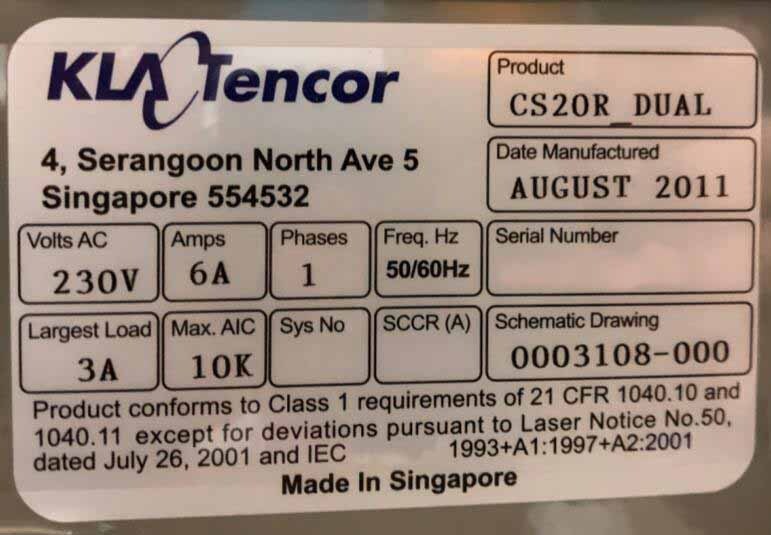

Used KLA / TENCOR Candela CS20R #293605955 for sale

URL successfully copied!

Tap to zoom

KLA / TENCOR Candela CS20R is a Mask & Wafer Inspection equipment designed to accurately measure and detect photomask, IC layout, and IC lithography defects. The system features a 2048 x 2048 pixel detector, providing the highest resolution for any repair resolution mask and wafer inspection unit currently available. It also includes a multi-axis scan stage, offering fast inspection and alignment capabilities, and a high intensity lamp head to ensure accurate measurements. The machine is also equipped with a variety of advanced process controls, including delay time and image optimization. KLA CANDELA CS 20R utilizes advanced optics and pattern recognition algorithms for mask revising, inspections and wafer characterization. This tool features a newly designed metal-oxide semiconductor (MOS) forward view camera and a rear-view (way) camera. The asset tasks patterned wafers with subpixel resolution, while the metal-oxide semiconductor (MOS) forward view camera is used to align the wafers and the rear-view way camera provides accurate measurements of the wafers. The model is also equipped with an array of software tools and proprietary algorithms to ensure detection of defects in the design before they can be observed on the wafer. In addition, the equipment supports the use of automated defect recognition and classification processes. TENCOR CANDELA CS-20 R has several features that are beneficial for mask revising and lithography operations. Its image optimization feature ensures accurate colorization of the reticles, while its delay and overlap scan capabilities ensure effective positioning and scanning of patches. Its fast inspection speeds provide the fastest and highest resolution for mask and wafer inspection currently available. The system is also compatible with Windows and UNIX systems for easy installation and usage. TENCOR CANDELA CS 20 R is a reliable and effective mask & wafer inspection unit that provides next generation results for photomask, IC layout, and IC lithography customers. It is designed to provide rapid inspection and classification of defects, while its array of advanced process controls and built-in corrective action are beneficial for any process involved in IC manufacturing. The machine is both stable and economical, providing an affordable solution to masking and photolithography inspections.

There are no reviews yet