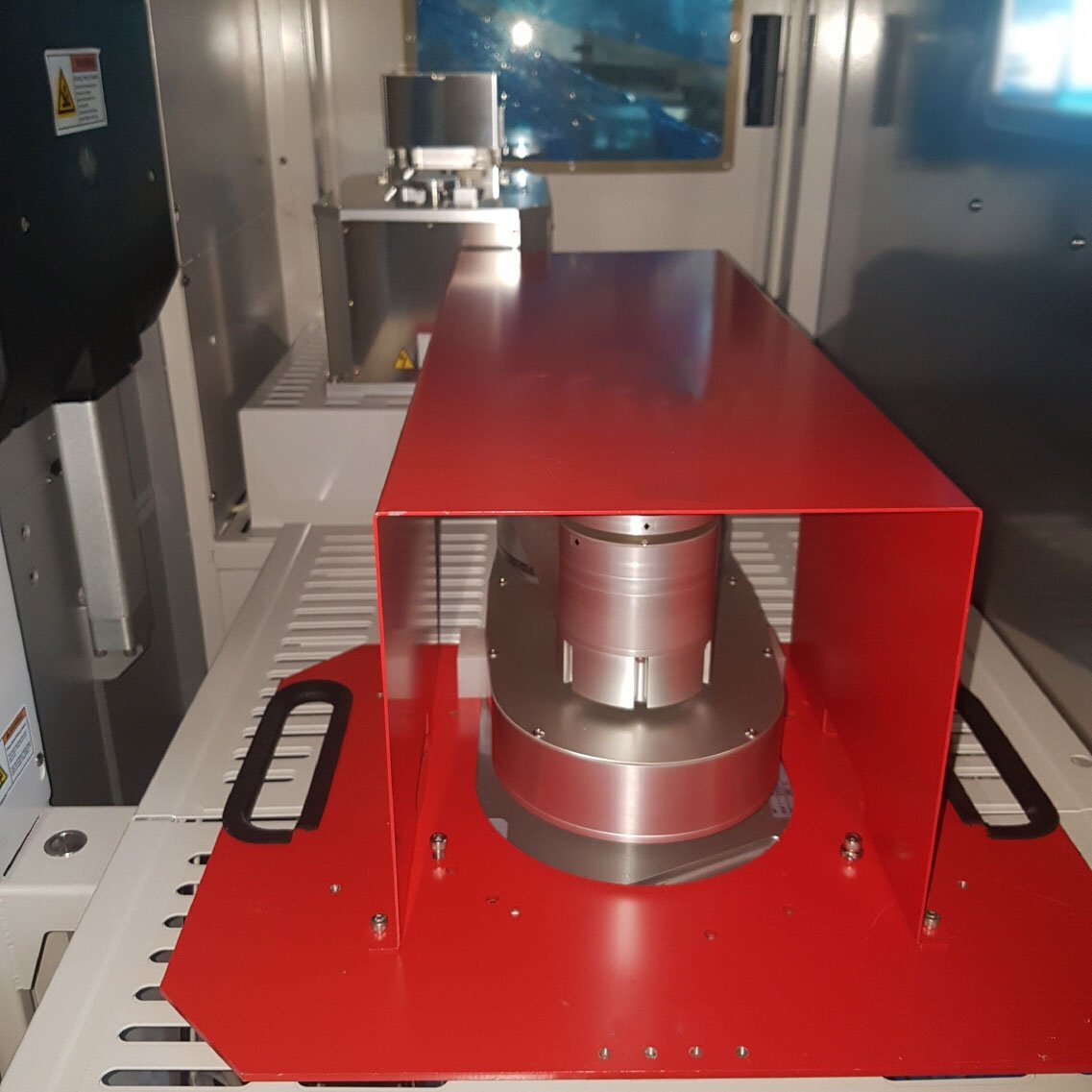

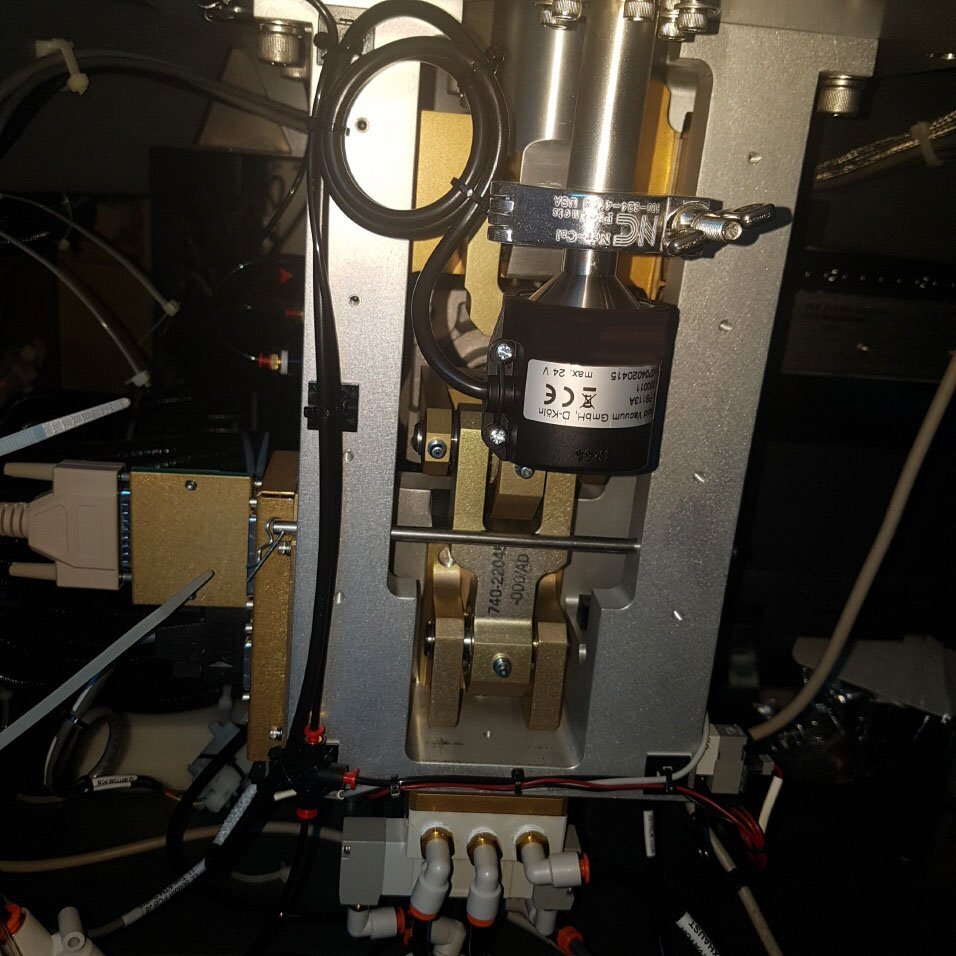

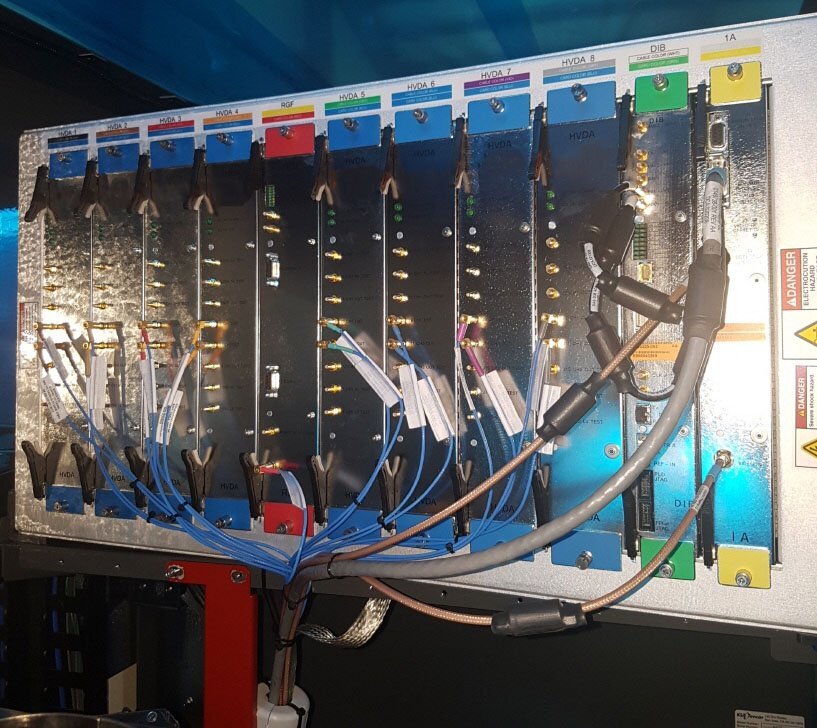

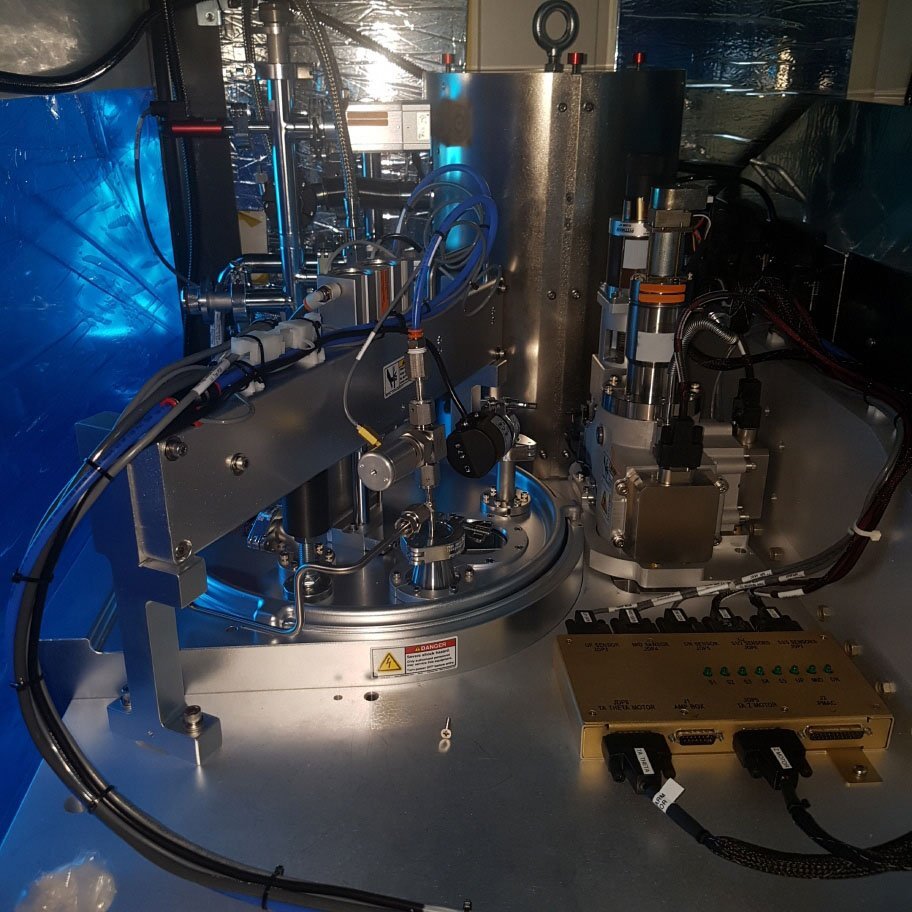

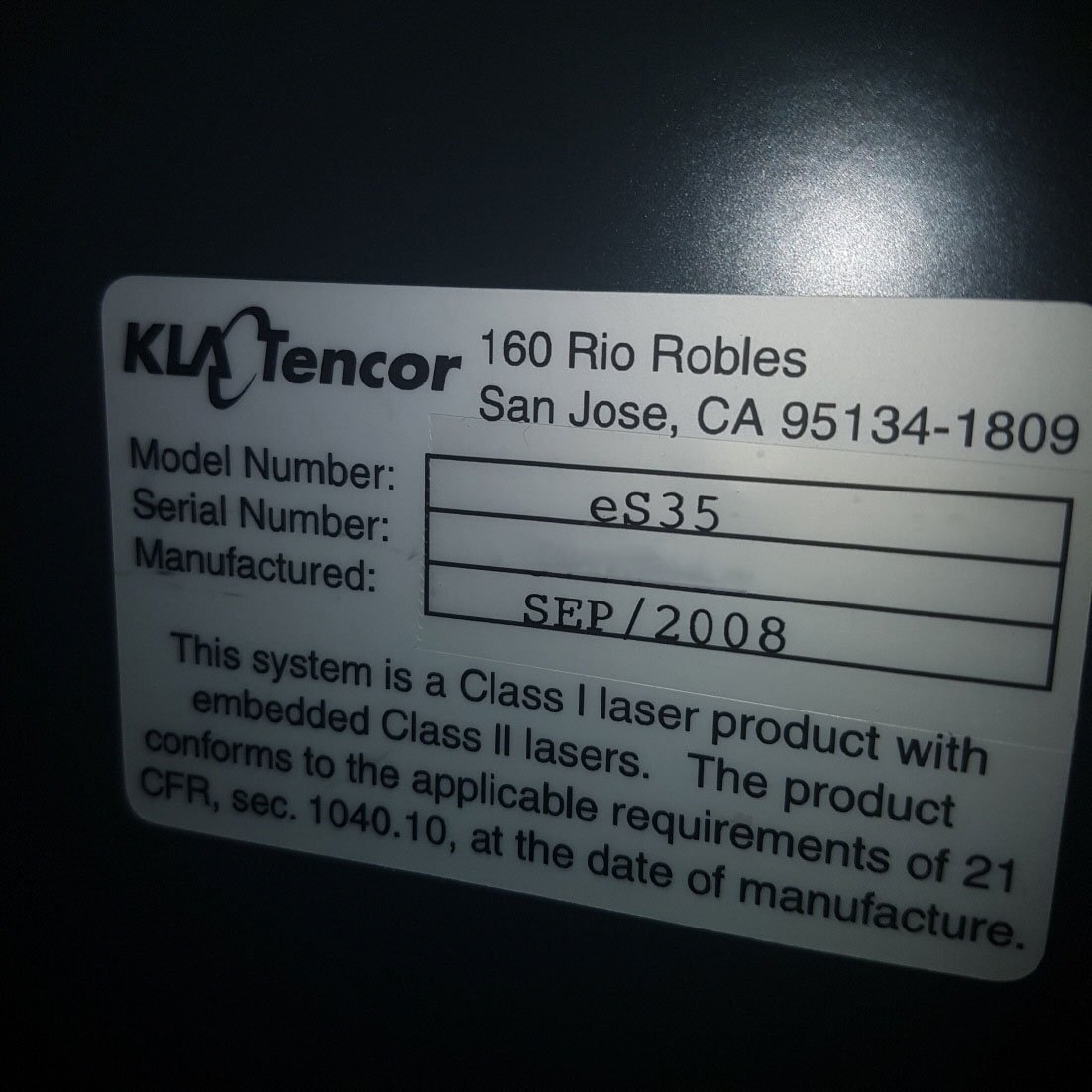

Used KLA / TENCOR eS35 #9366100 for sale

URL successfully copied!

Tap to zoom

ID: 9366100

Wafer Size: 12"

Vintage: 2008

E-Beam inspection systems, 12"

2008 vintage.

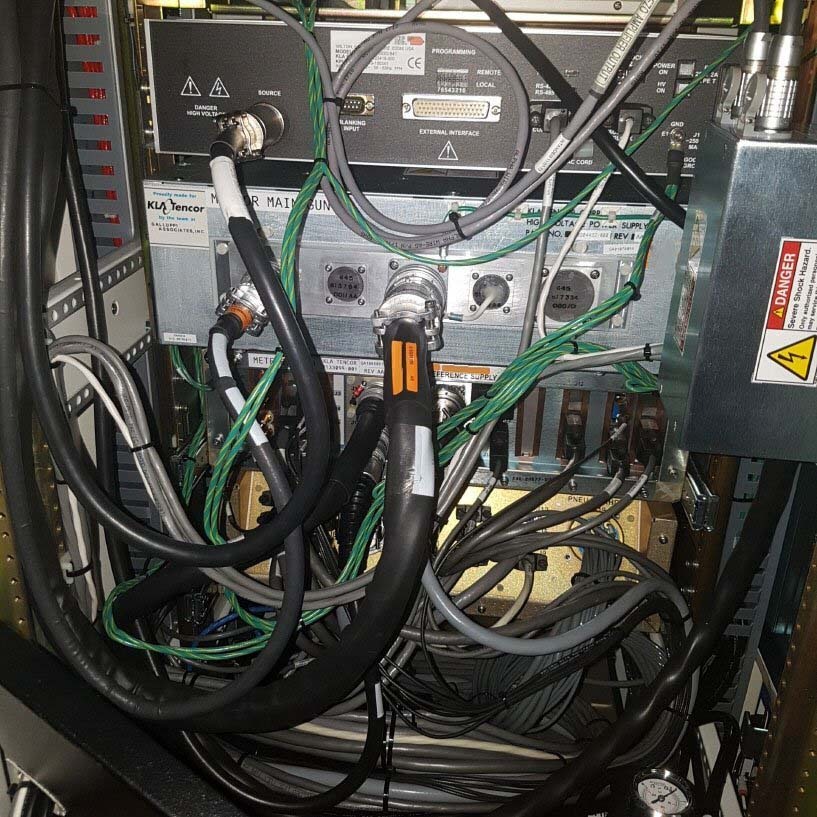

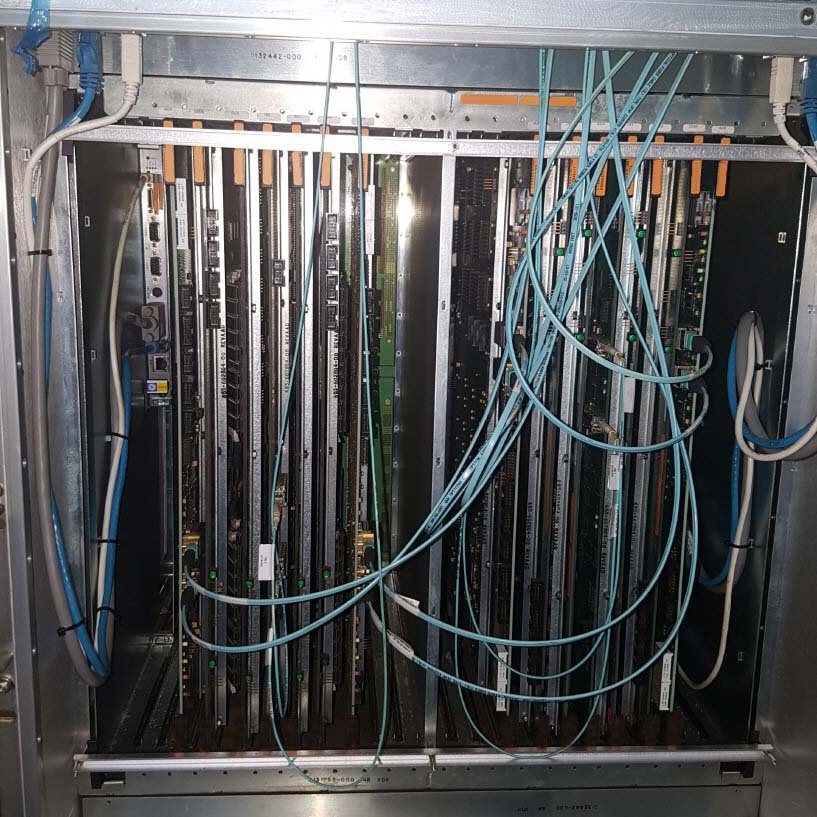

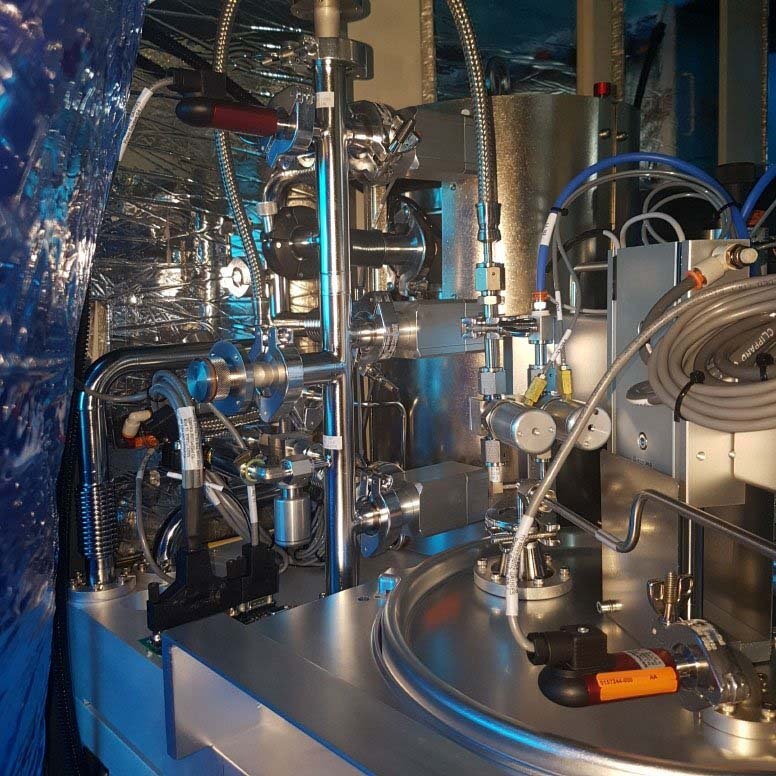

KLA / TENCOR eS35 is a high performance mask and wafer inspection equipment. It combines advanced optics systems, high speed image capture technology and proprietary software algorithms to provide highly robust 3D metrology for the semiconductor industry. Specifically, it is designed for use in high-volume production environments, helping to produce defect-free microchips with maximum yields. KLA eS35 utilizes laser-scanning technology and advanced image-based inspection to enable 3D critical dimension (CD) metrology and topography measurements. It is capable of measuring a wide range of materials, including advanced metals, organics and polymers. The system is controlled by proprietary software, which is backed by a large knowledge base of semiconductor related information. This knowledge base makes the unit easy for operators to understand and operate, and provides an intuitive interface that enables rapid analysis and control of the inspection process. Additionally, the software incorporates features such as automatic defect detection and classification, programmable tests, comprehensive on-screen defect reporting and a library of powerful statistical analysis tools. One of the primary benefits of TENCOR ES 35 is a significant reduction in fabrication defects. By detecting process-driven variations between wafers and masks, the machine is able to flag potential problems long before chips are mass-produced, which leads to more manufacturing uniformity and better overall chip yields. Furthermore, the tool can be customized to suit the needs of specific customers, enabling precision characterization of unique production processes. KLA / TENCOR ES 35 is also built to be user-friendly, as it is designed to integrate seamlessly into existing production facilities. Its modular architecture makes it particularly adept at handling complex high-speed production runs, while its asset-level diagnostics and user-friendly set-up wizards help to streamline many of the common tasks associated with producing wafers and masks. Overall, KLA ES 35 mask and wafer inspection model is an invaluable tool for semiconductor production, providing advanced 3D metrology, rapid defect detection, programmable tests and more. It offers superior precision and accuracy, as well as dramatically reduced risk of rejects during production runs. With the right configuration, this equipment can be configured to streamline the fabrication process, reduce costs and improve overall throughput.

There are no reviews yet