Used KLA / TENCOR eDR-5210 #9278887 for sale

URL successfully copied!

Tap to zoom

ID: 9278887

Wafer Size: 12"

Defect review SEM, 12"

SMC Thermo Chiller

Power supply CONE RC

Handler:

(2) Load ports / Fix load

BROOKS Robot and aligner and controller

Aligner:

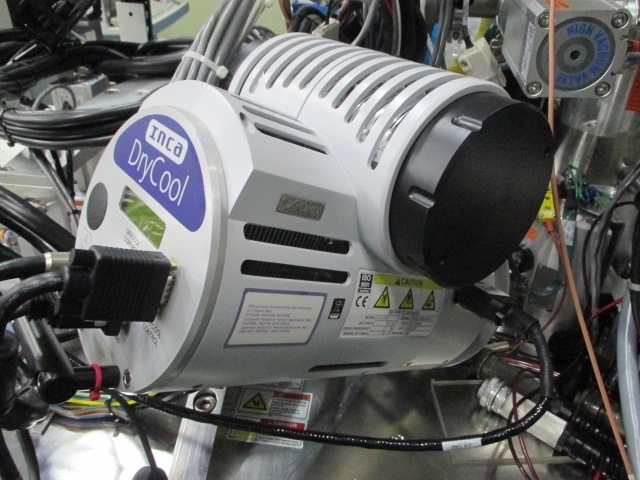

OXFORD 51-1100-109 Dry cool monitory

OXFORD 51-1100-108 Dry cool control

INCA 51-1100-103 X-Strear

Main body:

OXFORD INCA DOL7967 Dry cool

EDWARD Turbo Molecular Pump (TMP)

VARIAN Ion pump

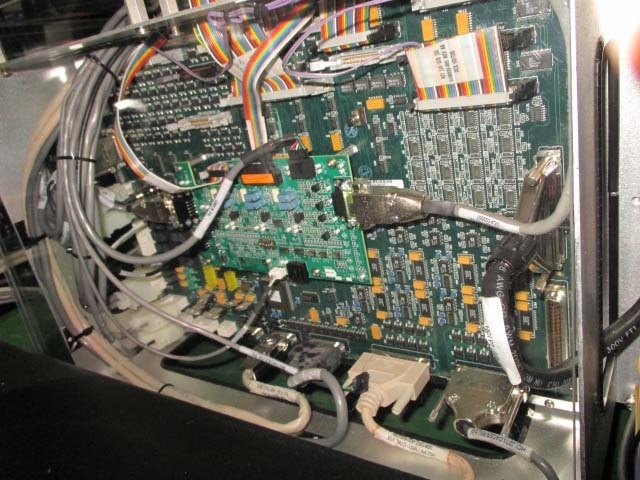

Control rack:

VARIAN Ion pump controller

EDWARDS STP-301-U DOC TMP Controller

TMC DC-2000 Precision valve controller

(2) Reset power supplies

High voltage power supply

Motion controller

Main PC

Does not included Hard Disk Drive (HDD)

Power distribution.

KLA / TENCOR eDR-5210 is a mask and wafer inspection equipment used in semiconductor production. It is designed to detect and analyze defects in wafers, as well as other mask-level precision defects. The system is capable of handling wafers up to 200mm in diameter and a wide variety of mask types. The unit's main components include an optical inspection machine, a wafer mapping stage, a digital image recognition algorithm, and an integrated metrology console. The optical inspection tool is a high-resolution, hyperspectral imaging asset that captures images of the wafer surface. The wafer mapping stage is a multi-axis positioning model which allows for precise measurement of the wafer's surface. The image recognition algorithm is used to identify and categorize any defects. Finally, the integrated metrology console provides a final review of the data to ensure accuracy. KLA eDR-5210 is equipped with a variety of advanced features to improve productivity. Additionally, the equipment is designed for easy installation and maintenance, making it a great option for semiconductor production lines. TENCOR EDR 5210 offers a wide range of applications, from mask inspection and defect analysis, to inspection and review of lithography stencils. Its high-quality and reliable image capture capabilities make it a great choice for inspecting masks and wafers. The system is efficient and provides precise results. The image recognition algorithm and metrology console also ensure accuracy. KLA EDR 5210 is an excellent choice for inspecting and analyzing masks and wafers in semiconductor production. With highly accurate image capture and a range of advanced features, it is one of the most reliable systems on the market today and is highly recommended for optimum productivity.

There are no reviews yet