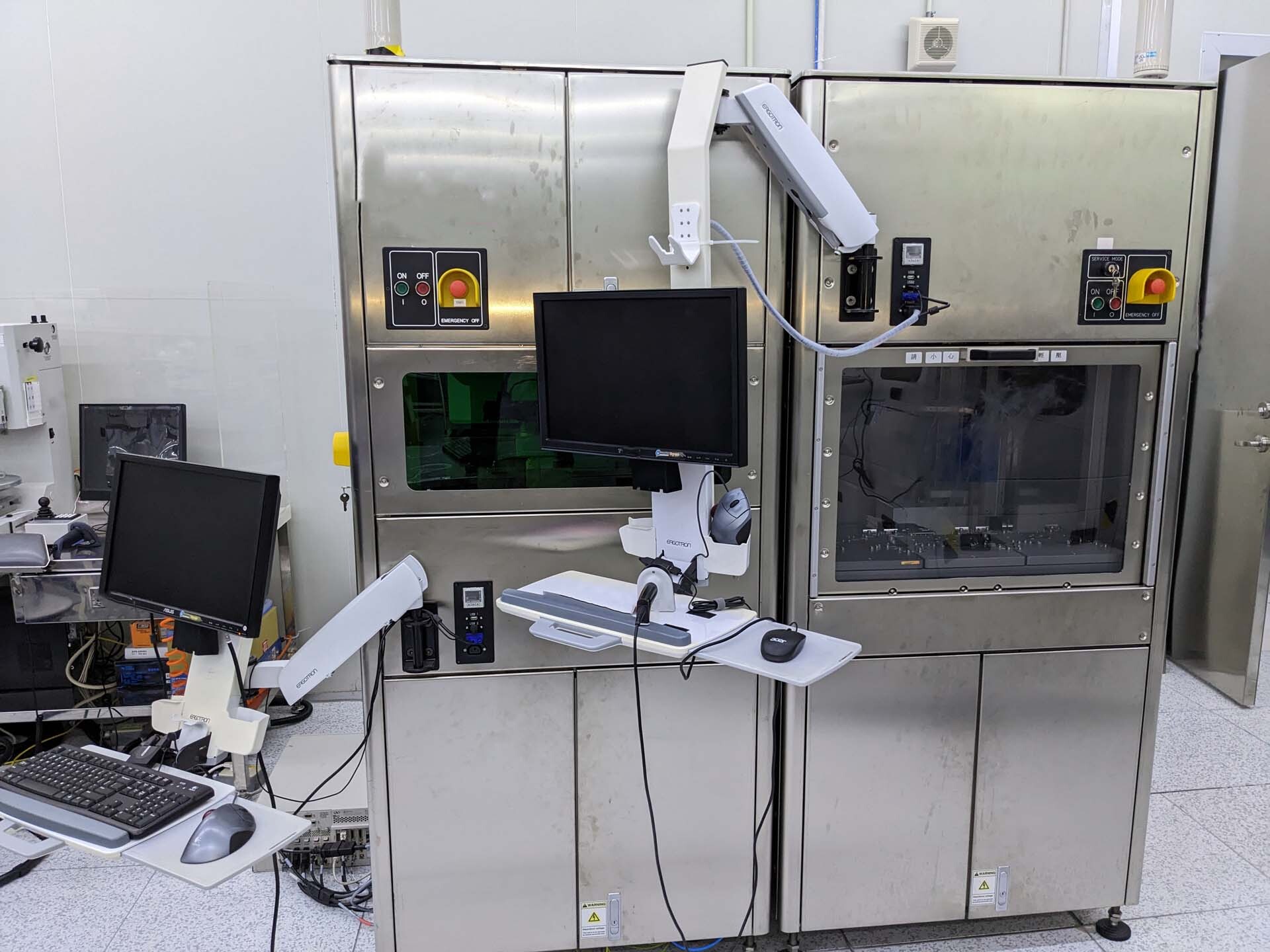

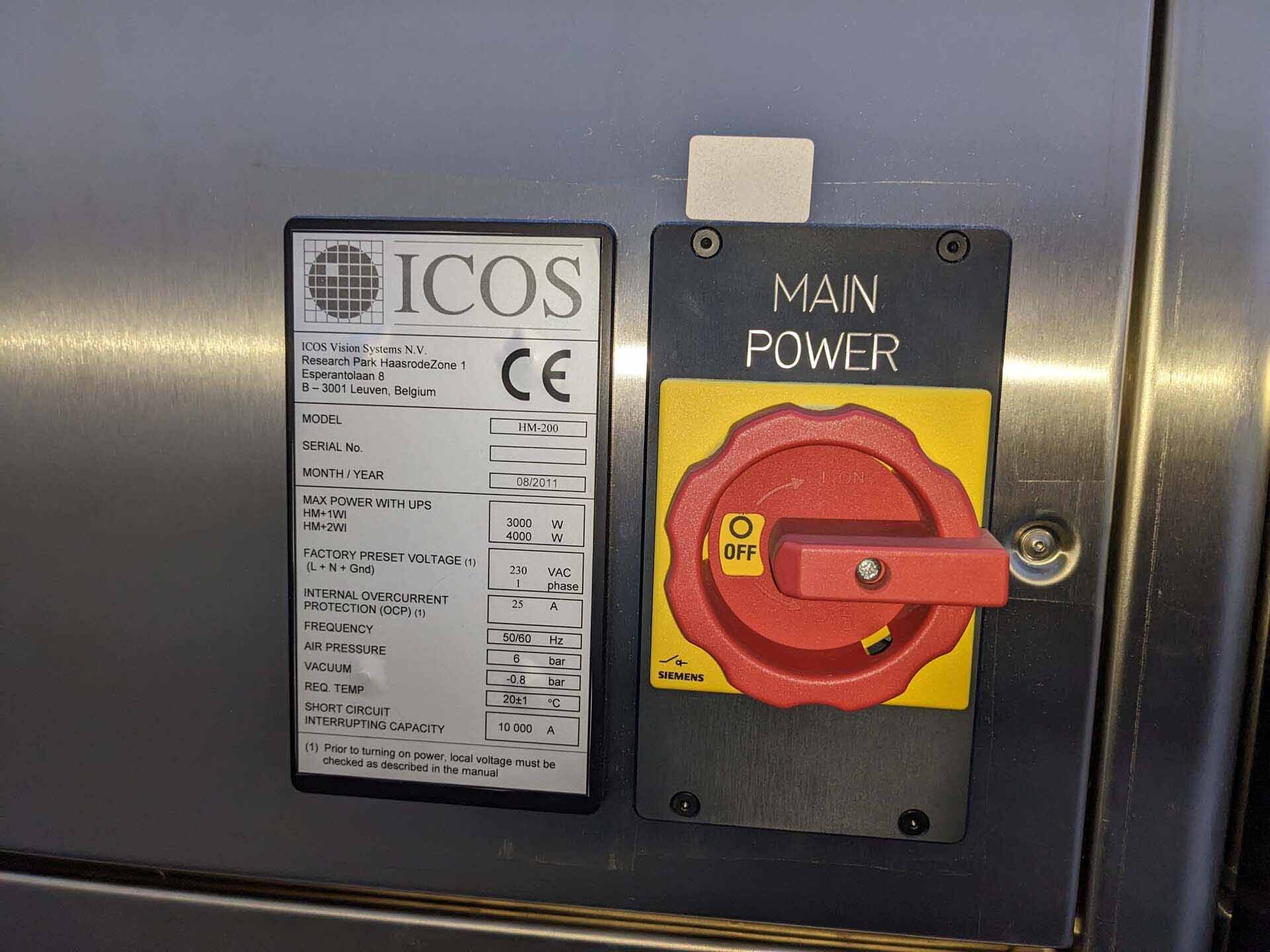

Used KLA / TENCOR / ICOS WI-2250 #293650418 for sale

URL successfully copied!

Tap to zoom

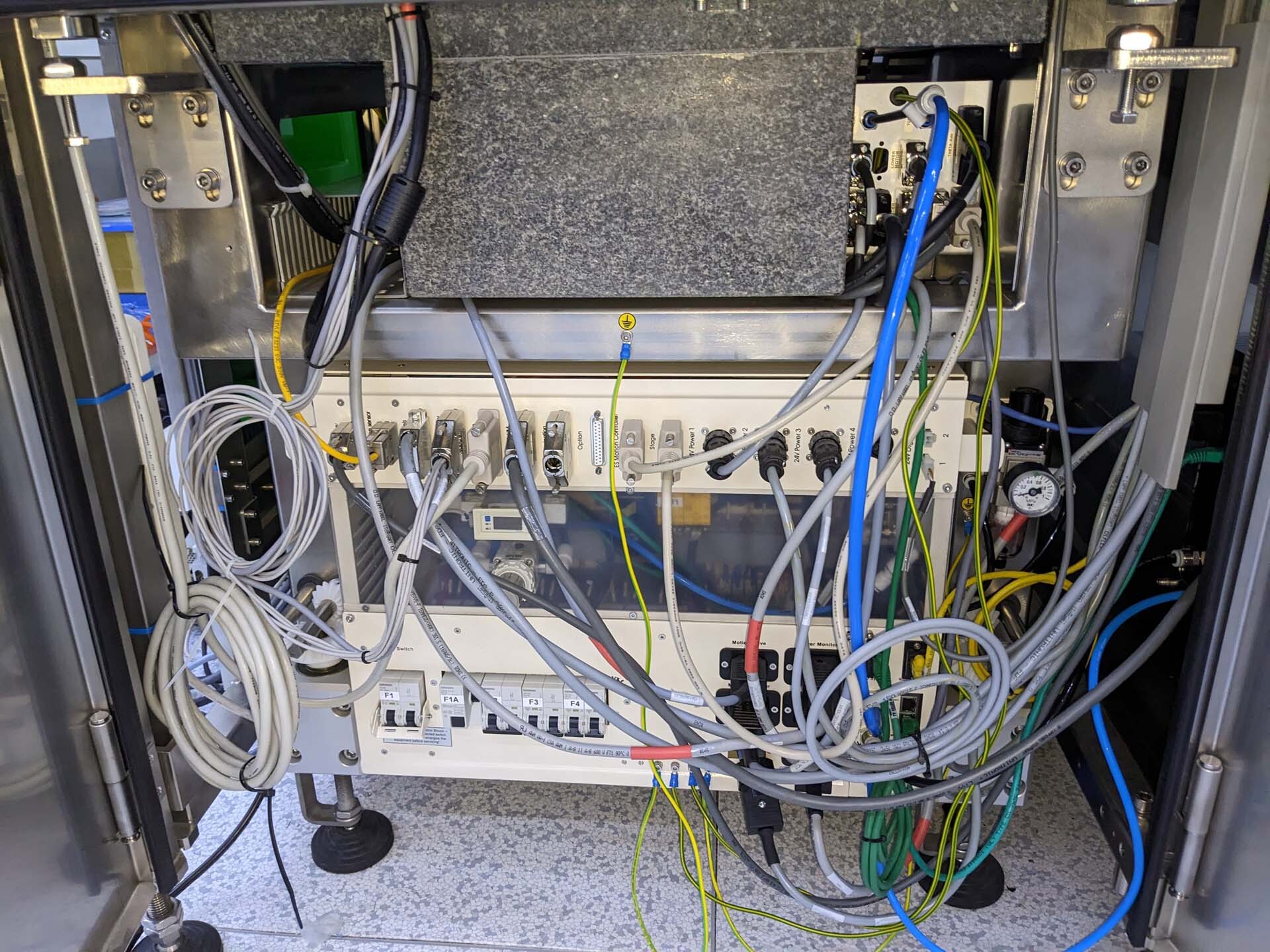

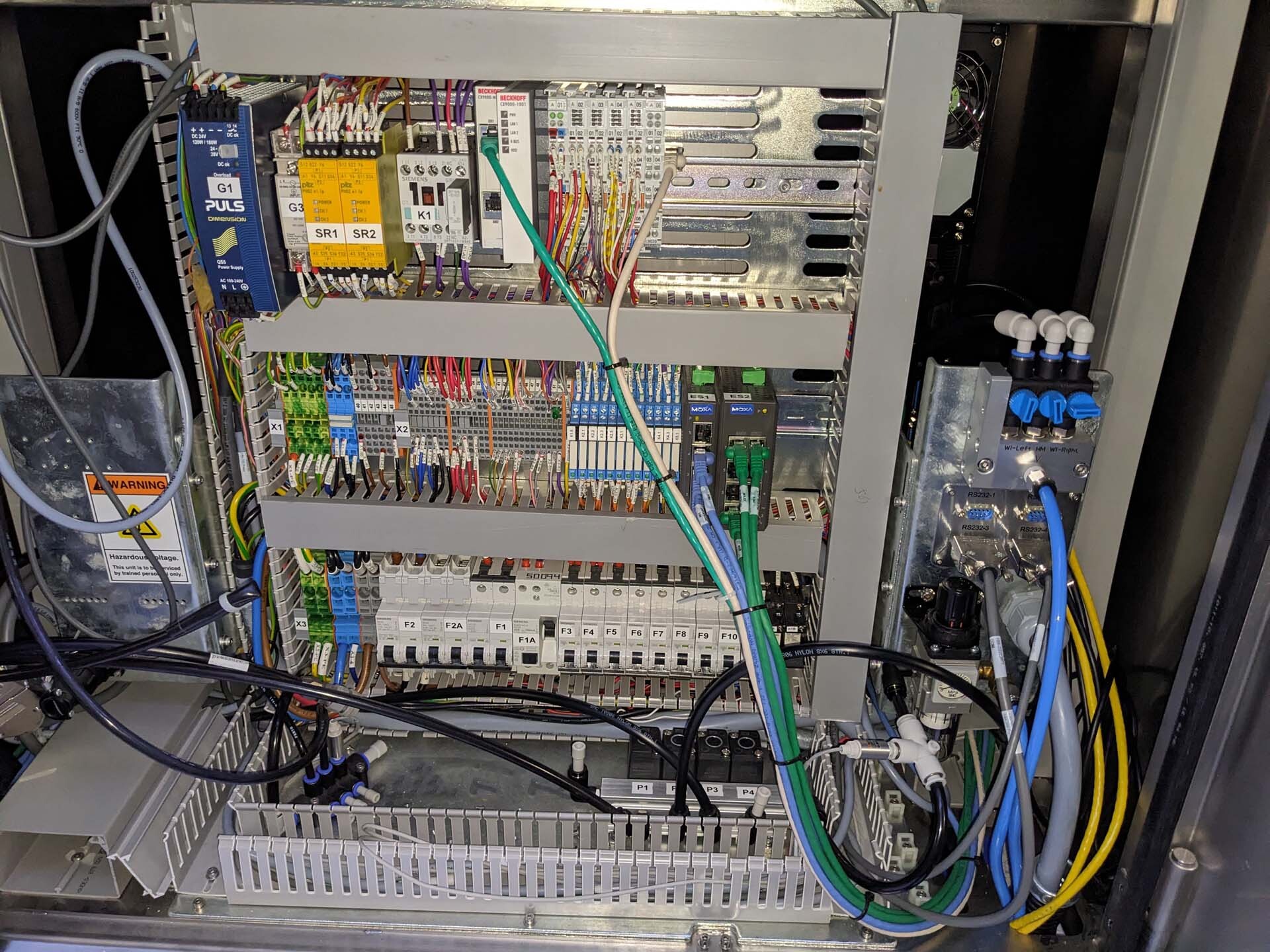

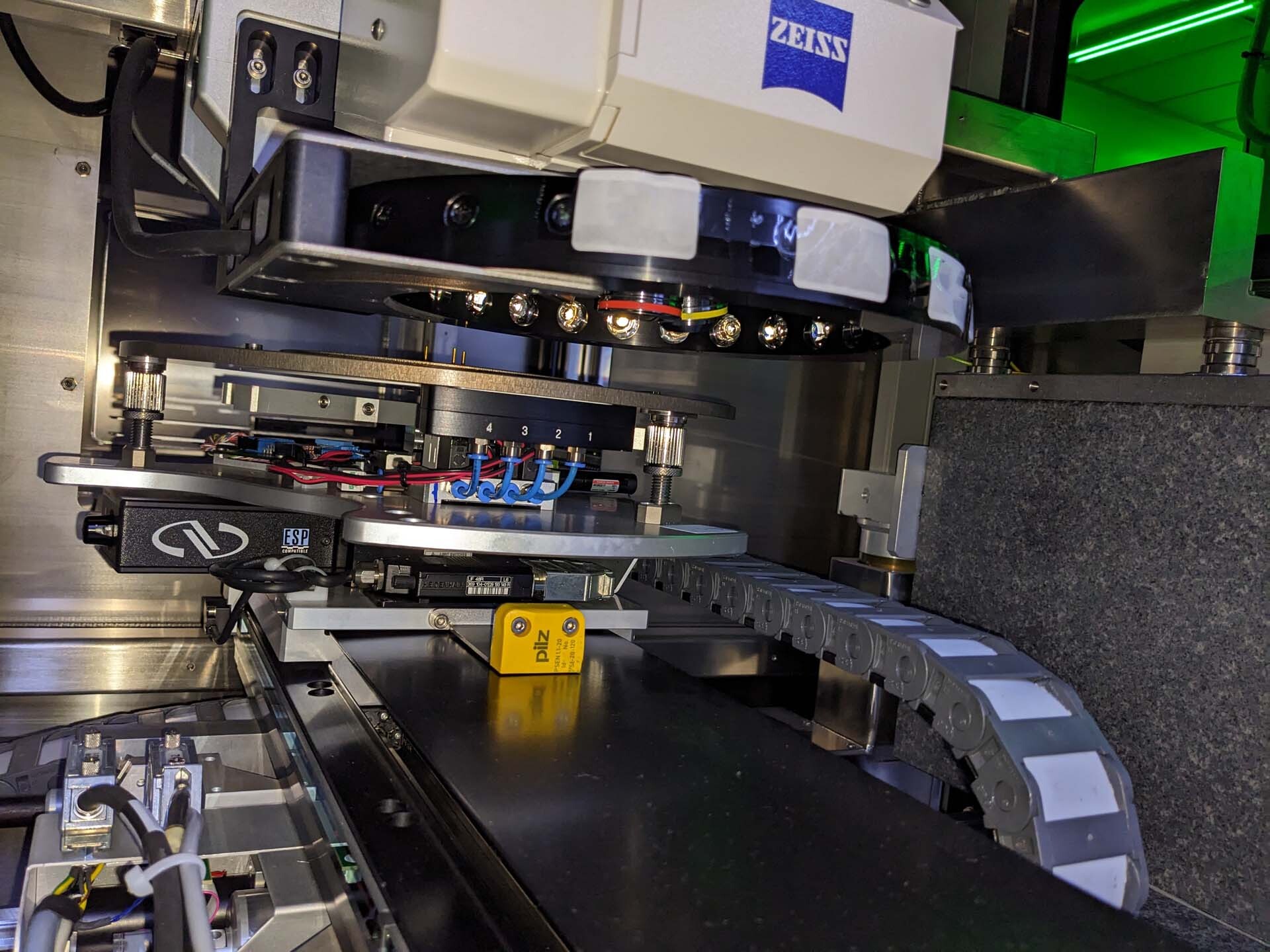

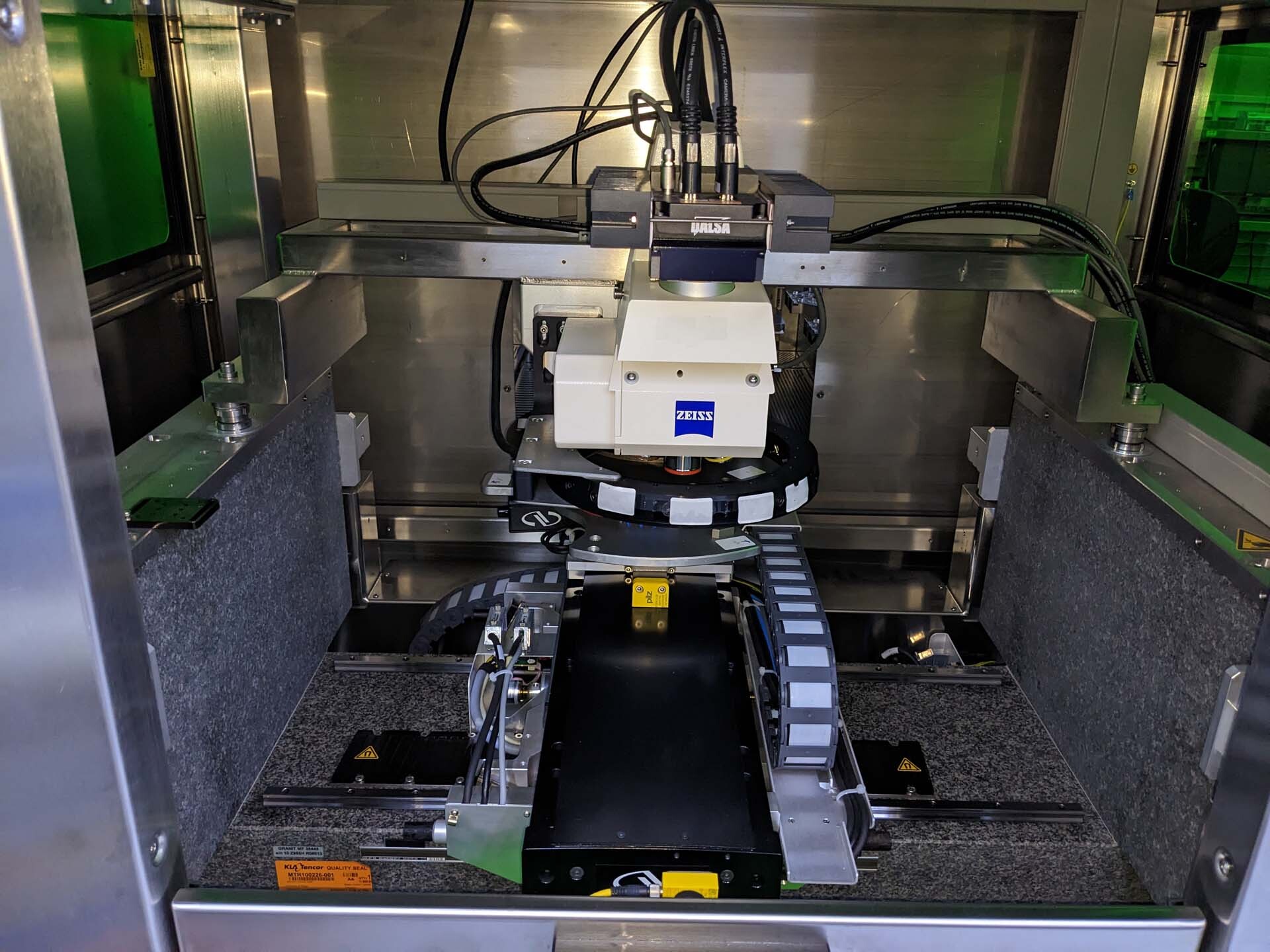

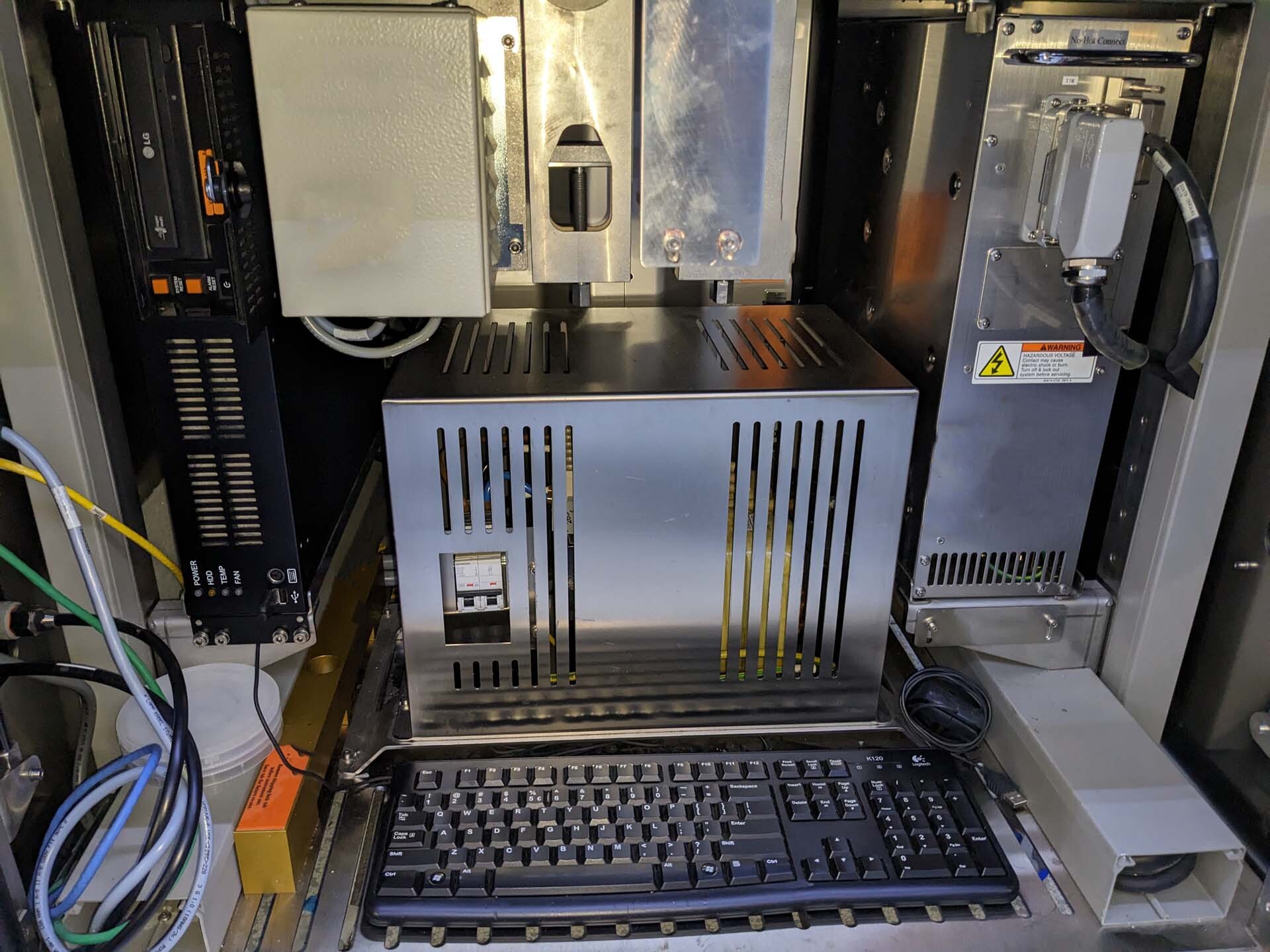

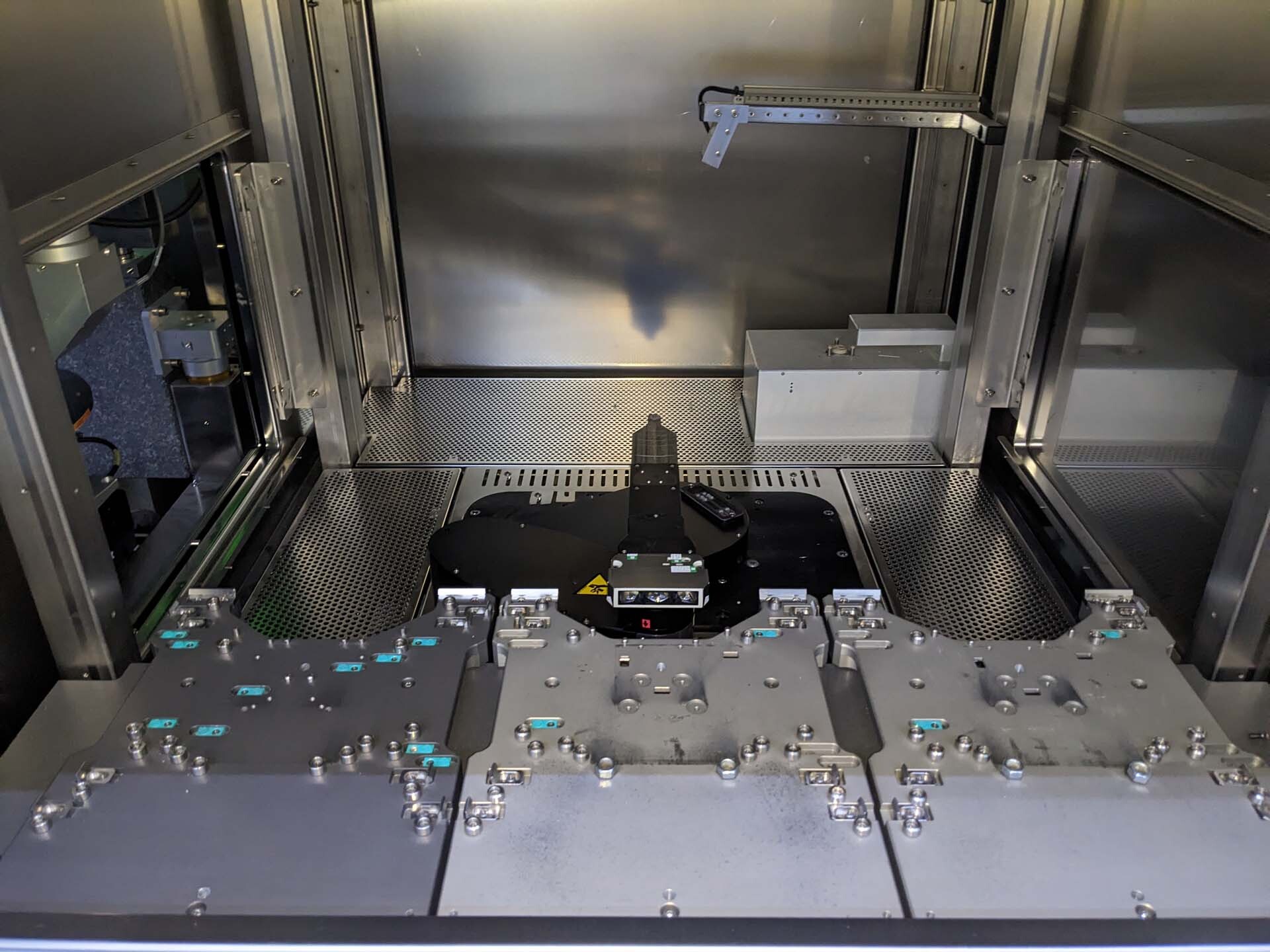

KLA / TENCOR / ICOS WI-2250 Mask & Wafer Inspection equipment is a precision imaging system used in applications such as micro-electronics and data storage. It provides a high-resolution image of the surface of substrates with a field of view up to 400 mm. It enables detailed inspection of both mask and wafer surface features due to its sophisticated technology such as pattern recognition, automatic sectioning and advanced algorithms. KLA WI-2250's key features include 8-inch imaging area, 4-inch viewing area and high-resolution zoom capability of up to 16x. Its imaging speed and time to first image can be customized based on the specific application. The unit features high-definition resolution for multi-dimensional wafer inspection as well as for mask inspection. The integrated Image Enhancement Tools provide excellent image sharpness and contrast, along with a range of image display options. ICOS WI-2250 also offers advanced imaging algorithms that allow the user to pinpoint even the slightest flaws or defects on both mask and wafer surfaces. It is compatible with standard masks used in masking applications, and compatible wafer materials include Silicon, Semiconductor, Photomask and Quartz. The Mask & Wafer Inspection machine is equipped with a vacuum chamber with electronic suction control and programmable auto shut-off. This ensures proper sealed contact and held in place without damage to the mask or wafer. The vacuum also helps to transfer heat and pressure along the surface which helps reduce the wear and tear on the mask or wafer surface. In addition, WI-2250 features a P and DR detection tool that helps in maximizing the resolution for detecting small defects. The PDR asset allows users to monitor any particle movement on the surface. The model also has the ability to detect contaminated surfaces. Overall, TENCOR WI-2250 from KLA is a high-performance mask and wafer inspection equipment that provides excellent image resolution and various image processing tools. Its integrated imaging technology, precise alignment between images and mask, and direct vacuum pressure all contribute to a precise and reliable inspection. Its advanced imaging and detection algorithms also ensure that even the most minute defects or flaws are quickly detected and resolved.

There are no reviews yet