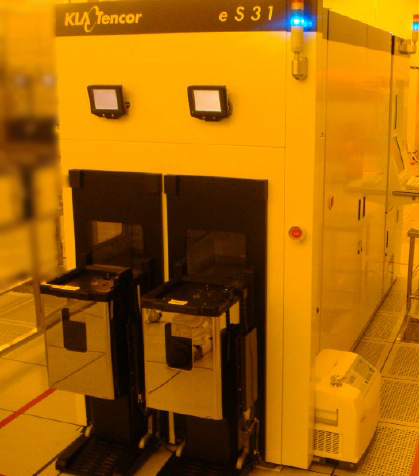

Used KLA / TENCOR eS31 #191476 for sale

URL successfully copied!

Tap to zoom

ID: 191476

Vintage: 2006

Wafer inspection system

SMIF

Currently installed

2006 vintage.

KLA / TENCOR eS31 is a fully automated, high-resolution inspection equipment designed specifically for advanced metrology and process control applications in the mask and wafer process. The system performs a range of critical functions, including wafer defect review and classification, mask pattern examination, and wafer data analysis. The unit provides analysts with detailed information on process stability, process consistency, defect characteristics, and defect classification. KLA eS31 uses an innovative design to achieve high resolution images and data analysis—it combines multiple imaging and spectroscopic techniques to unlock the secrets of the wafer and mask surfaces. The integrated microscopy machine is capable of detecting and measuring nanoscale features through its advanced illumination, image collection, and analysis functions, while the spectroscopic tool can quantify spectral data from raw material to finished product. The asset is equipped with a high-speed autoloader that allows the user to quickly and safely load and unload wafers and masks, with no manual intervention required. TENCOR eS31 features multiple inspection modes to accommodate various inspection requirements, including defect-specific, area-specific, and full-surface scans. The model also has advanced pattern recognition capabilities, enabling it to detect subtle pattern defects, as well as false recognition. ES31 provides an automated data analysis and reporting capability. The equipment can generate clear, actionable reports that help define wafer and mask process stability and consistency, as well as quantify the characteristics of defects and their potential root causes. The system can also be used to generate product quality reports to document the performance of both the machine and the process. KLA / TENCOR eS31 is an ideal tool for monitoring wafer and mask processes to ensure they remain defect-free and consistent. The unit's high-speed, high-resolution optics and data analysis capabilities make it an invaluable asset for the automated detection and classification of wafer defects and mask patterns. The machine's ease of use, fast loading speed, and powerful data analysis and reporting capabilities make KLA eS31 an essential part of a complete defect detection and process control solution.

There are no reviews yet