Used KLA / TENCOR CRS 3000 #9137166 for sale

URL successfully copied!

Tap to zoom

ID: 9137166

Vintage: 2001

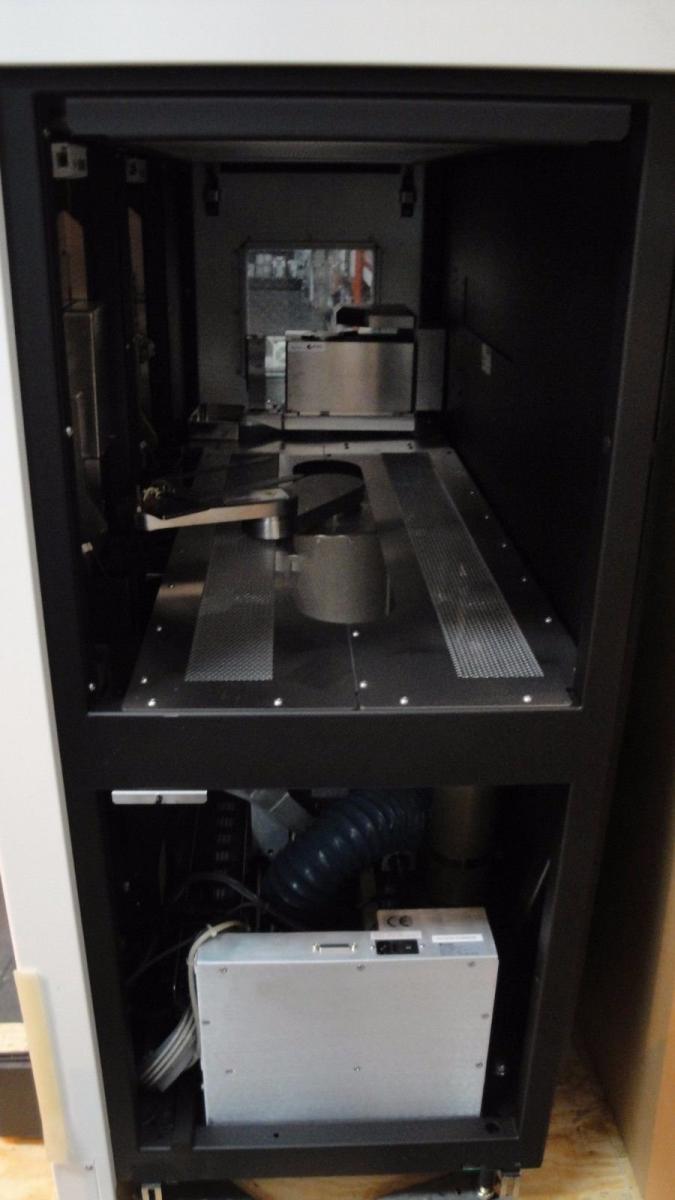

Wafer inspection tool

Part no: 300DFF1P

PRI robot part no: ABM-407B-1-S-CE-S293

KLA Part no: 0011623-00

PRI Controller part no: TRA035-LPS

KLA Part no: 0000666-000

PRI Prealigner part no: PRE-300BU

KLA Part no: 0011623-000

Loadport part no: 9700-6240-01, Rev. A, (Qty. 2)

Brooks controller part no: ESC-218BT-FWS

REV. 1

Version: V4.5513A1SF

2001 vintage.

KLA / TENCOR CRS 3000 is a mask and wafer inspection equipment designed to detect defects caused by lithography and etching during semiconductor manufacturing. It is used to inspect semiconductor masks and wafers for features such as roundness, edge profile, and other geometrical patterns. The system uses state-of-the-art, high-end optical devices and technologies along with advanced optics, illumination sources, and imaging software. The inspection optics combine high-resolution aerial images with a series of dedicated focus levels. This allows for a quick and accurate assessment of defect features, such as tonal details, spacings, and contrast. The unit also features a clever articulating 6-axis wafer alignment machine which increases the speed and accuracy of the inspection process. The tool's scanner can zoom in on features of interest to allow for a more detailed inspection. Moreover, a high-speed image processor is integrated into the asset which further increases the speed and accuracy of the inspection process. KLA CRS 3000 can detect defects as small as 5 nanometers in size, with sensitivities up to 100%. The model also has a wafer map overlay which allows for an additional level of defect detection. TENCOR CRS-3000's inspection monitoring capabilities include tracking-level control and measurement limits. In terms of automation, the equipment is highly automated and can be configured to inspect across a variety of wafer sizes. The system can also be operated using its accompanying software package. The user interface is user-friendly and intuitive, allowing for quick and accurate interpretation of inspection results. CRS-3000 is a highly effective mask and wafer inspection unit that has been designed with the latest technologies in order to achieve the highest accuracy and speed. Its integrated optics and image processor make it one of the most reliable tools in the industry, allowing semiconductor manufacturers to quickly and accurately identify and address defects.

There are no reviews yet