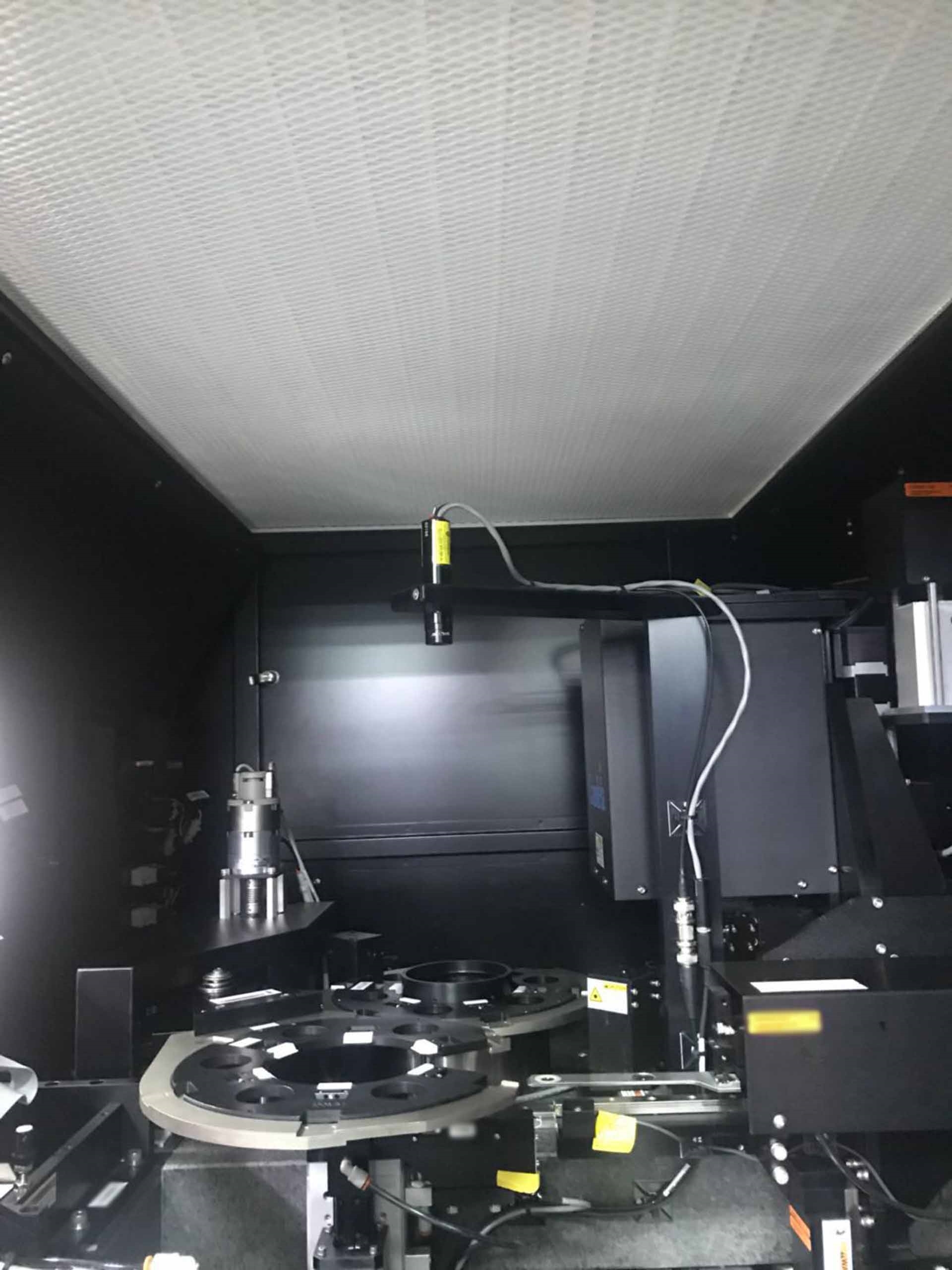

Used KLA / TENCOR Candela CS20 #9214843 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9214843

Wafer Size: 2"-8"

Surface measurement system, 2"-8"

Thickness: 350 μm – 1100 μm

Materials:

Any opaque

Polished surface

Scatters: ≥ 10% of incident light

Defect sensitivity

Size: 0.08 μm Diameter

PSL Sphere equivalent capture rate: ≥ 95%

Depth of focus

Maximum allowable under bow: +/- 15 μm

Edge exclusion:

Imaging: No exclusion

Defect analysis: User configurable, varies with wafer size

Nominal: 2"-8"

R-θ Co-ordinates:

Co-ordinate precision: 80th Percentile ≤ 150 μm

Co-ordinate accuracy: 80th Percentile ≤ 150 μm

Spatial resolution

Spacing: ≥ 10 μm

Minimum wafer outer edge: 8"

Cassette handling

Standard: Single puck up to 200 mm

Illumination source

Laser: 50 mW

Wavelength: 405 nm

Operator interface

Trackball and keyboard standard

Options:

Dual cassette handling

GEM-SECS

Light tower

Diamond scribe

Calibration standards

Air: CDA 95-110 PSI, 2 CFM

Power supply:

110 – 120 VAC, 8A, 50/60 Hz

100 VAC, 10A, 50/60 Hz

220 VAC, 5A, 50/60 Hz.

KLA / TENCOR Candela CS20 is an advanced mask and wafer inspection equipment designed to detect sub-micron particles, defects, and contamination on wafers and masks used in the semiconductor industry. The CS20's design is based on a scanning electron microscope (SEM), making use of a variable pressure chamber that allows for inspection of opaque materials with a large field-of-view. With its digital optical inspection, dual-beam system, and advanced beam current control, it can detect variations in pattern edges down to sub-micron level. The unit is also designed to work with its own suite of specialized software. KLA CANDELA CS-20 is capable of fast, high-resolution area scanning with its proprietary designs and advanced imaging technologies. It allows the user to detect minute, hard-to-spot defects and contaminations that traditional inspection systems are often not able to detect. The machine is capable of identifying even the smallest features on a mask or wafer, such as scratches, pits, defects, pattern misalignments, and intra-die-particles. The CS20 is also designed to increase productivity, with features such as an automated Z-axis control, programmable image processing, and self-learning algorithms that allow it to recognize and monitor defects automatically. Additionally, the CS20 is compatible with current industry test wafer microscope systems, making it even easier to incorporate into existing inspection processes. The tool comes with a number of safety features, such as a fail-safe operation asset and an in-built monitoring model to ensure that the equipment is operating safely at all times. As well as this, there is KLA own custom service and support that can assist you throughout the setup and running of the system. Overall, TENCOR CANDELA CS 20 offers an advanced, fast, and reliable inspection unit that is able to quickly detect particle, defect, and contaminated matter from wafers and masks, while also being highly productive, reliable, and safe to use.

There are no reviews yet