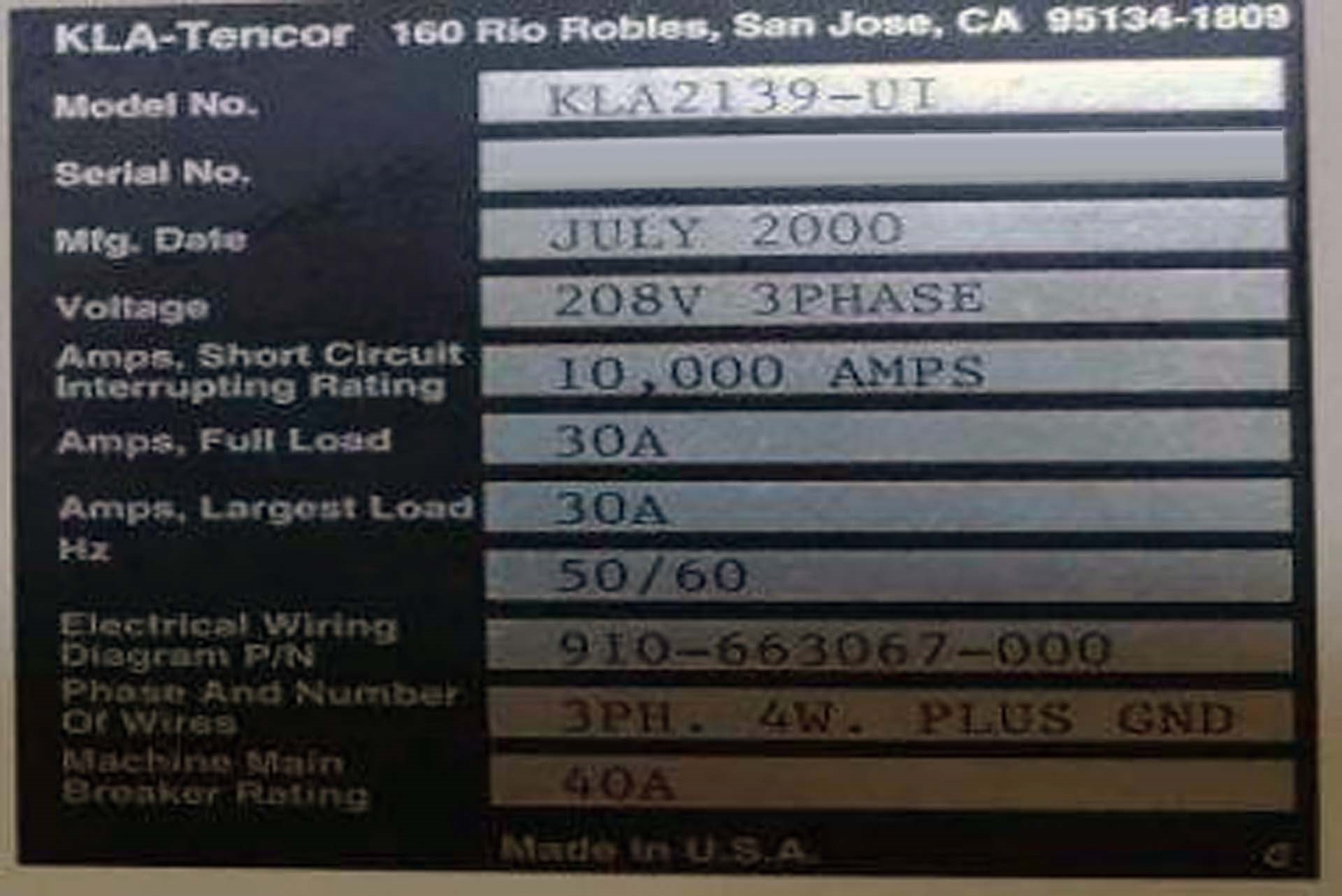

Used KLA / TENCOR 2139 #9230684 for sale

URL successfully copied!

Tap to zoom

ID: 9230684

Wafer Size: 8"

Vintage: 2000

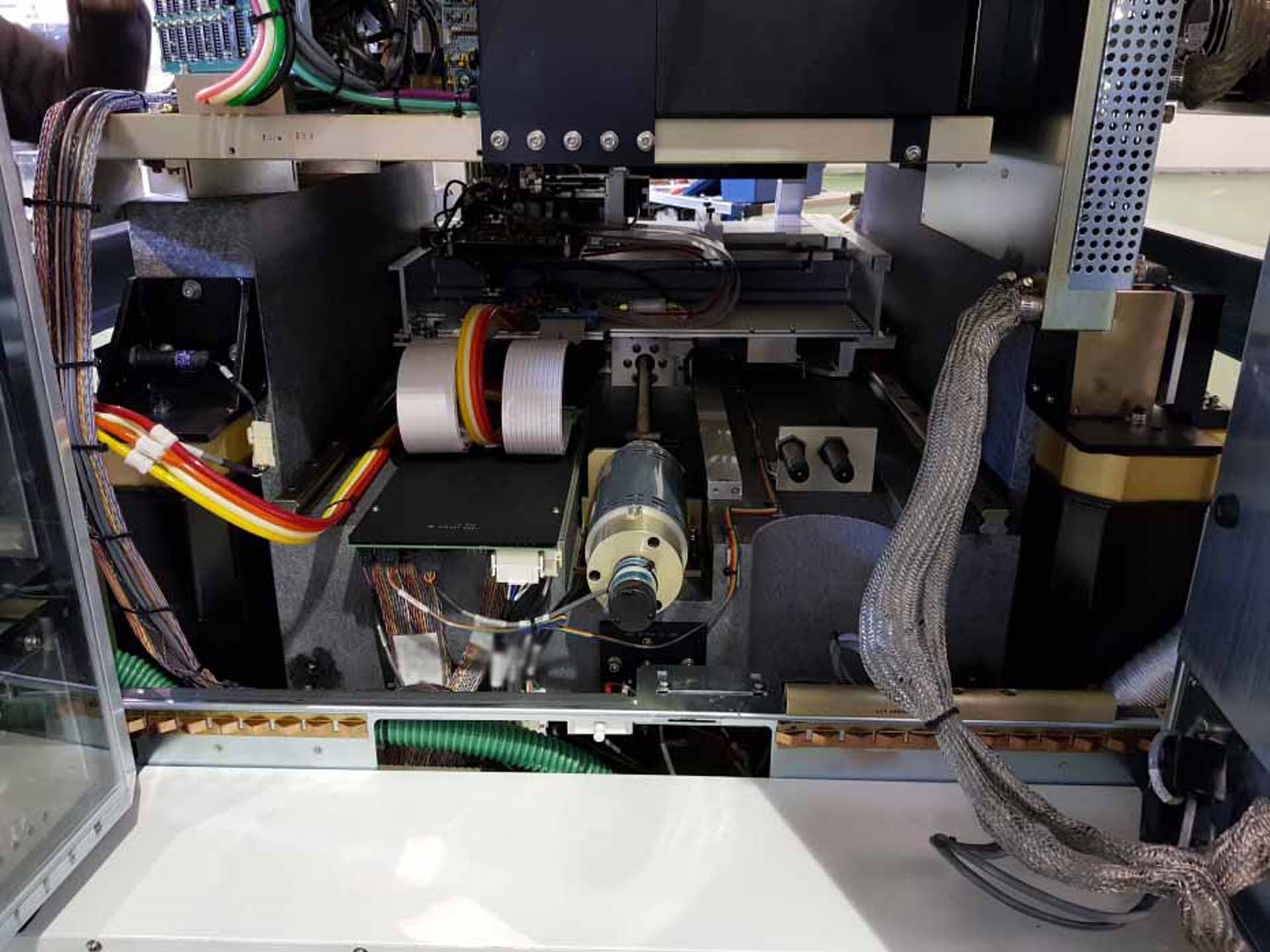

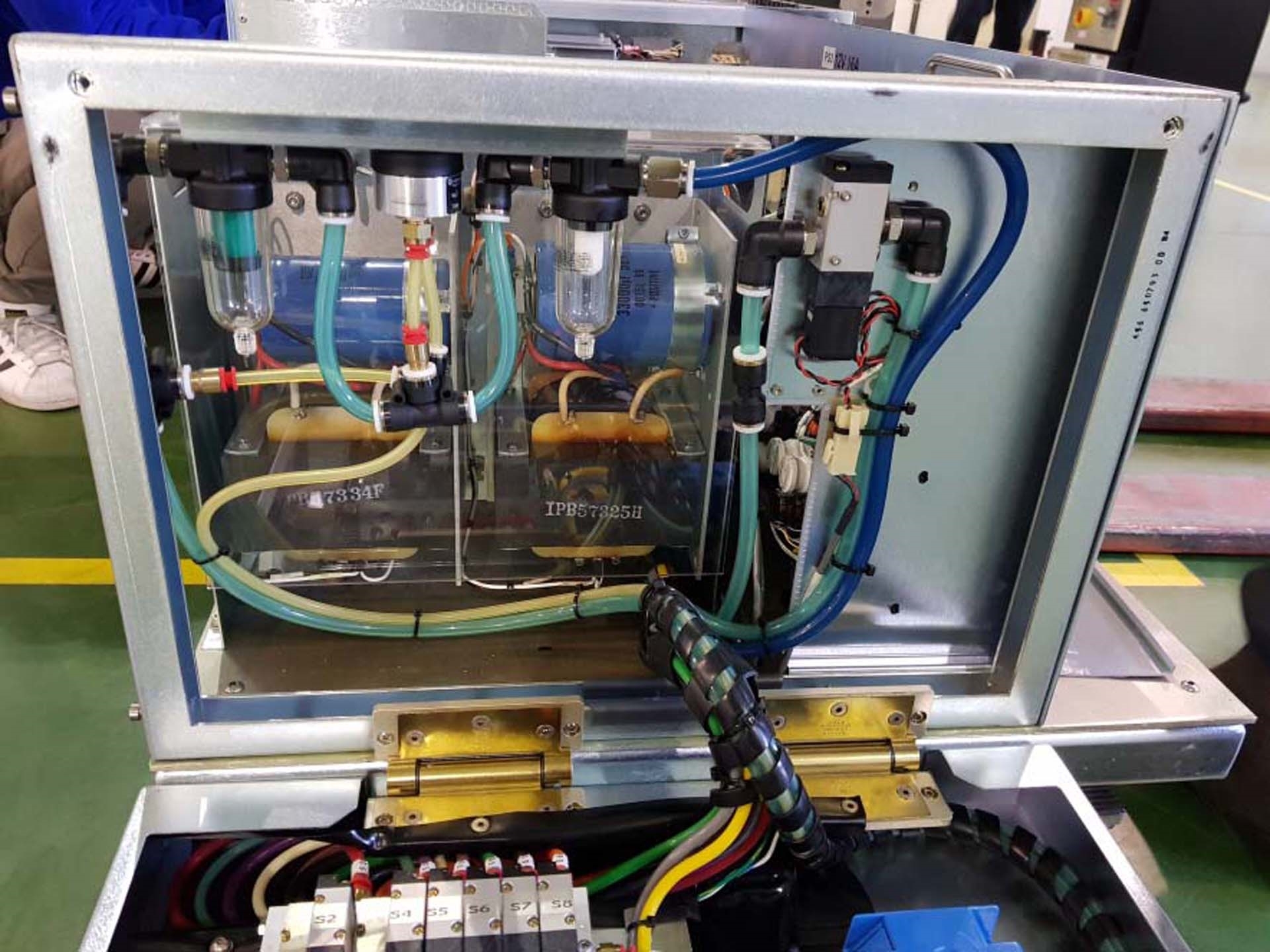

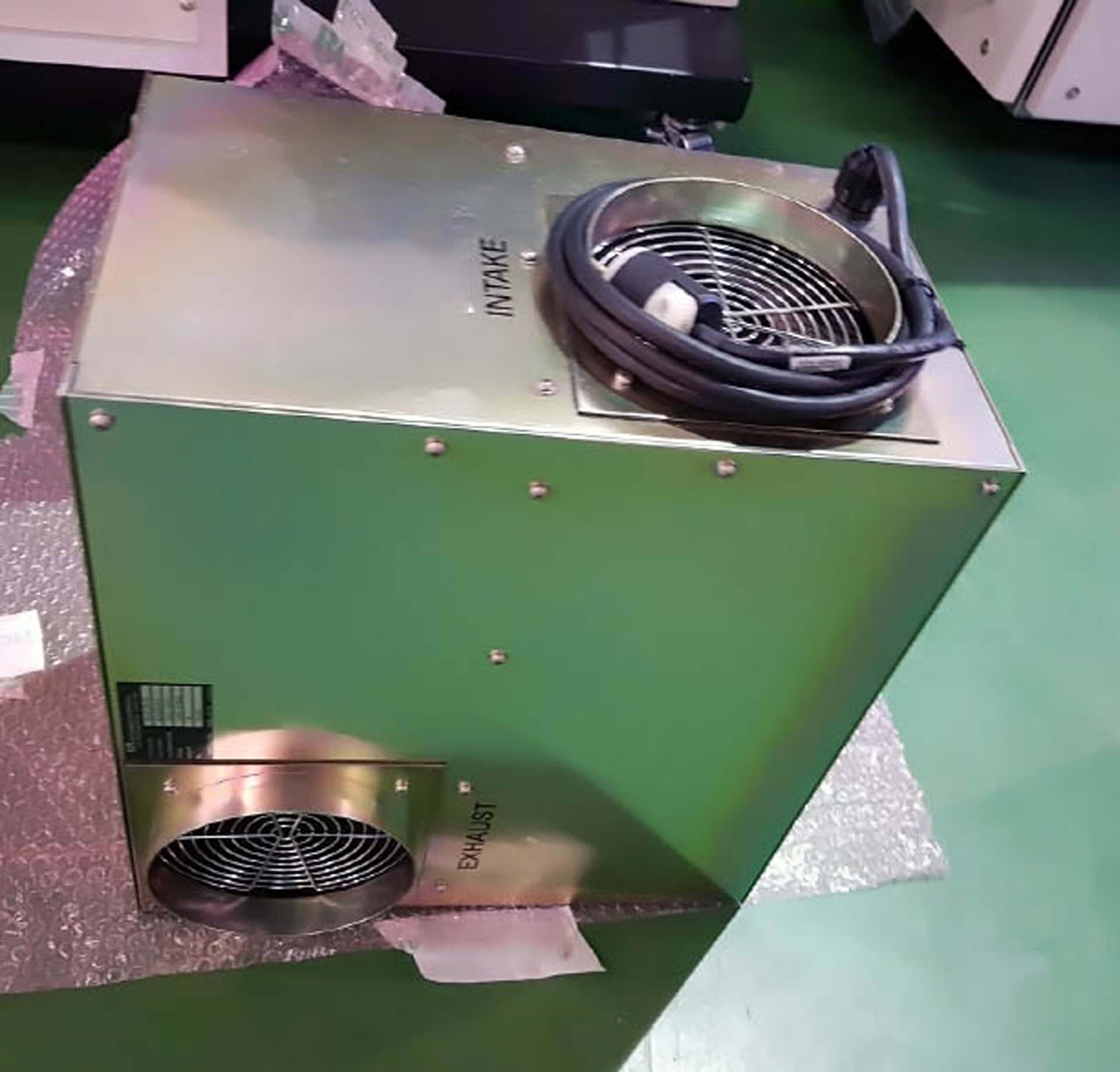

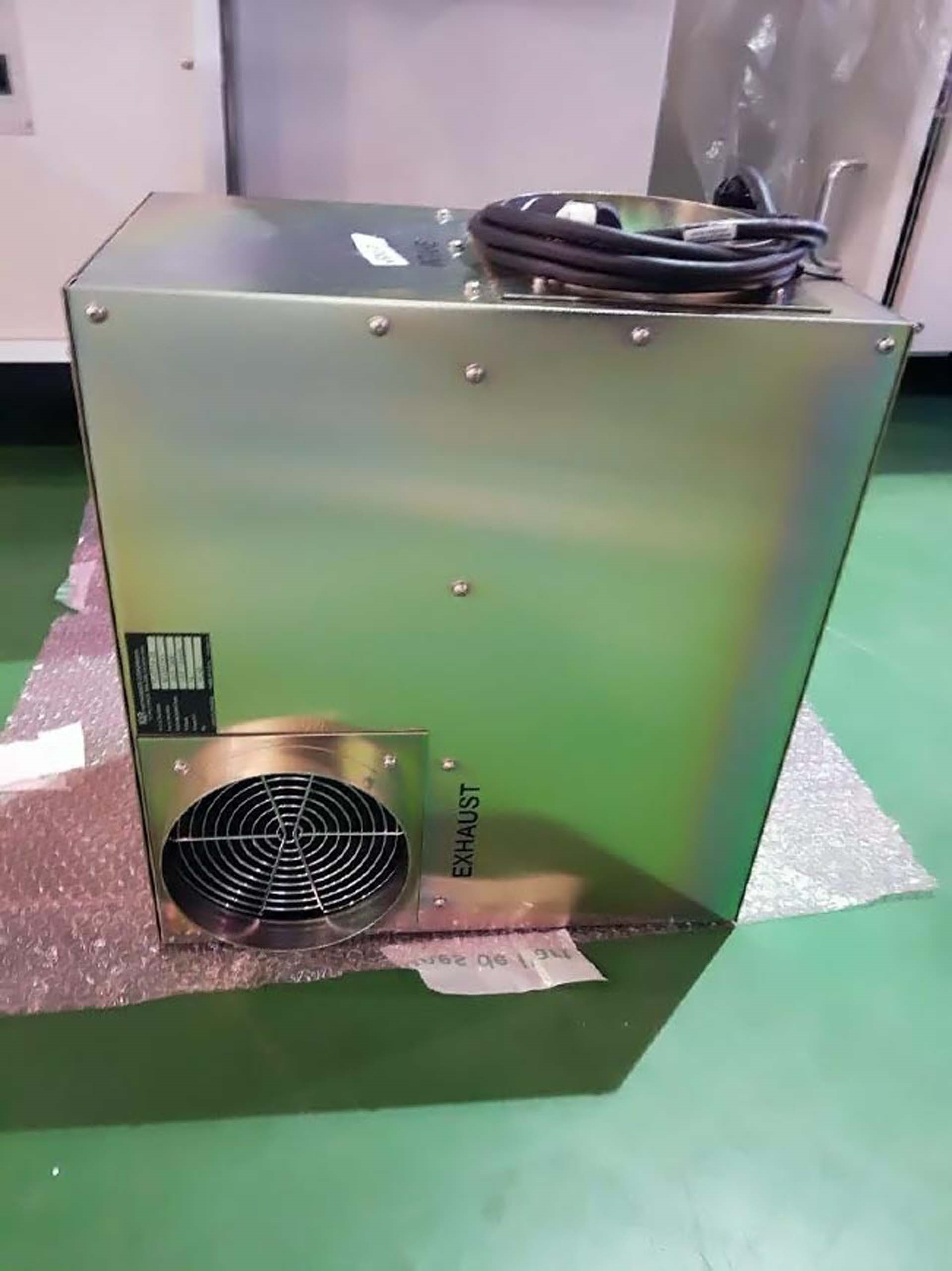

Wafer inspection system, 8"

Open cassette

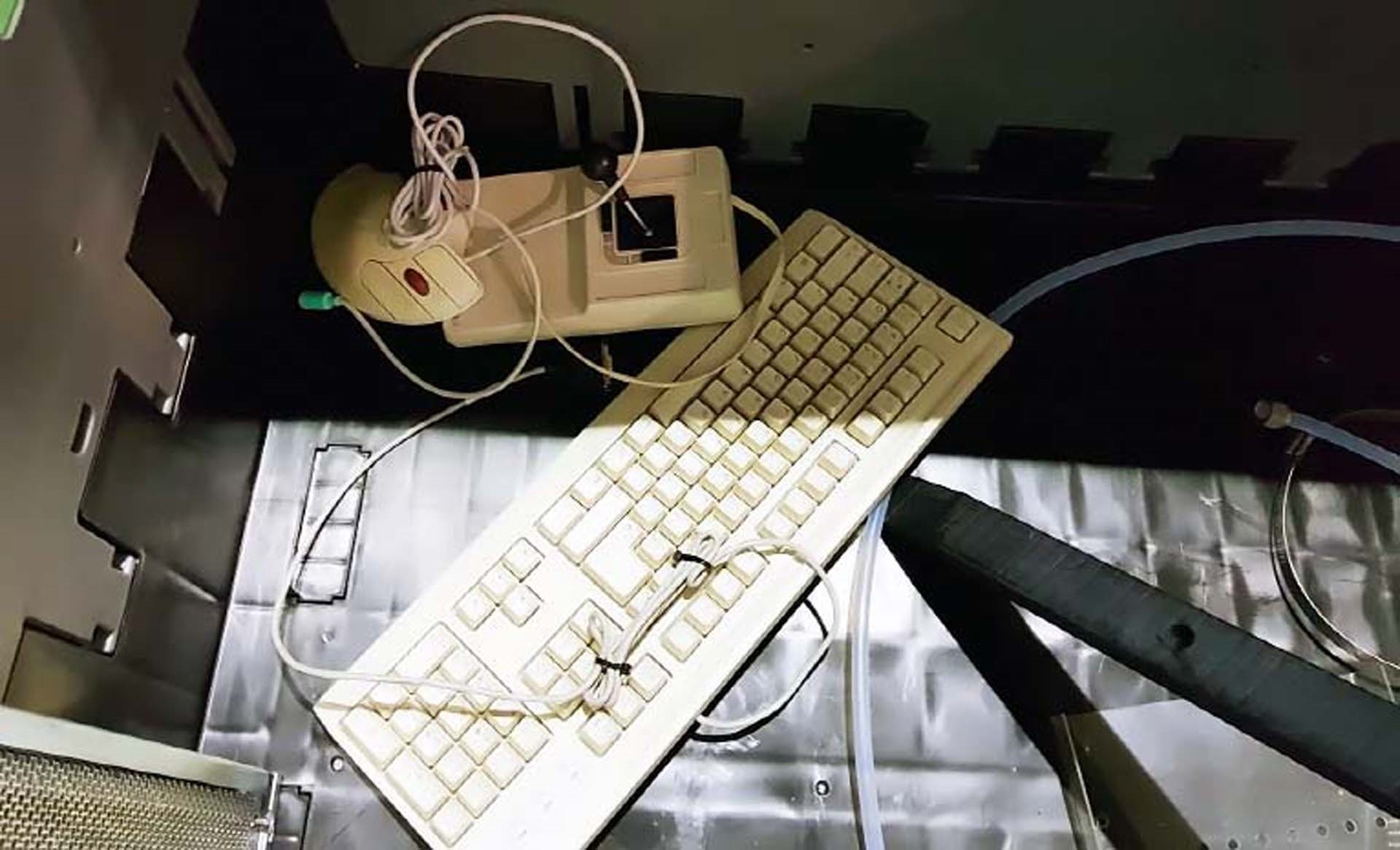

User interface

Monitor with PC

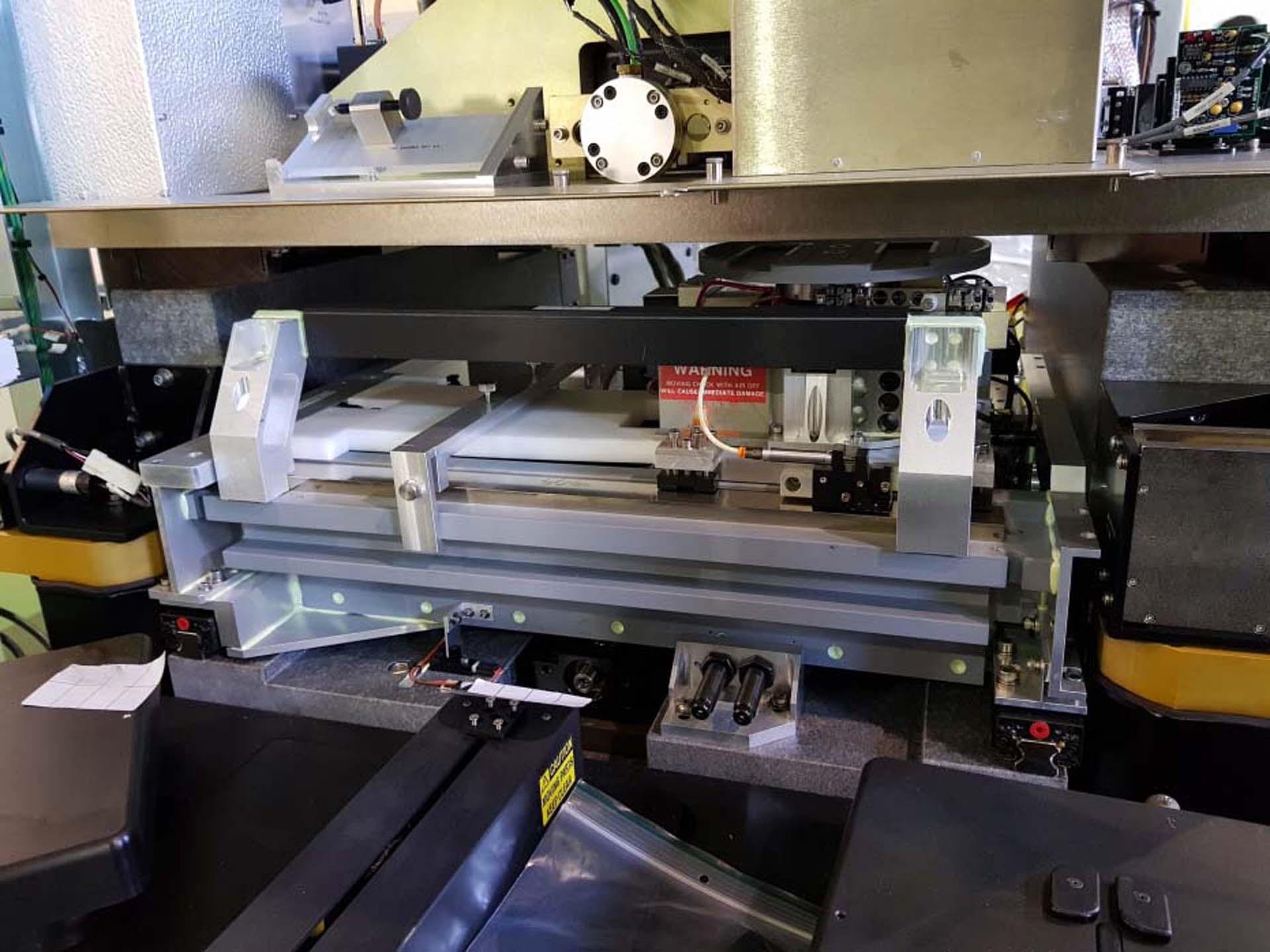

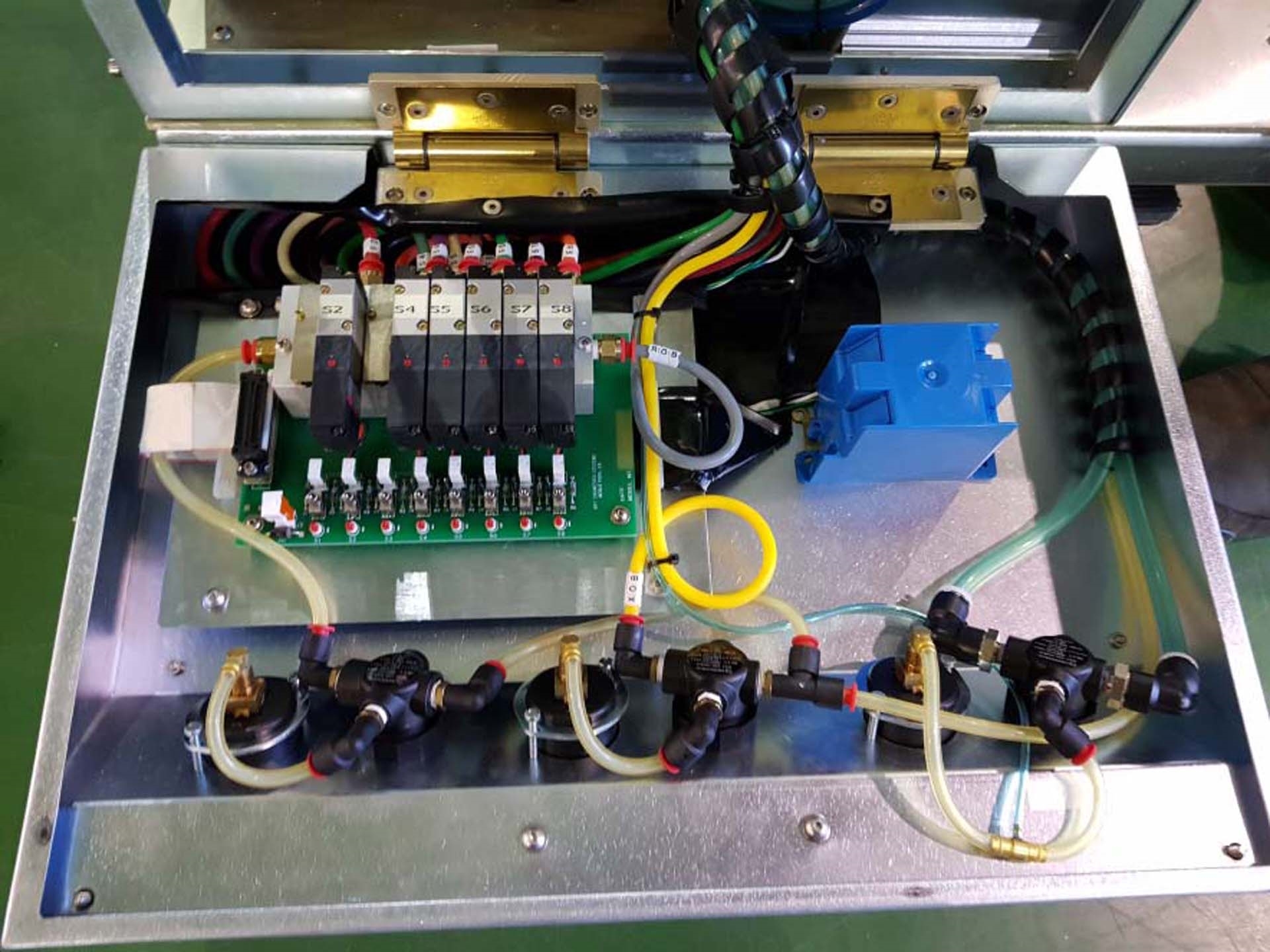

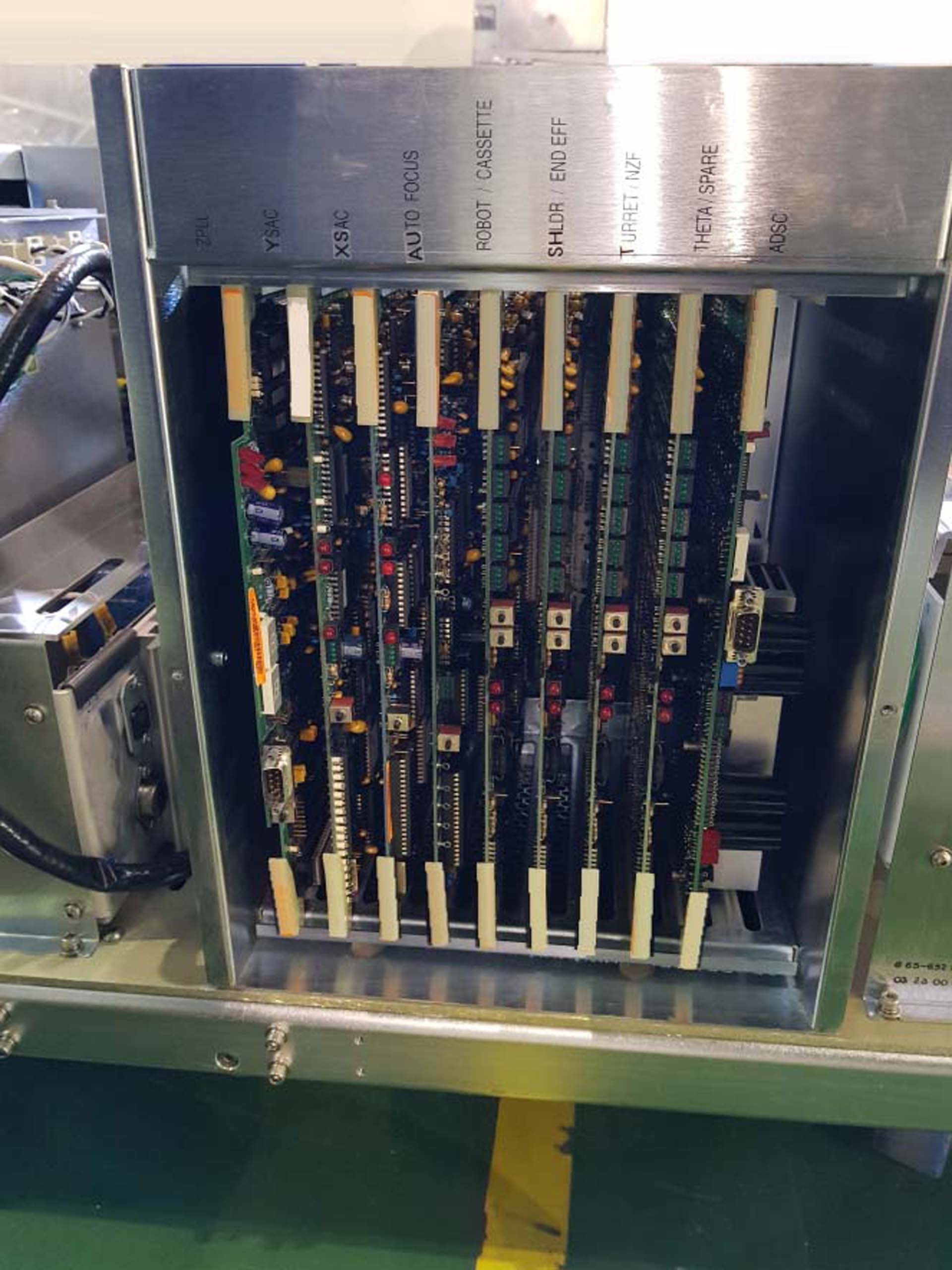

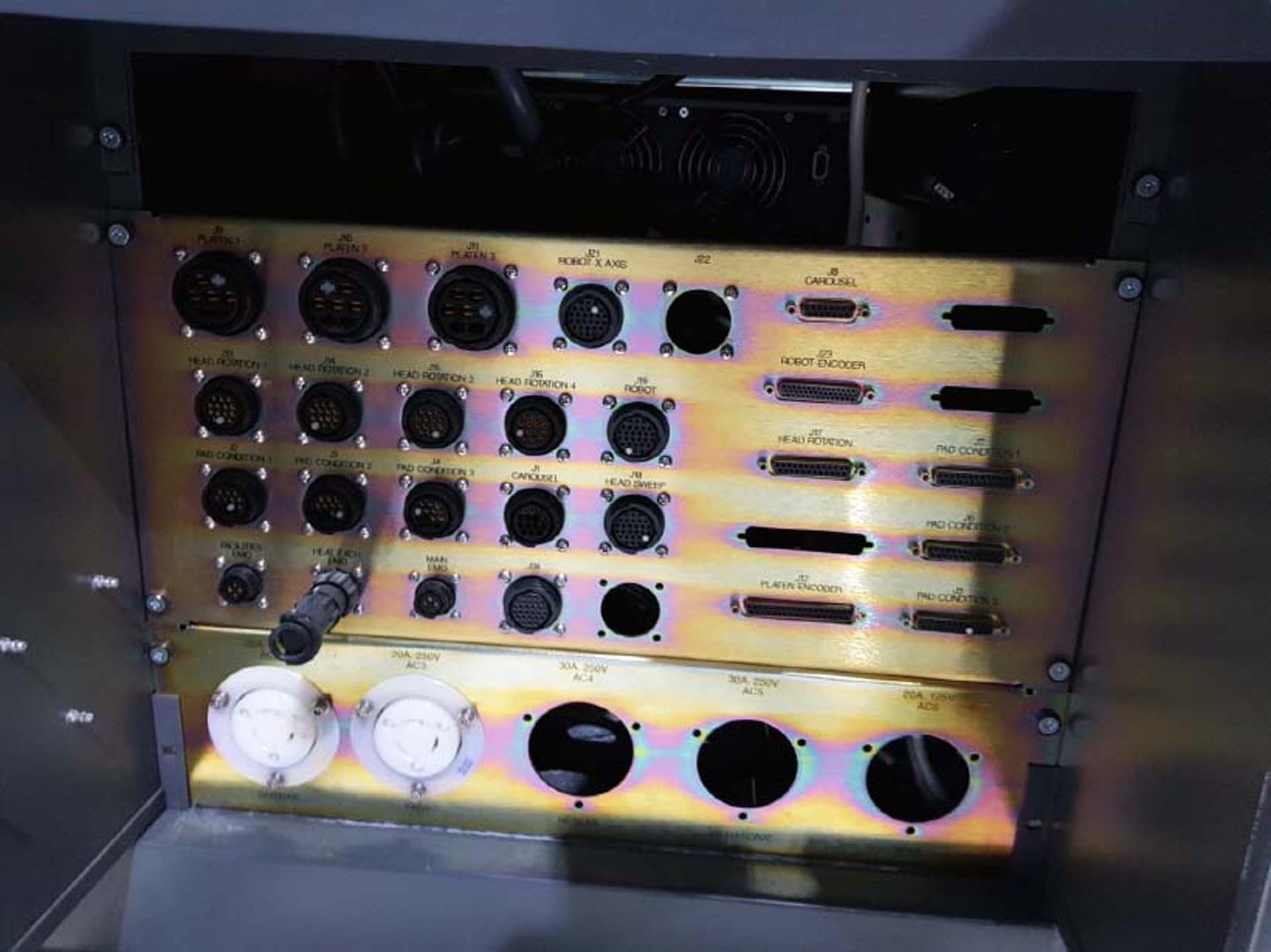

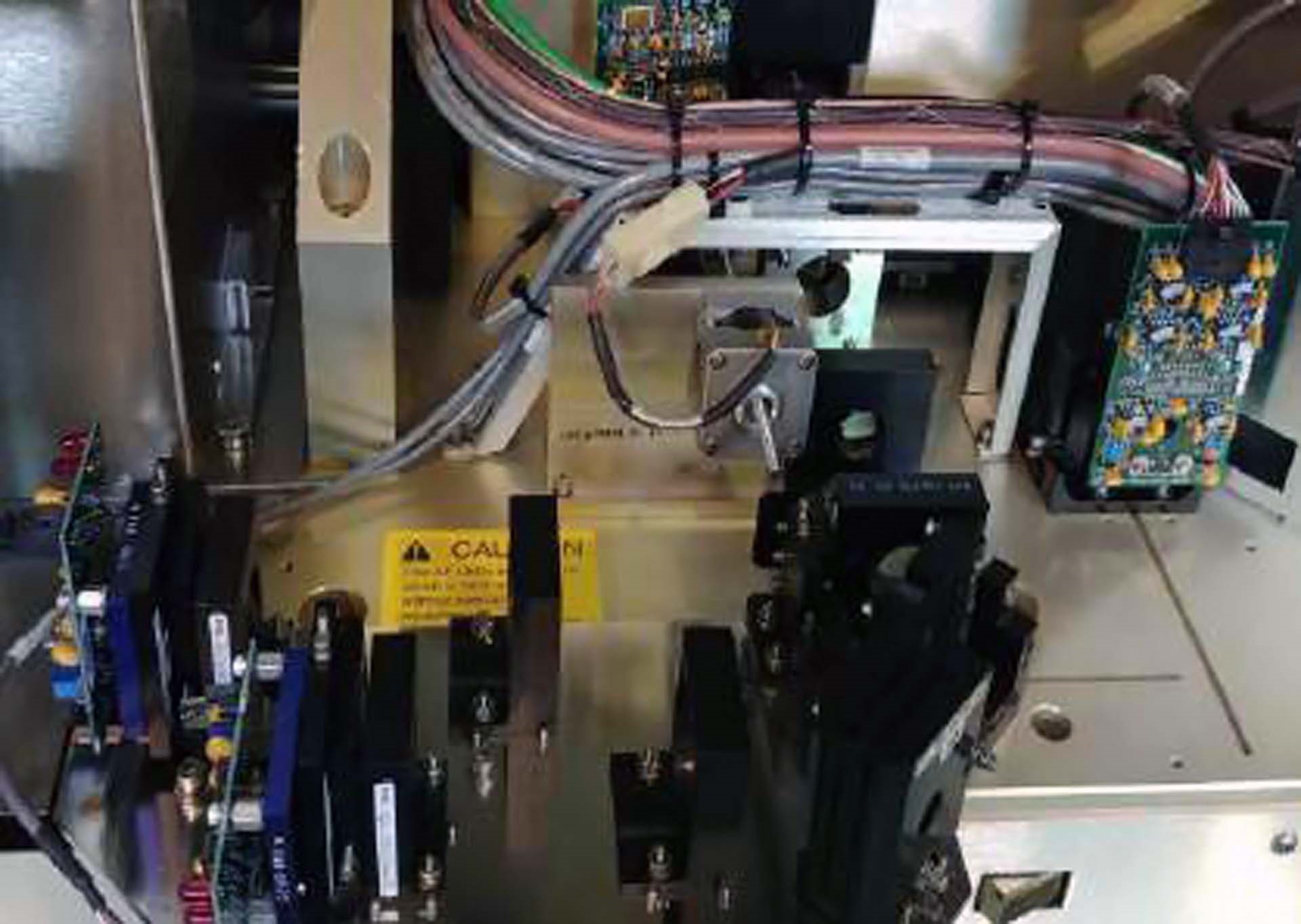

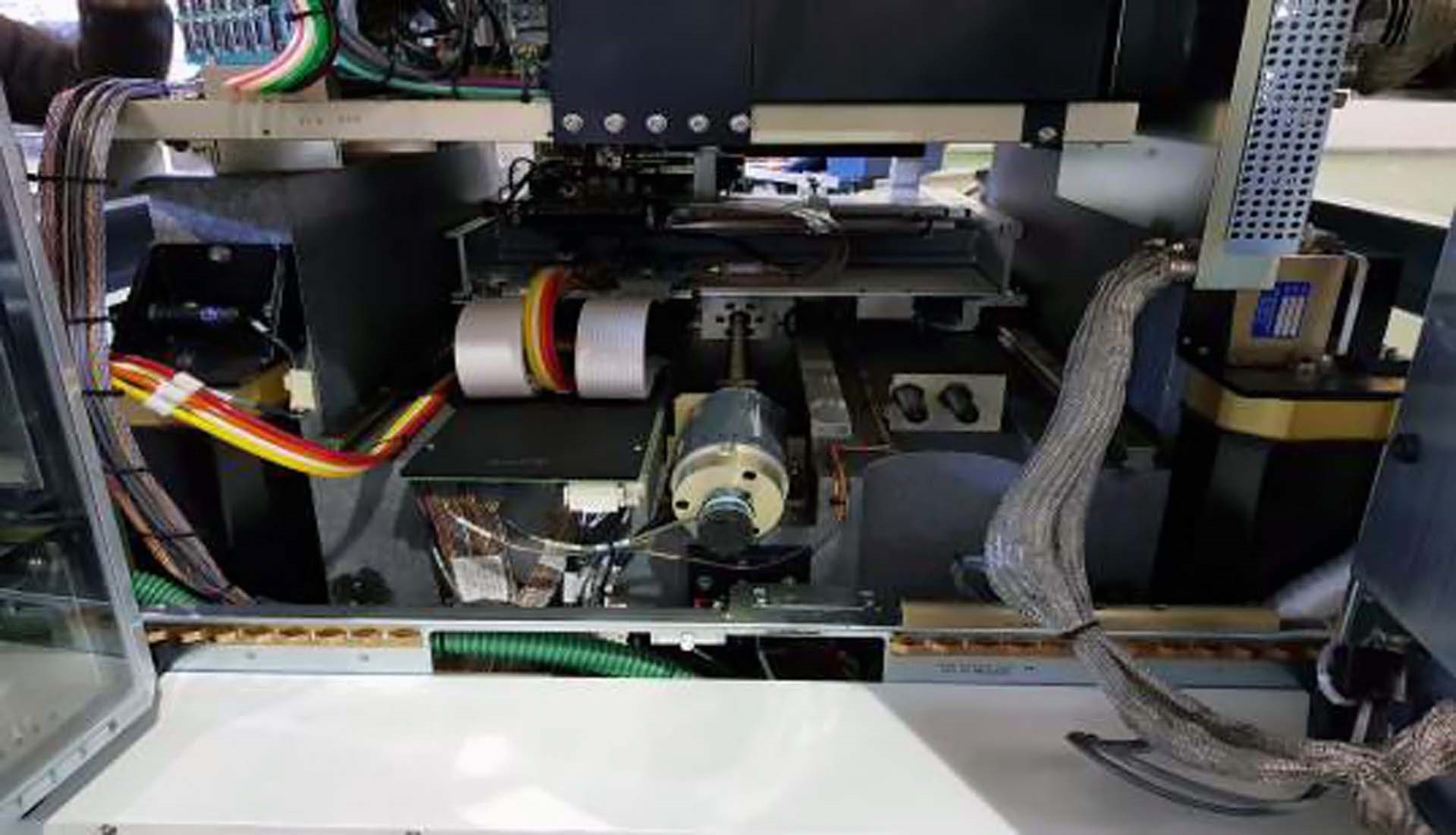

Stages:

X Stage bracket

Theta stage

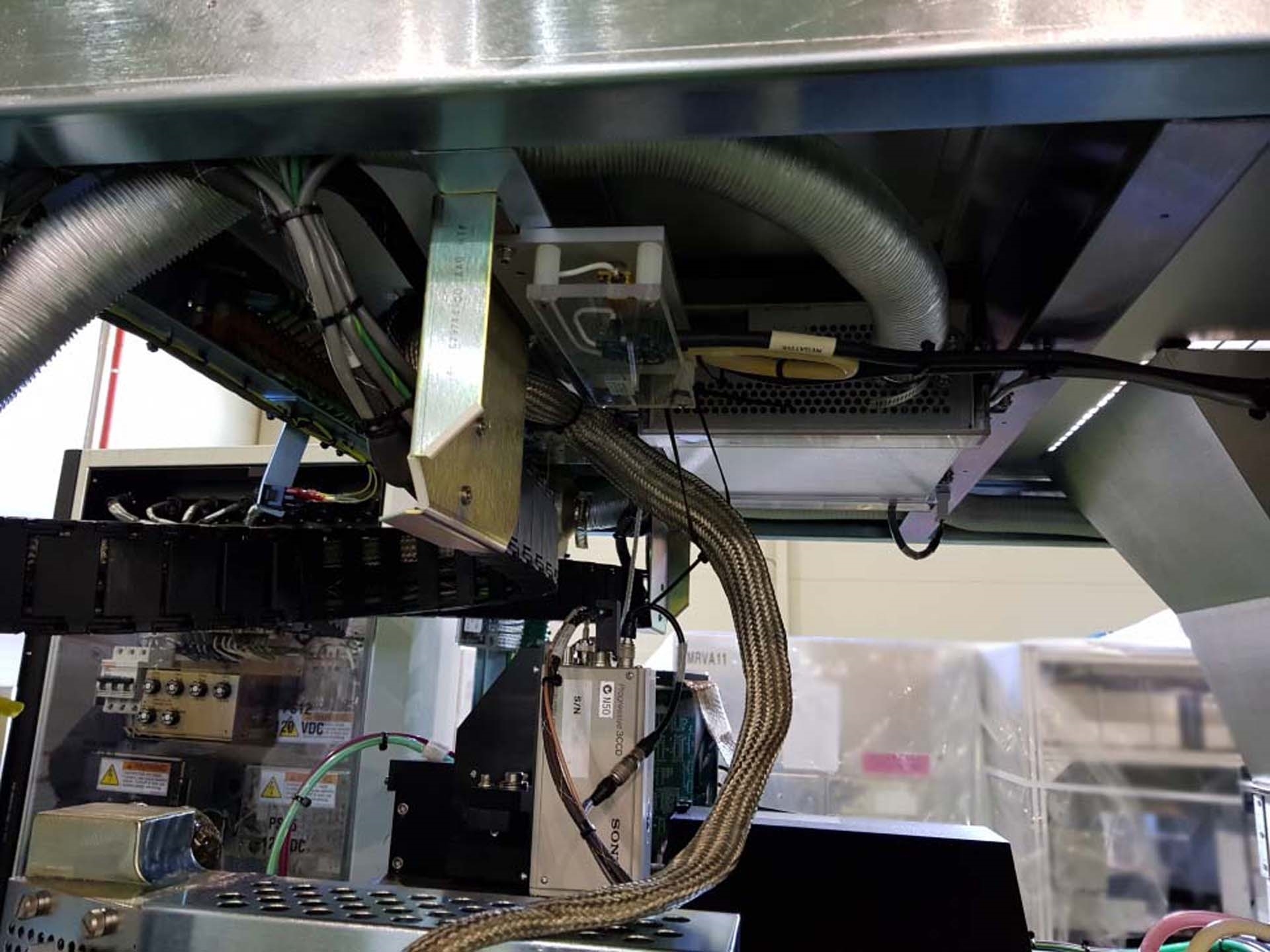

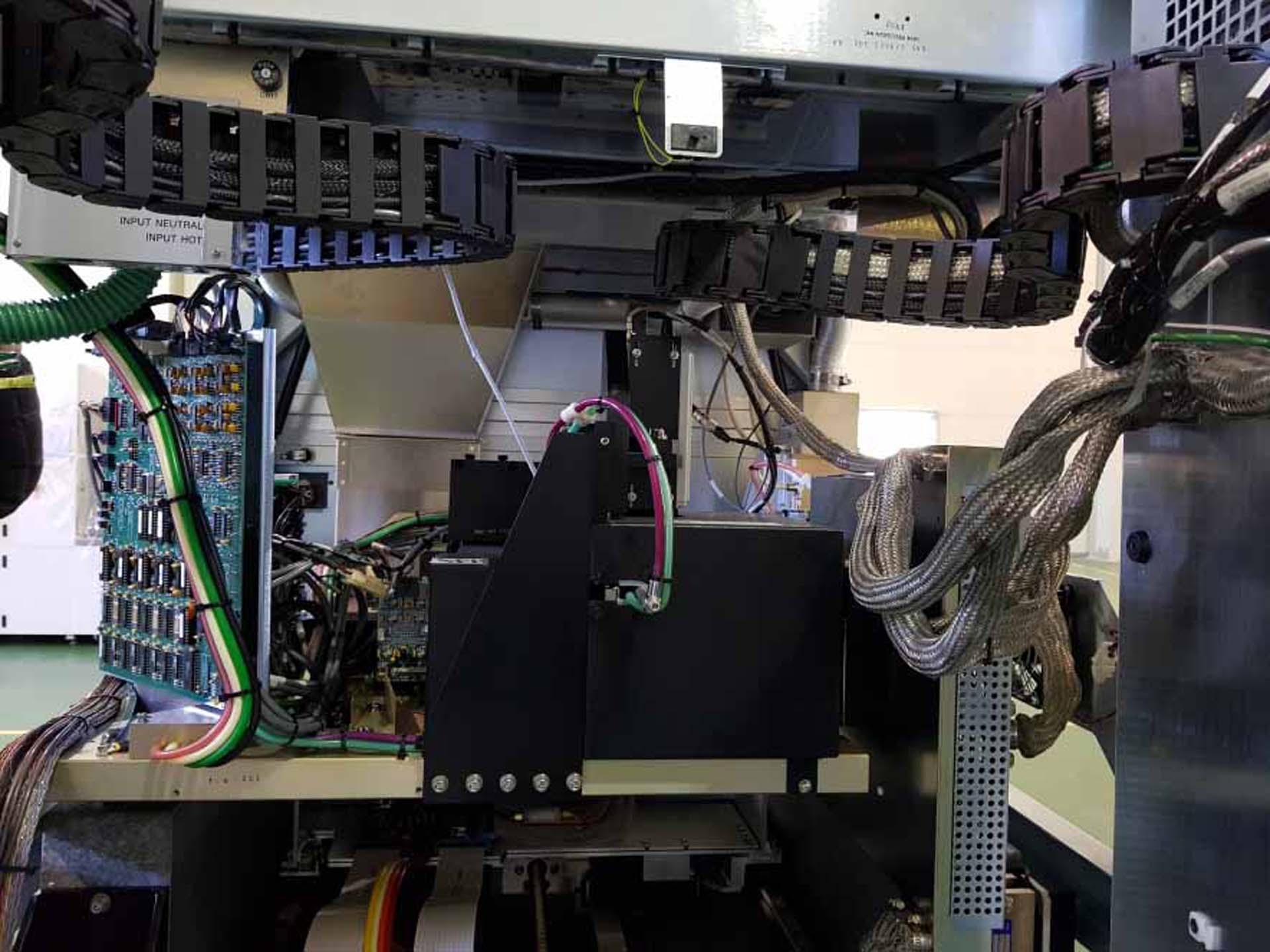

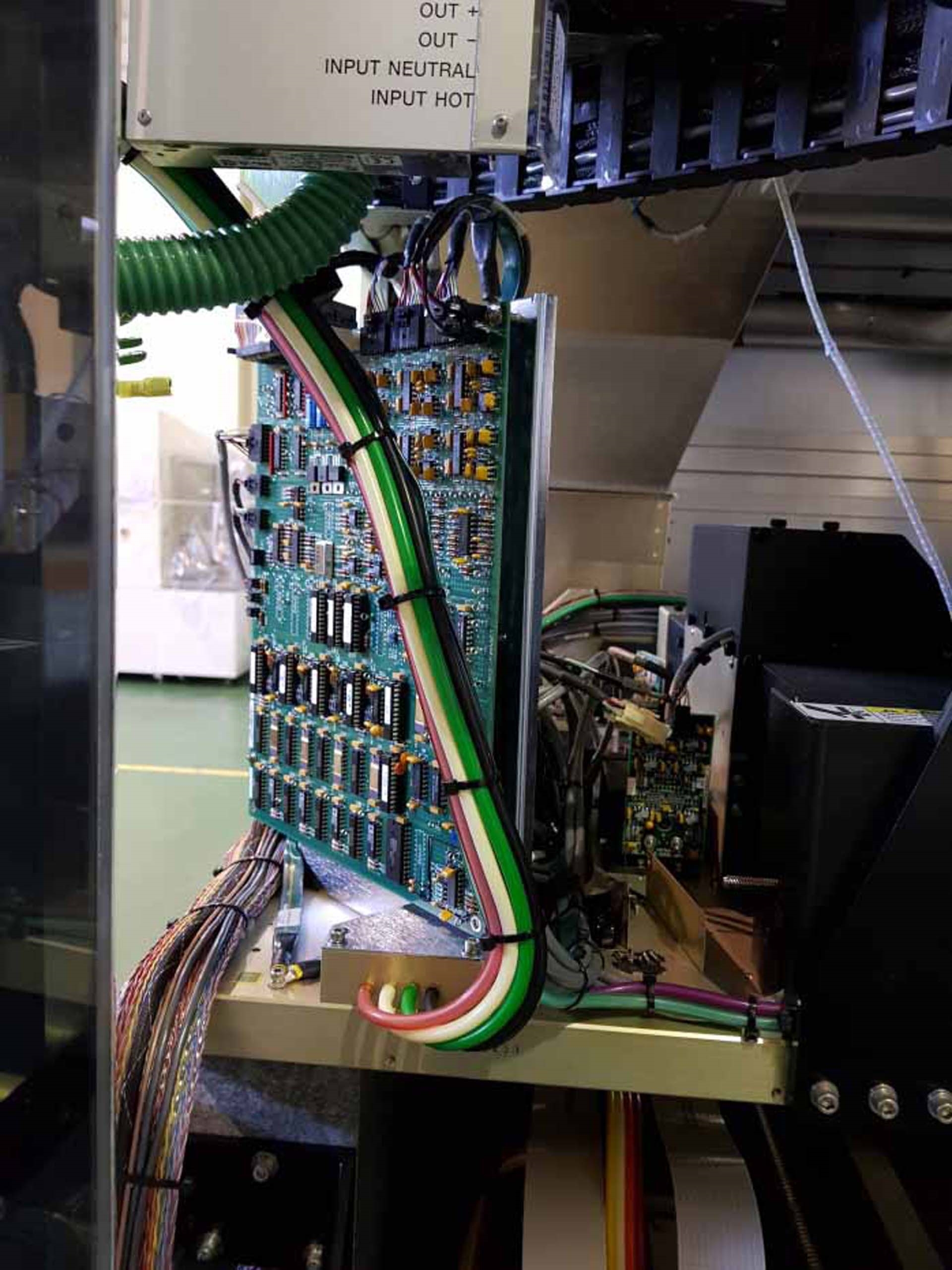

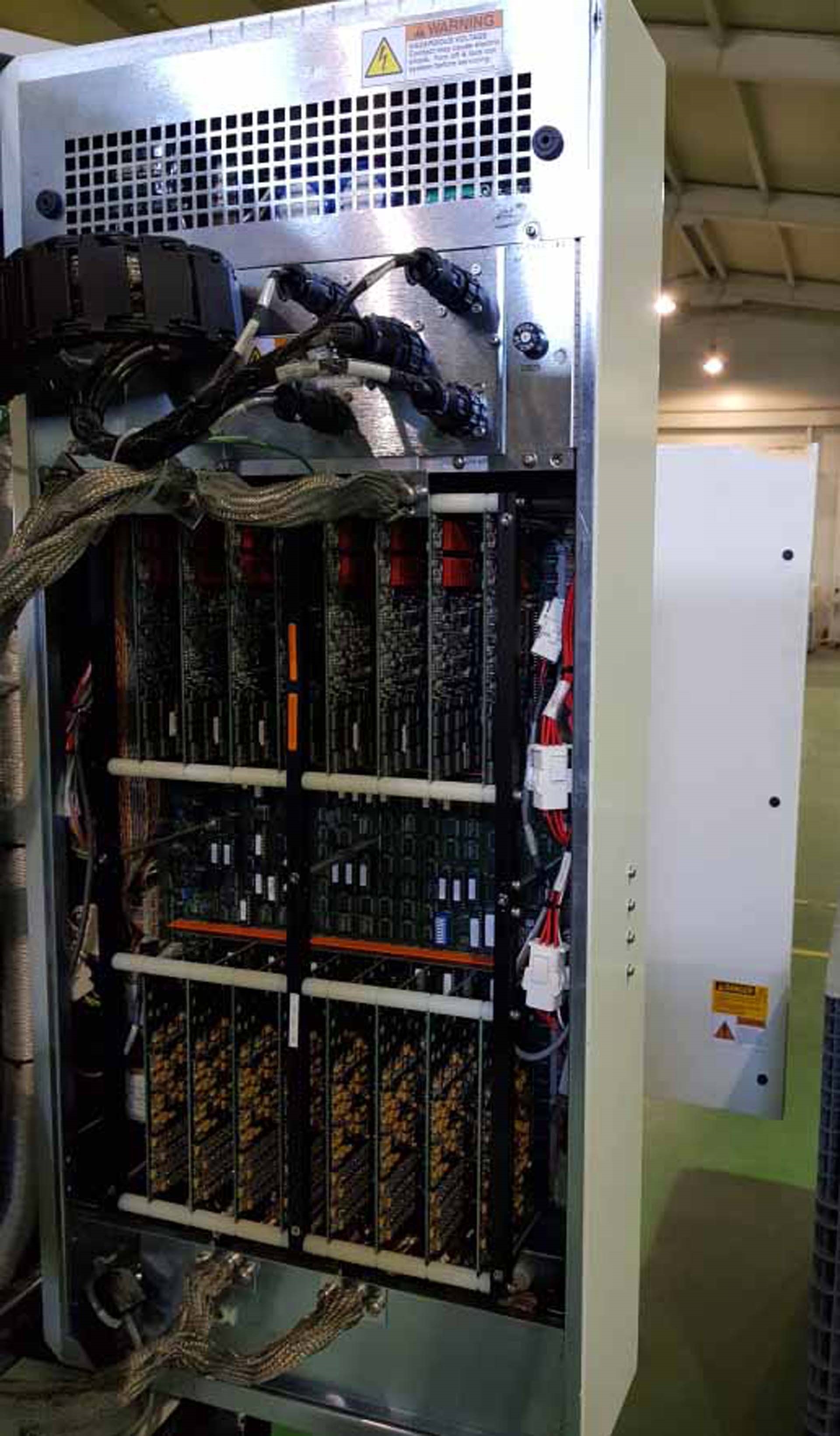

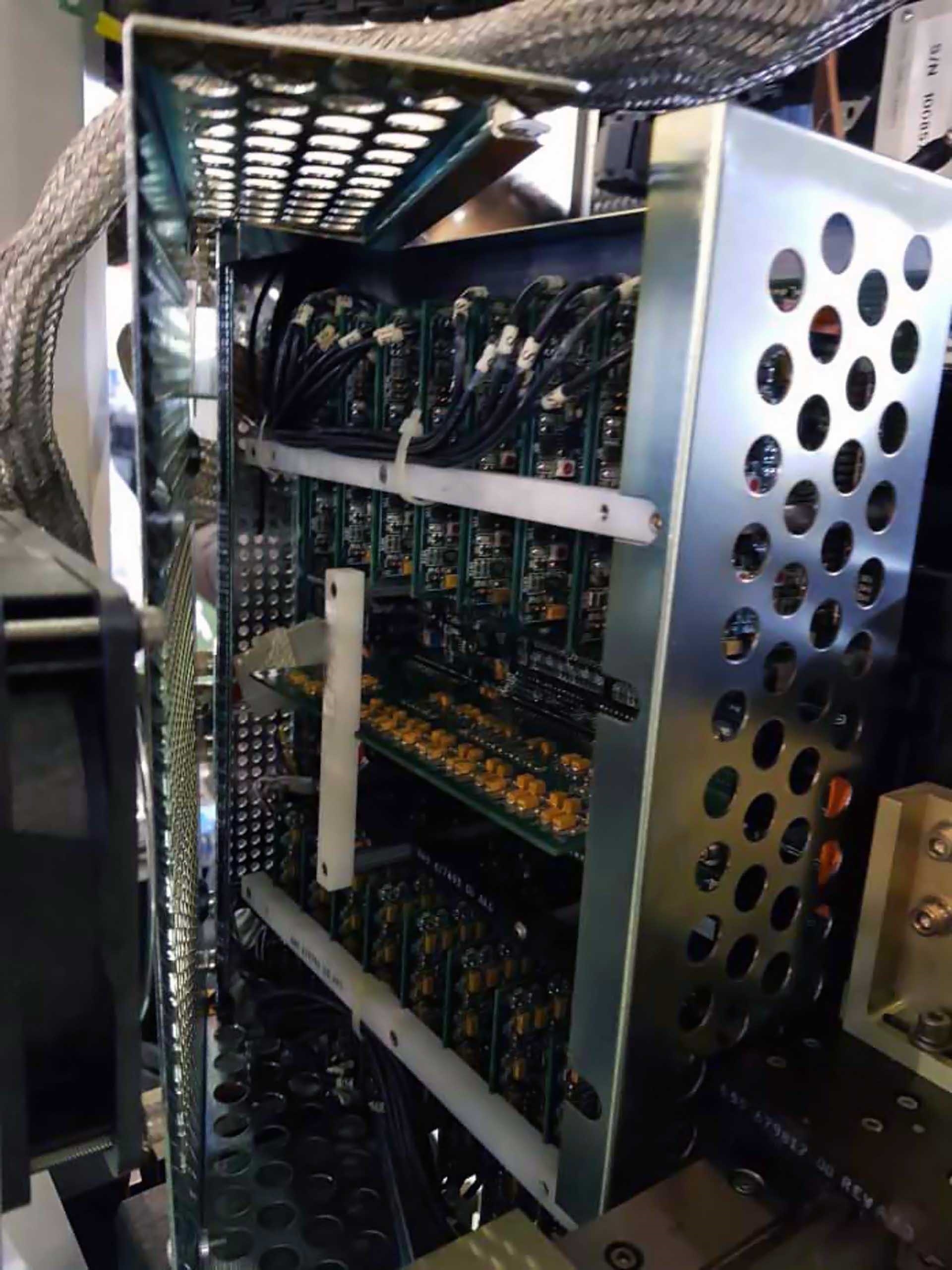

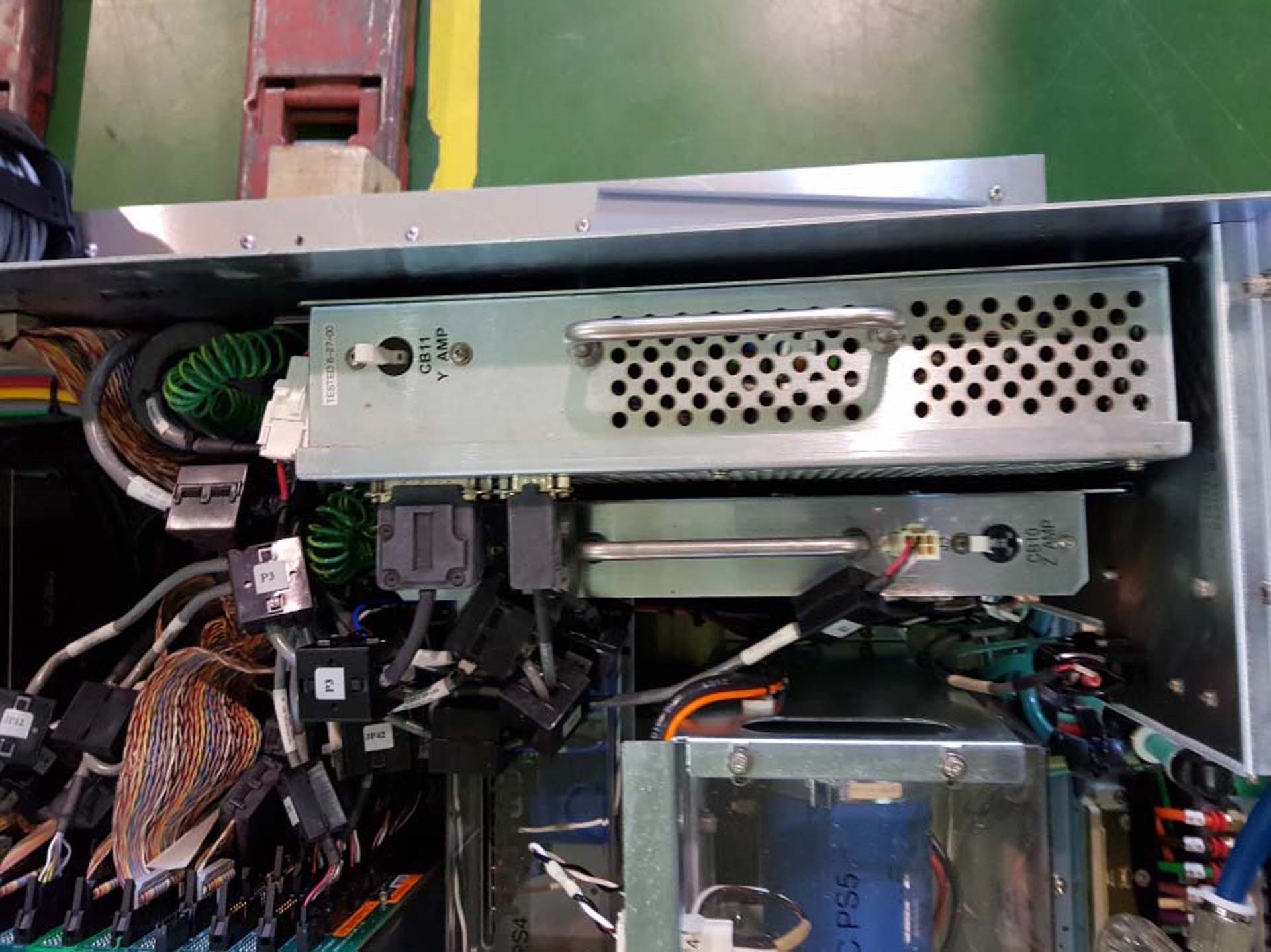

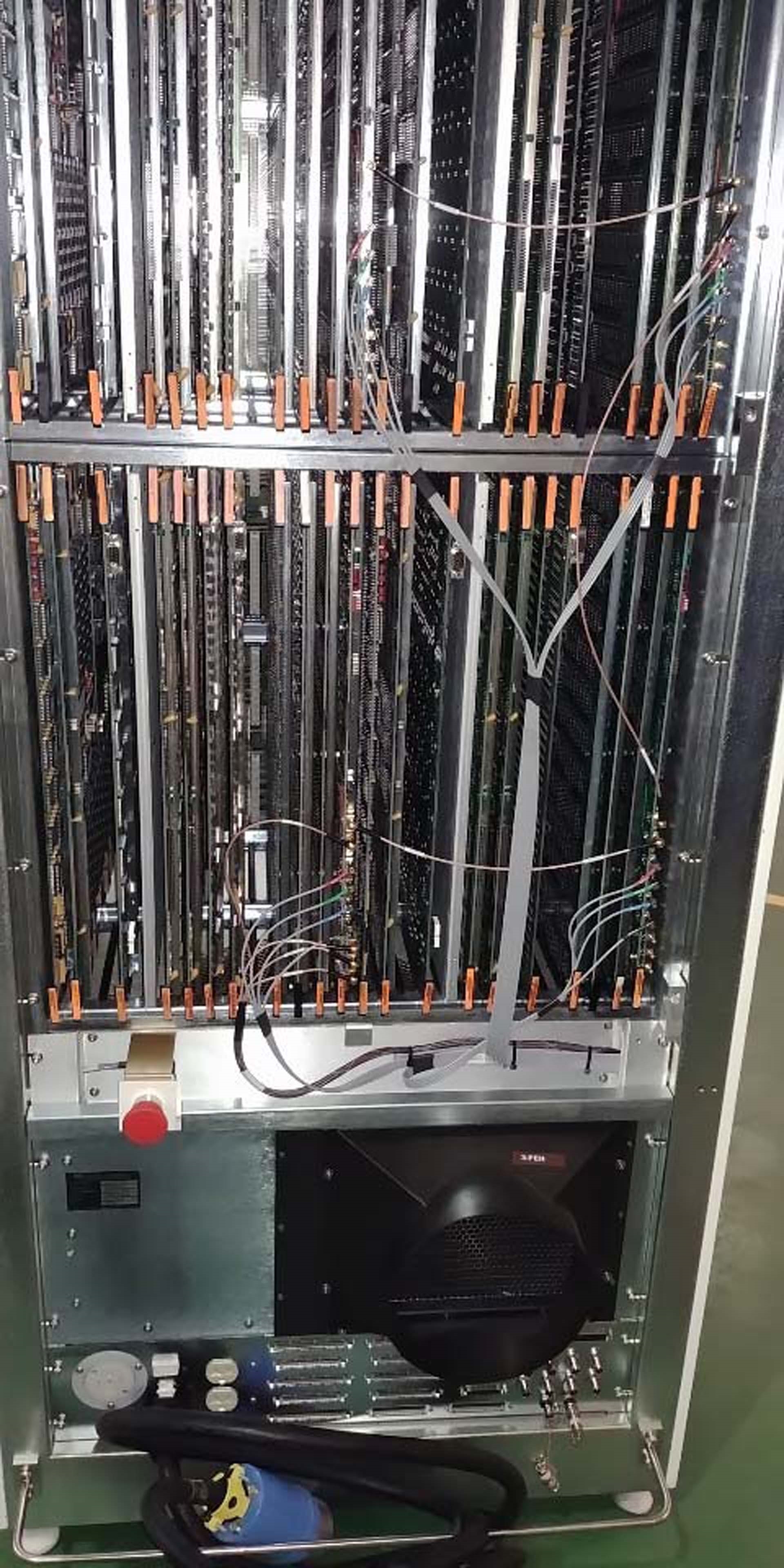

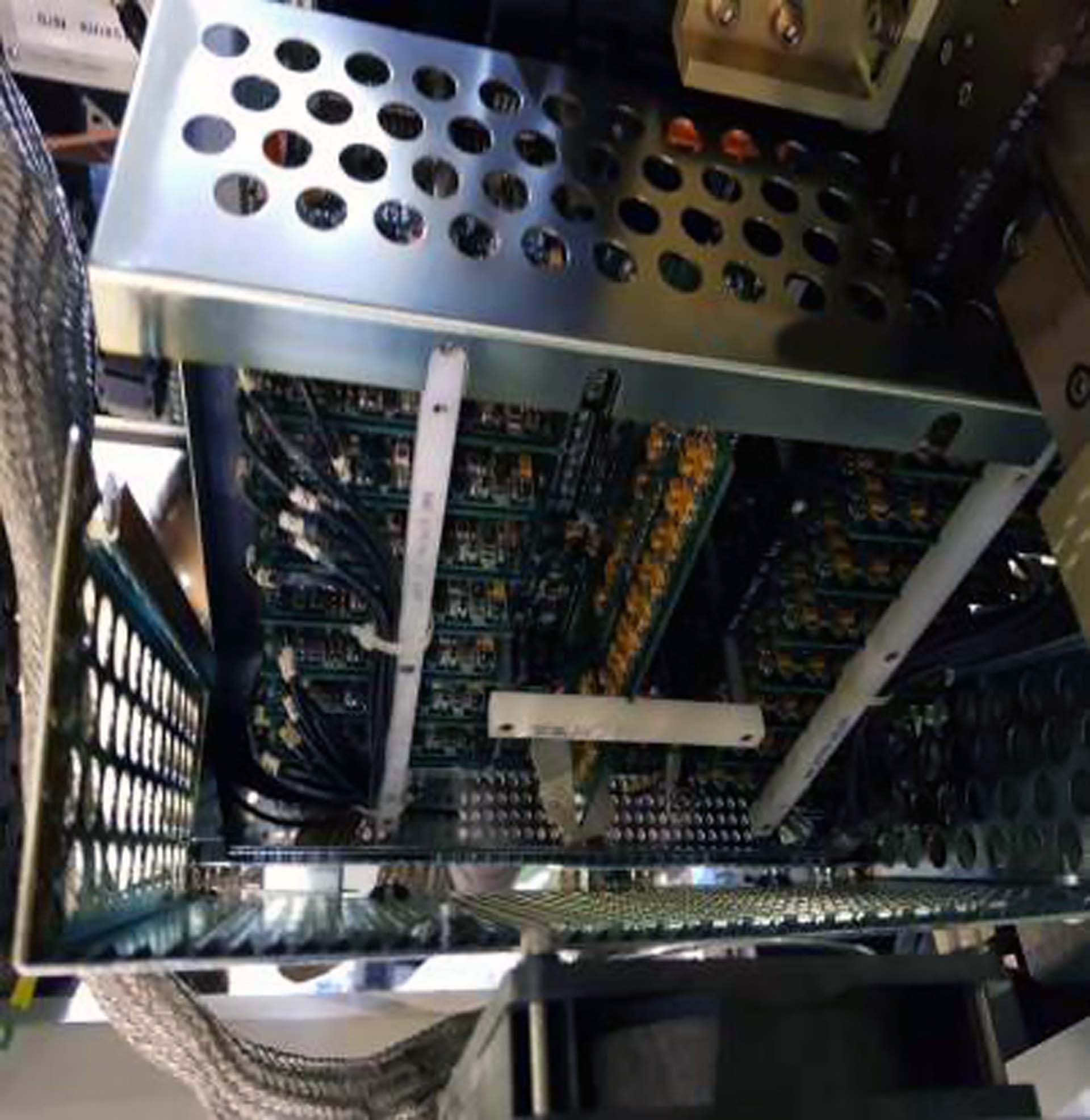

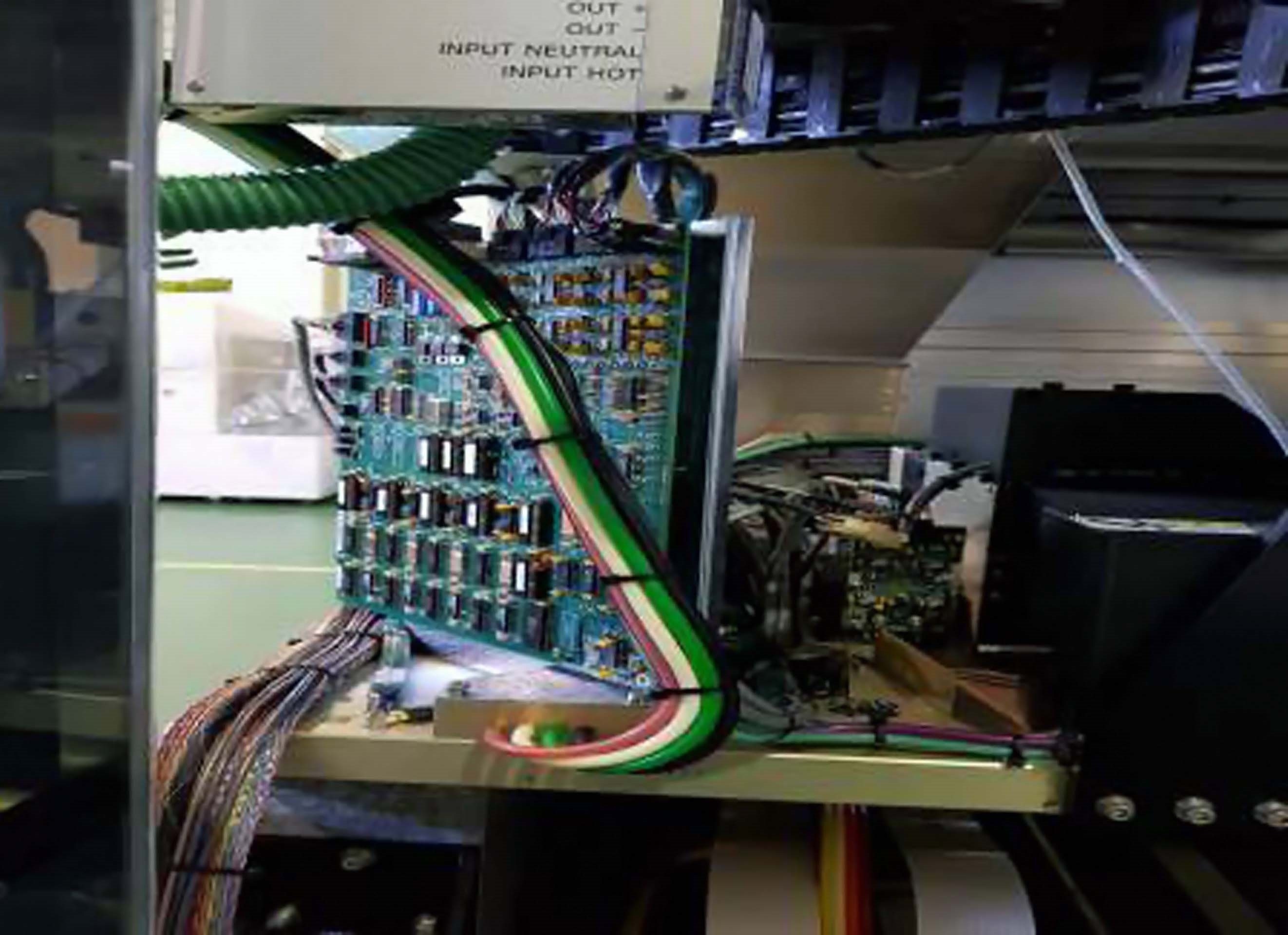

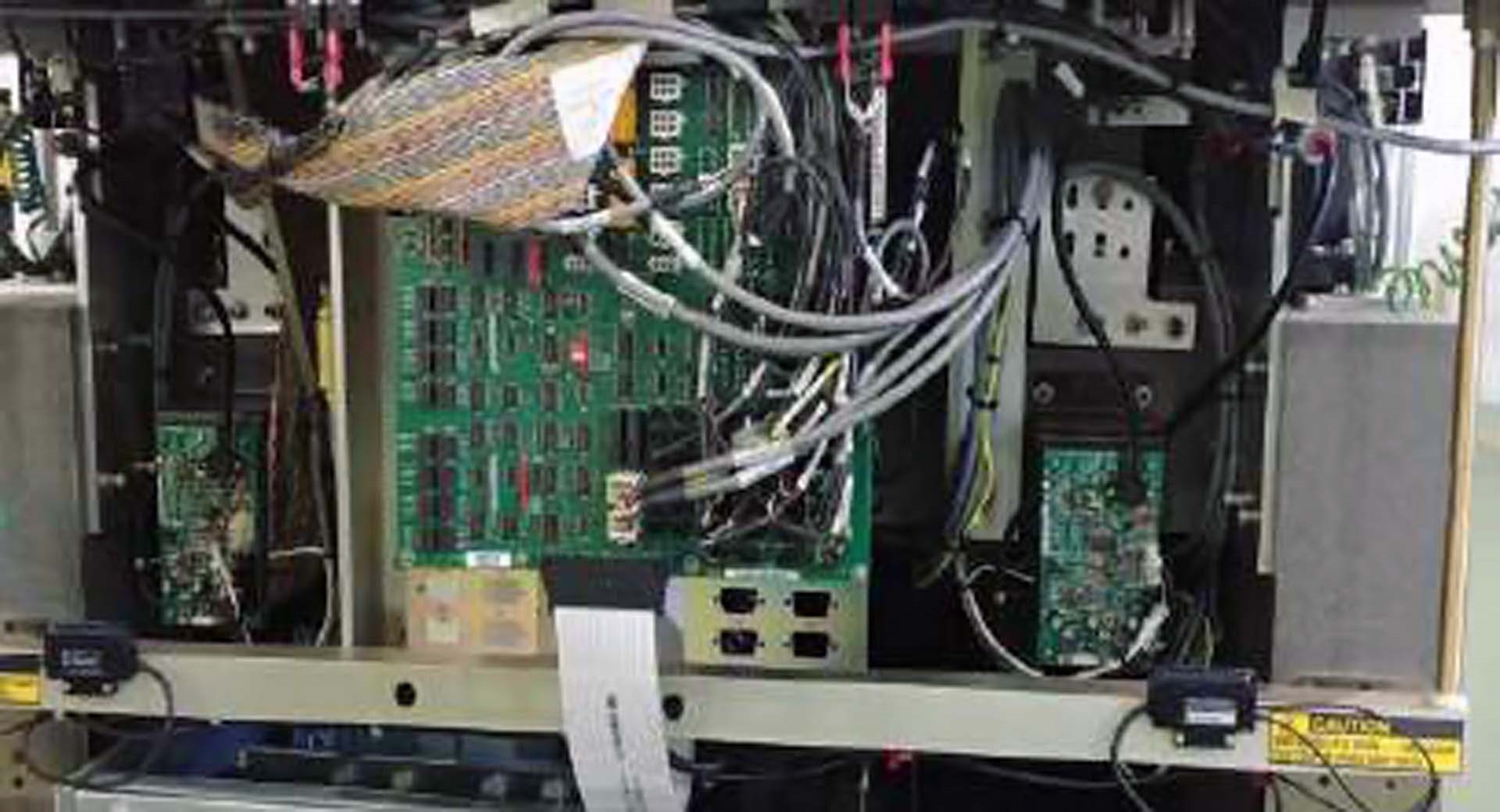

Image computer:

IMC0

IMC1

IMC2

IMC3

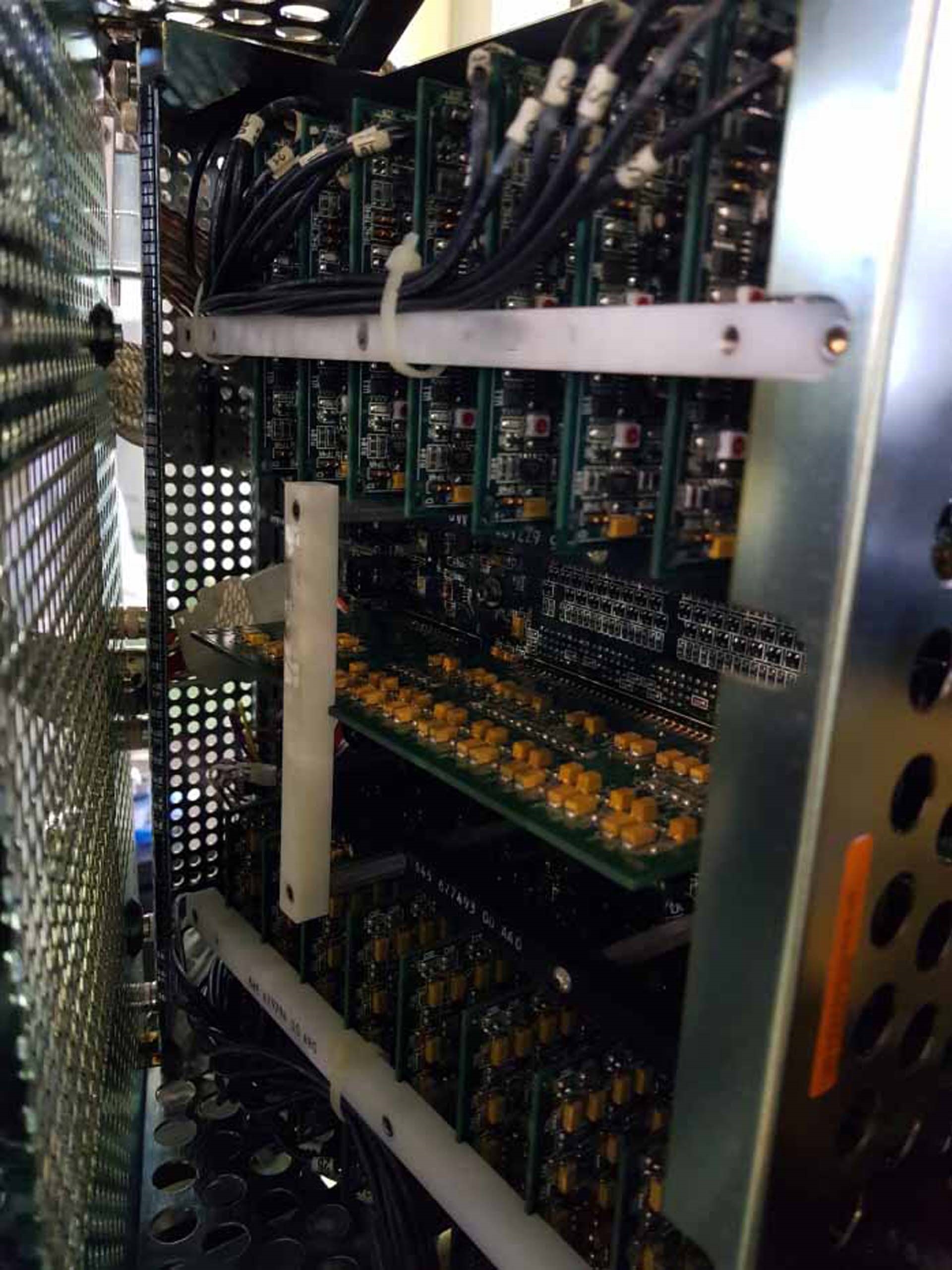

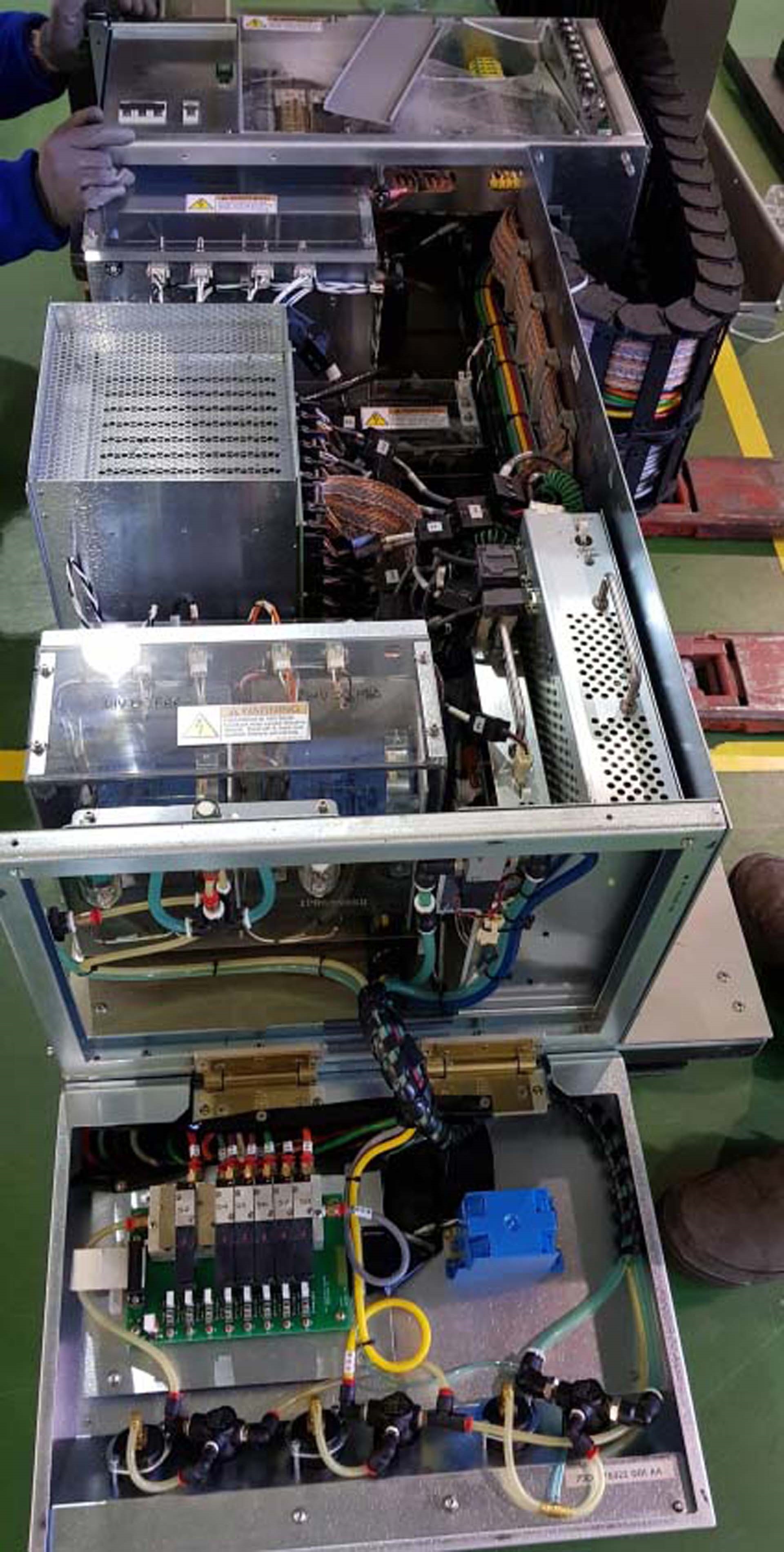

Power supplies:

+12 VDC E-Drawer

24 VDC E-Drawer

-24 VDC E-Drawer

+48 VDC E-Drawer

+65 VDC E-Drawer

2000 vintage.

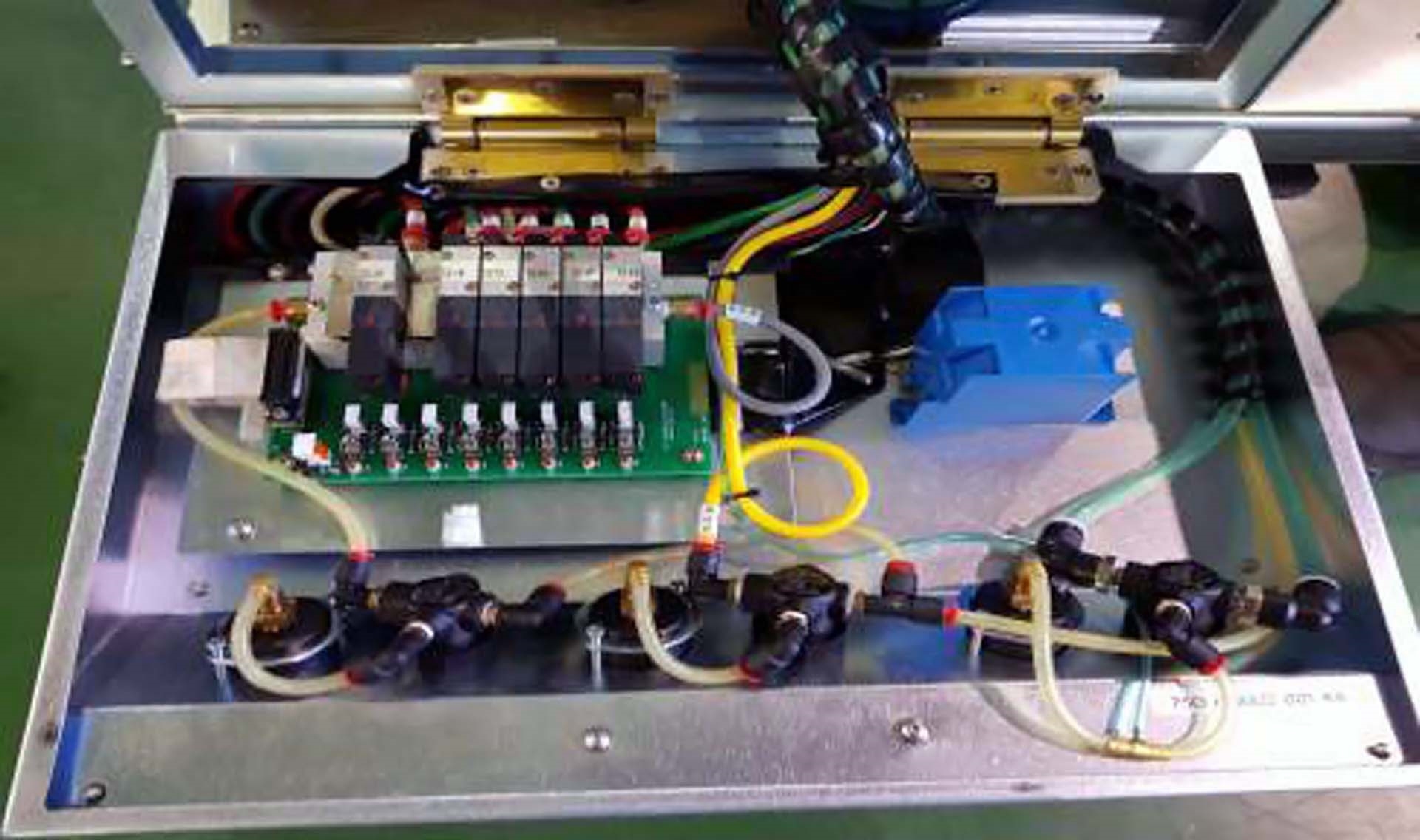

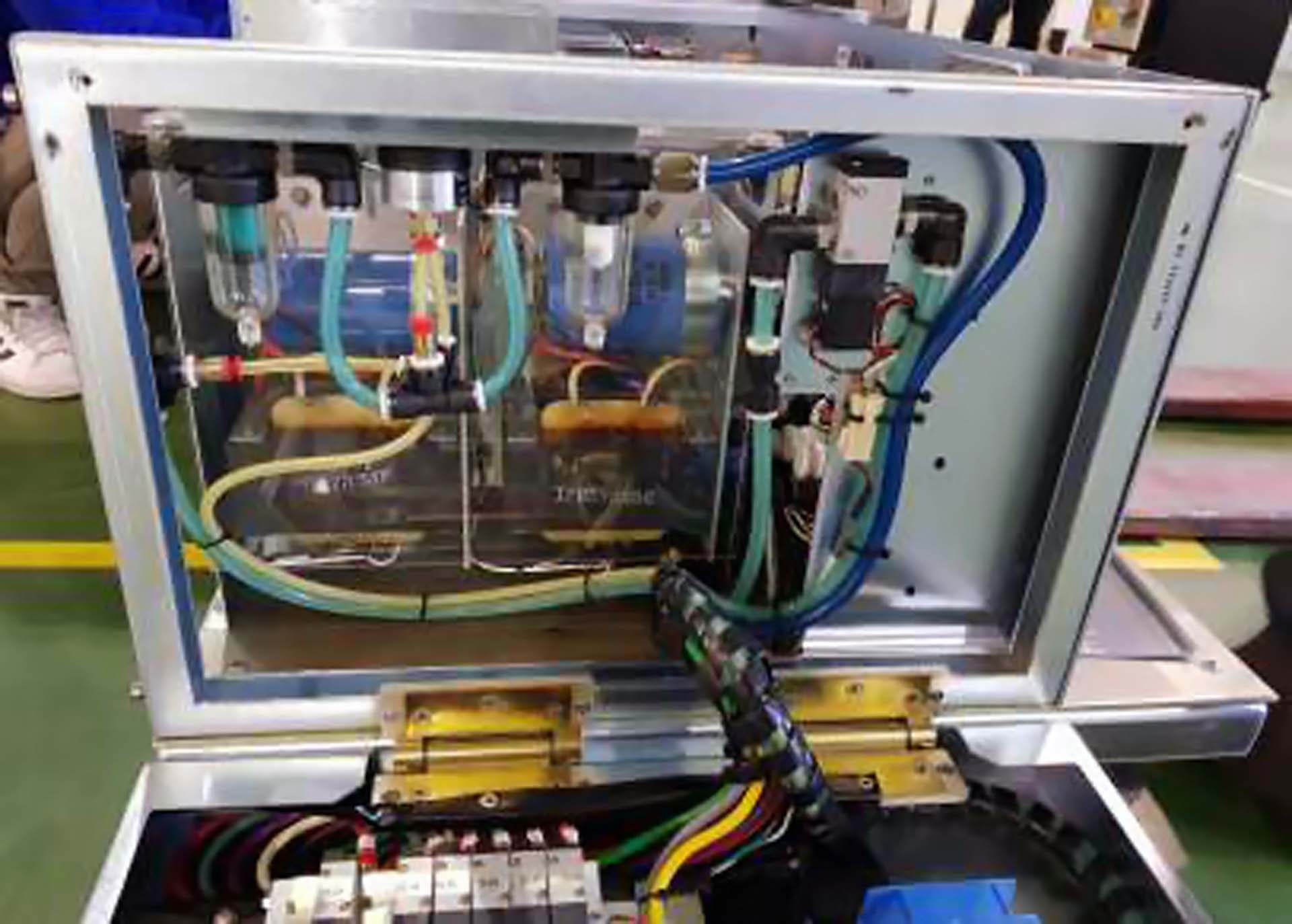

KLA / TENCOR 2139 equipment is a mask and wafer inspection solution that detects defects on wafer processes upstream and downstream of the photomask fabrication. The system offers a combination of imaging ports, mask aligners, advanced optical and illumination systems, and sophisticated algorithms to detect subtle but critical defects on the photomask. The imaging ports on KLA 2139 provide high-resolution imaging of the photomask by detecting differences in light reflections and displaying them to the user. It features a full-frame inspection, which ensures complete coverage of the entire inspection area and can detect features as small as 0.25 micrometer. Its optical and illumination systems include advanced beam deflection, direct/variable focus, oblique illumination, and backscatter/through transmission to accurately capture subtle defects. The mask aligners, on the other hand, ensure precise alignment between the mask and the wafer. TENCOR 2139 features a sophisticated software platform that offers specialized functions for mask and wafer inspection. Its advanced algorithms enable automated examination of defects on the photomask and enable efficient sorting of pure defects from false indications. The unit includes an intelligent auto-focus machine that automatically collects the focus positions of every field inspected. It also features context-sensitive commands that allow for intuitive operation and yield improved productivity. Overall, 2139 tool is an ideal solution for the detection of defects on photomask processes and provides a cost-effective and efficient solution for inspecting masks and wafers. It combines high-resolution imaging, advanced optical and illumination systems, reliable mask alignment, and sophisticated algorithms to ensure accurate, precise, and reliable inspection of photomask processes.

There are no reviews yet