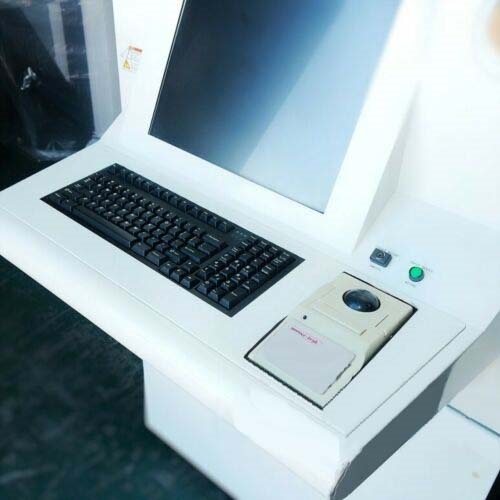

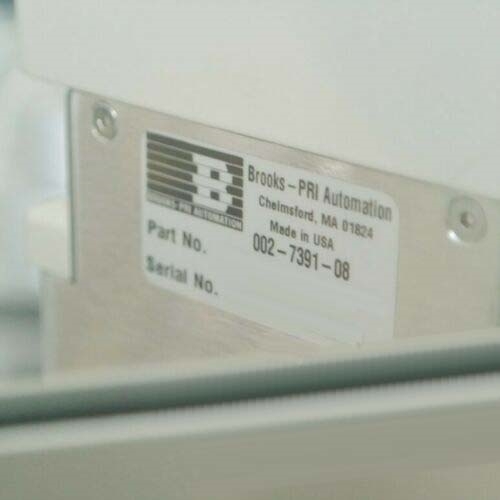

Used KLA / TENCOR eS30 #9258336 for sale

URL successfully copied!

Tap to zoom

KLA / TENCOR eS30 is a specialized mask and wafer inspection system, used in the semiconductor production process. Designed to provide industry-leading reporting capabilities and yield control, the eS30mask and wafer inspection system is a robust, minifab-level solution. KLA eS30 is able to combine optical and electrical metrology systems, allowing it to deliver accurate data quickly and reliably. This includes advanced imaging technology that captures fine-grain geometry details, as well as advanced patter recognition capabilities to identify patterns or defect sources. TENCOR eS30 is able to accommodate a variety of substrates and masks, from 12-inch square masks up to 25-inch square wafers. It is equipped with automated alignment technology, ensuring accurate placement of the mask or wafer for high-volume production with the highest possible accuracy. In addition to its automated scan capabilities, eS30 offers comprehensive reporting features for ultimate traceability. This includes detailed defect reports, where detected defects are assigned to a source and reported down to the level of the intrinsic fault. This traceability data is then used to track process trends, measure yield metrics, and com[are foundry metrics against planar data. In addition, KLA / TENCOR eS30 allows users to select specific defects or patterns to observe or analyze in 'data management' mode. In terms of metrology, KLA eS30 can measure both types of surface structures—be it flat-grain or overlay structures. Complimented by advanced pattern recognition capabilities, precise visualization and analysis of pattern information is enabled. This includes detection of all types of non-ideal processes such as 3D patterning and nonuniformity. TENCOR eS30 also offers imaging and classification capabilities for imaging of peripheral zone defects and wafer clearings. Combined, eS30 offers a comprehensive set of features and capabilities for inspecting and validating mask and wafer layers. This system is the perfect choice for improving detection and analysis, yielding total insight into processes and performance. This ensures fabrication and assembly are running smoothly and efficiently with maximum yields, assuring product quality and reliability.

There are no reviews yet