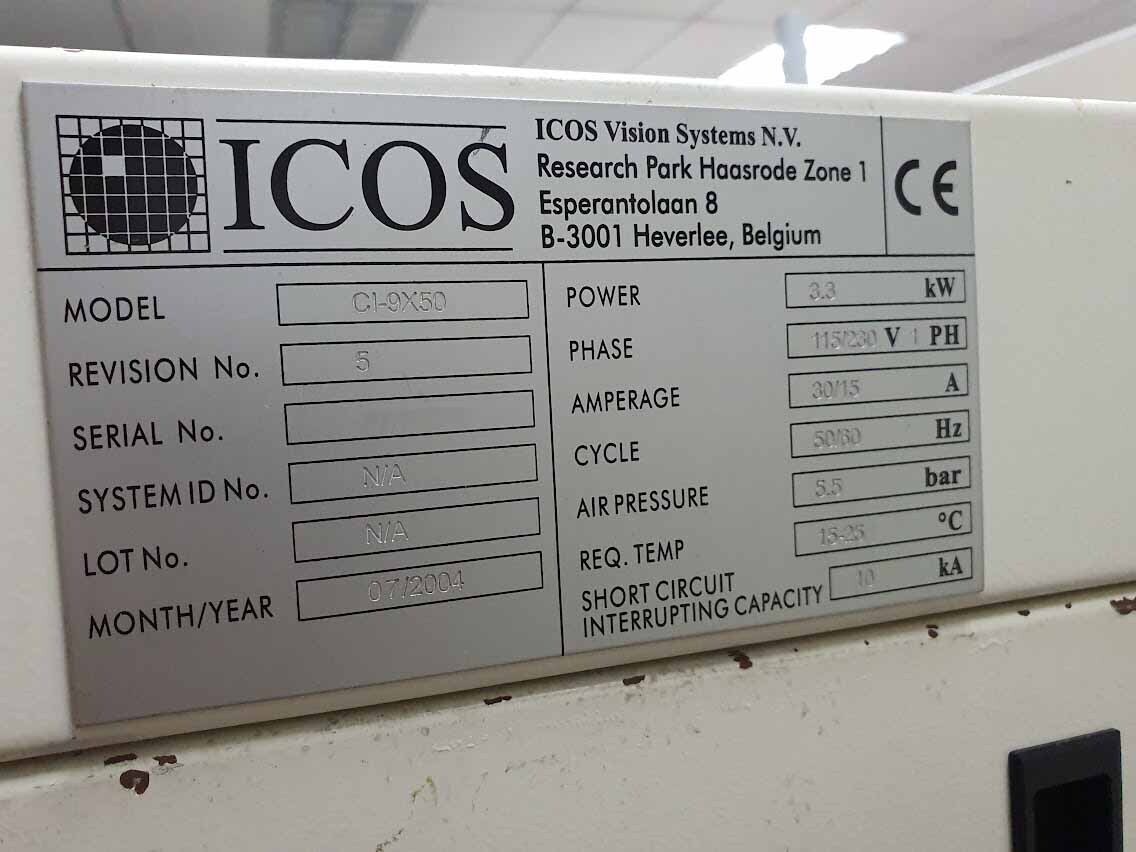

Used KLA / TENCOR / ICOS CI 9450 #293614776 for sale

URL successfully copied!

Tap to zoom

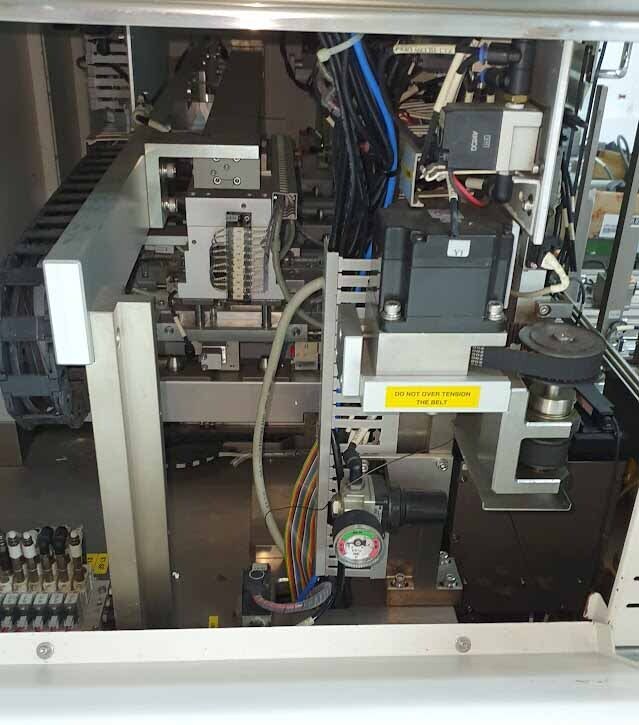

KLA / TENCOR / ICOS CI 9450 Mask & Wafer Inspection Equipment is an advanced, high-precision, automated system designed for inspecting masks, reticles and wafers used in semiconductor technology. It combines several technologies—including optical inspection, image analysis and automated defect evaluation—to ensure that every inspected mask or wafer meets the highest quality standards. The integrated optical unit of KLA CI 9450 includes high-magnification objectives, low-magnification objectives and zoom lenses that can be selectively deployed to provide the best image resolution and accuracy. An interferometric stage helps to maintain high levels of accuracy and repeatability over time. The machine can also be equipped with multiple illuminators, including a broadband LED light source and ring LED illuminators that help to ensure optimal image quality and contrast for defect resolution. Image analysis is based on custom tools and algorithms that are designed to optimize mask and wafer inspection, as well as support classification of different types of defects. Automated defect evaluation is handled by two types of defocus systems: an integrated high-precision defocus tool and a hybrid digital/analog defocus asset. Both systems offer superior performance, ensuring accurate and repeatable defect classification. The model also offers several other features, including an automated calibration function that ensures maximum reliability and accuracy over time, a user-friendly and intuitive graphical user interface, and convenient task automation. Additionally, ICOS CI-9450 offers easy integration with existing production and inspection systems, providing streamlined operations, improved cycle times and maximum efficiency. In summary, TENCOR CI 9450 is a highly advanced mask and wafer inspection equipment that helps to ensure the highest quality and reliability standards in the semiconductor industry. With its state-of-the-art optical capabilities, image analysis functions and automated defect evaluation, it is able to ensure that wafers and masks meet the highest levels of performance and reliability.

There are no reviews yet