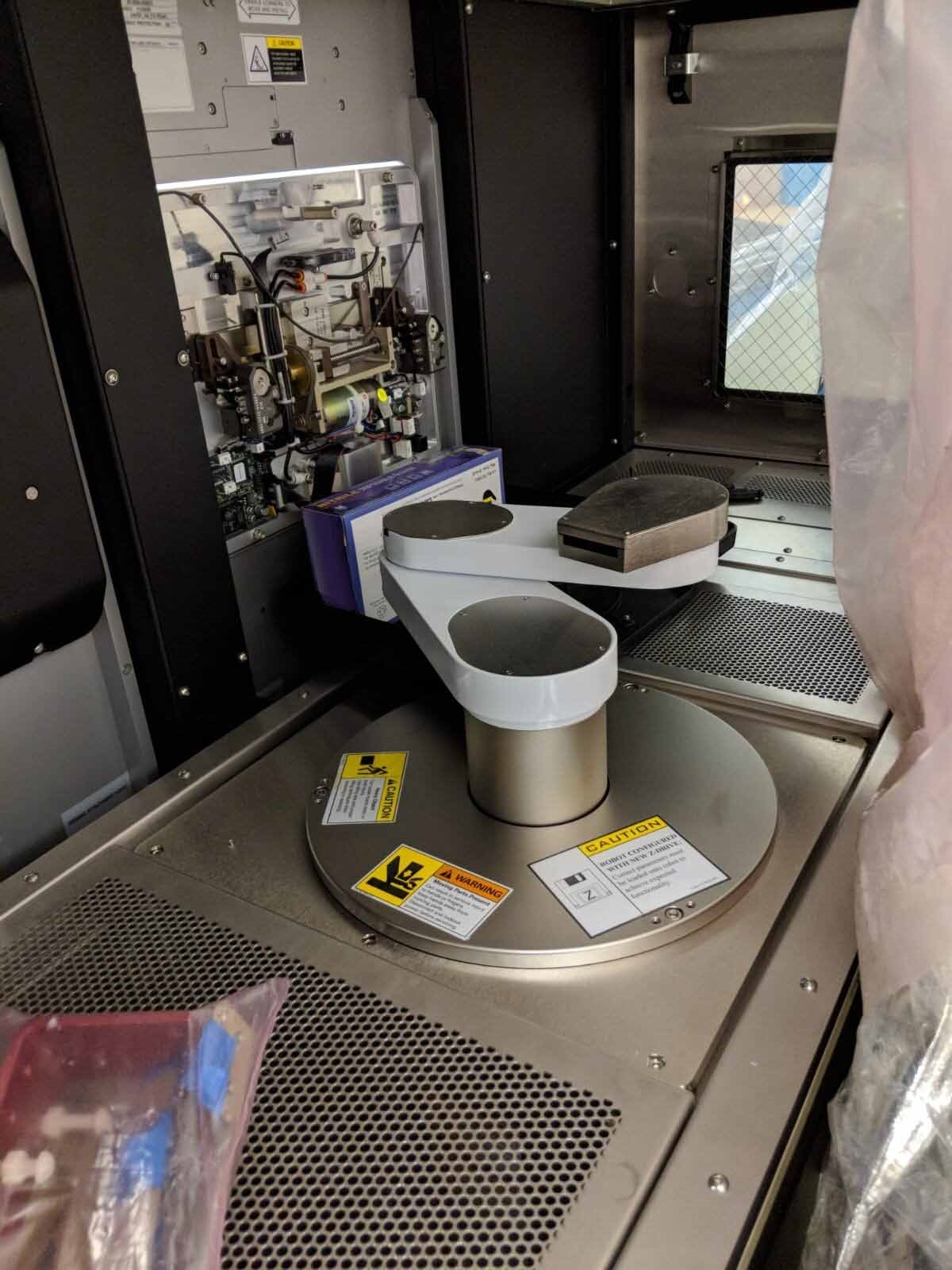

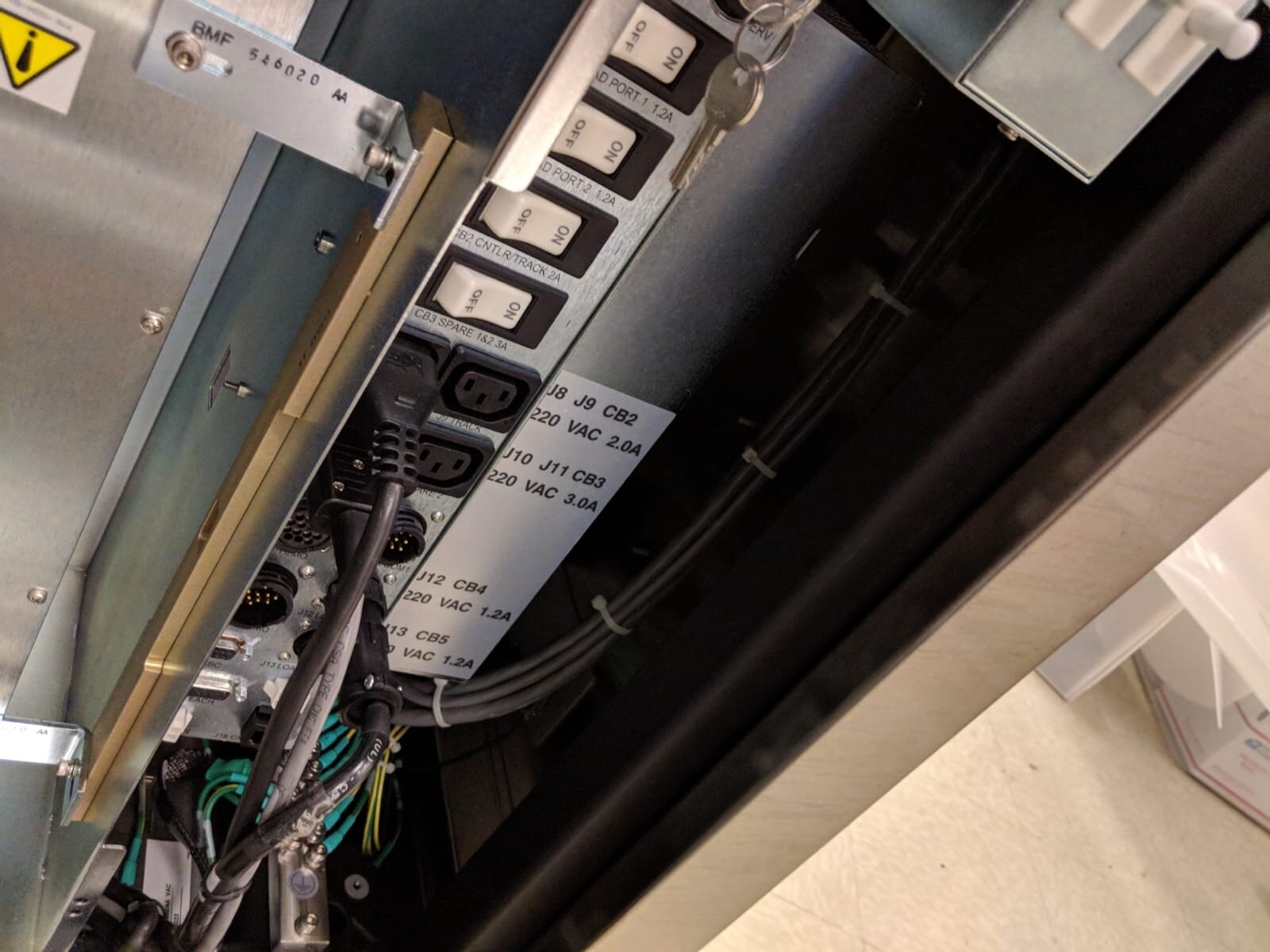

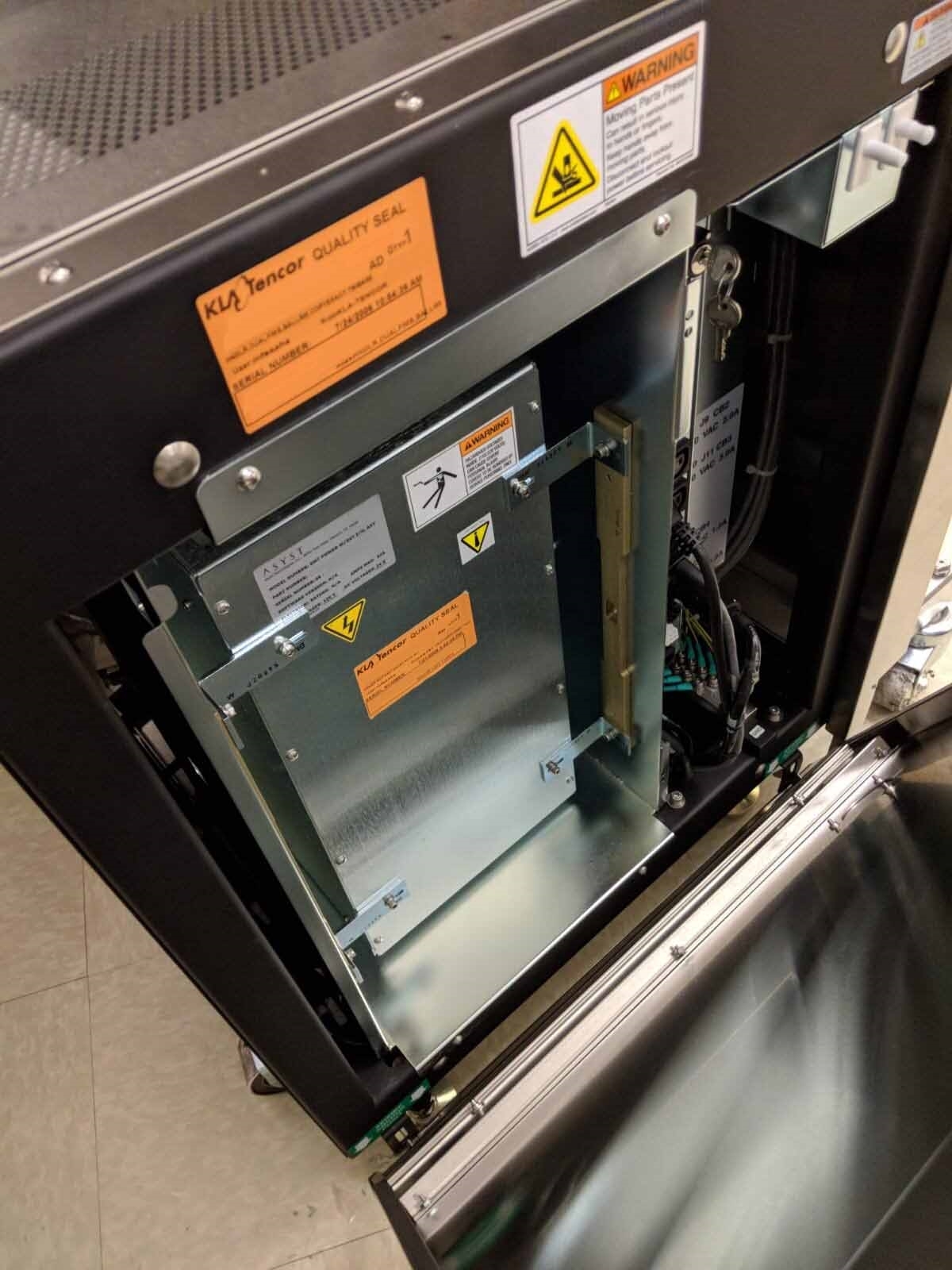

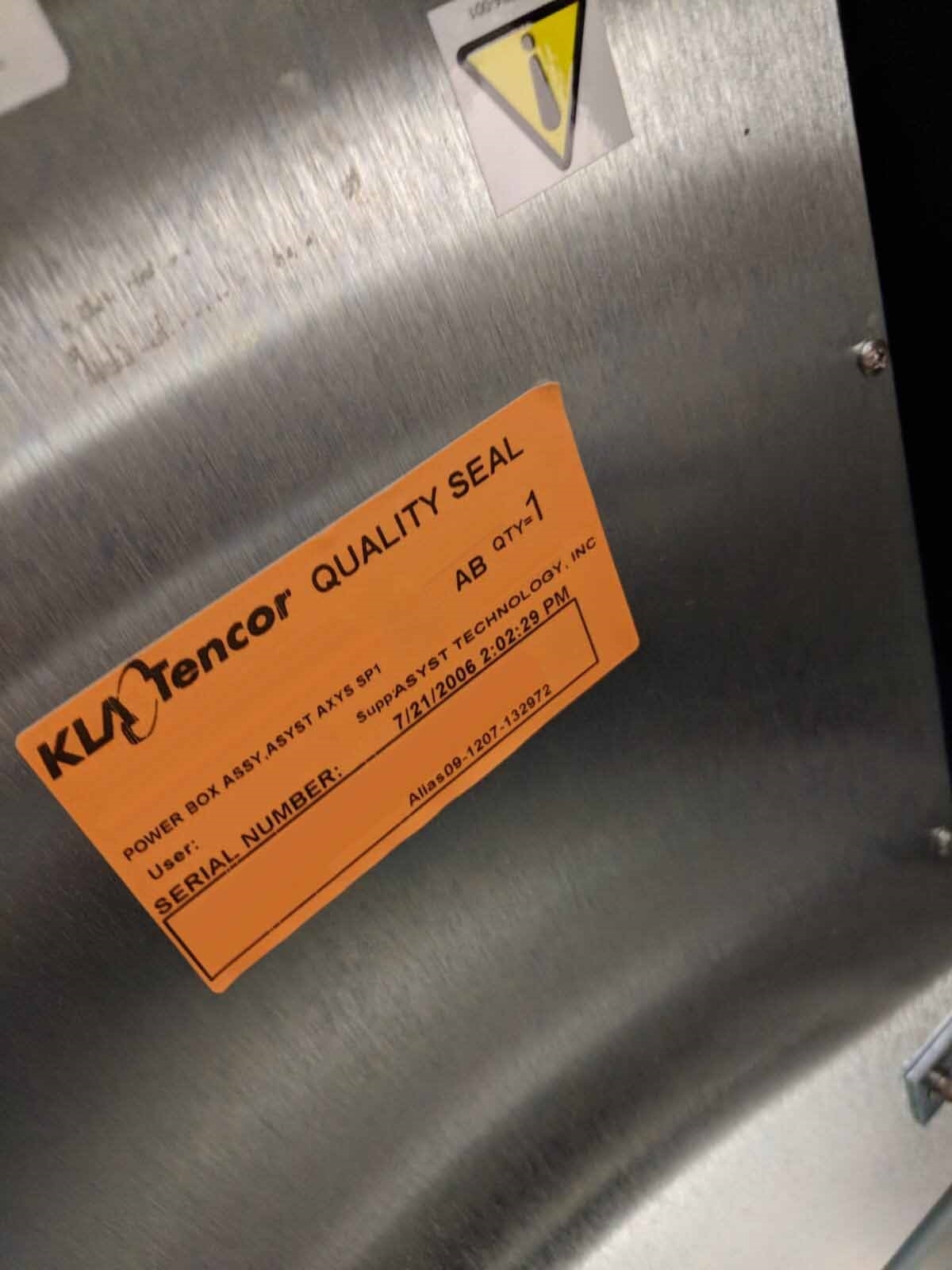

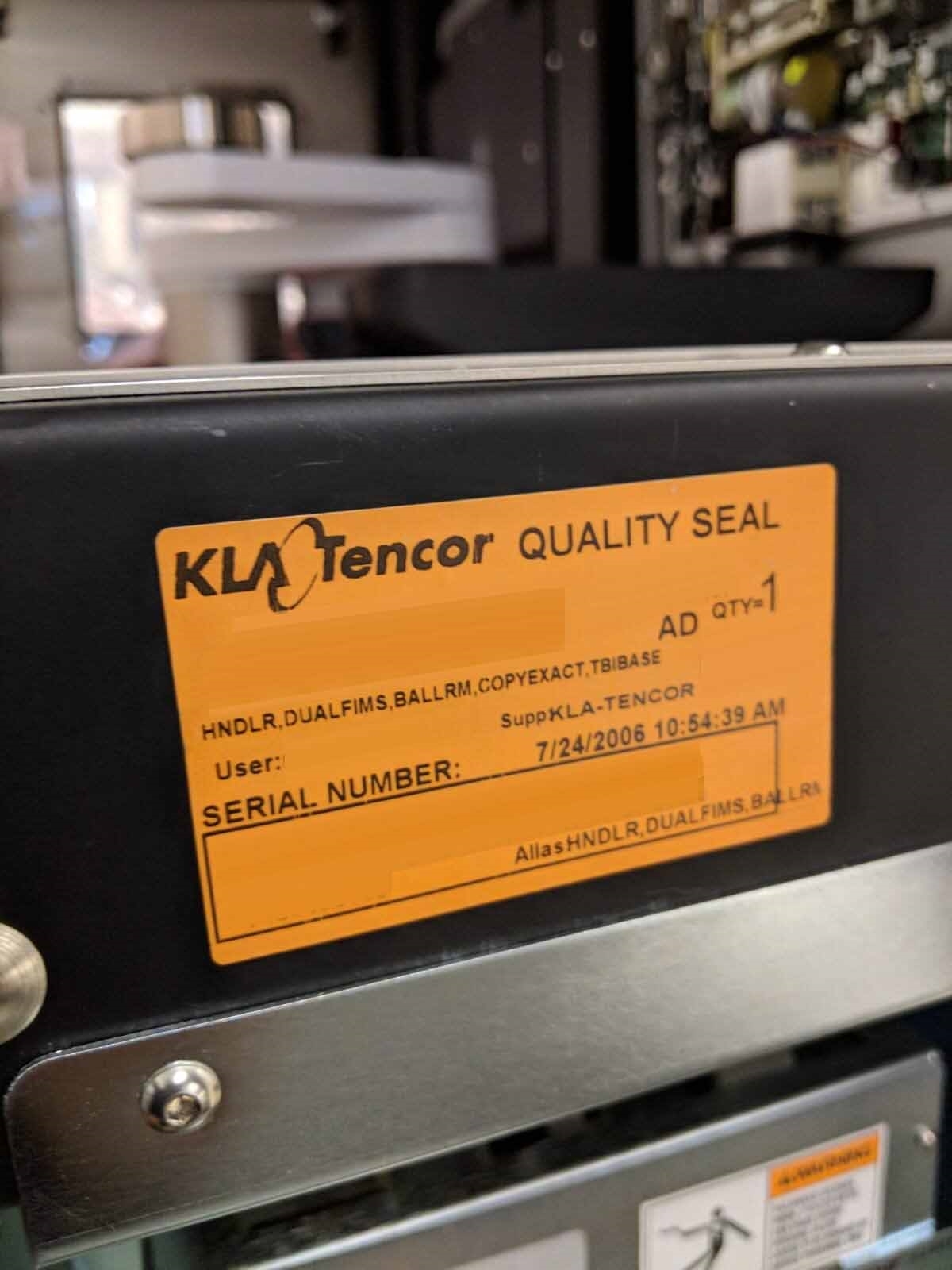

Used KLA / TENCOR DFIMS Handler for SP1 #9262248 for sale

URL successfully copied!

Tap to zoom

ID: 9262248

KLA / TENCOR DFIMS Handler for SP1 is a state-of-the-art fully automated wafer and mask inspection equipment designed to provide enhanced process control and speed for semiconductor fabrication. Boasting a multi-sensor platform capable of optical and electrical measurements on up to 500 wafers per hour, the system lets fabs and OEMs manufacture, test and verify process steps with an unprecedented level of speed, accuracy and reliability. KLA DFIMS Handler for SP1 utilizes a combination of advanced imaging technologies such as Acquisition Multiple-Beam (AMB) imaging, Digital Image Correlation (DIC) and image understanding algorithms to deliver rapid and accurate data on a wide range of parameters including surface and patterned features. The unit employs a unique process control machine that automatically verifies process parameters such as gate thickness, gate sidewall angle, line width, line edge roughness, defect size and defect location. Advanced image processing tools enable the tool to make detailed, nanometer-level measurements (up to 2nm) of all process parameters. Additionally, the asset can measure the global uniformity of a wafer, even detecting the smallest process variations at a lower size level. This data allows the model to make valuable decisions such as when corrective measures have to be taken. The SP1 has the capability of performing inspections on both front side and back side or contact layers of devices. As a result, it can analyze the surfaces of both standard and special devices such as high aspect ratio split-gates, line ends, vias and trenches. Furthermore, the equipment makes use of specialized multiplex wafer inspection tools, which make it possible for the system to analyze multiple parameters from a single scan. To enable accurate data acquisition, TENCOR DFIMS Handler for SP1 has am ultra-fast processor with 128kb of cache that can process 6 to 7 million data points every second. To improve workflow, the unit includes integrated positional encoders and real-time data acquisition and analysis for faster, more precise defect detection. The machine has a floating head vacuum head that ensures greater flexibility and reliability in the positioning of wafers. To ensure a higher quality of mask performance, the tool employs an advanced edge inspection technology that guarantees the die-edge alignment is correct with critical accuracy. Finally, the SP1 features an intuitive user-friendly operation asset that allows users to customize the parameters of the inspection job according to their own requirements and preferences. With its high speed, precision, and wide range of measurement performance capabilities, DFIMS Handler for SP1 is the ideal tool for semiconductor fabricators, OEMs, and research laboratories that need to keep close tabs on their process performance.

There are no reviews yet