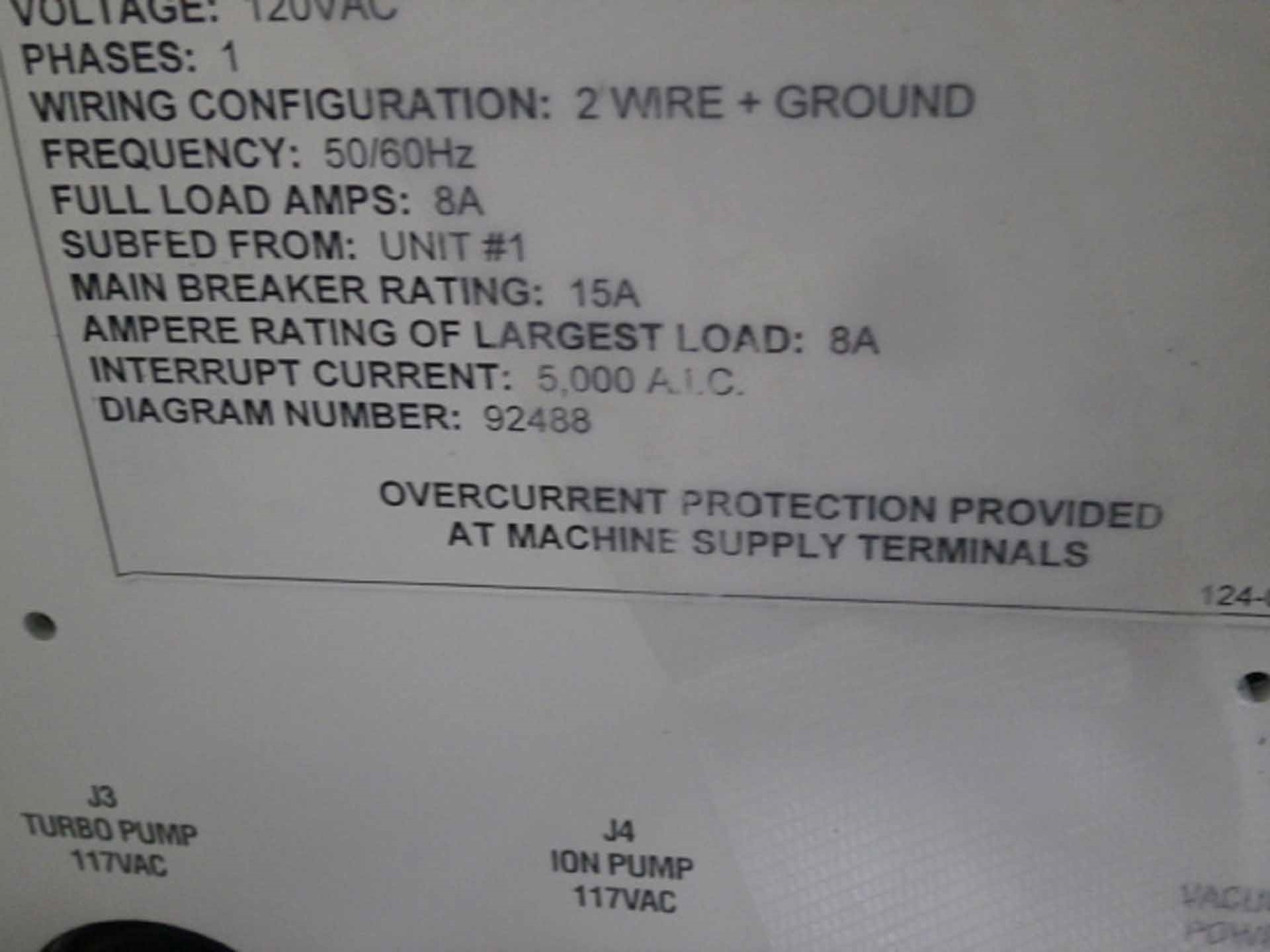

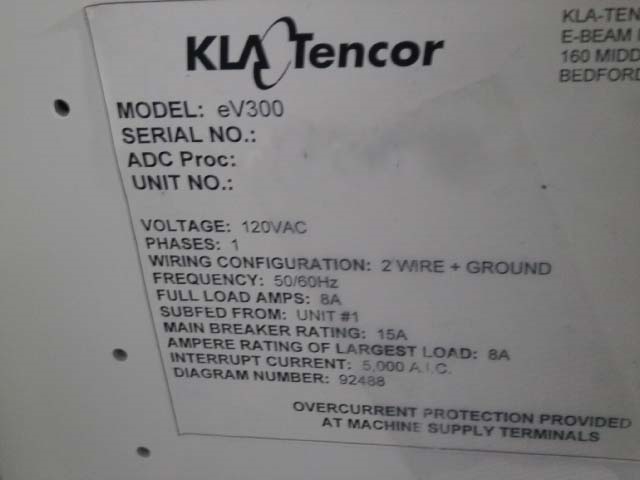

Used KLA / TENCOR EV300 #9191448 for sale

URL successfully copied!

Tap to zoom

ID: 9191448

Vintage: 2002

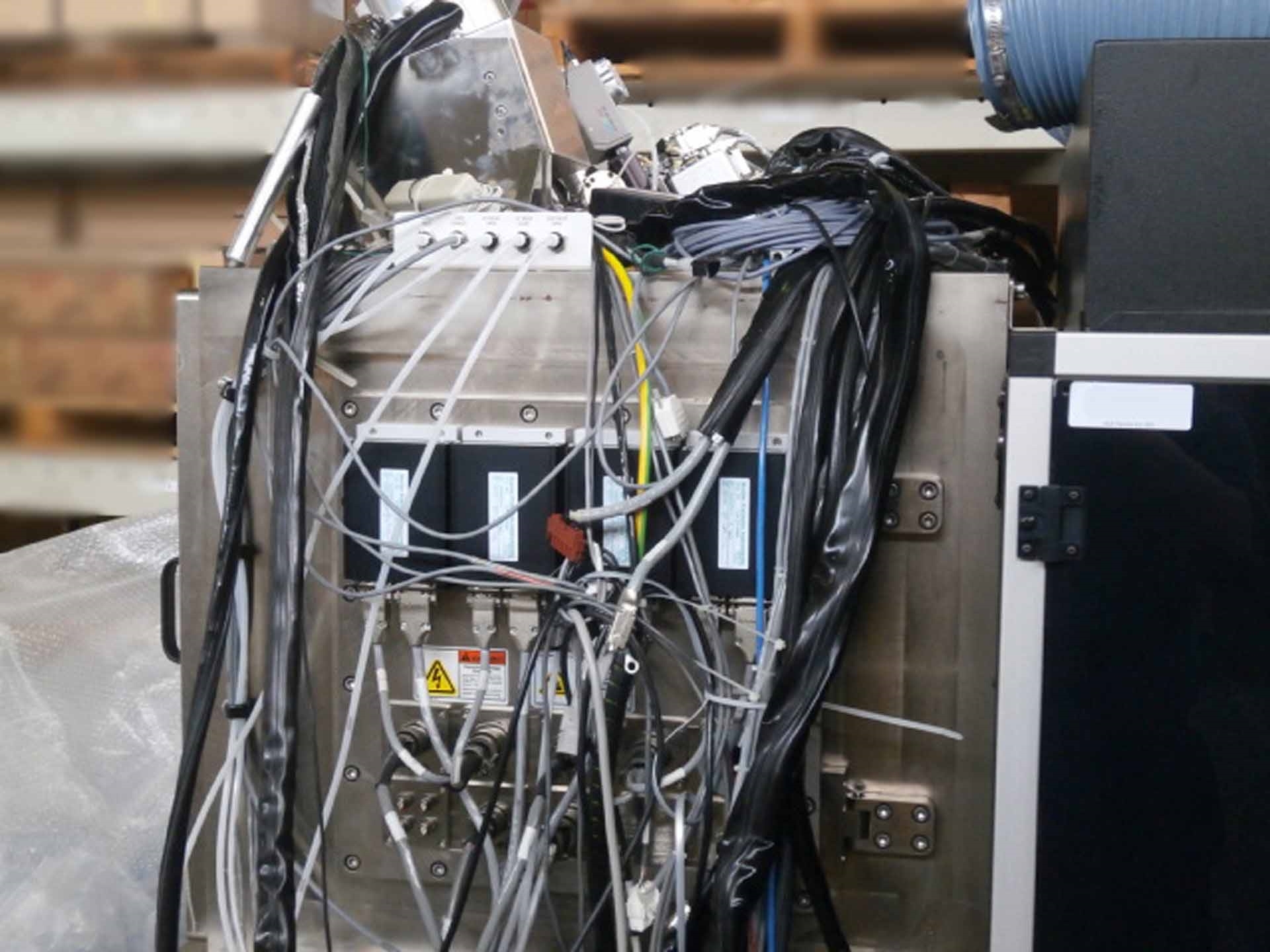

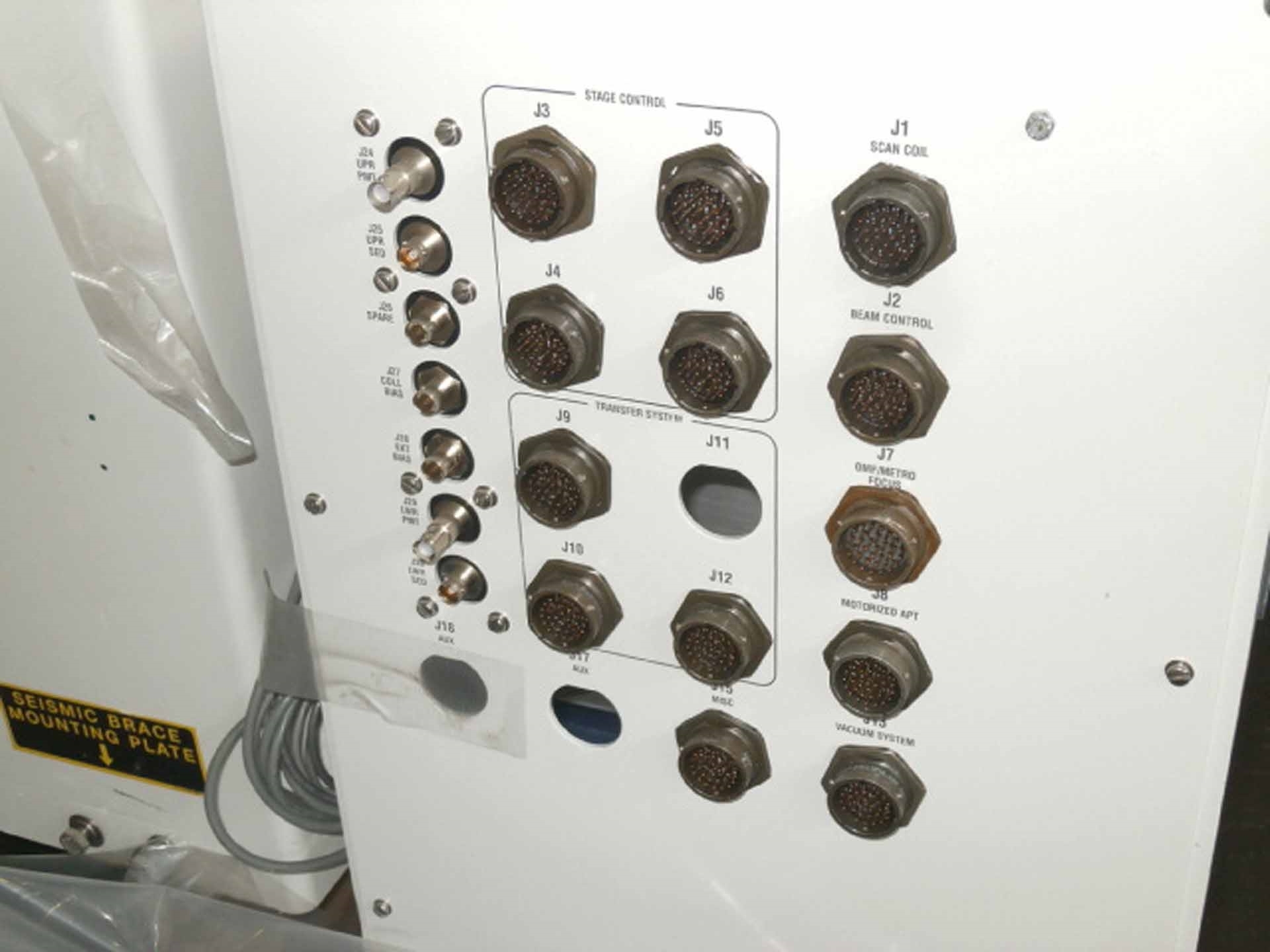

Defect review system

Open cassette

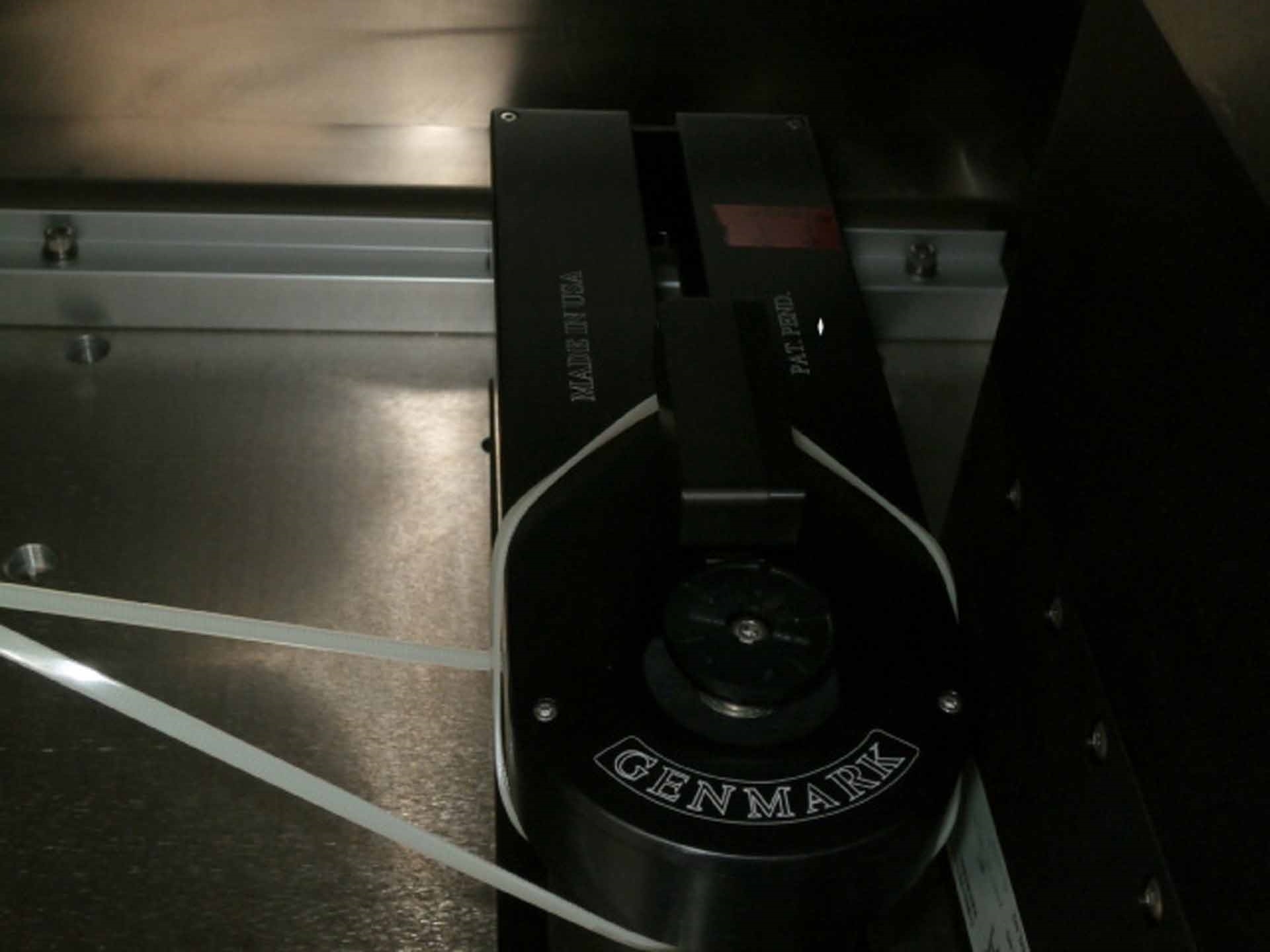

With GENMARK single end-effector robot

Cassette type: Dual open cassette, 8"

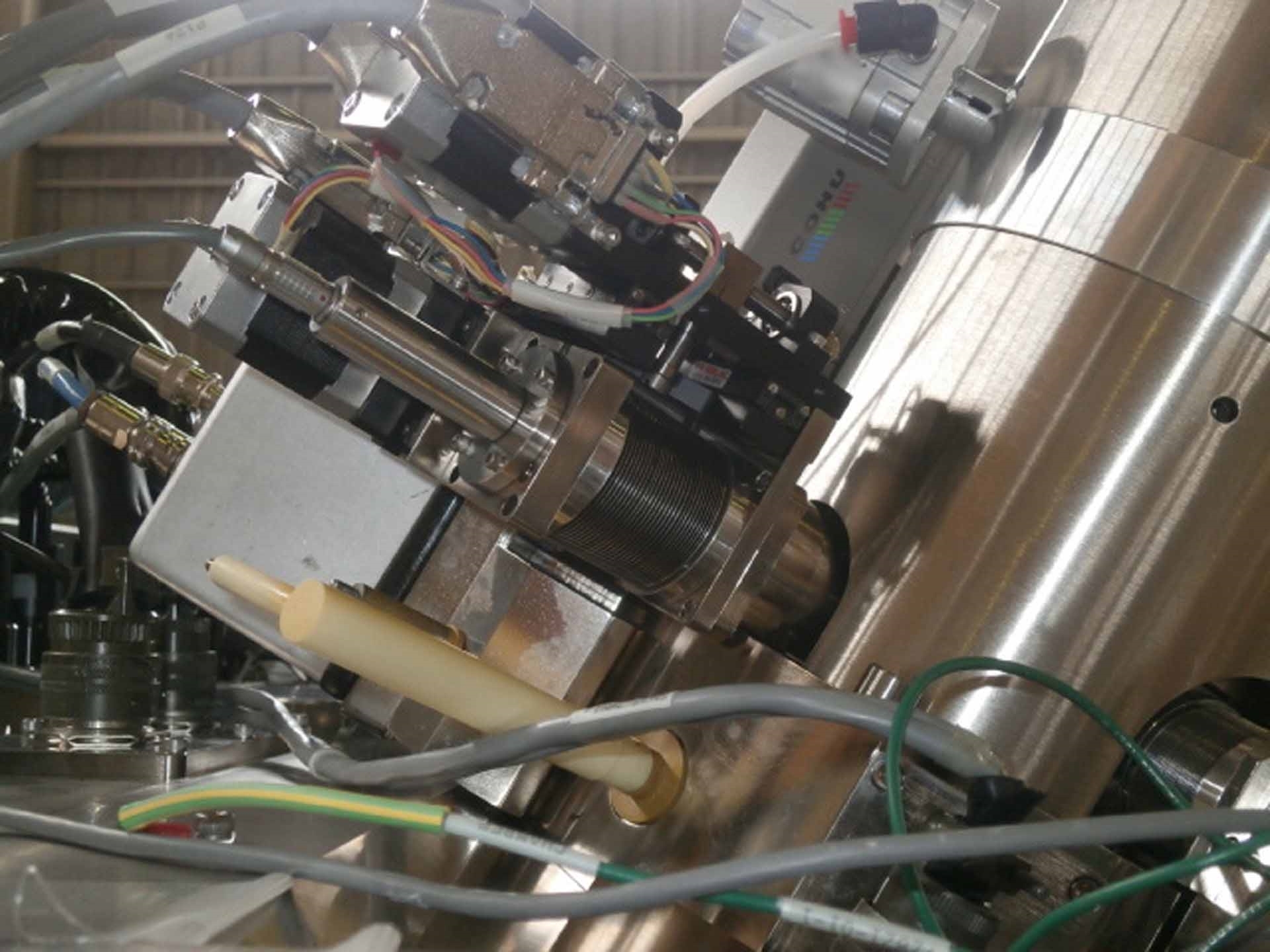

Camera: High & Low MAG

With EDX in box and line conditioner

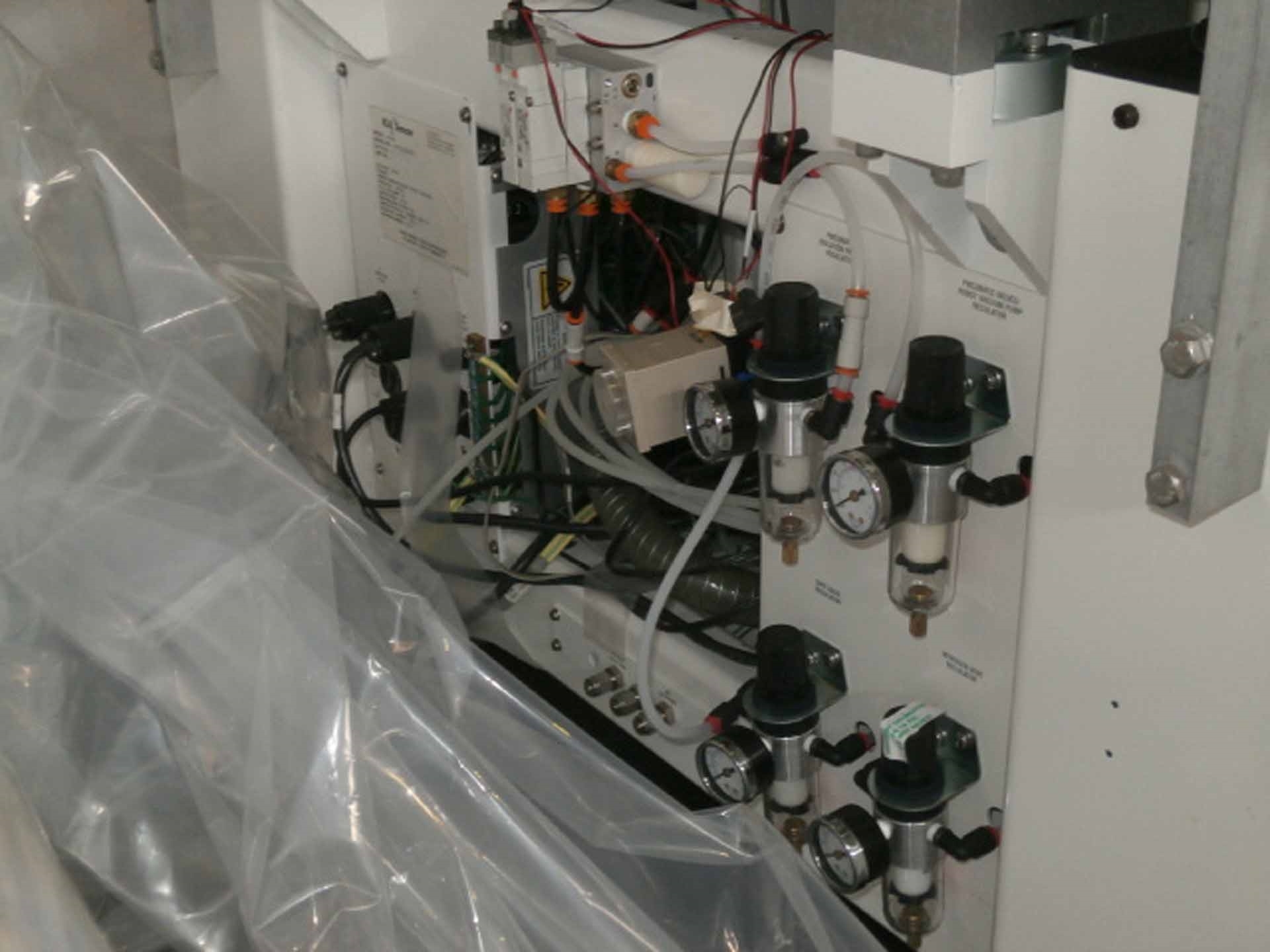

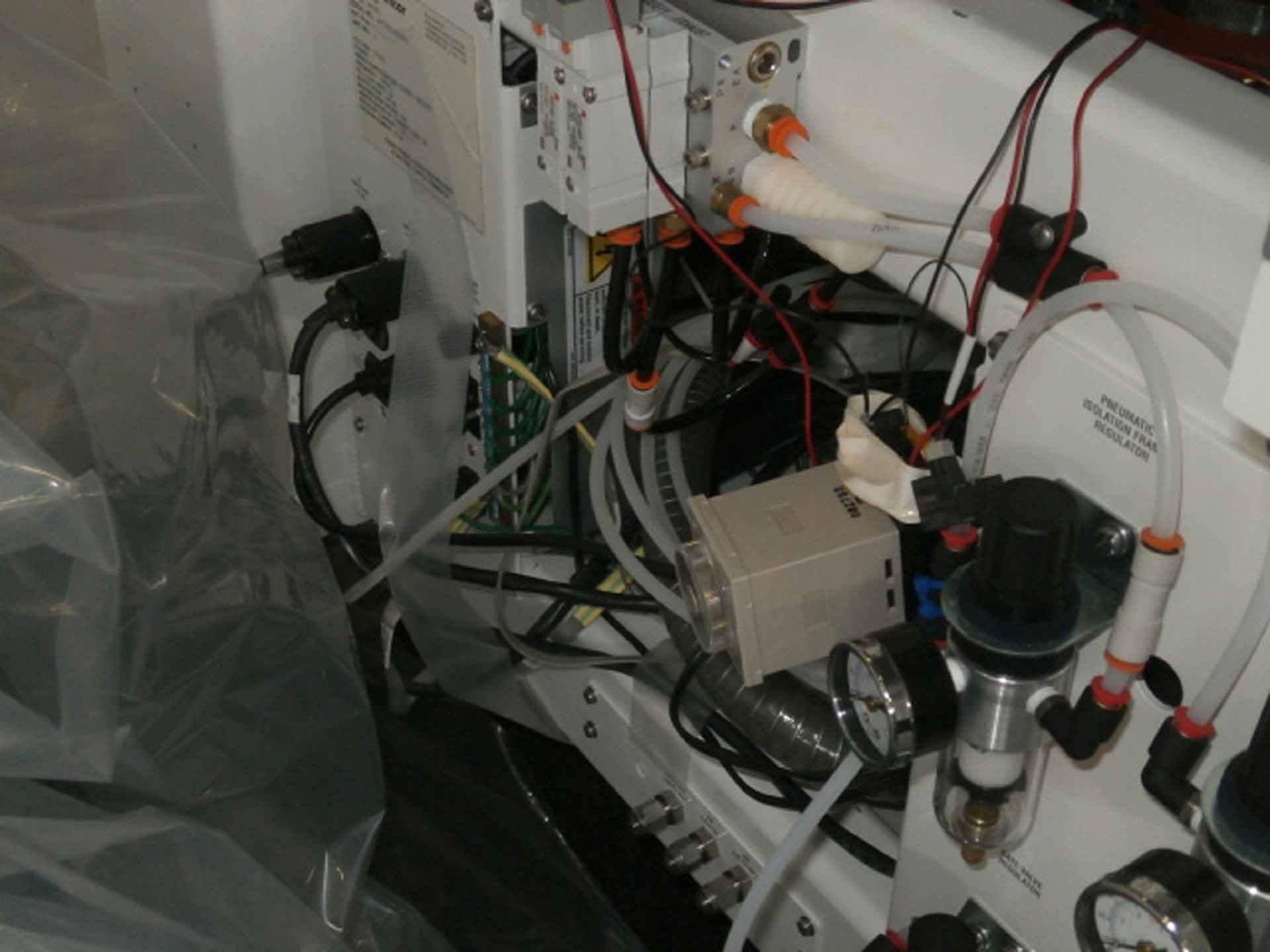

With Dry pump console powered box and vac-pump included

2002 vintage.

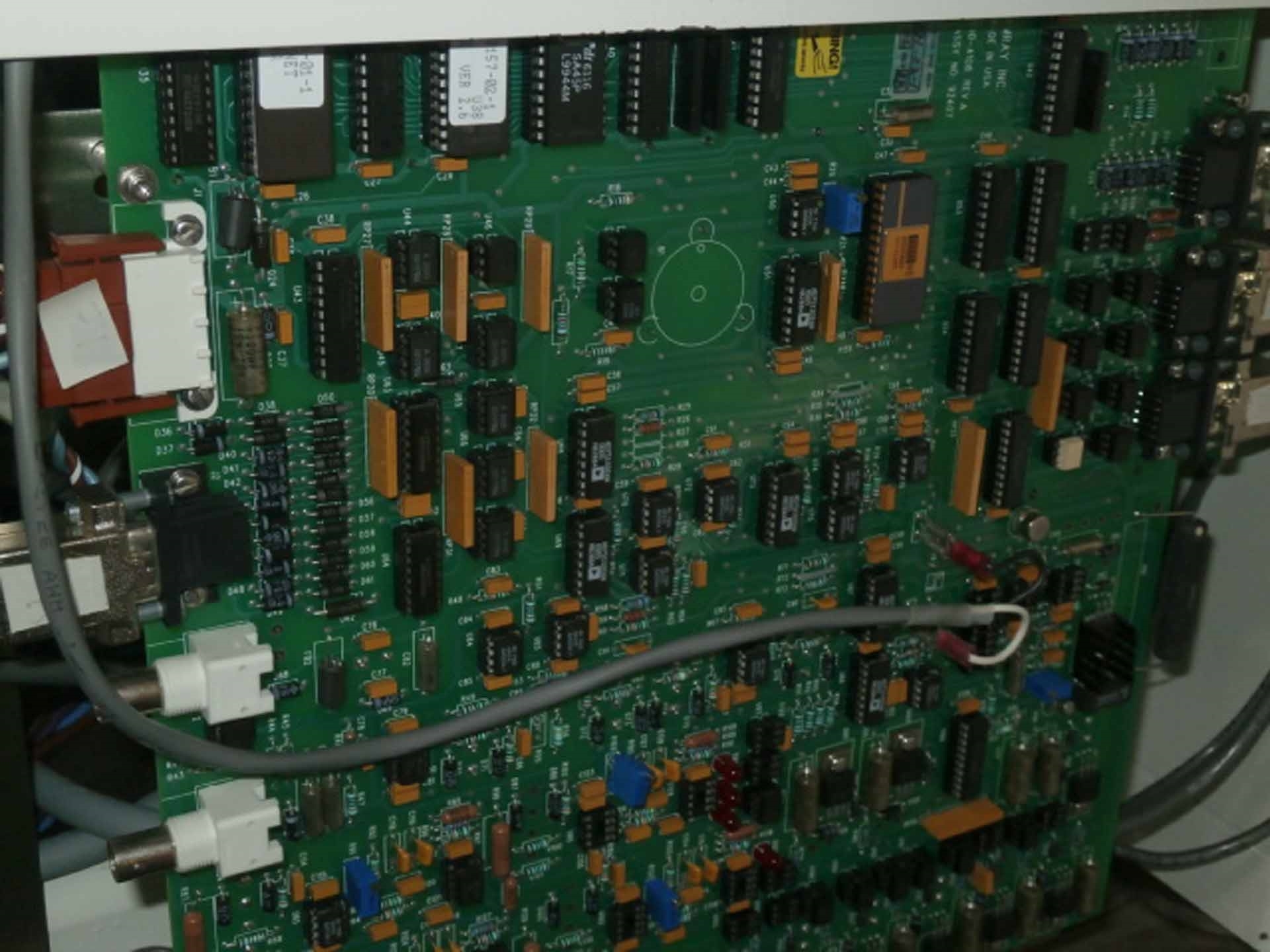

KLA / TENCOR EV300 is a mask and wafer inspection equipment which helps to ensure the highest quality of advanced semiconductor components. It offers superior performance when measuring, validating and verifying features on both the mask and the wafer production. KLA EV 300's scanning electron microscope (SEM) technology enables discovery and isolation of production defects on both mask and wafer layers. Its resolution capability is significantly greater than that of a traditional optical imaging system. This allows TENCOR EV-300 to inspect larger pattern sizes with improved measurement accuracy and faster throughput. In addition, KLA / TENCOR EV-300's proprietary FocSEM algorithms provide superior imaging resolution, making it easier to detect defects that could have gone undetected with conventional REI systems. KLA EV300 unit also enables simultaneous inspection of a variety of features on the mask and wafer including lines, edges, vias, contact pads, and wires. Additionally, it has a built-in validation algorithm that checks for both spacer and alignment-per-die. KLA / TENCOR EV 300 machine also includes KLA proprietary ScanType layout measurement solutions (STM) which allow for pixel-level accuracy of each pattern on the mask and wafer. In addition, EV-300's Renalogix inspection suite offers thorough inspection/failure analysis of critical defects, yield monitoring, and tool performance trending. TENCOR EV300 also includes an array of specialized tools. These specialized software packages provide additional analysis of mask and wafer patterns. TENCOR Defect Analysis Solution (DAS) module offers an easy-to-use solution to analyze, classify and filter defect data, providing detailed information on defects and their size, shape, location and orientation on the mask and wafer. KLA / TENCOR Alignment certification Suite (ACS) provides visualization tools to analyze alignment errors, as well as the ability to measure size, rotation and positional shifts from the initial design. EV 300 features the advanced software and hardware control systems needed for modern process control and quality assurance. It includes a robust combination of control features, such as automated stage calibration, wafer size detection, wafer selectivity, pattern detection, forward/reverse/reflection pattern stitching, automated defect analysis and reporting, as well as advanced inspection algorithms and software. All these features make TENCOR EV 300 a powerful and effective mask and wafer inspection asset. EV300 is both highly automated and easy to use, so it can be integrated into existing production processes quickly. It can also keep up with new process challenges as a result of its highly configurable feature set. With this model, users can be sure that their products meet the most stringent quality standards.

There are no reviews yet