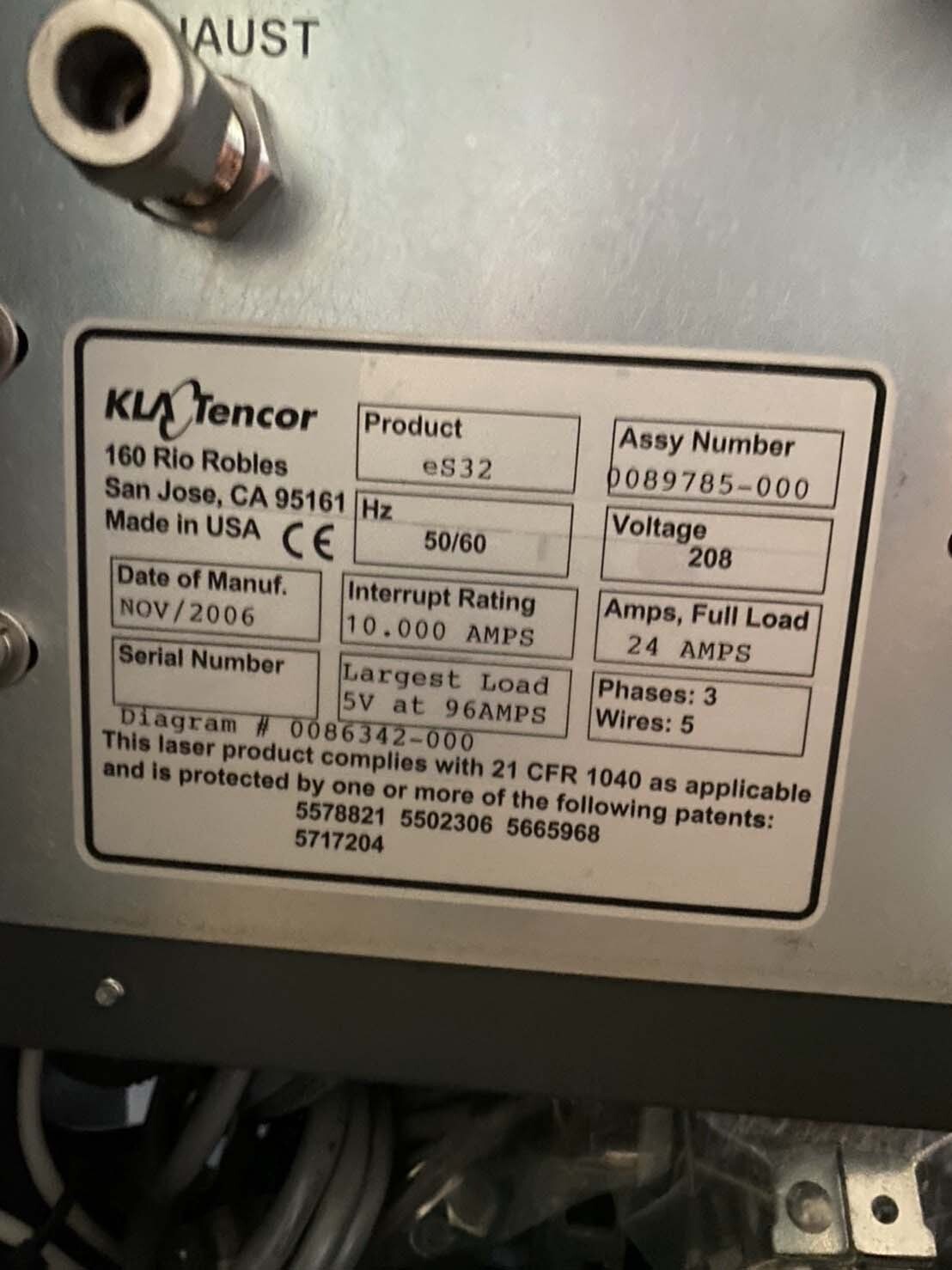

Used KLA / TENCOR eS32 #9386158 for sale

URL successfully copied!

Tap to zoom

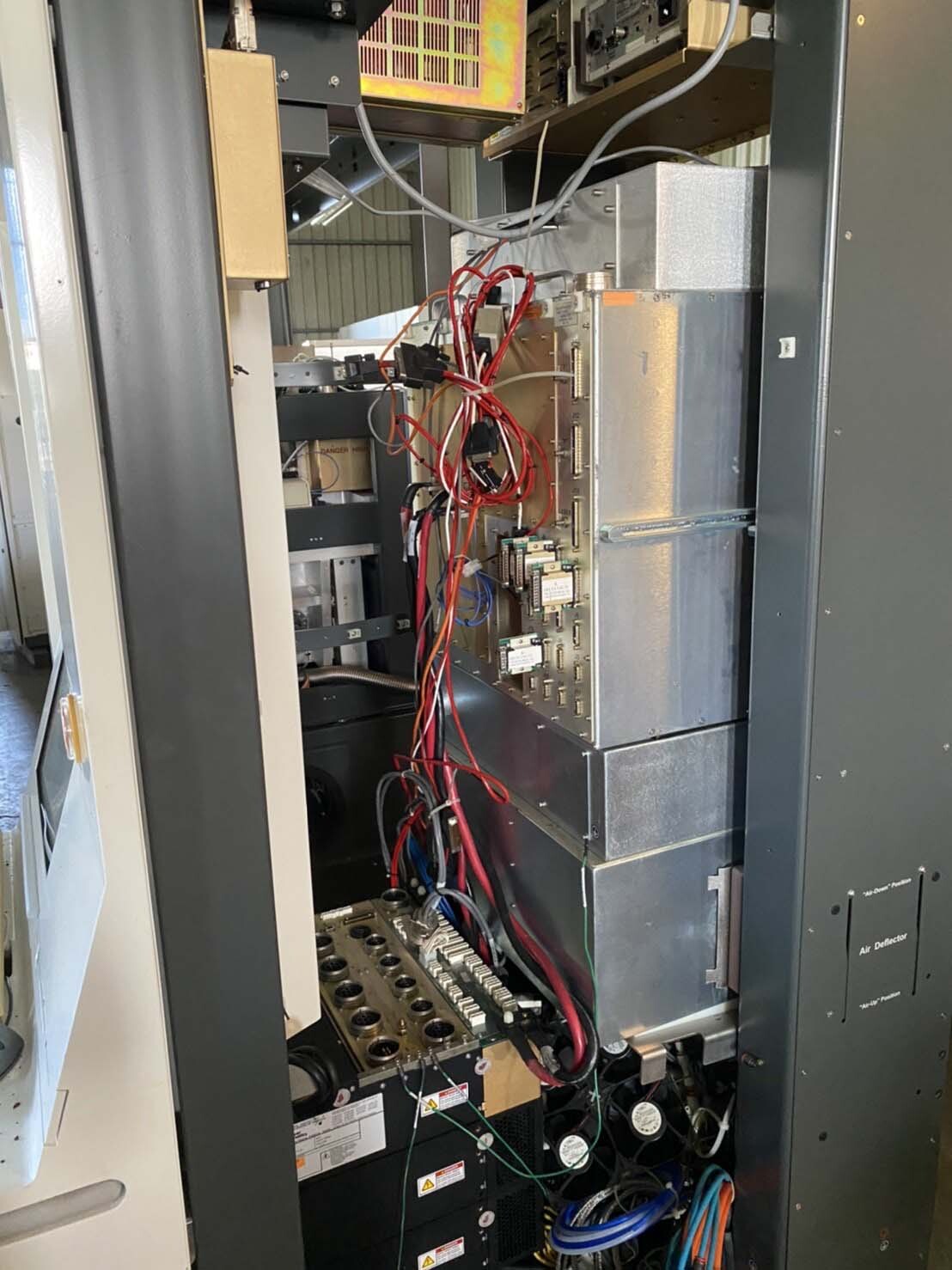

KLA / TENCOR eS32 mask and wafer inspection equipment is designed for specific measurements of semiconductor mask and wafer patterns. It is powered by an open architecture that enables the integration of advanced technology solutions and FOUP robot interfaces for advanced inspection and measurement capabilities. This system provides an interactive user interface which allows for quick and easy wafer pattern inspections. KLA eS32 unit uses a die-to-database software machine that allows users to rapidly and accurately identify defects. This tool has multiple wafer stages for automatic die placement accuracy measurement and adjustment. The die-to-database asset enables a single DieID for each die, and the ability to accurately measure die-to-die accuracy differences. TENCOR ES 32 mask and wafer inspection model has several advanced technologies to enable precise and repeatable measurements. These technologies include Dual-Side High-Resolution Pattern Recognition (DSPR), MyVuTM On-Sample Adjustment and On-sample Alignment. The DSPR technology performs an extremely precise shape recognition process to identify defects on both sides of the mask or wafer without changing the focus position. This increases the ability to detect small defects such as dislocations and stitching errors. MyVuTM On-Sample Adjustment is a technology that enables the equipment to automatically adjust the focus position based on the actual die shape on the wafer, allowing for a more precise inspection. The On-sample Alignment technology of ES 32 enables accurate mapping of the entire sample surface to prevent errors due to displacement. The advanced technology also maps both the top and bottom surfaces of the die for more accurate defect detection. KLA ES 32 system also features the latest FastFluxTM Defect Detection software, which is able to detect defects that are as small as 0.08 microns in size. The unit can also detect multiple types of defects including particle, hillock, delamination, and shorts. In conclusion, TENCOR eS32 mask and wafer inspection machine provides users with an interactive user interface, advanced die-to-database software, advanced pattern recognition, MyVuTM On-Sample Adjustment, On-sample Alignment, and FastFluxTM Defect Detection software. This tool is designed to provide pinpoint accuracy in identifying defects, enabling higher yield and more cost-effective manufacture of semiconductor devices.

There are no reviews yet