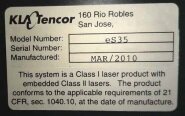

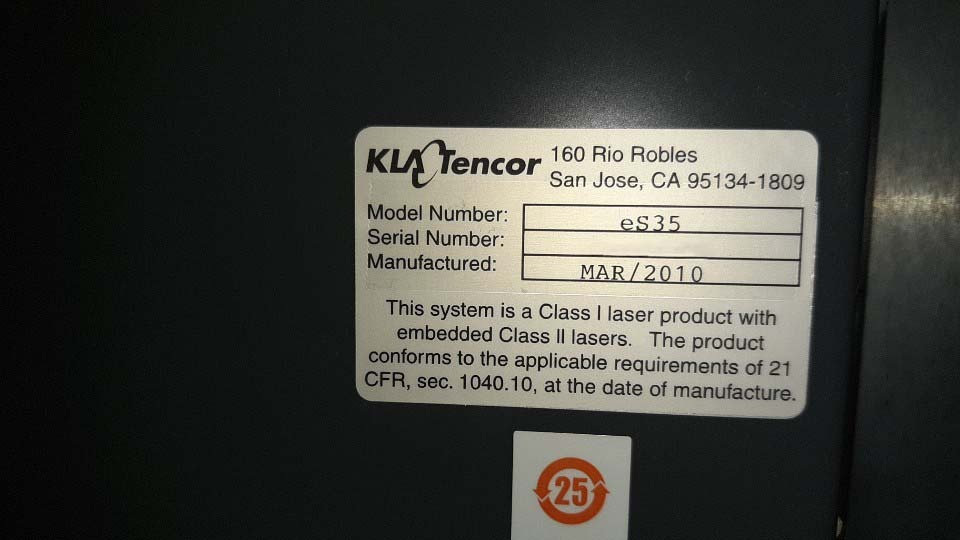

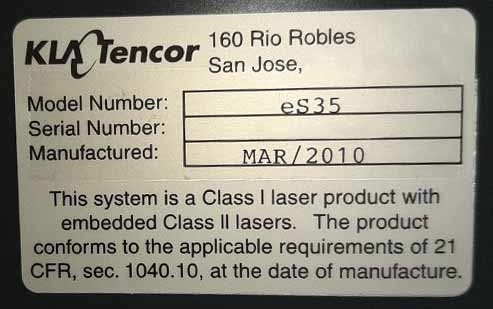

Used KLA / TENCOR eS35 #9225299 for sale

URL successfully copied!

Tap to zoom

ID: 9225299

Wafer Size: 12"

Vintage: 2010

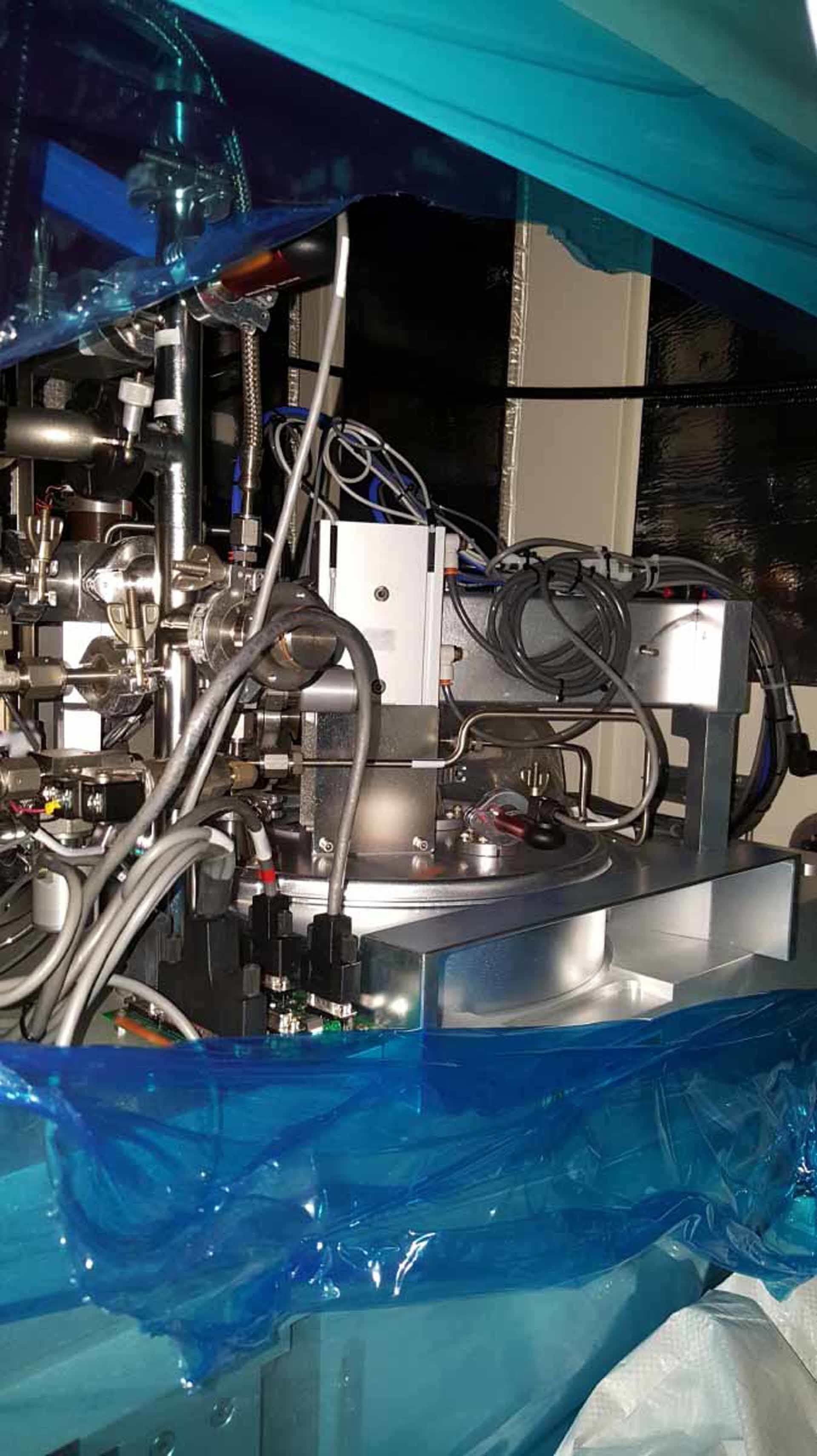

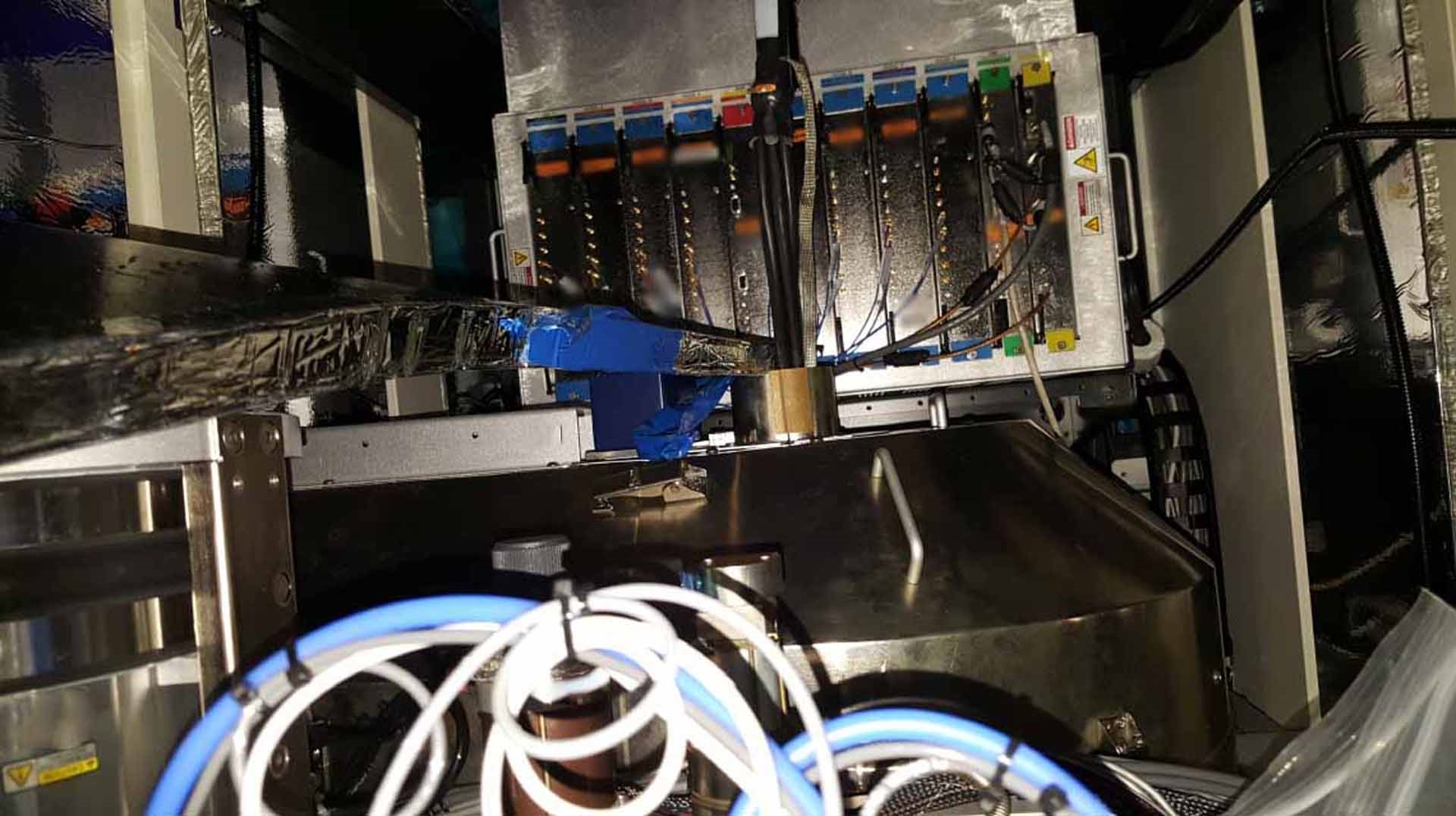

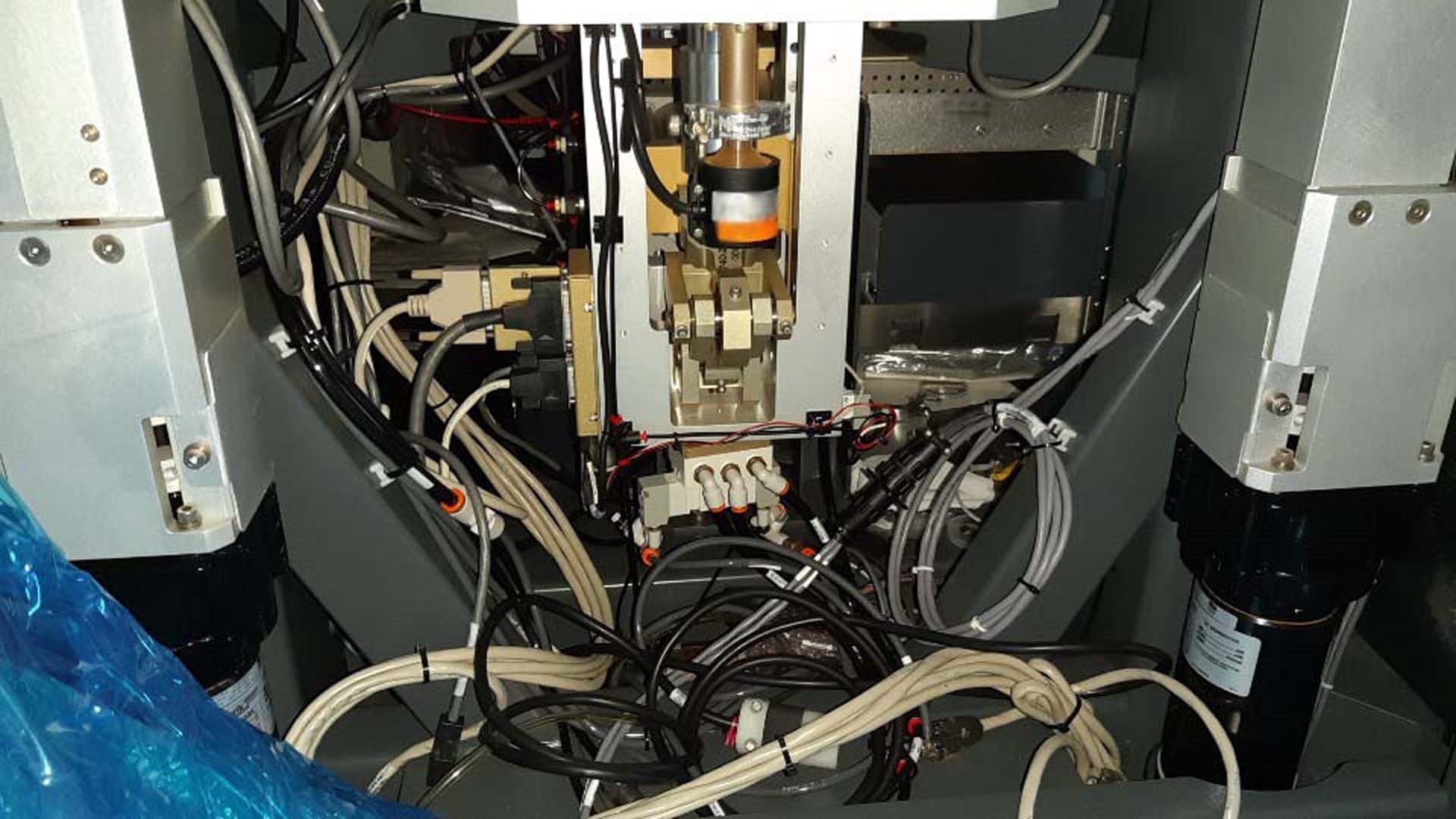

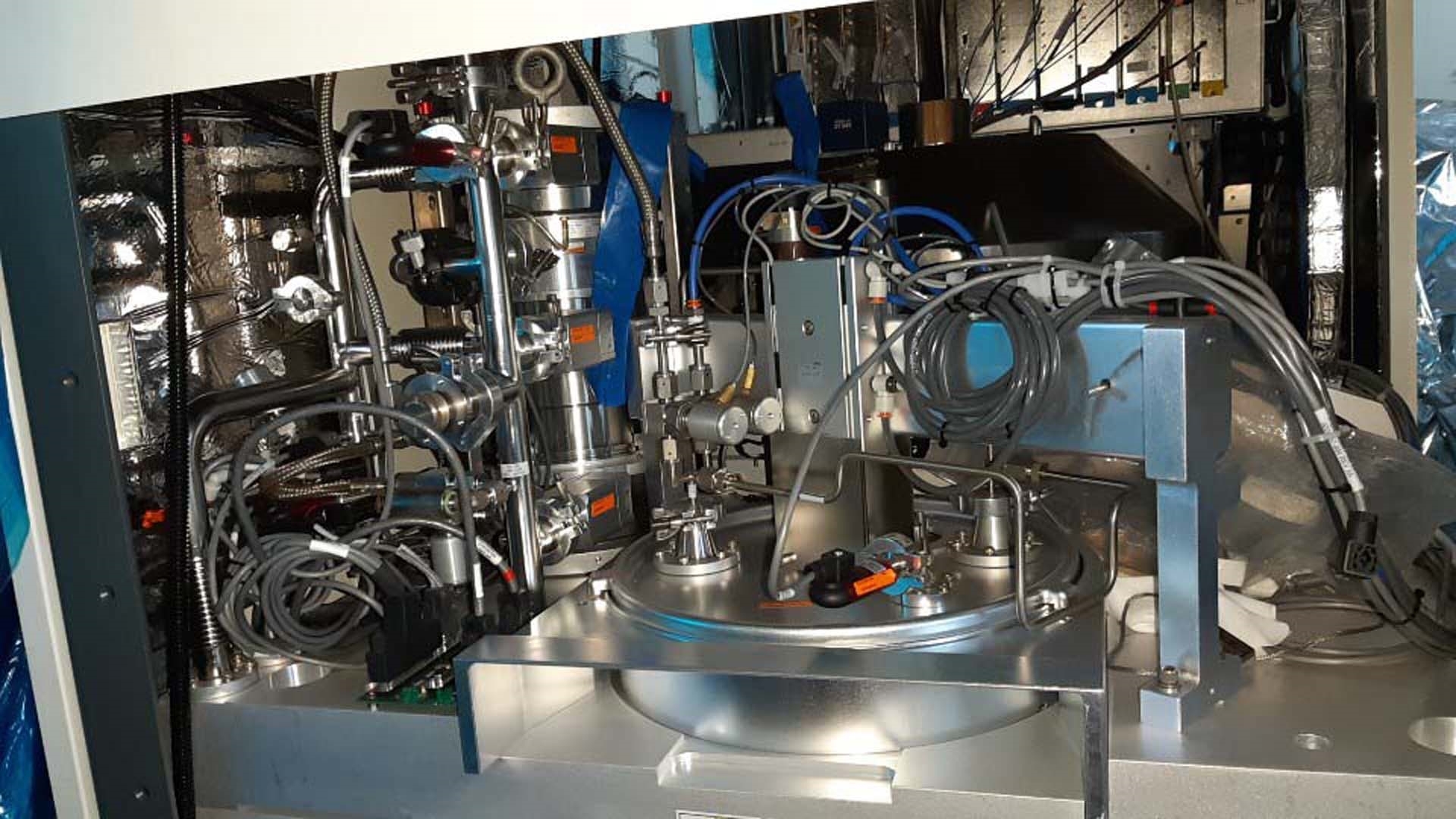

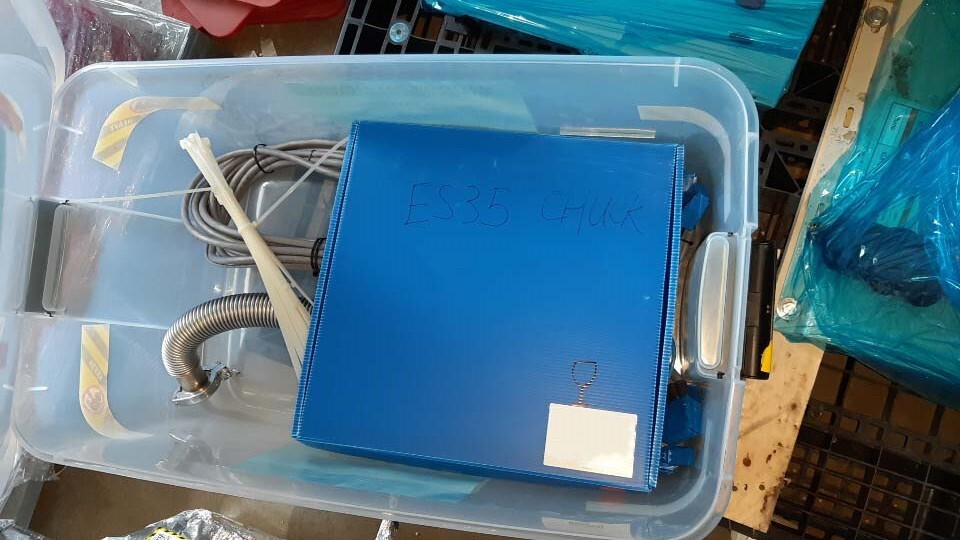

E-Beam inspection system, 12"

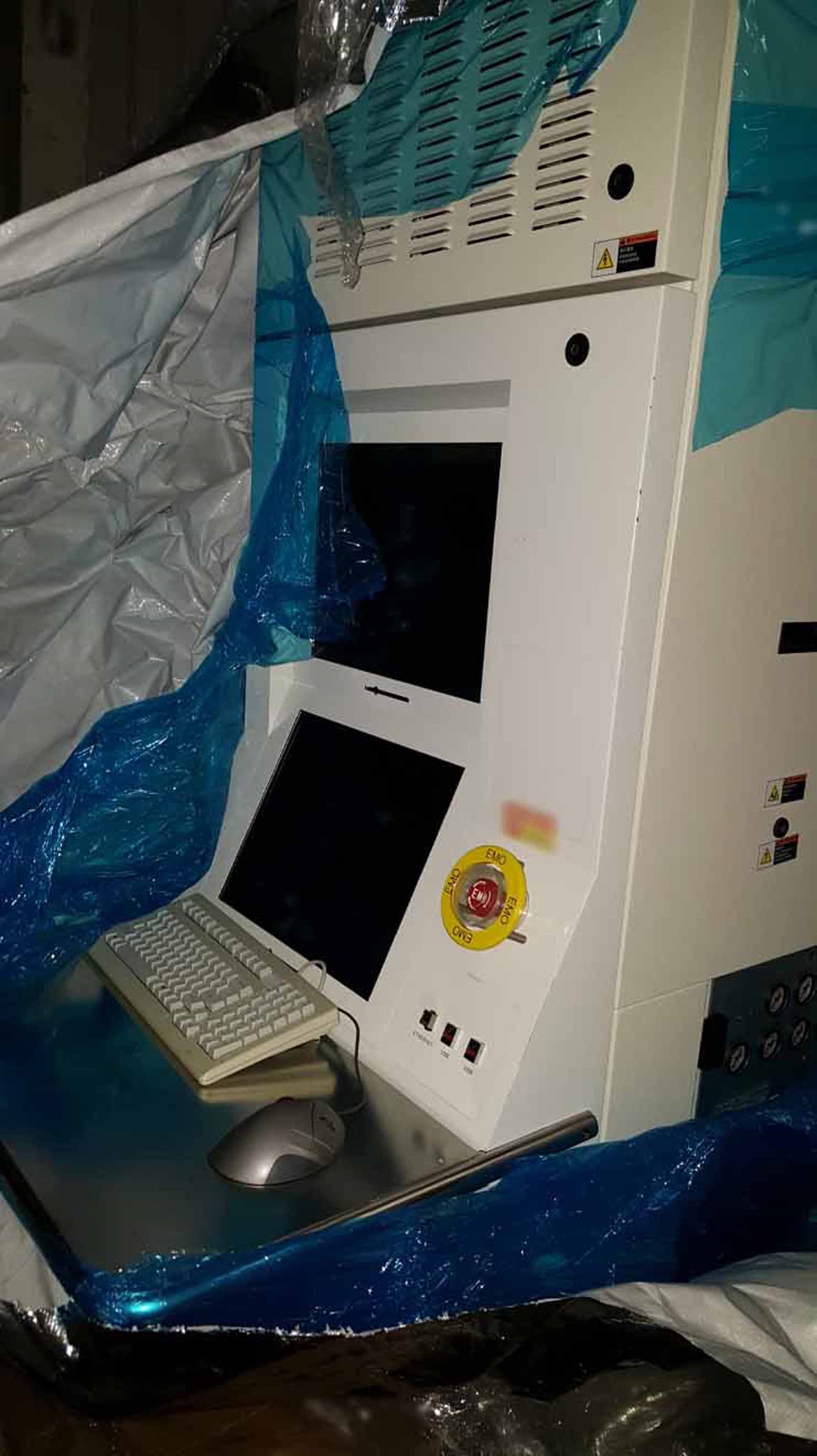

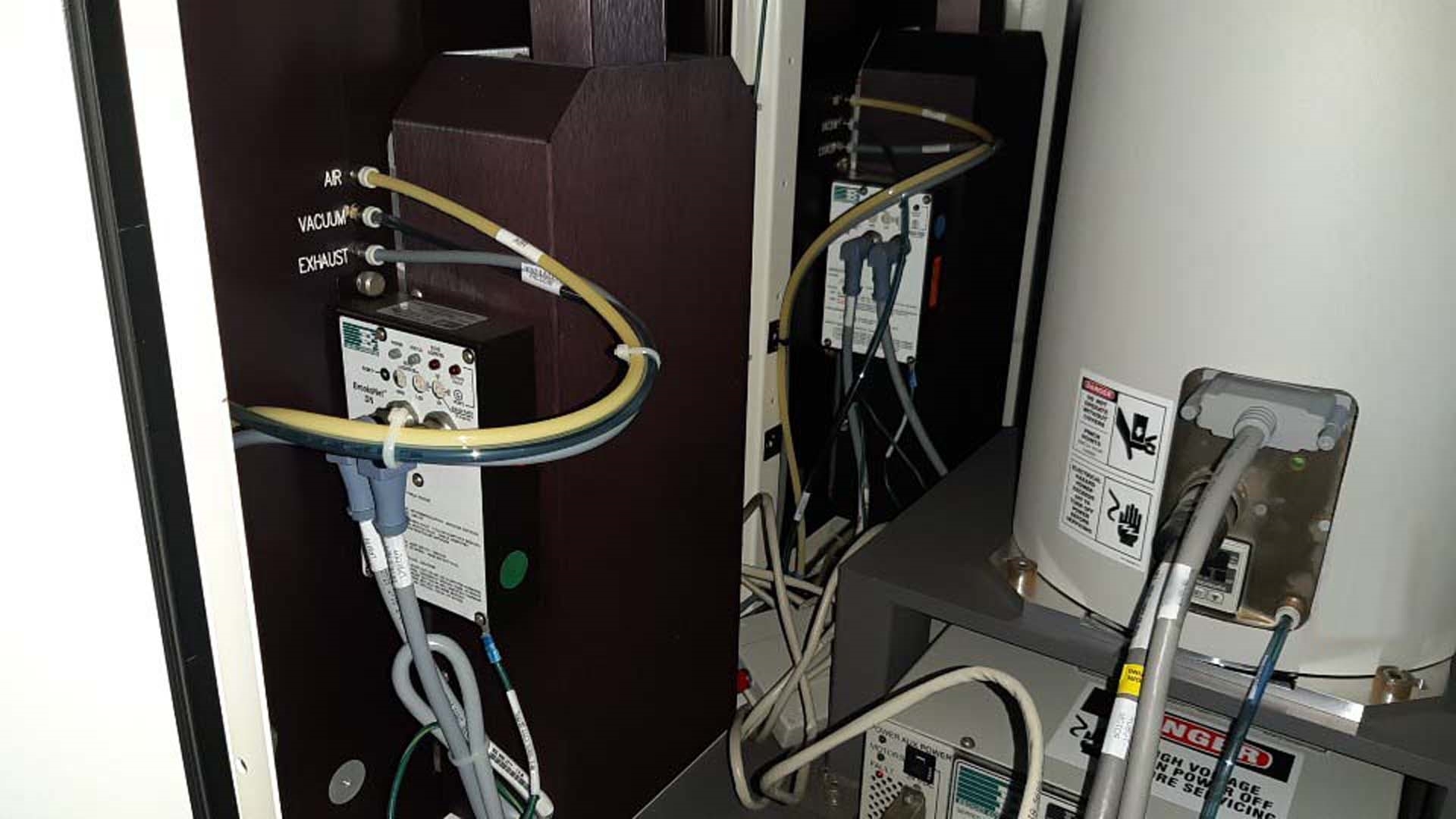

EFEM

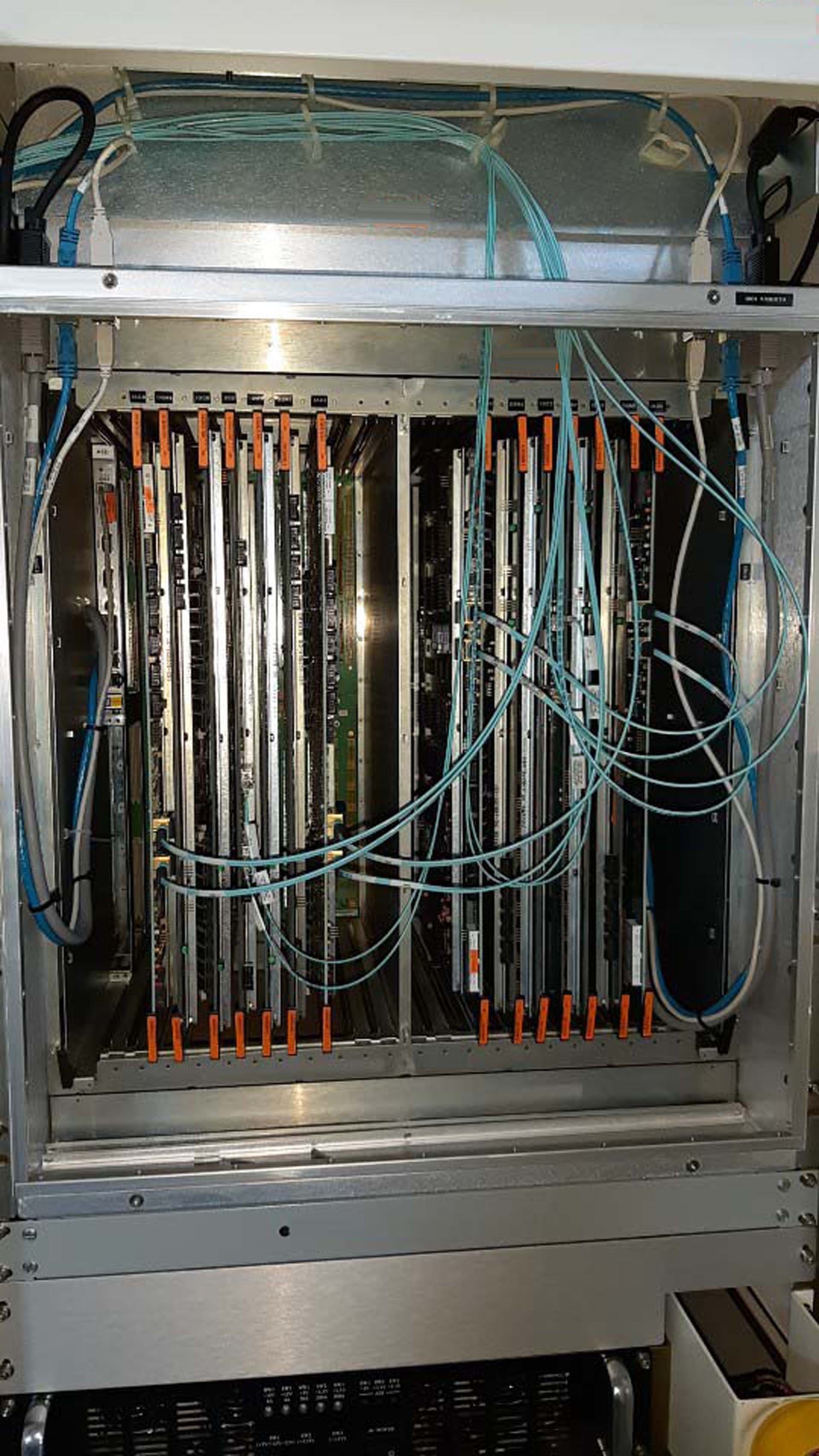

UI

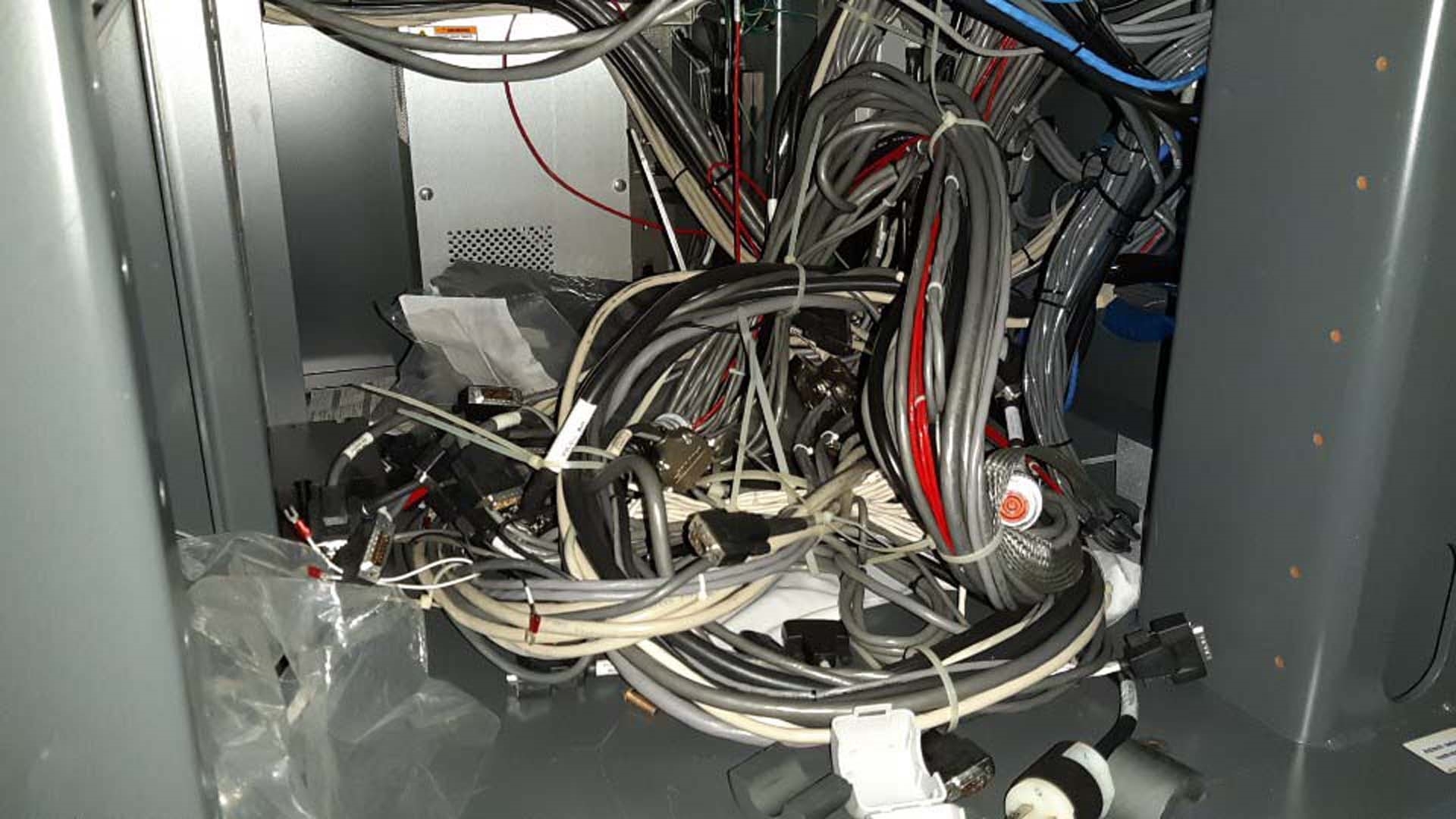

Power box

IPDU

2010 vintage.

KLA / TENCOR eS35 is a mask and wafer inspection equipment designed for high-end semiconductor manufacturing. It uses a combination of optical, electrical and mechanical sensors to detect defects and defects on the surface of masks and wafers. KLA eS35 uses five patented technologies to accurately detect and identify potential defects, and can collect data on up to 1000 sample sites per second. The system uses an integrated mask and wafer imaging unit based on high-resolution lasers and cameras. This machine captures image data which is then processed and analyzed by a high-performance computer tool. The asset can detect features such as quaternary pattern areas, pits, cracks, dust, dirt, and particle residues on both masks and wafers. TENCOR ES 35 utilizes a patented 'Off-Axis Technology' to detect defects. This model employs a unique off-axis imaging technique which enables the equipment to detect defects on the surface of masks and wafers more accurately. It is capable of measuring micron-scale defects, which often go unnoticed on conventional systems. The system creates a 3D profile of the the sample surface, which allows for detection of even the smallest defects. ES 35 is equipped with a sophisticated defect-classification algorithms. The unit is able to categorize defects as critical or non-critical, and is also capable of classifying defects according to size, shape, location, coplanarity and contamination. The machine also has an advanced learning algorithms which allows for automated learning based on results from past inspections. TENCOR eS35 has an advanced operator interface which enables users to customize inspection parameters, view real-time images, graphs, DICE reports, and more. The tool is also compatible with industry-standard communication protocols, allowing for in-line integration into existing semiconductor production systems. Overall, eS35 is a powerful and reliable asset which is designed to identify and classify defects on the surfaces of masks and wafers accurately and quickly. The model is highly configurable and yet simple to use, making it a great choice for those seeking to reduce costs without compromising on quality.

There are no reviews yet