Used KLA / TENCOR 2835i #9384468 for sale

URL successfully copied!

Tap to zoom

ID: 9384468

Wafer Size: 12"

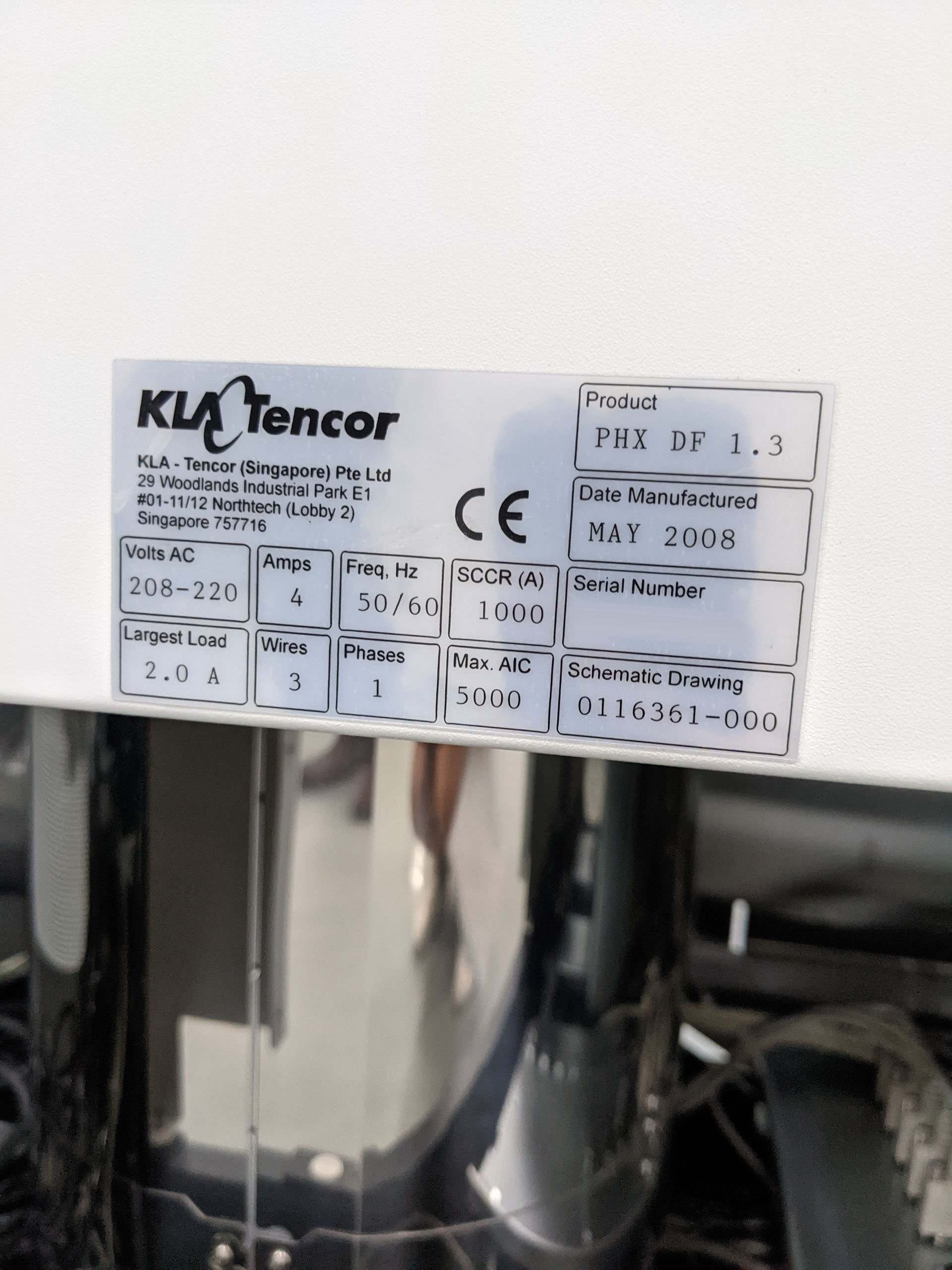

Vintage: 2008

System, 12"

EFEM Module

YASKAWA Robot 9206

With (2) IsoPorts

2008 vintage.

KLA / TENCOR 2835i is a mask and wafer inspection equipment used to detect small defects and nonuniformities on photomasks and wafers. It utilizes a unique and advanced combination of advanced imaging technology and specialized software algorithms to provide detailed information on the full spectrum of device defects, from surface-level abnormalities to contamination and material malfunctions. The system contains a high-resolution imaging head that takes images of the features on the photomasks or integrated circuits at a microscopic level. The imaging head is powered by a Pentium computer with 4GB of RAM and up to 64GB of hard disk space. A dedicated, automated wafer-handling unit precisely positions the wafer in the field of view of the imaging head, allowing for accurate defect location and inspection. KLA 2835i offers both light- and dark-field imaging for complete defect detection. This includes both topographical measurements and elemental spectra to identify chemicals and compounds. Specialized software and algorithms measure the size, shape and orientation of suspected defects, which in turn assists the user in defect classifications. TENCOR 2835i can also measure a variety of parameters such as topological, ultraviolet (UV), optical, and electron-beam. Using advanced watershed segmentation algorithms, combined with a specialized feature-based classification machine, 2835i can accurately identify, classify and measure a variety of defects. KLA / TENCOR 2835i is capable of detecting defects smaller than 10nm and provides a repeatability accuracy of 1nm (1% of image dimension). This highly accurate tool allows for reliable mask and wafer inspections in a wide range of industries including semiconductor, lighting, optics, solar, biotechnology and MEMS. Comprehensive defect analysis with KLA 2835i is easy and efficient, due to its intuitive and user-friendly interface. It has a built-in manual defect review asset to ensure all defects are checked and documented. In conclusion, TENCOR 2835i is an advanced mask and wafer inspection model that provides accurate, automated defect detection and classification with comprehensive defect analysis. This equipment is effective in a wide variety of industrial applications, making it an invaluable tool in the production and testing of photomasks and integrated circuits.

There are no reviews yet