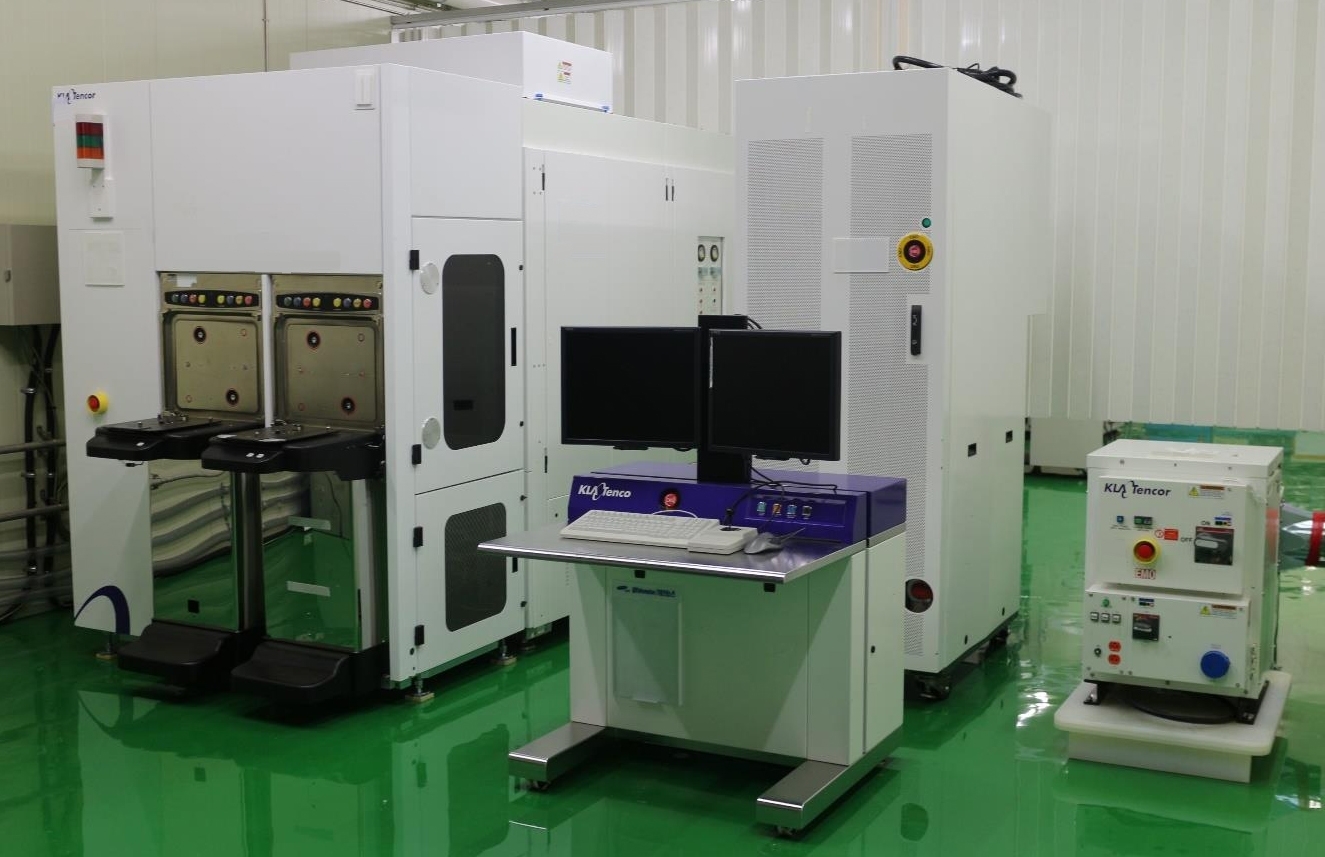

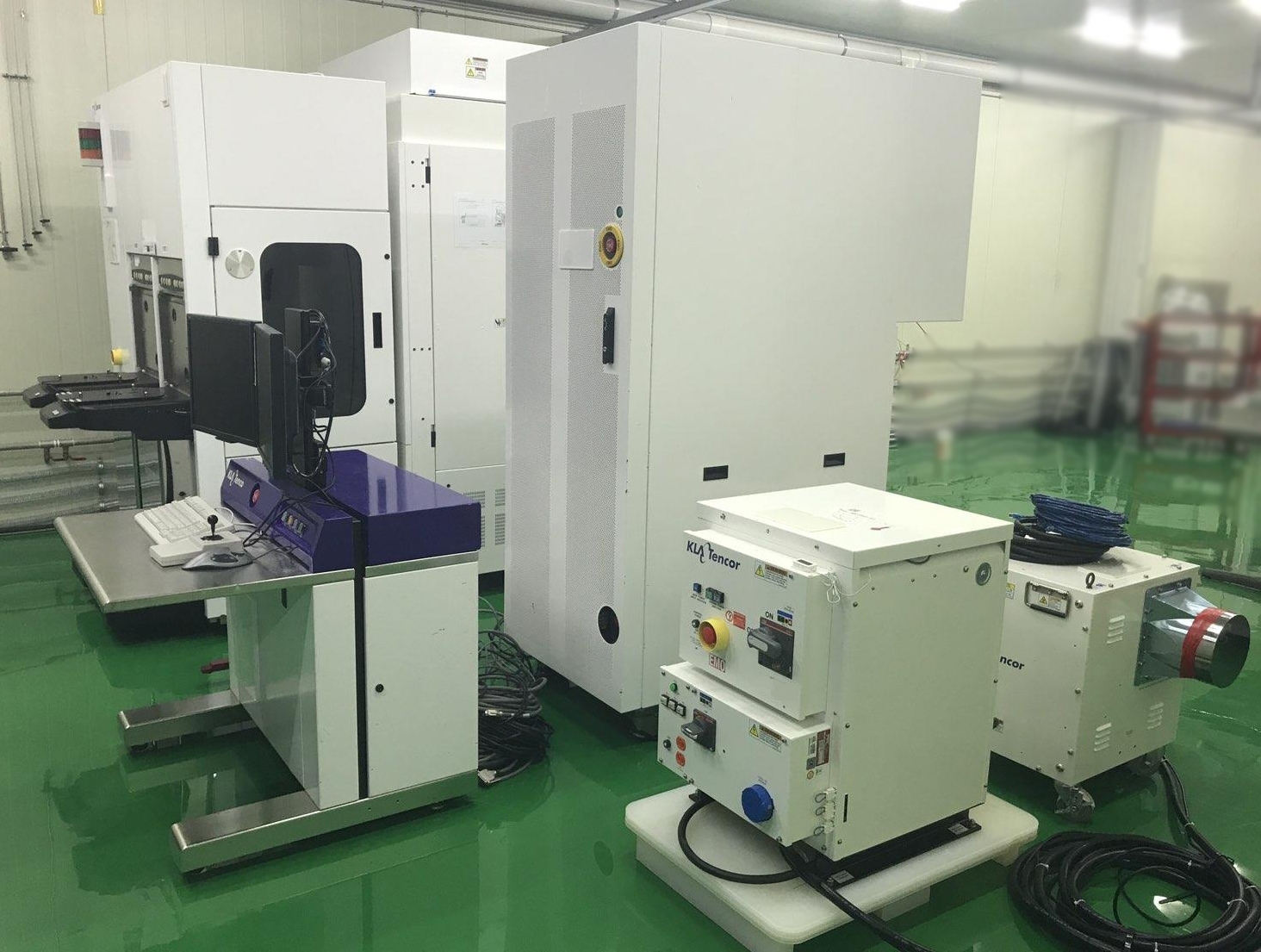

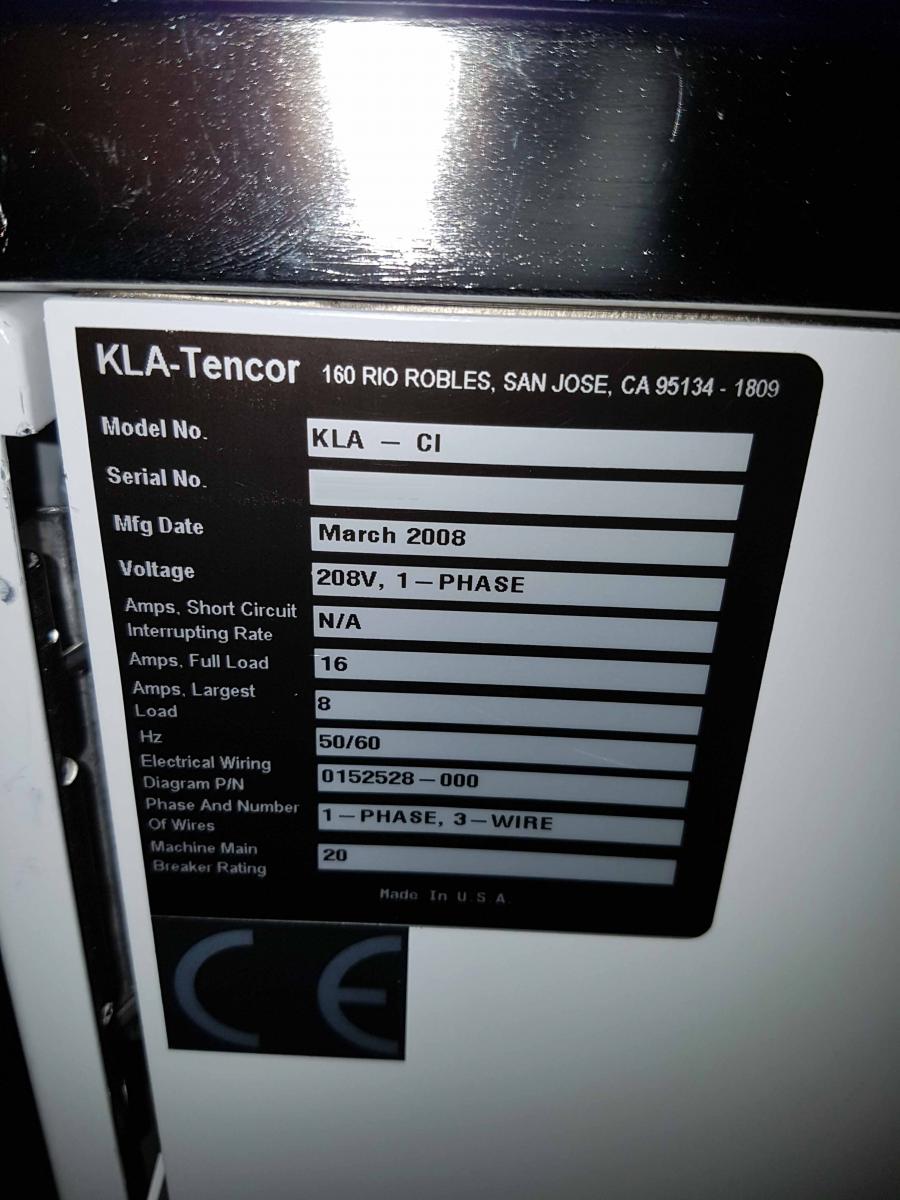

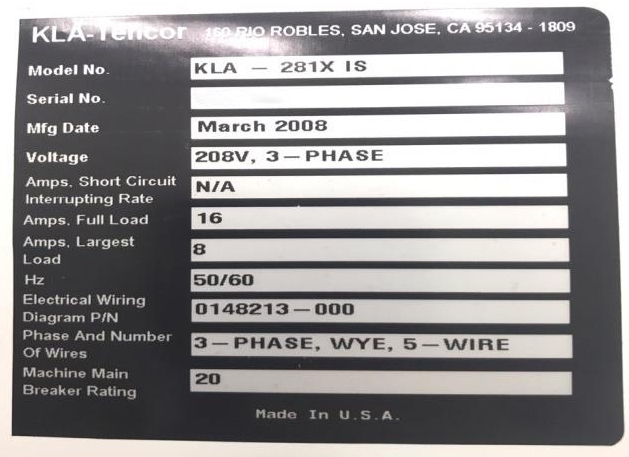

Used KLA / TENCOR 2810 #9178483 for sale

URL successfully copied!

Tap to zoom

ID: 9178483

Wafer Size: 12"

Vintage: 2008

Inspection system, 12"

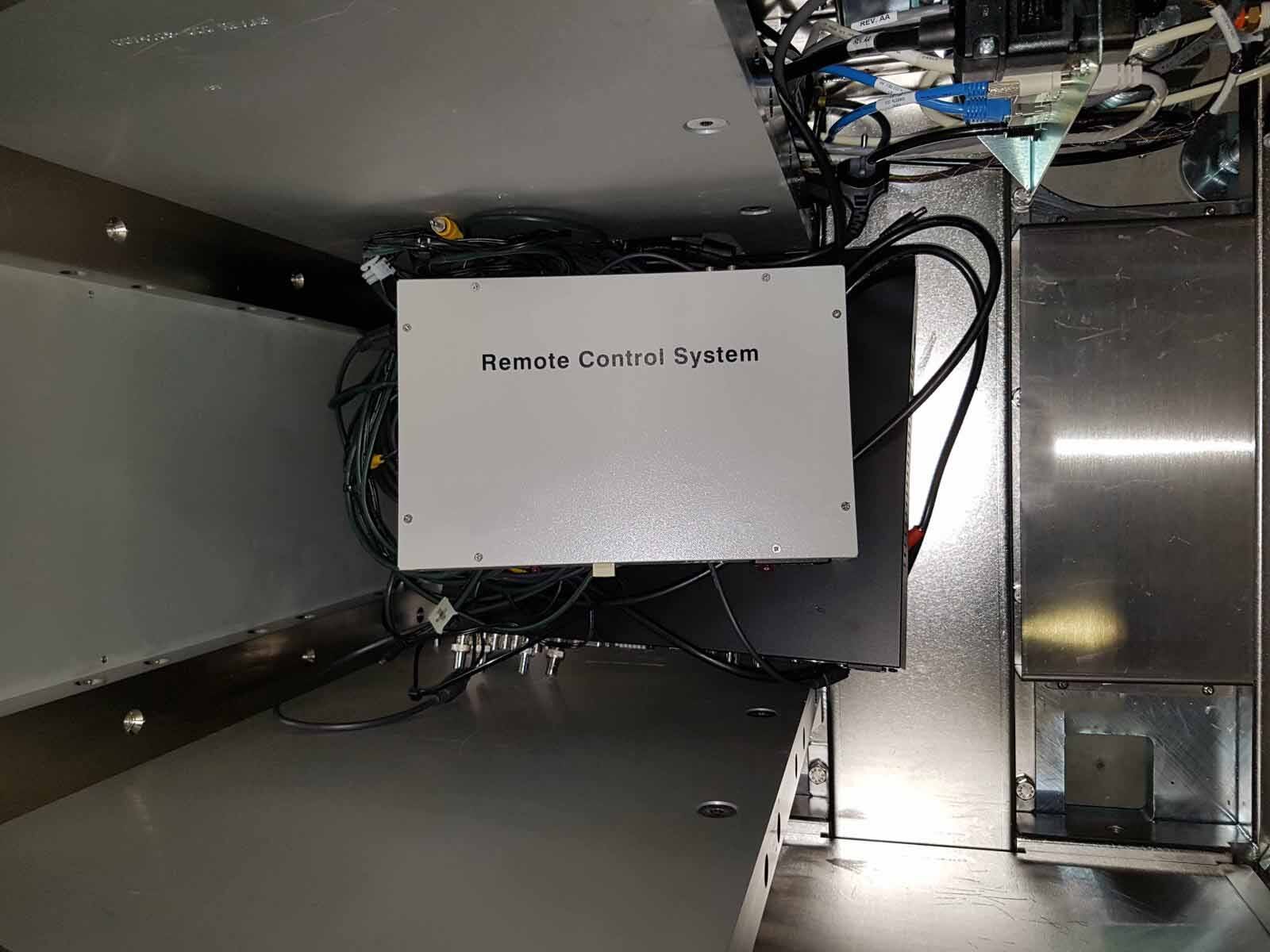

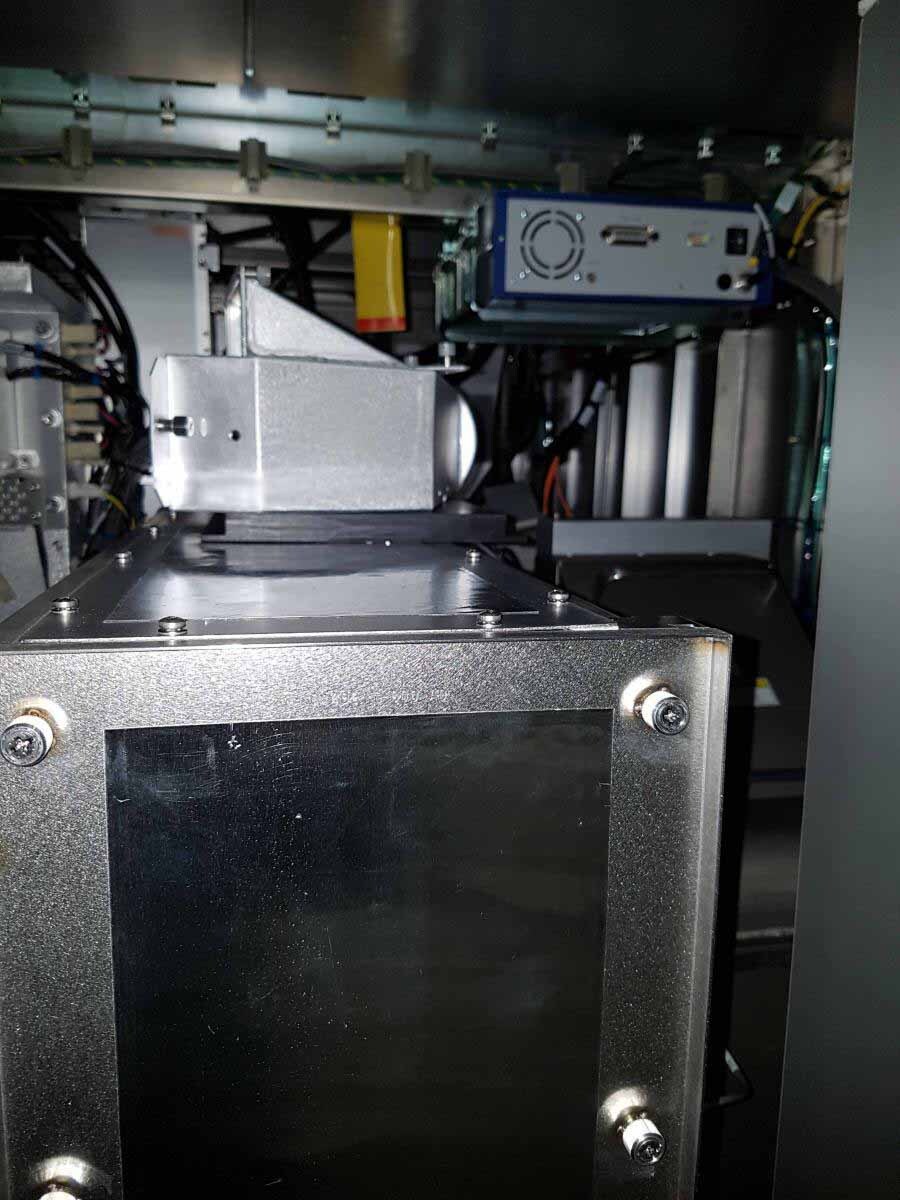

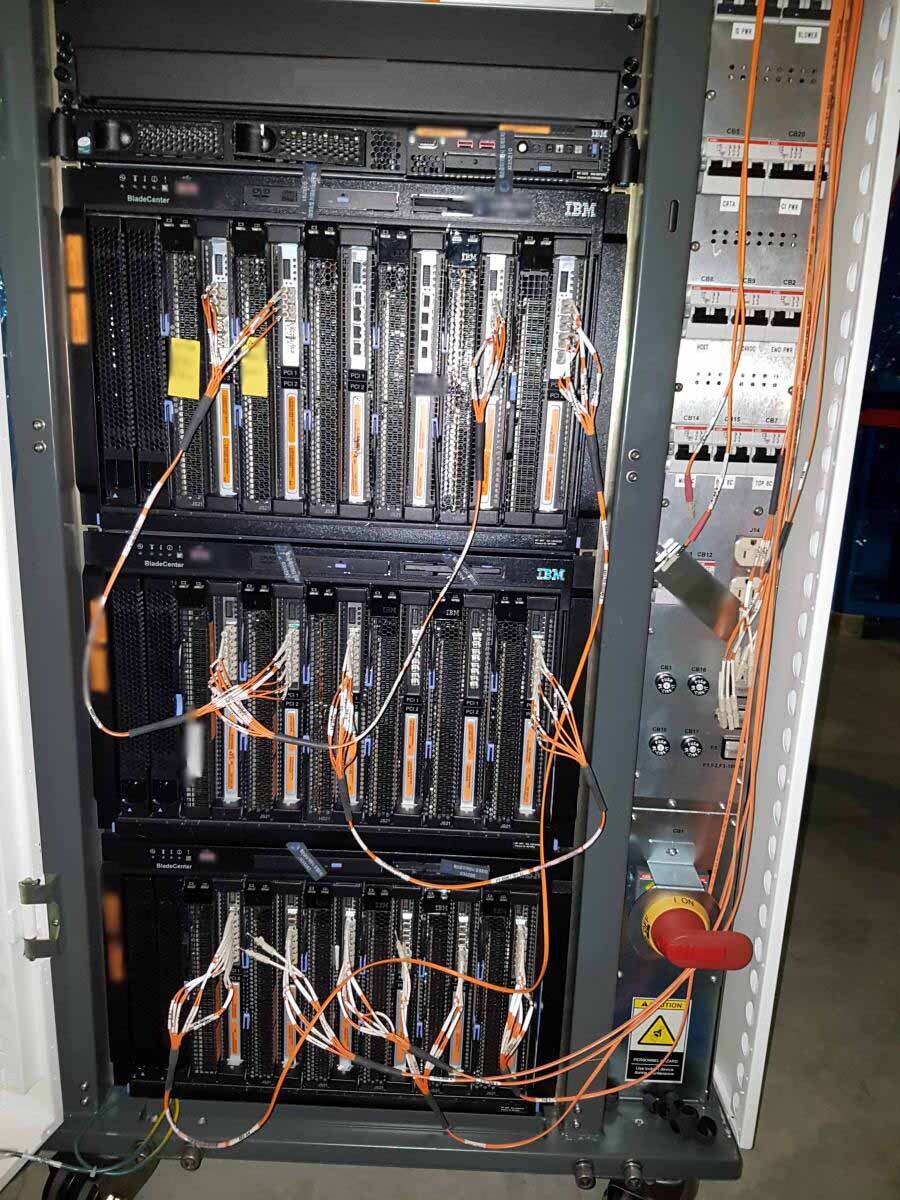

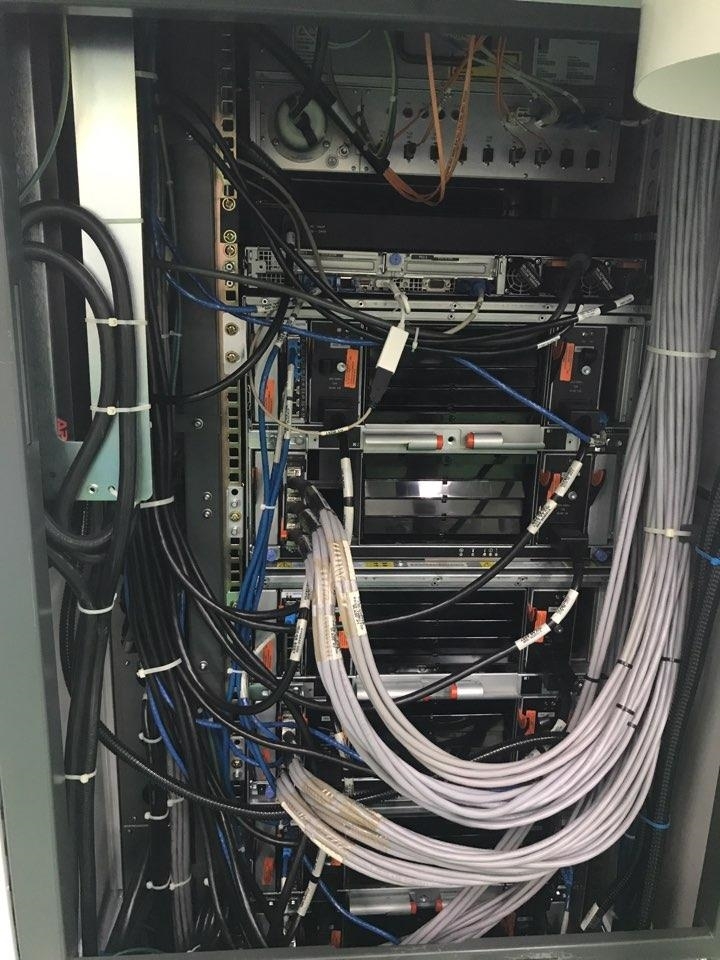

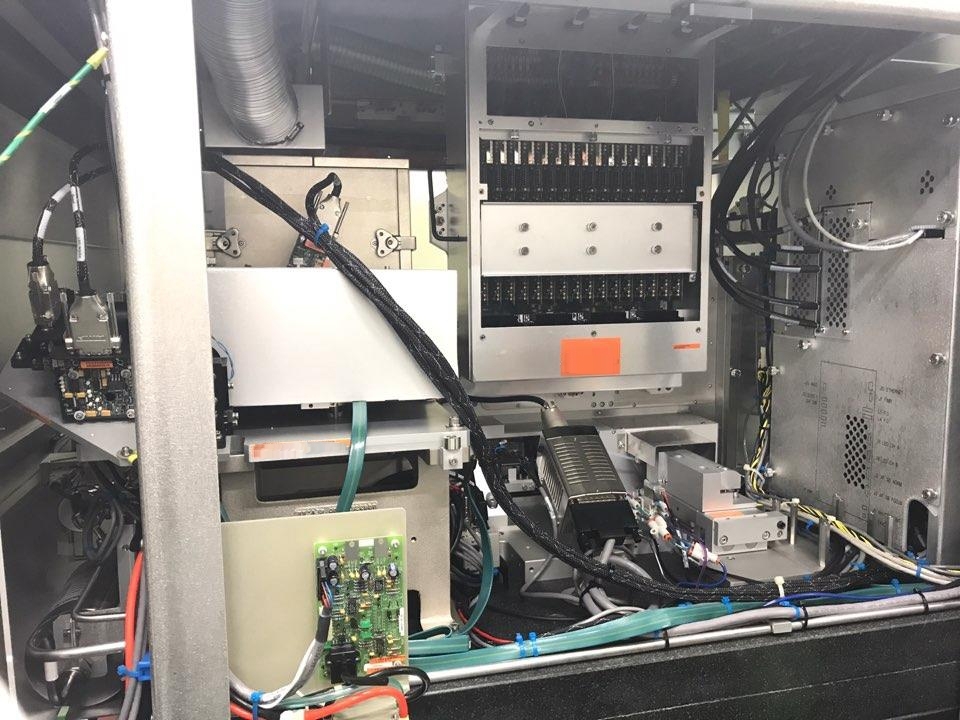

UI and PC:

(2) Monitors

Joystick

Keyboard

System Control Computer (SCC)

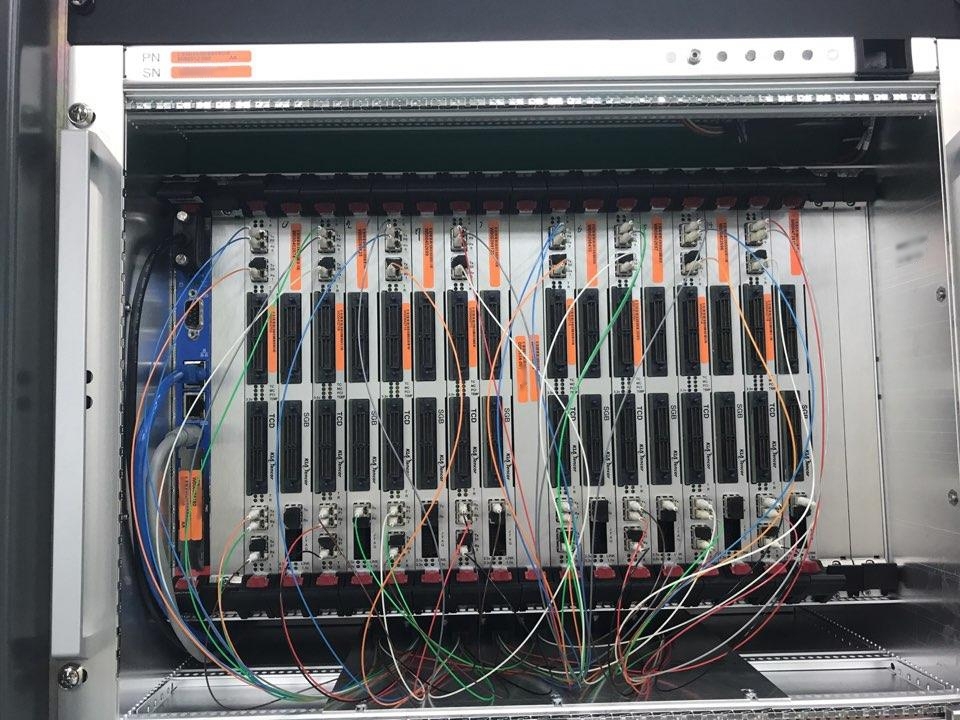

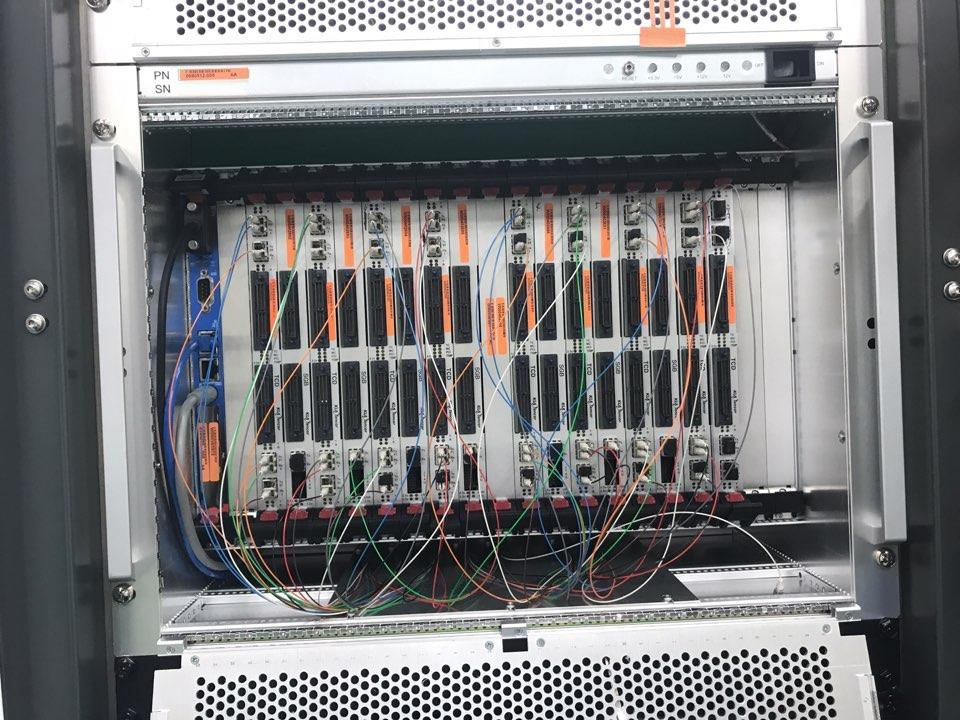

IMC Rack (RMPU): CRT 0 and 1

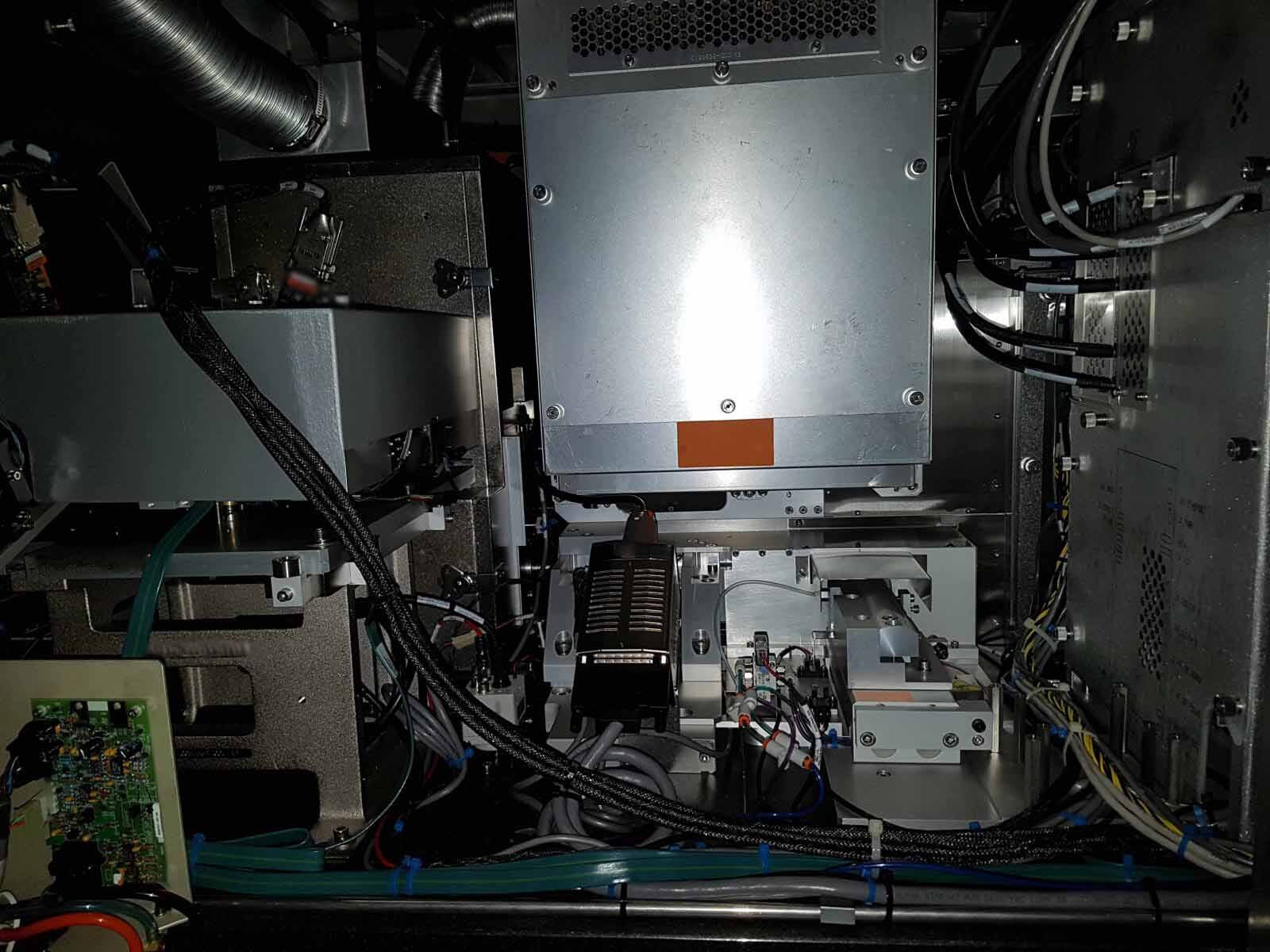

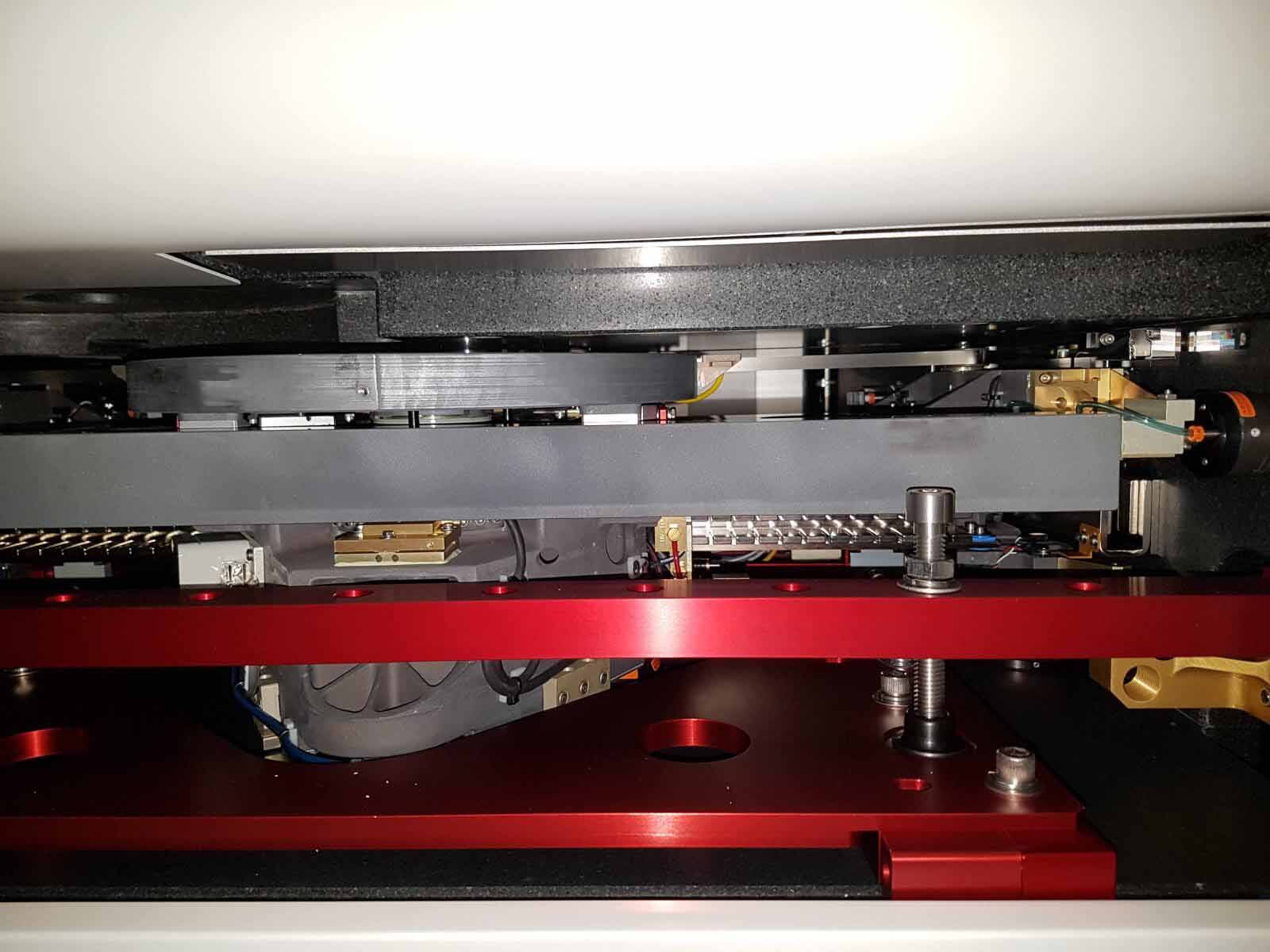

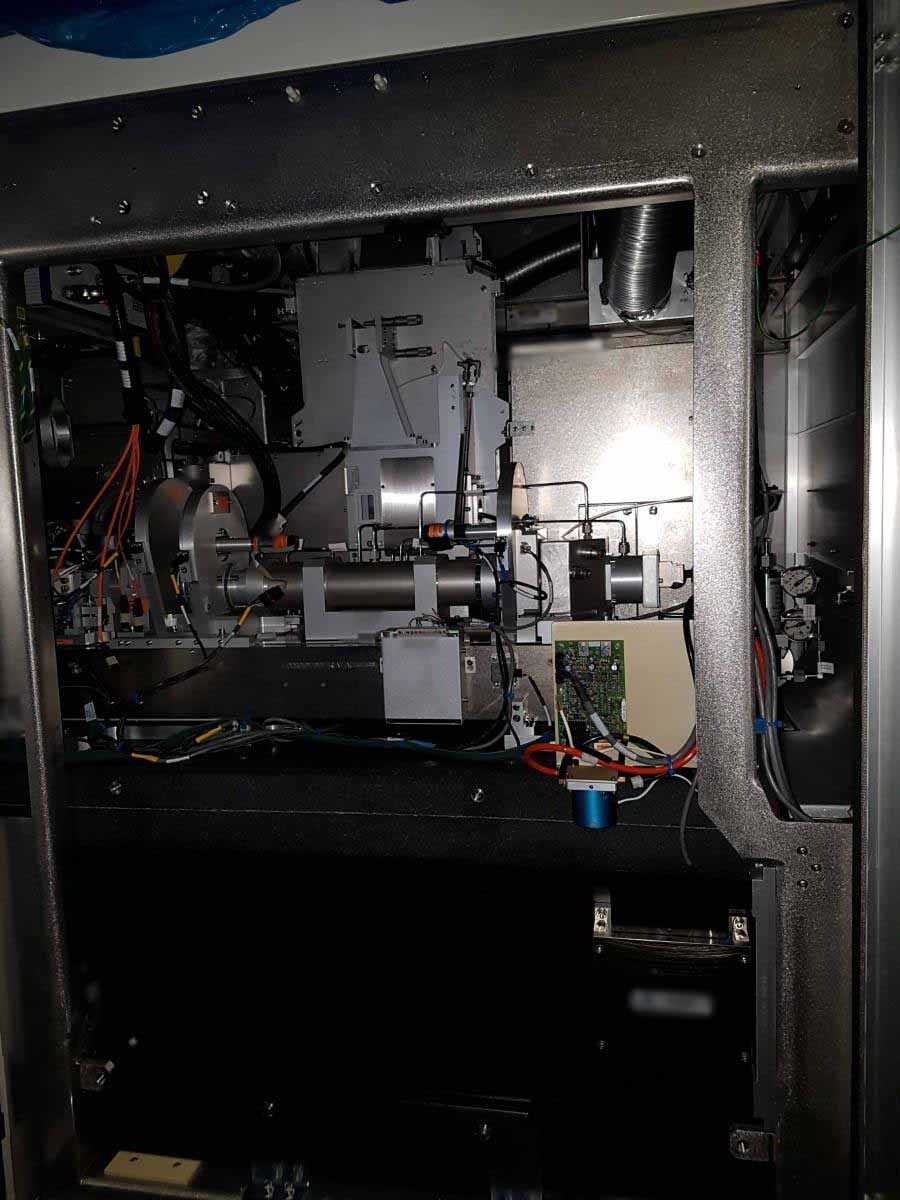

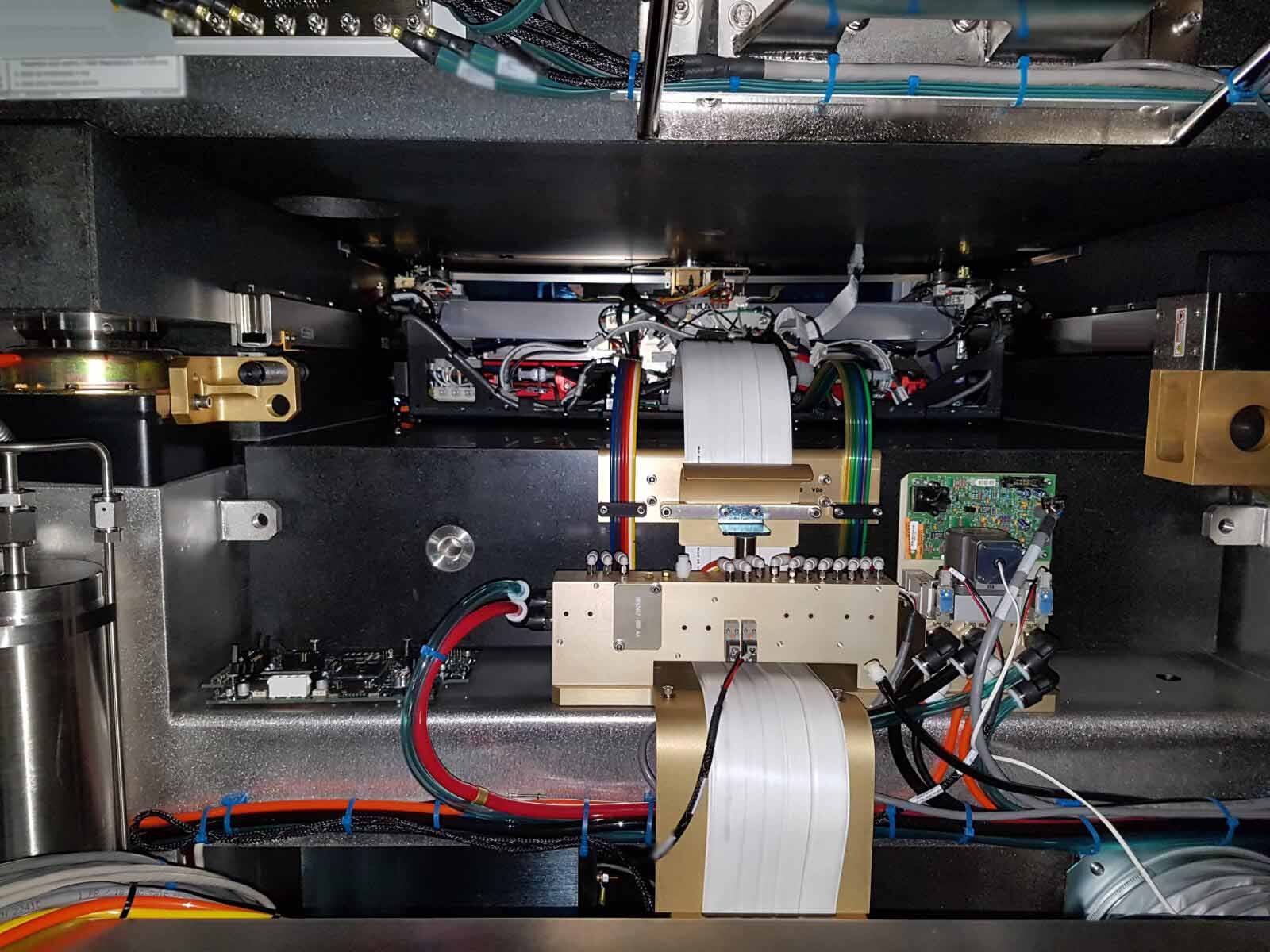

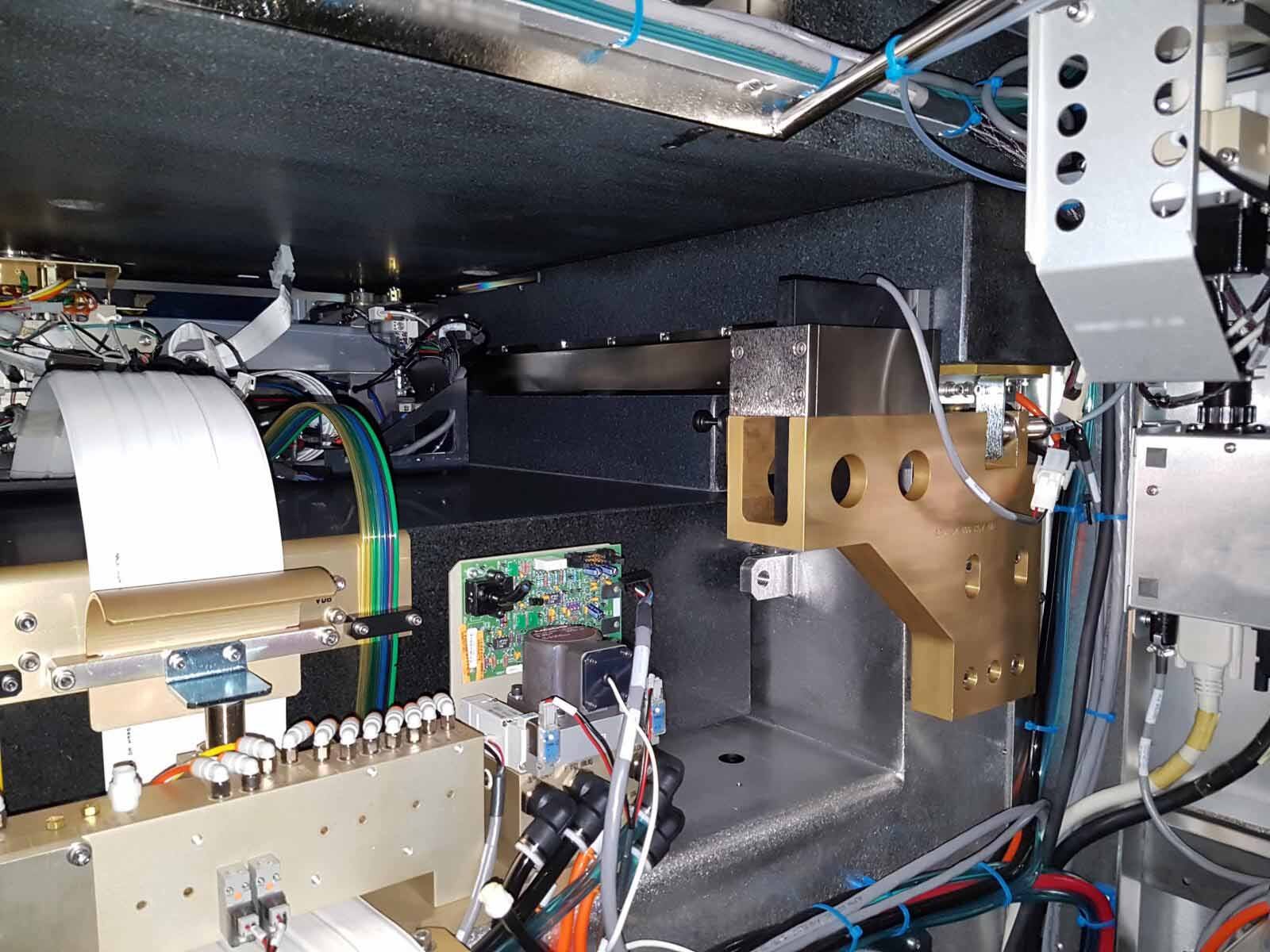

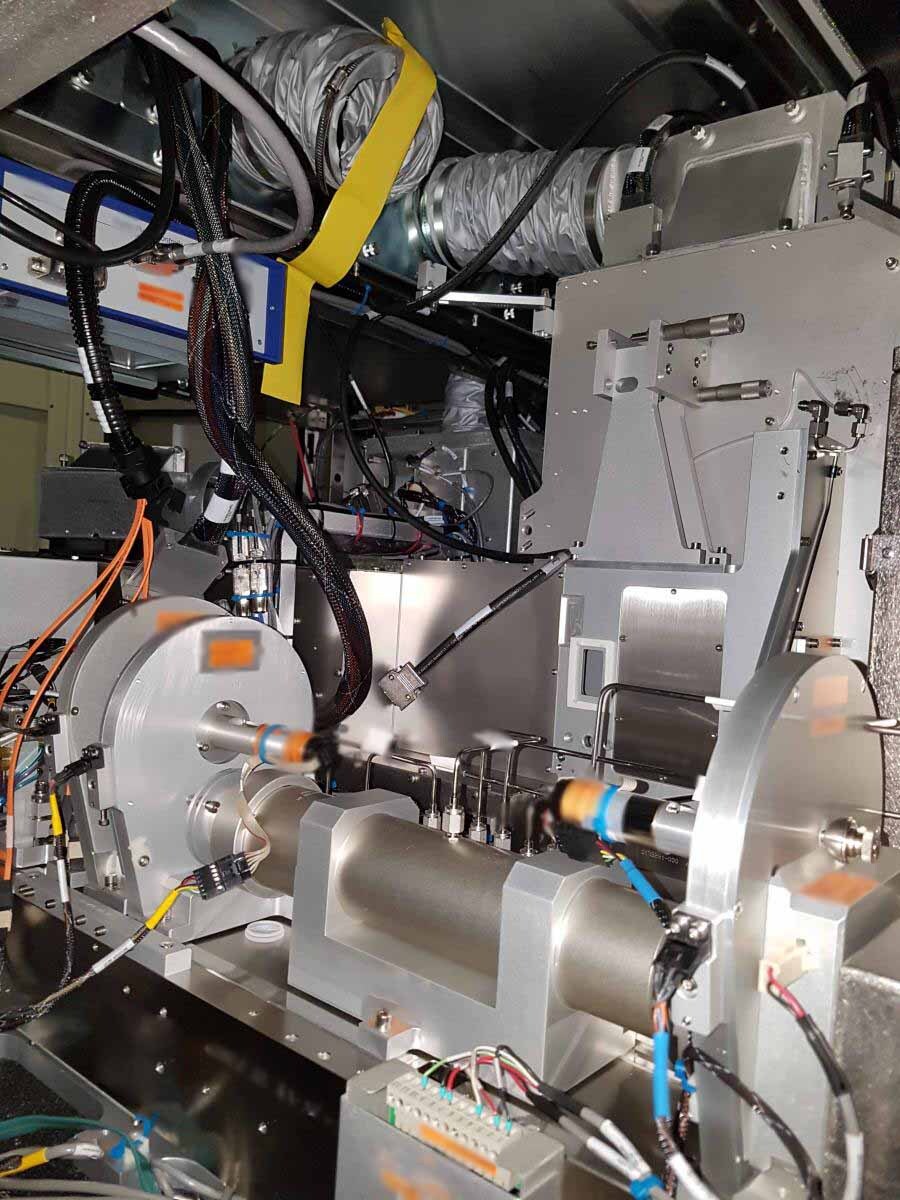

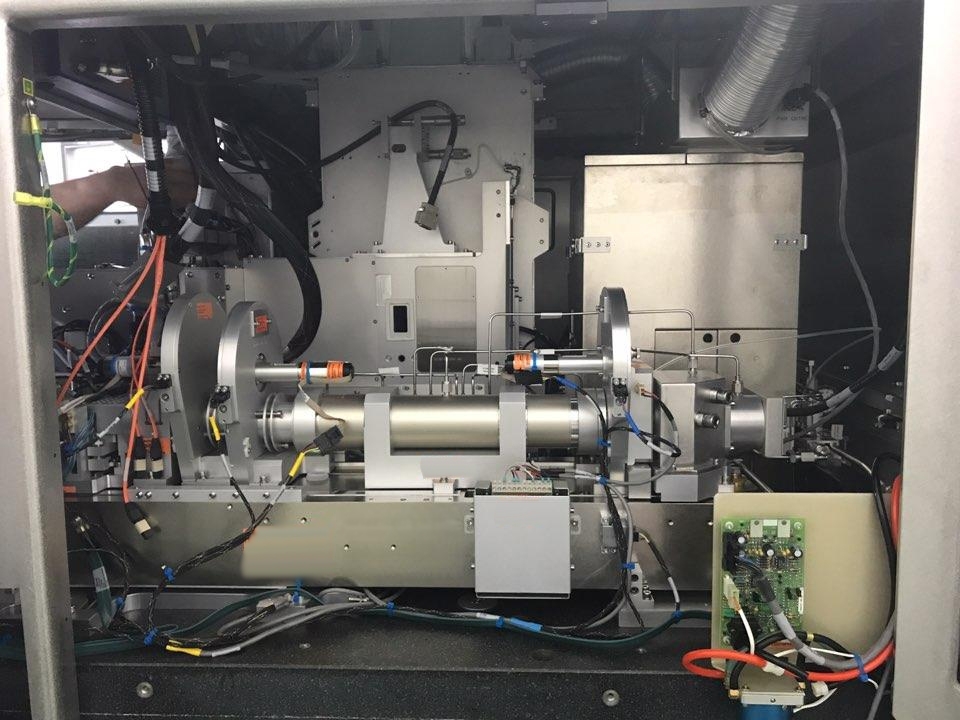

Optics and stage:

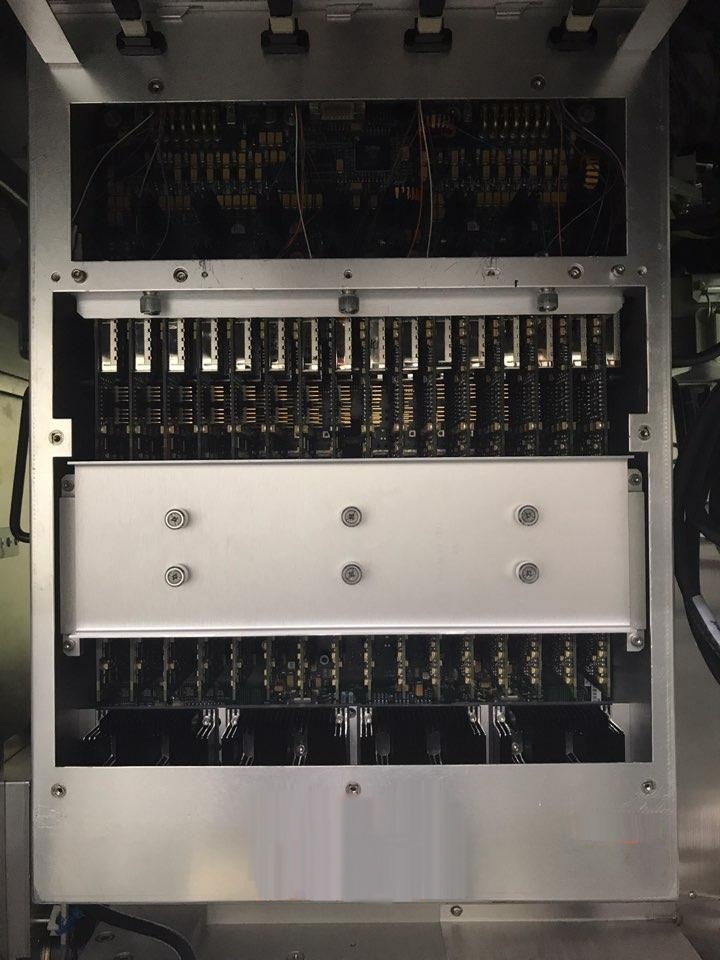

TDI0: (16) Daughter boards

Chuck, 12"

AMAC Stage controller

Stage shipping brackets

AF Plate

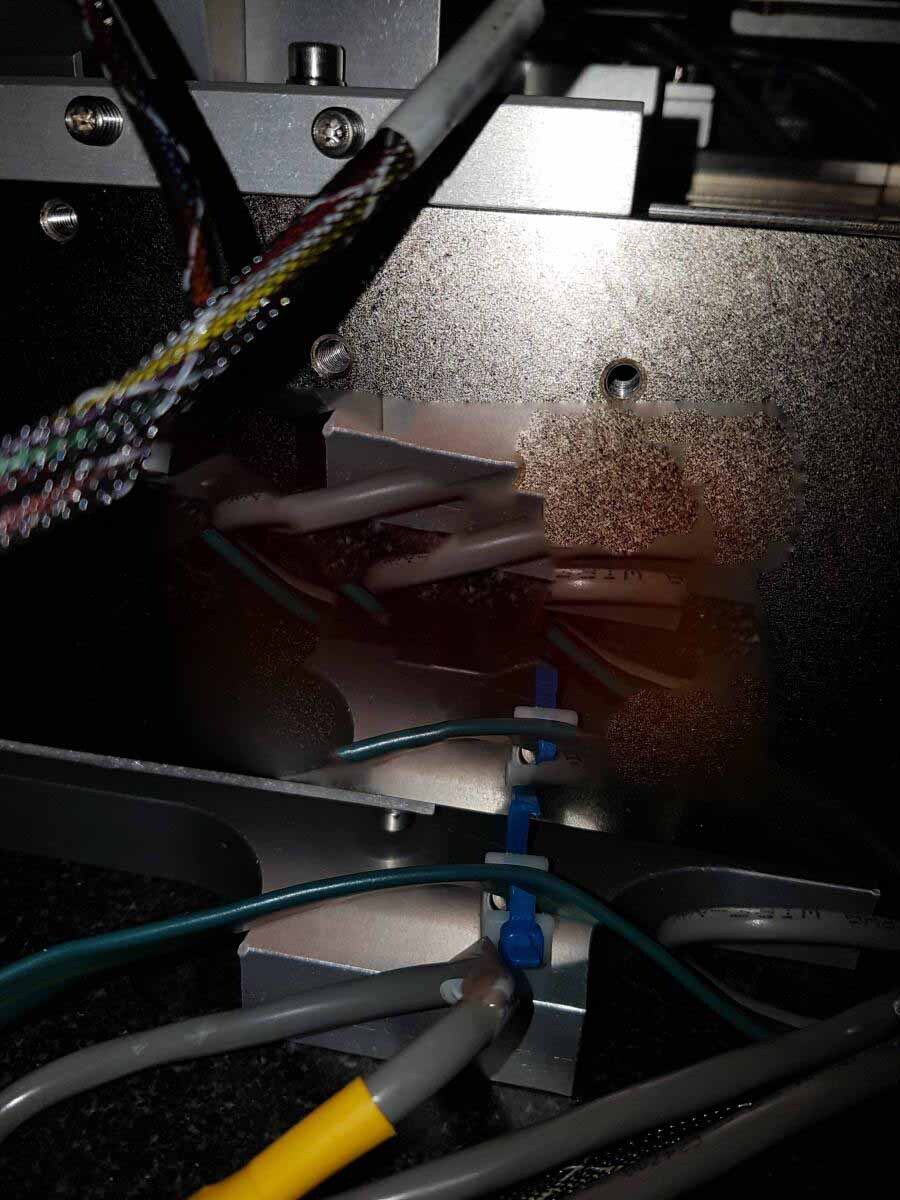

XTC Board cables

High mag camera

Pixel size: 35 nm / 50 nm

Load port and robot:

ASYST ISO Dual load ports

Pre-aligner

FEC Handler control computer

Line conditioner / Exhaust boxes

Includes:

EFEM

RMPU

Monitor and table

Power supply

Missing parts:

Track ball

(6) Hard Disk Drives

Middle blade center power supply

AMM of Middle and bottom blade center

TDI1 Assy

GALIL 1 and 2 boards

(6) Stage AMP boards

AMAC Cover

(4) Stage air regulators

YASKAWA Robot

2008 vintage.

KLA / TENCOR 2810 Mask & Wafer Inspection equipment is a high-speed, high-resolution automated optical wafer and mask inspection system designed to detect defects in semiconductor wafers, reticles, flat panels, MEMS and other types of thin film materials. The unit utilizes five-axis motion, two-dimensional/three-dimensional imaging, and a wide range of analytical and inspection capabilities to deliver quality control, process control, and quality assurance. The inspection machine is built on a multi-axis platform and provides high-resolution image acquisition along all axes of operation. The tool utilizes 5-axis motion capabilities and variable beam angle selection to cover all parts of the inspection target. The variable beam angle selection ensures that all parts of the wafer or mask are inspected in order to find defects. The asset is powered by KLA IR Proximity alignment model. This equipment utilizes proprietary software algorithms to precisely align the acquired images to the target geometry of the wafer/mask under inspection. This allows the system to detect very small defects and shadows, particularly near edges and corners of the wafer/mask. KLA 2810 utilizes two-dimensional (2D) and three-dimensional (3D) imaging for superior defect detection. The unit is armed with advanced 3D imaging capability and feature recognition algorithms to extra highly accurate topography images, allowing for more effective defect detection and faster analysis. The machine is equipped with a wide range of defect detections capabilities, including particle analysis, defect characterization analysis, and defect review classification. This ensures that any defects detected are accurately analyzed and classified so that the appropriate actions can be taken. Finally, TENCOR 2810 features a high-speed data transfer capability, which enables quick evaluation and reporting to the customer. The tool also features a fully-automated asset, which reduces operator fatigue and improves the accuracy of the results. Overall, 2810 Mask & Wafer Inspection model offers a comprehensive and cost-effective solution for semiconductor wafer, reticle, flat panel, MEMS, and thin film materials inspection. The equipment offers superior sensitivity, high-speed imaging, features automated features and a comprehensive range of defect detection capabilities, making it a powerful tool for quickly and accurately inspecting wafers and masks.

There are no reviews yet