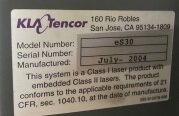

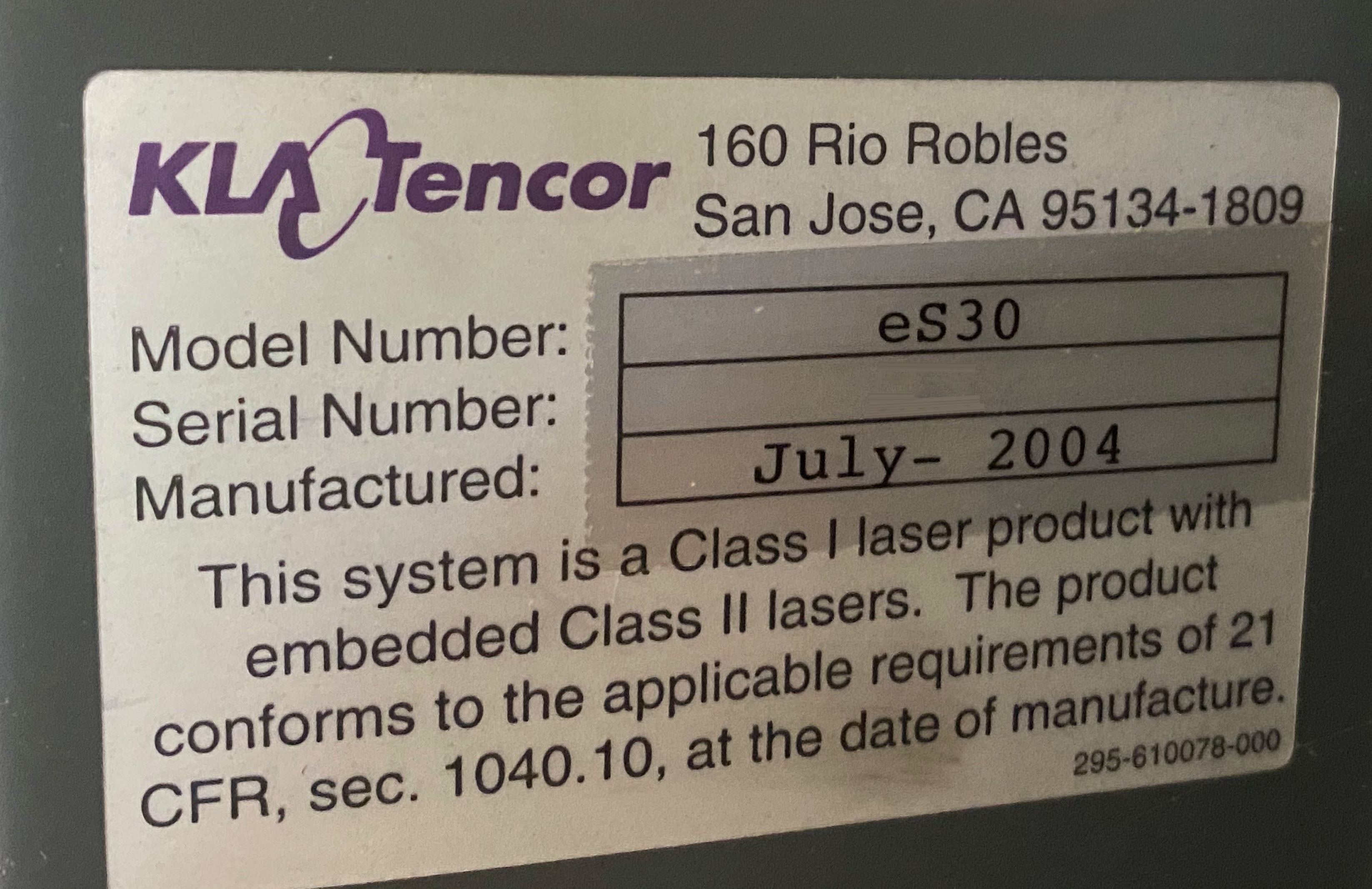

Used KLA / TENCOR eS30 #9280537 for sale

URL successfully copied!

Tap to zoom

ID: 9280537

Vintage: 2004

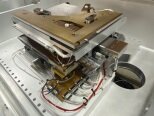

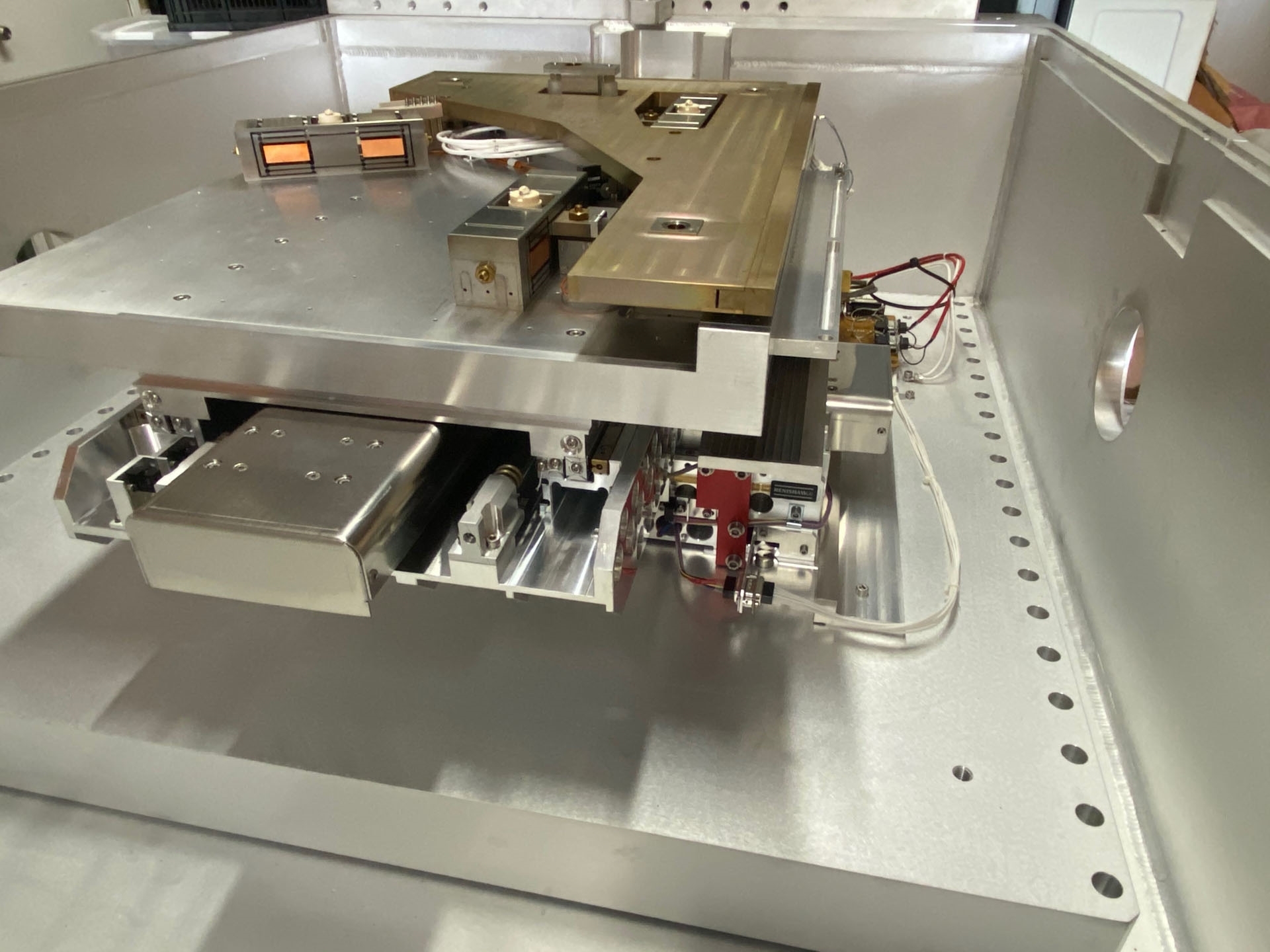

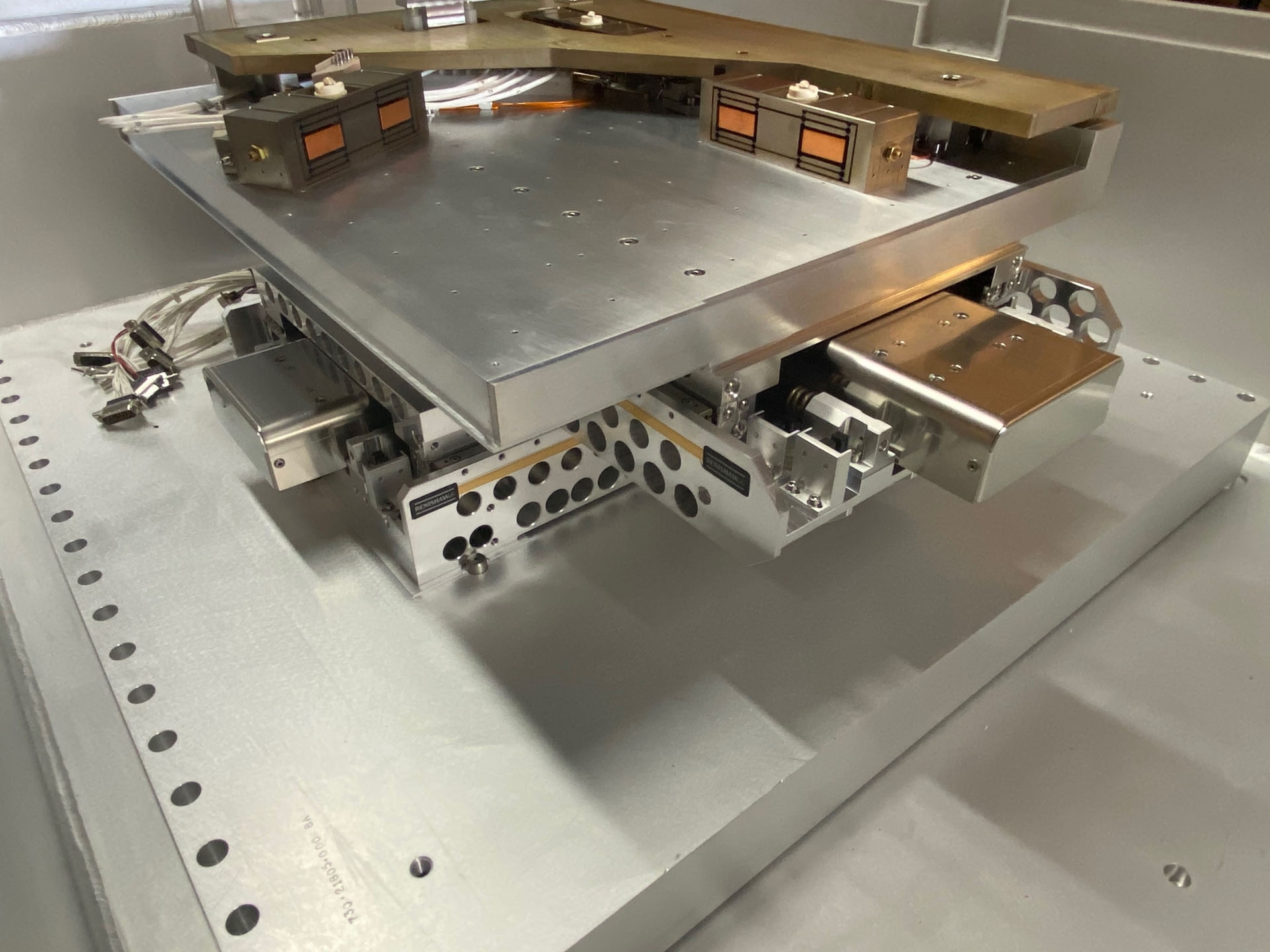

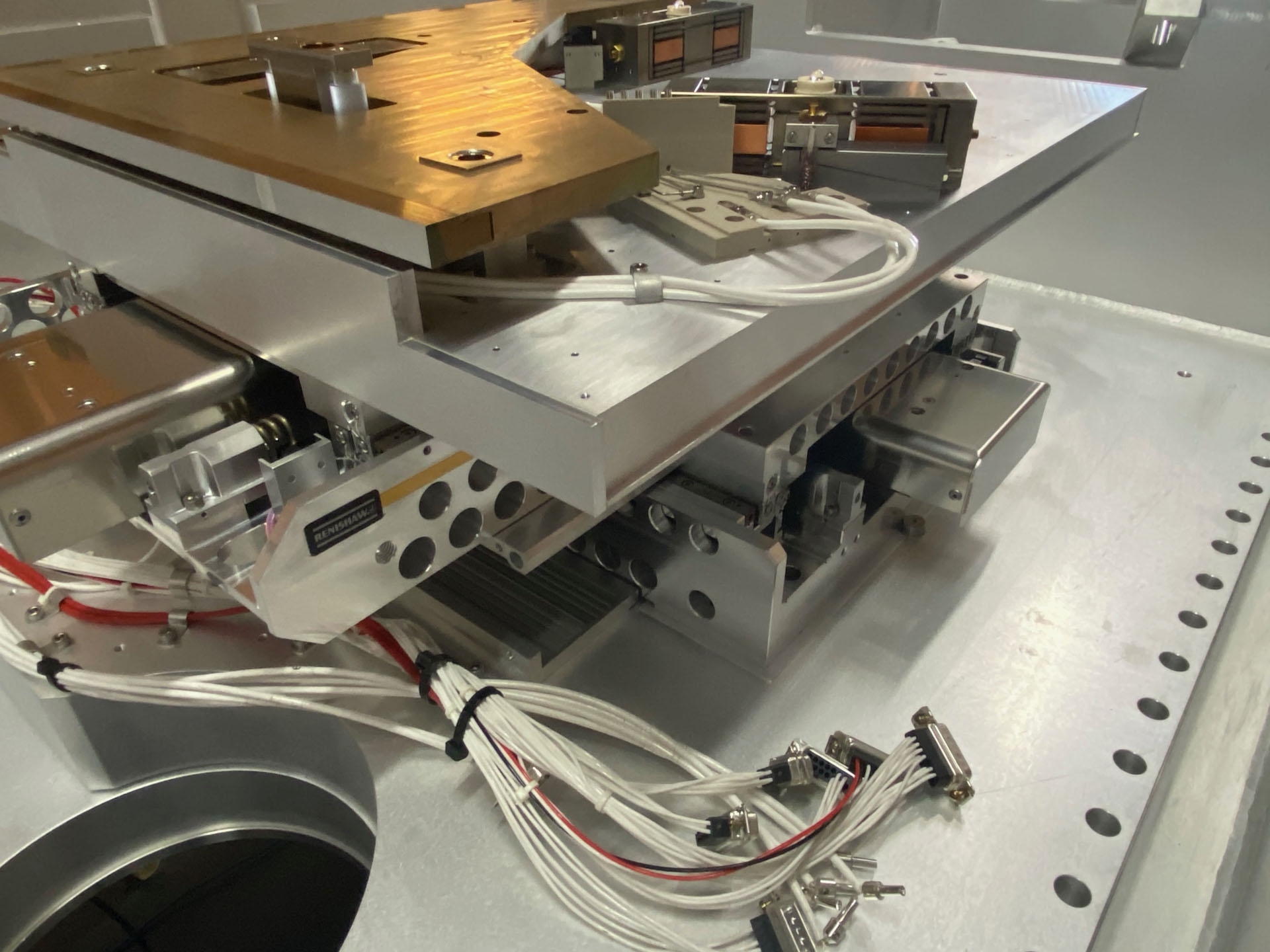

Defect inspection system

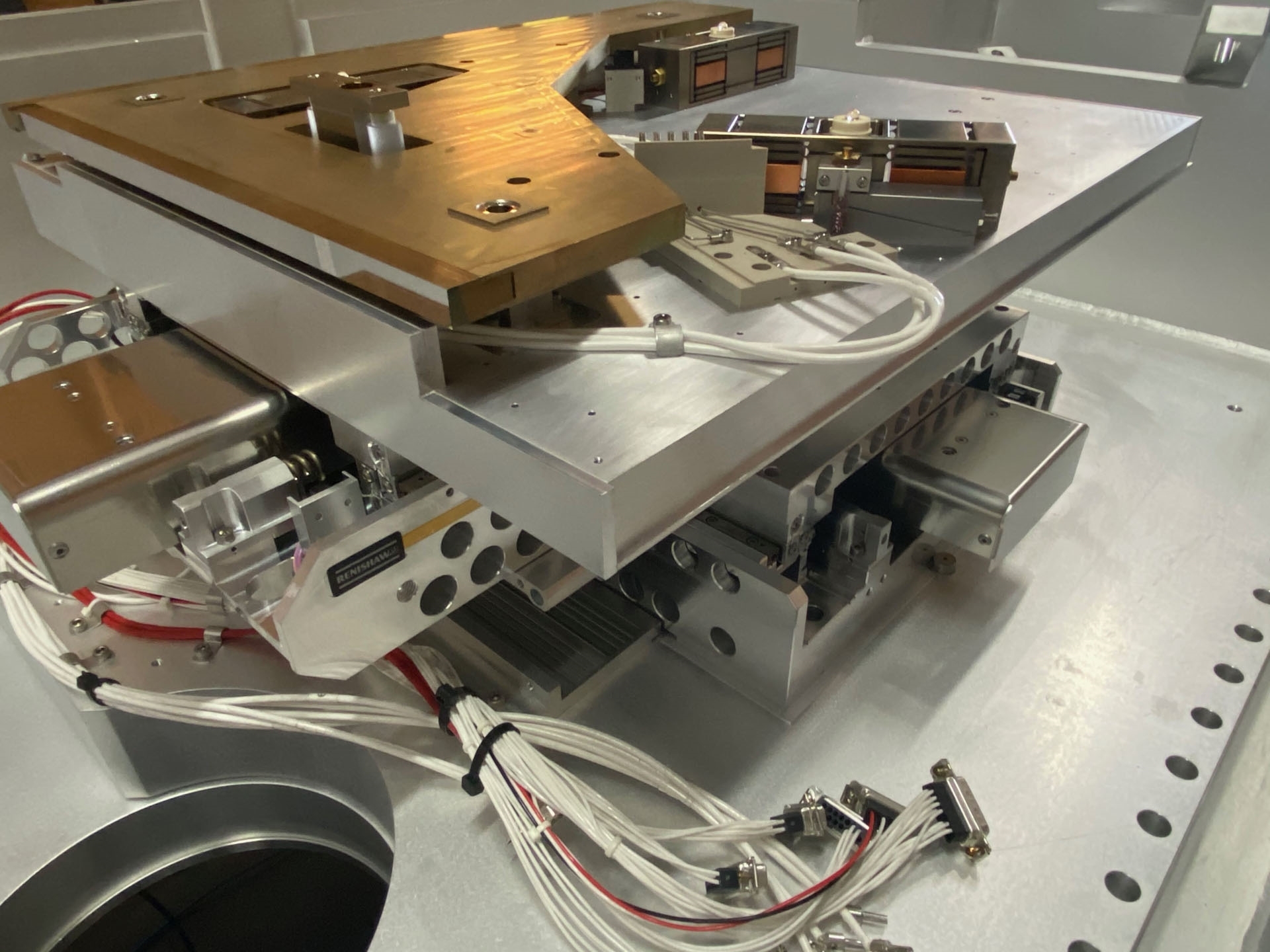

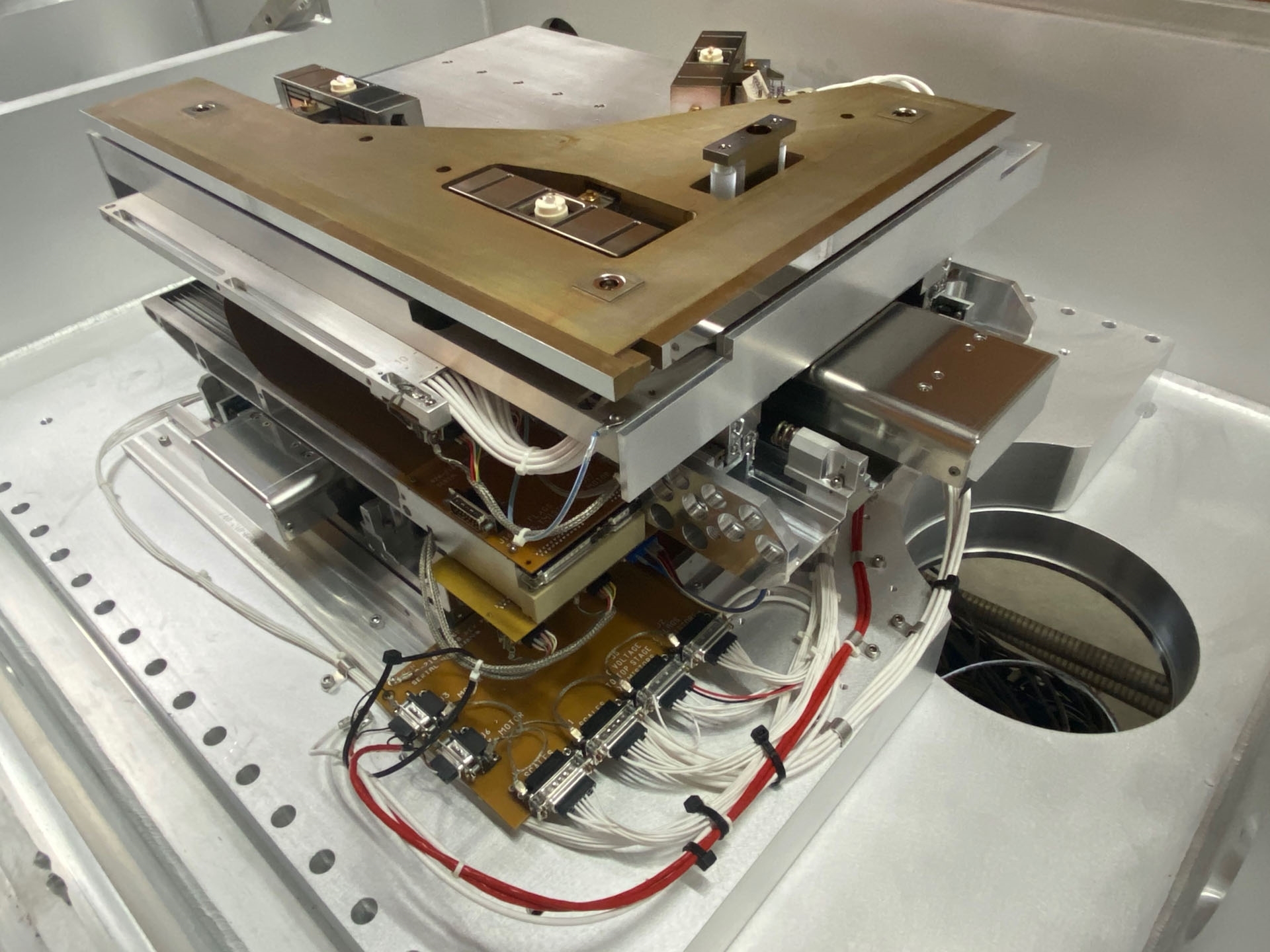

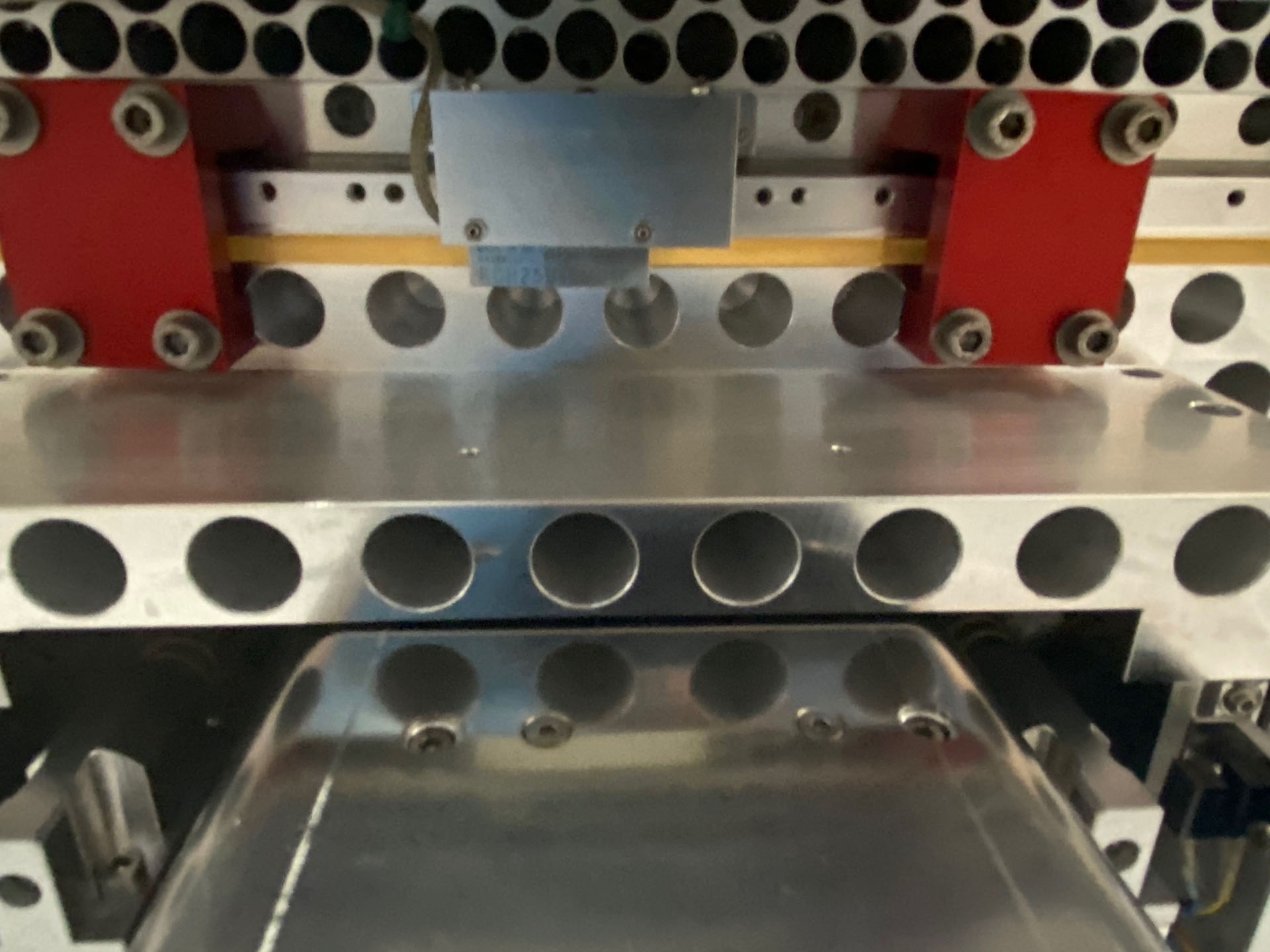

Stage: X, Y, Z

ESC Interface

Piezo actuators

Faraday cup

Description / Part number

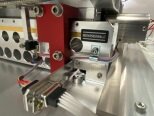

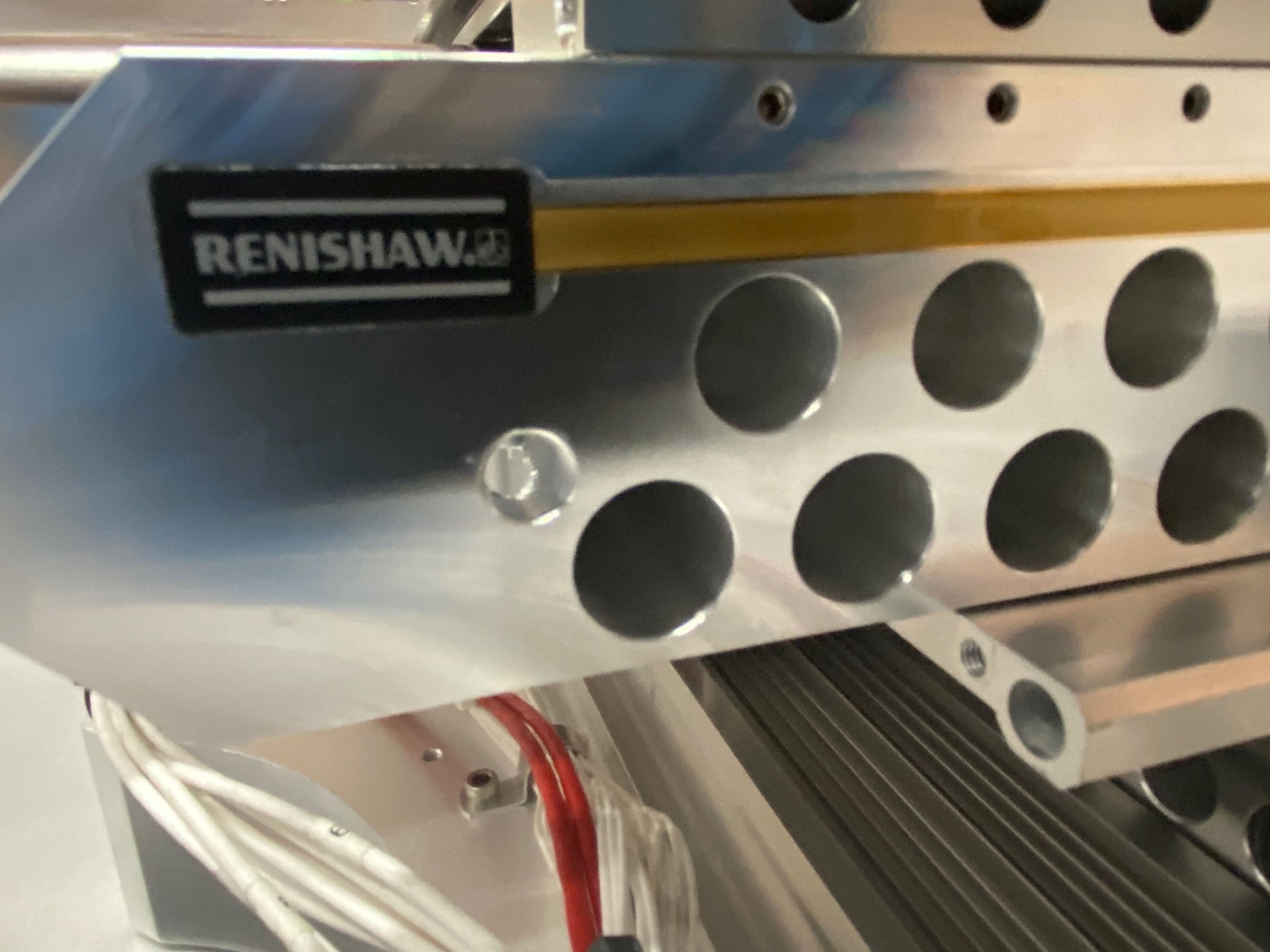

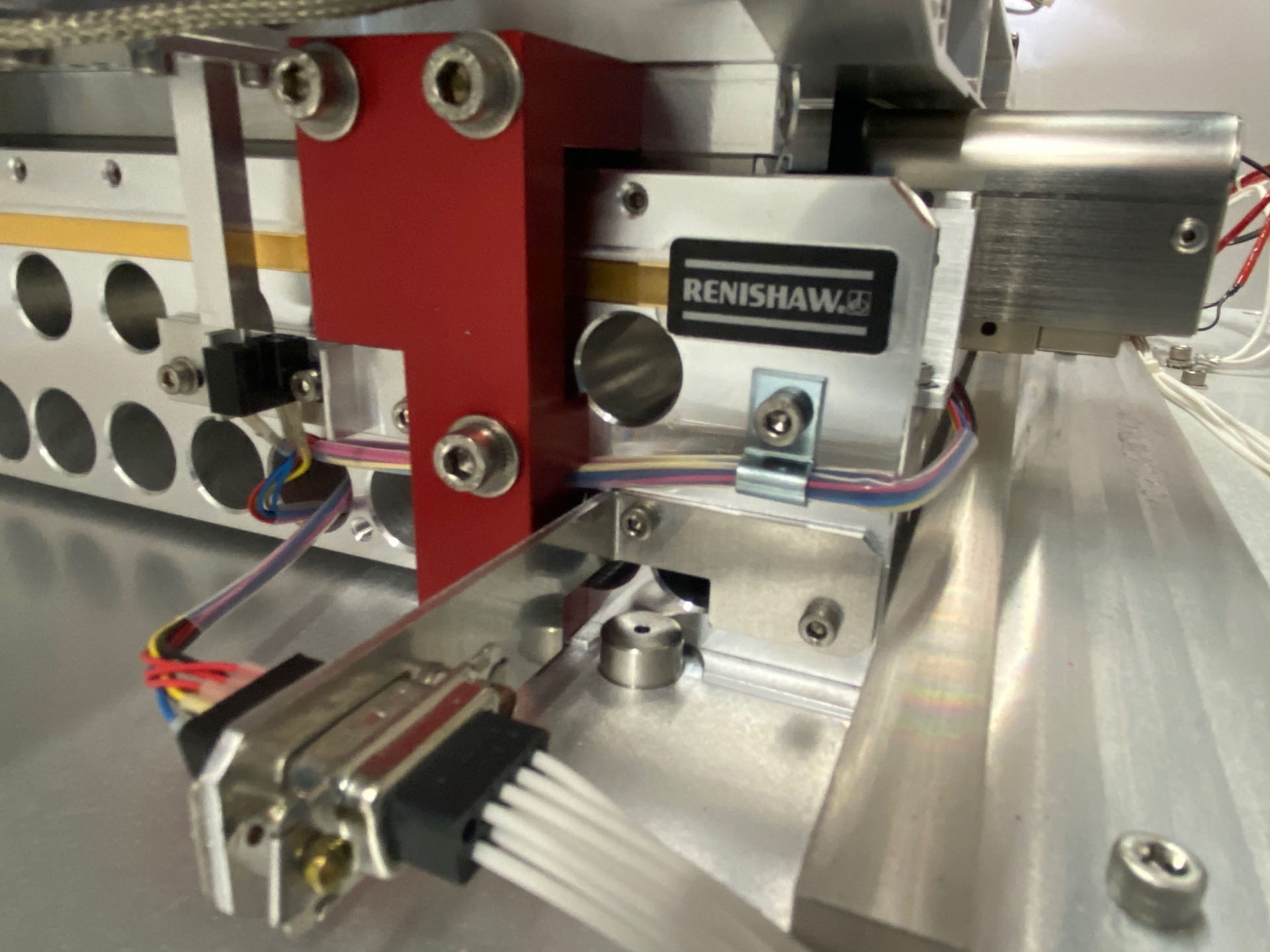

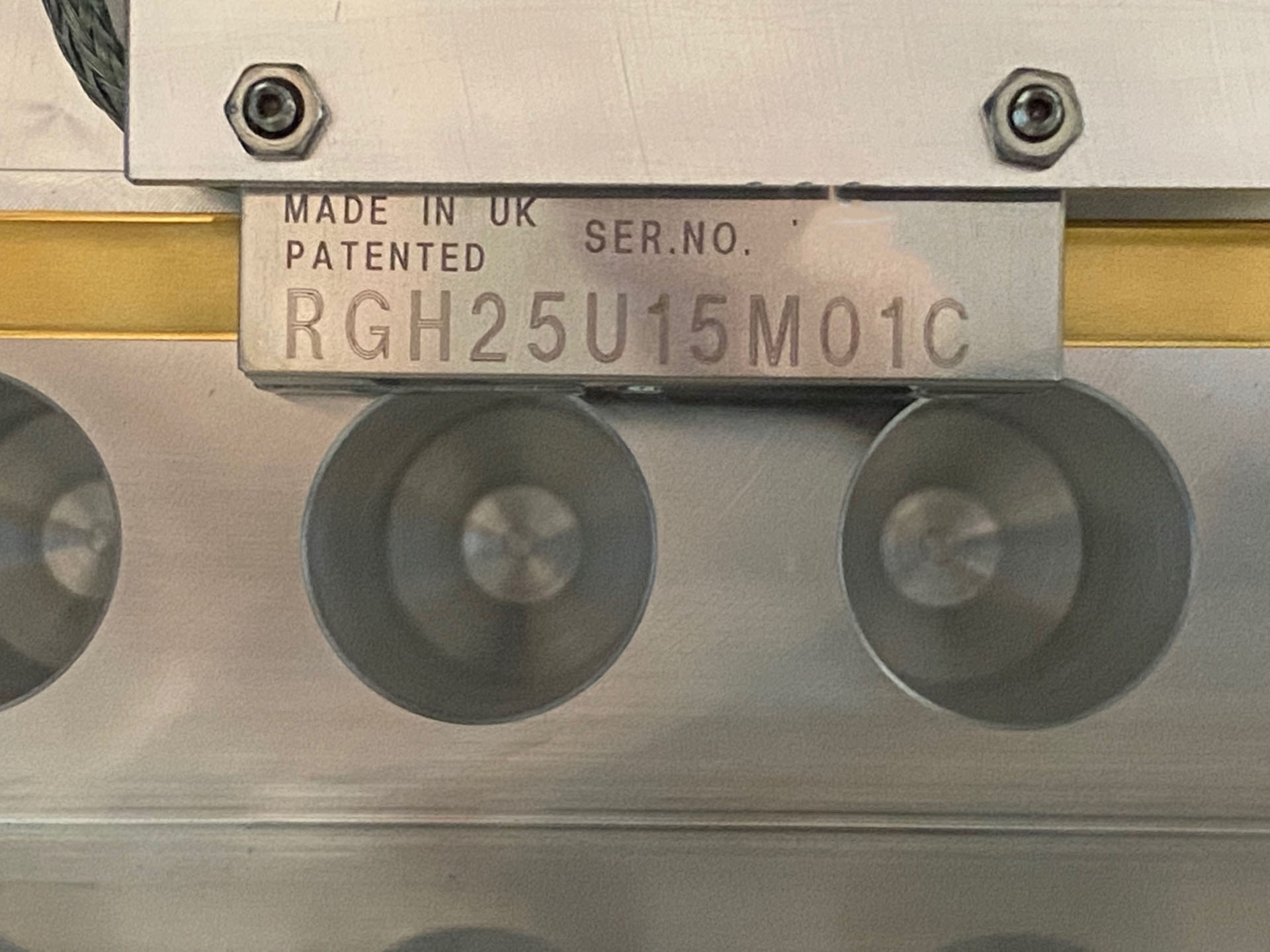

RENISHAW / HEIDENHAIN / P/N: RGH25U15M01C

Precision flatness 6061 aluminum base X, Y Mounting plate / P/N 730-21805-000 Rev BA

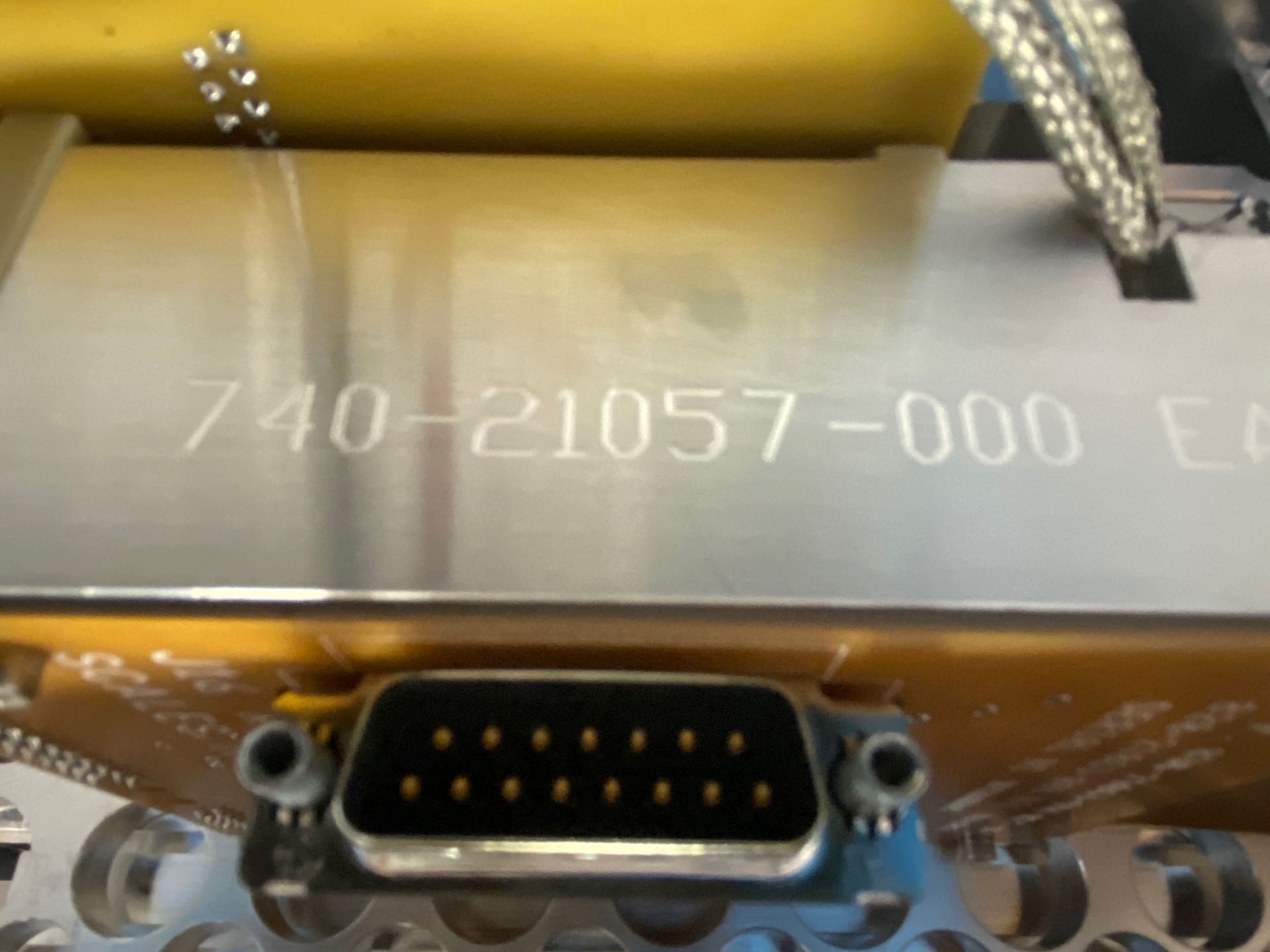

X-Axis / P/N: 740-21057-000 Rev EA

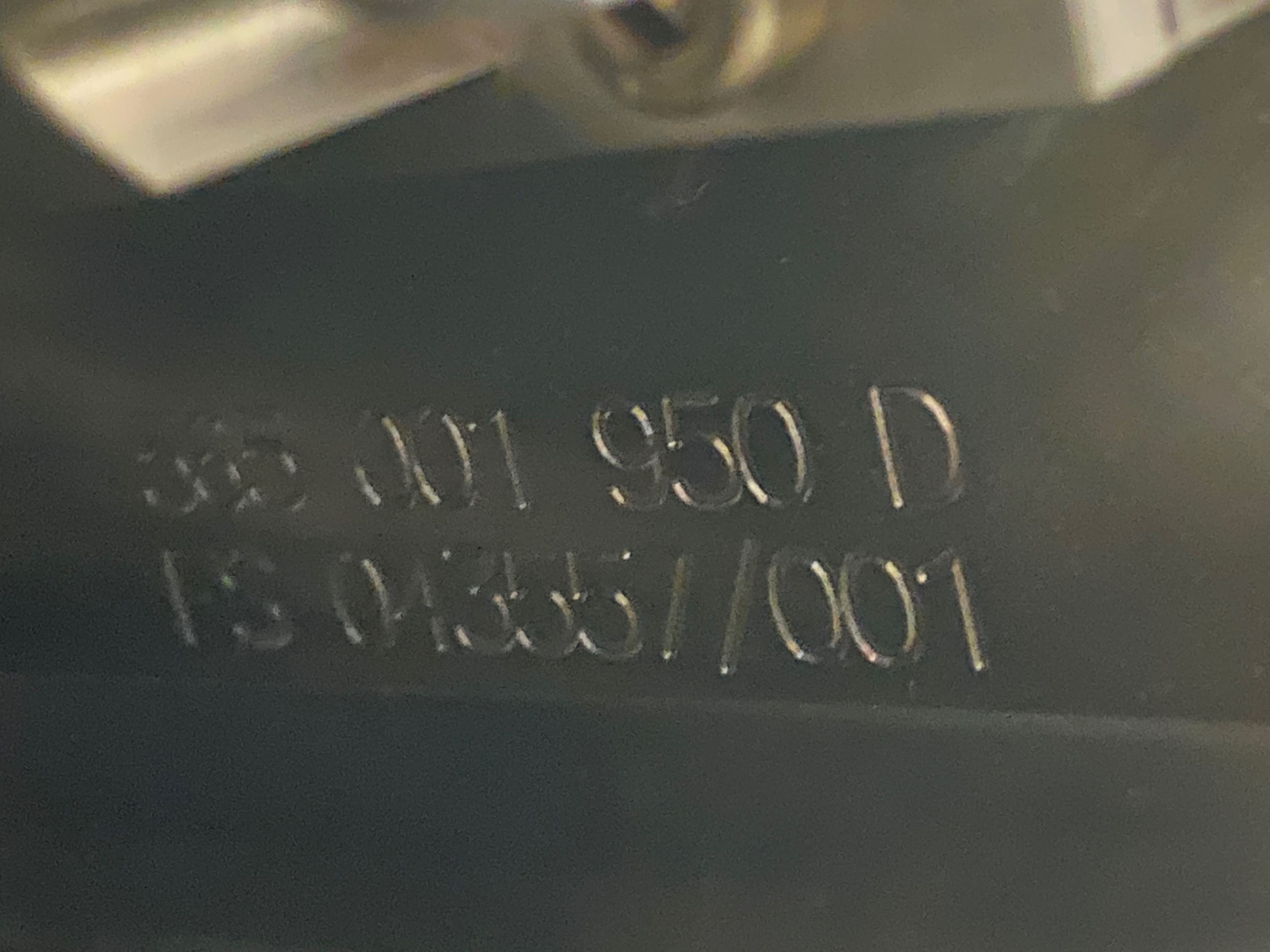

Y-Axis / P/N: 585-001-950 Rev D

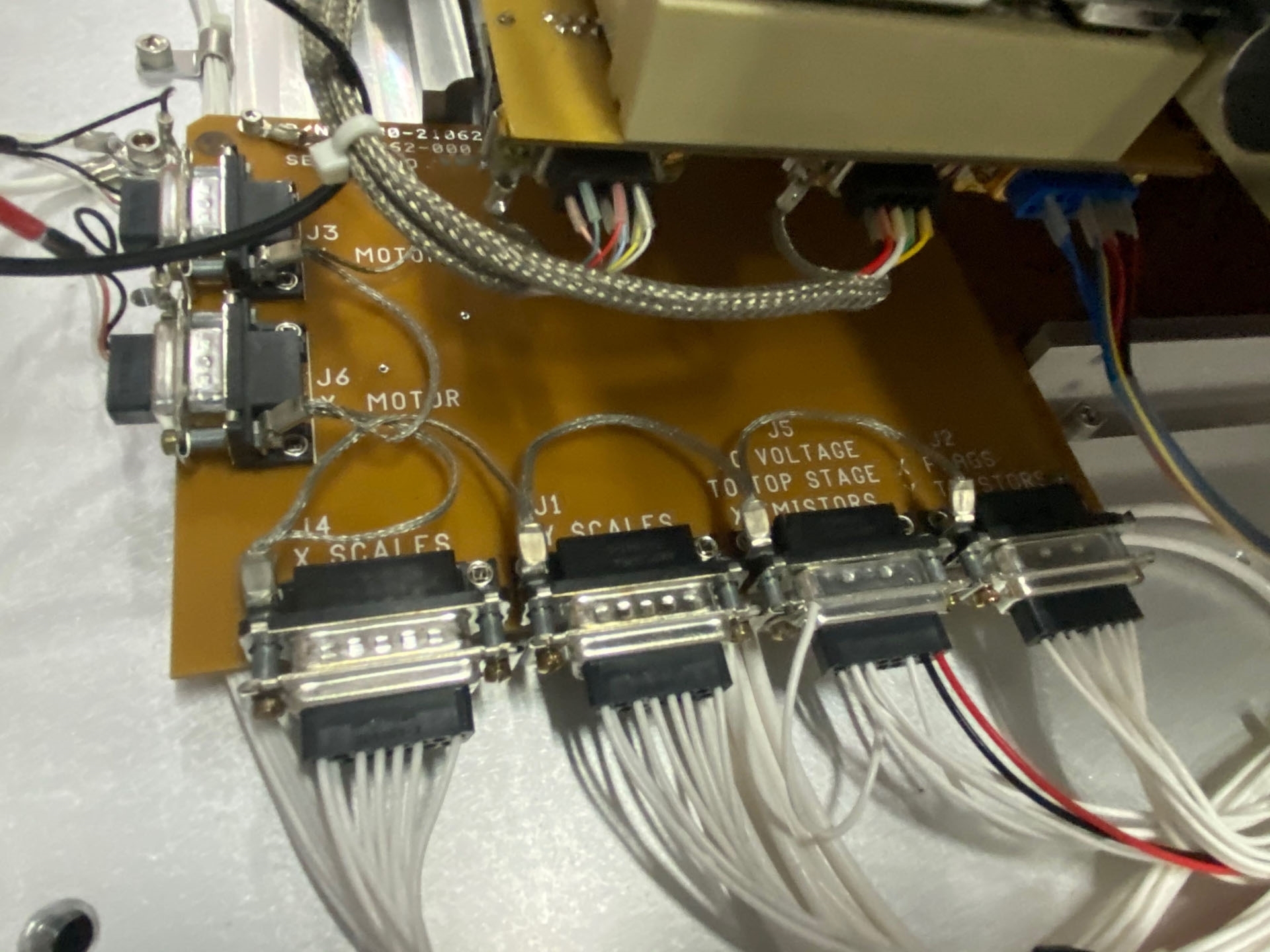

Y Driver motors / Scales / X, Y Thermistors / Flags interface board 830-21063-000 Rev CB / P/N: 820-21063-000 Rev CB

X Driver interface board (X Flags J16, X Motor J17, Y Motor J3) 831-21062-000 Rev CB / P/N: 820-21062-000 Rev DB

High and low voltage wiring cables included

2004 vintage.

KLA / TENCOR eS30 is a mask and wafer inspection equipment used in production and engineering/research environments. It is capable of simultaneously providing high precision measurements of critical layer parameters such as line widths and edge placement. The system is built on KLA proprietary OpticVision technology, featuring a 3-segment BDI Laser, a laser scan head assembly with a FocusLens, and an ultra-high speed digital camera. The combination of these components provides the unprecedented speed, flexibility and accuracy needed for today's advanced production and research applications. The 3-segment BDI Laser utilizes three laser beams which allow higher throughput and better performance than traditional single laser systems. The lasers are individually tunable allowing for a wide range of measurement speeds, giving the unit exceptional capabilities as a production tool. The laser scan head assembly uses a large-aperture FocusLens to focus the laser beams on very small features and features inspected with very low surface irregularities. This provides superior coverage of the wafer surface, including edges and corners, which can be difficult to inspect with a single laser. KLA eS30 also features an ultra-high speed digital camera, which has the ability to capture fluorescent images at very high speeds, making it perfect for optical lithography applications. It also has an integrated, high precision stage that can rapidly traverse a wafer or reticle from start to finish in a single scan. Moreover, TENCOR eS30 also has an automatic offline measurement feature, which can be used for rapid reticle or wafer assessment, as well as for automated data analysis and recording. The machine is backed by a powerful software suite featuring measurement, analysis and reporting capabilities, allowing users to quickly evaluate their data, produce reports and make comparative masks using data collected from eS30. Overall, KLA / TENCOR eS30 provides unsurpassed performance and accuracy, making it the ideal solution for a wide range of wafer and mask inspection needs. Its combination of features, including the laser scan head assembly, ultra-high speed digital camera and automated offline measurement feature, make it the perfect choice for any production and/or engineering/research environment.

There are no reviews yet