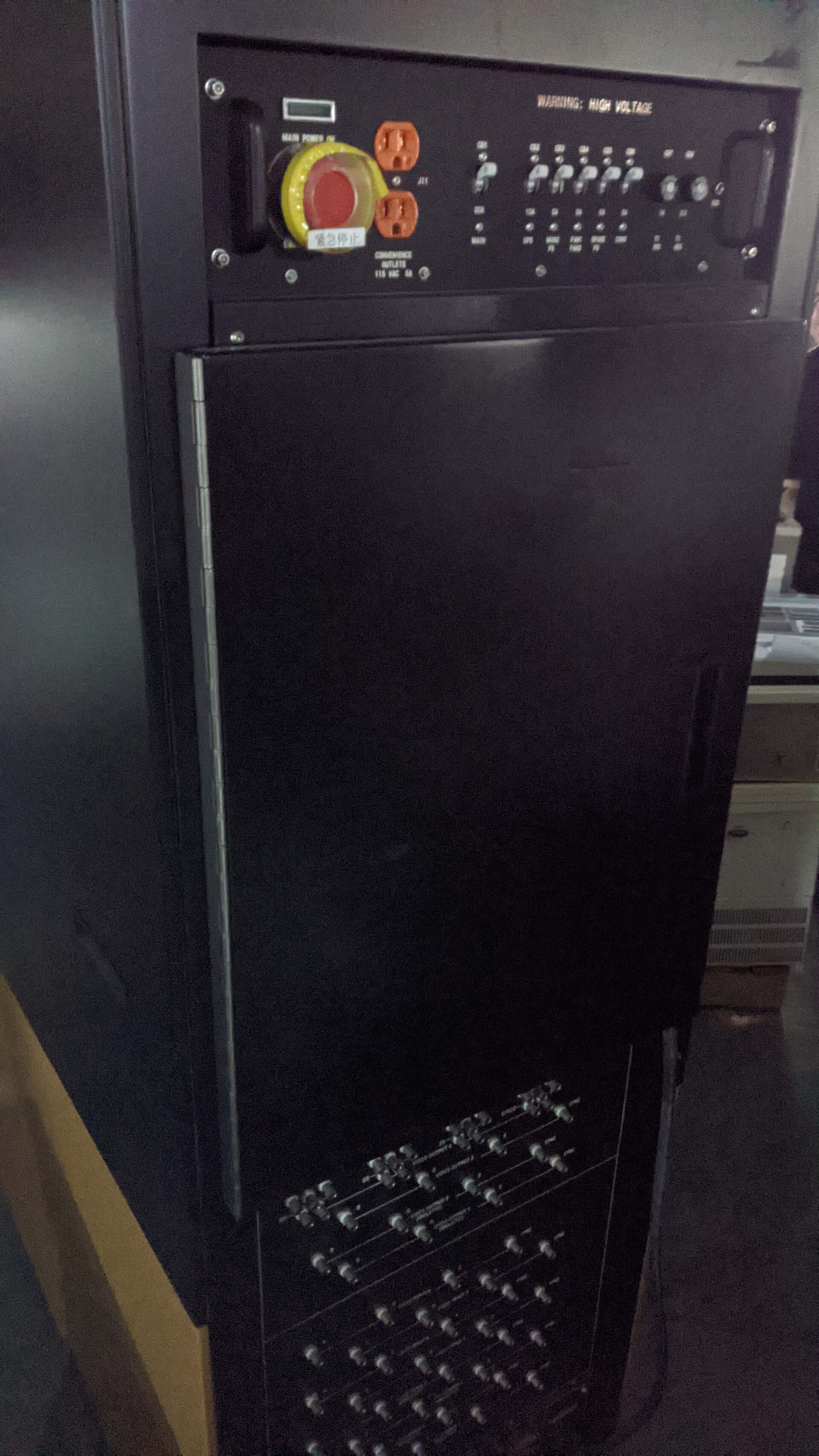

Used KLA / TENCOR 2552 #293616227 for sale

URL successfully copied!

Tap to zoom

KLA / TENCOR 2552 mask and wafer inspection equipment is a versatile, fast and accurate detection system that offers scanning of a variety of materials. It works by illuminating the item to be inspected with a light source and then capturing an image of the item with a high-resolution CCD camera or optical microscope. The unit is capable of measuring critical dimensions and feature detections on all types of die, mask and wafer materials, from wafer and MEMS devices to nano-scale features. The inspection machine offers advanced imaging features, fast data acquisition speeds, real-time image processing, and a sophisticated analysis engine, which can be easily operated. KLA 2552 offers automated, high-resolution imaging of even the most challenging die and mask metrology tasks with its automated microscope camera and optical focus register. Its Dielectric Barrier Tool (DBS) adds even greater power, allowing for the efficient collection of terabytes of data in the field of high-resolution imaging and data collection. The DBS feature uses an advanced signal processing algorithm, providing a significant improvement in the detection of defects and other features on a die or mask surface. Furthermore, the asset has an adjustable working distance, which can be adjusted between 8 and 20 mm as needed, making it ideal for inspecting larger die. This is supplemented by its advanced optomechanical design, including the Microner Opti-stable Specular Finish, which ensures that the optical filters placed within the model are stable and reliable throughout the inspection process. TENCOR 2552 mask and wafer inspection equipment also comes with a host of other capabilities and features that enable it to maximize the accuracy and repeatability of any inspection job. This includes automated data analysis, metadata capture, and notification of test results, allowing for reliable and repeatable test results. Furthermore, its upgradeable software package can provide additional functions, including feature detection and source detection, defect detection and analysis, area coverage analysis, and process analysis. The comprehensive software package also includes wafer mapping software and registration mark tools, which increase the accuracy of the system's data capture and results. All of this combined makes the unit an ideal solution for any mask or wafer inspection task. Those looking for an effective, efficient, and reliable inspection machine for die, mask, or wafer applications should look no further than 2552.

There are no reviews yet