Used KLA / TENCOR 45 #38072 for sale

URL successfully copied!

Tap to zoom

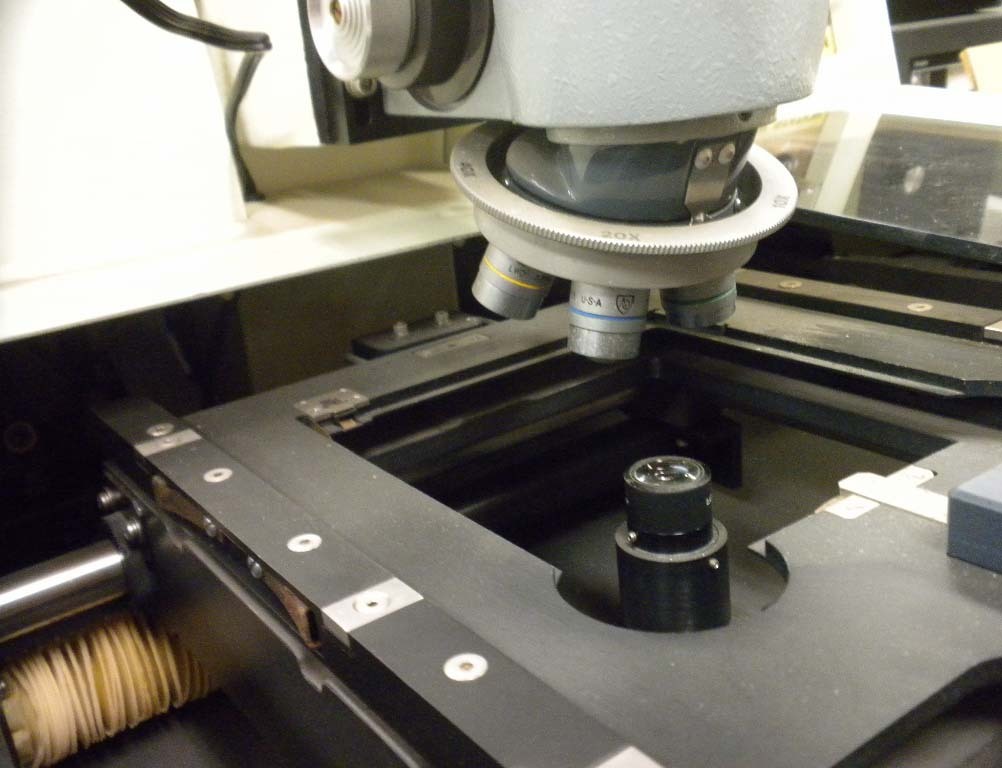

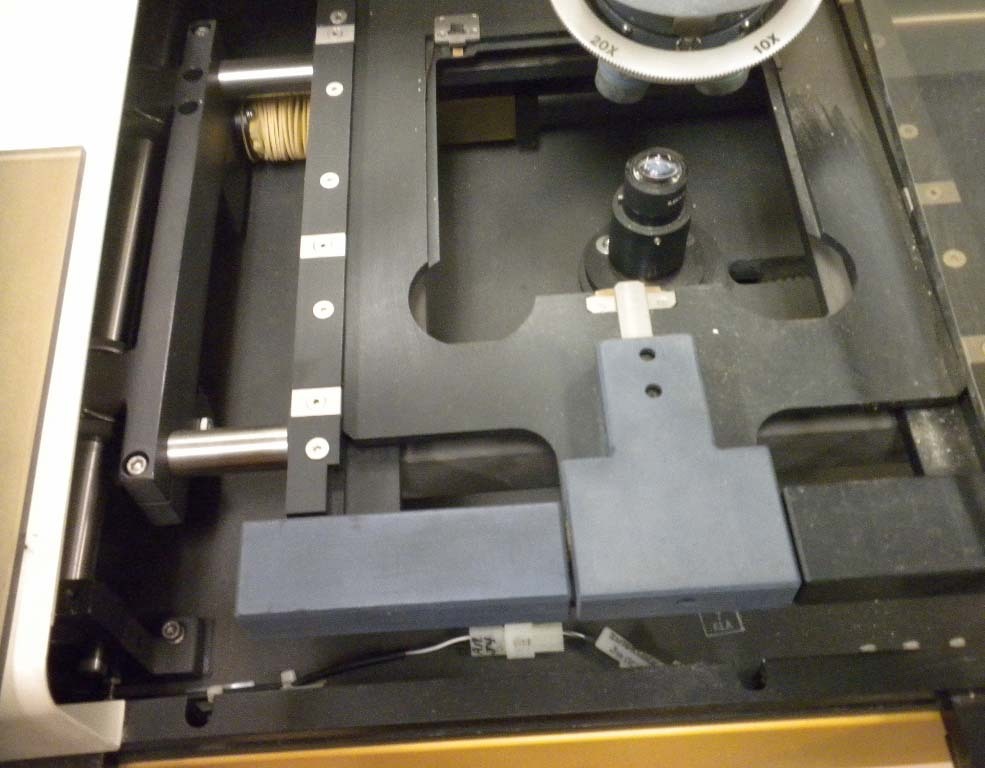

KLA / TENCOR 45 Mask & Wafer Inspection Equipment is designed for use in wafer fabrication processes for both production and research and development. The system is capable of inspecting up to KLA 45 wafers simultaneously at a resolution of up to 1 micron per pixel. The unit features a 5-axis stage that can be programmed to travel over the wafer, enabling comprehensive coverage without the need for additional stages. The machine is equipped with a variety of image capture and processing technologies including advanced RGB, infrared and ultraviolet (UV) illumination, and a coaxial interferometric tool. RGB illumination is used to provide high dynamic range imaging, while infrared and UV illumination allow the asset to inspect wavelengths not visible to the naked eye. The coaxial interferometric model allows the user to capture three-dimensional images of the wafer surface. The inspection equipment is controlled by a graphical user interface (GUI) running on a Windows PC. This allows the user to easily navigate the system, display and analyze images, and export results for further review. The unit is capable of detecting a wide range of defects including particles, scratches, wraparound, short- and open-circuits, bridge and shape defects. In addition, the machine provides valuable process feedback by providing automated die yield estimates, and spatial data analysis for overlay and mini-volume assignments. The tool is highly configurable, allowing users to set up and customize their own inspection parameters and profiles. This allows users to optimize the asset for their specific application. The model also supports a range of file formats, giving users the flexibility to view and analyze their data using the latest third party software tools. In summary, TENCOR 45 Mask & Wafer Inspection Equipment provides a powerful, yet flexible, platform for inspection and analysis of production and research wafers. The system has a wide range of capabilities, from image capture and analysis to defect detection and feedback. With its easy-to-use GUI and wide range of file formats, the unit offers users a high degree of flexibility and control over their wafer inspection processes.

There are no reviews yet