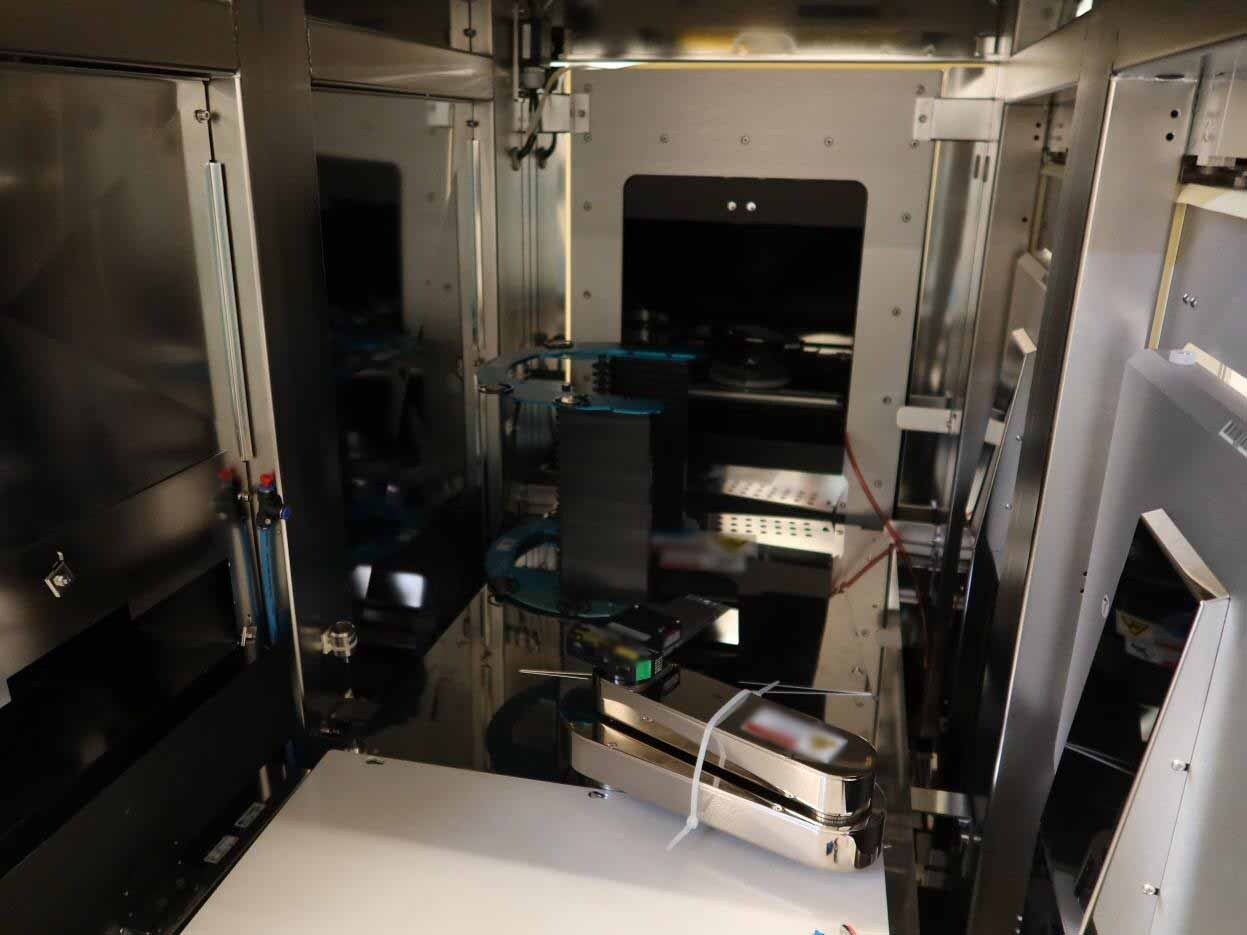

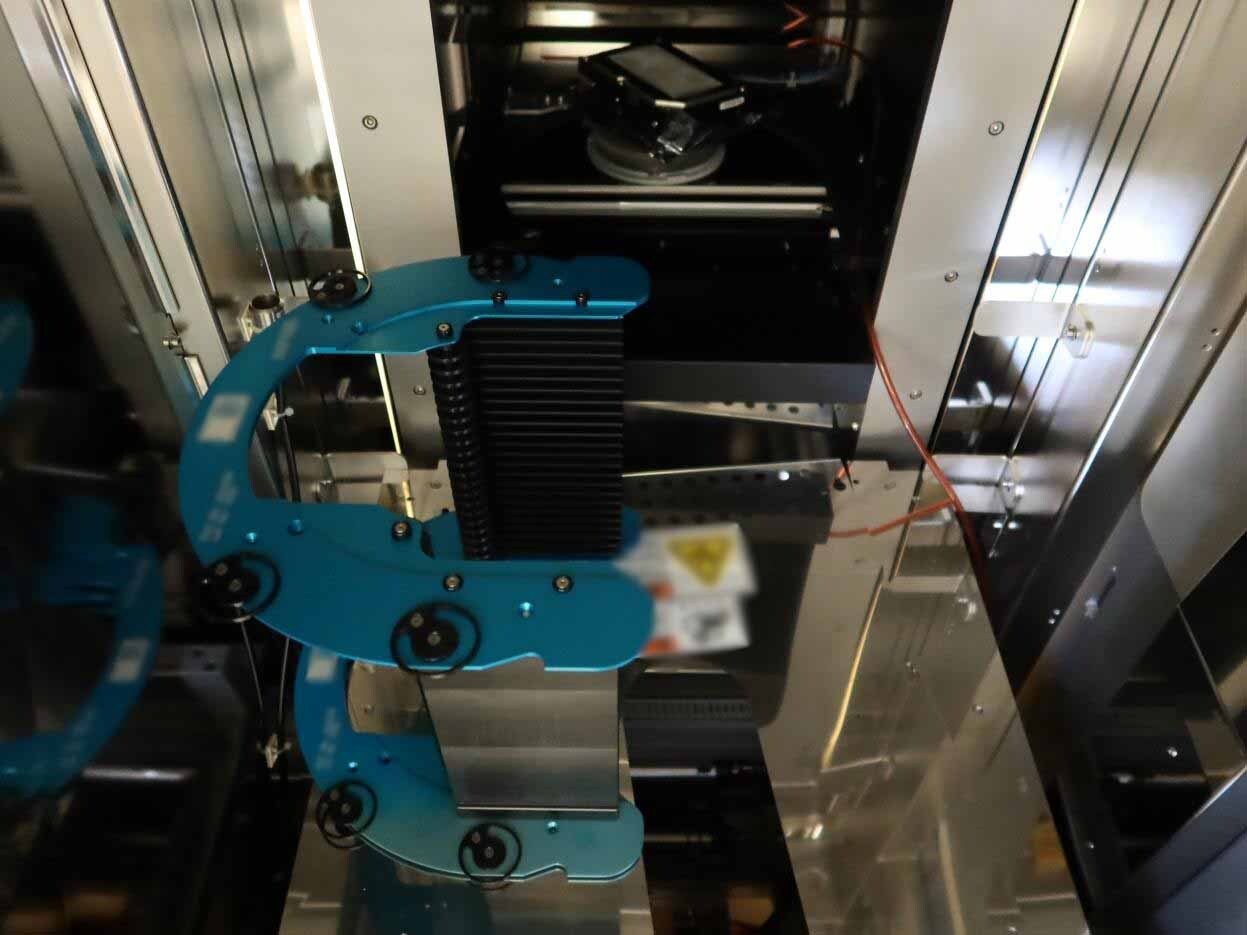

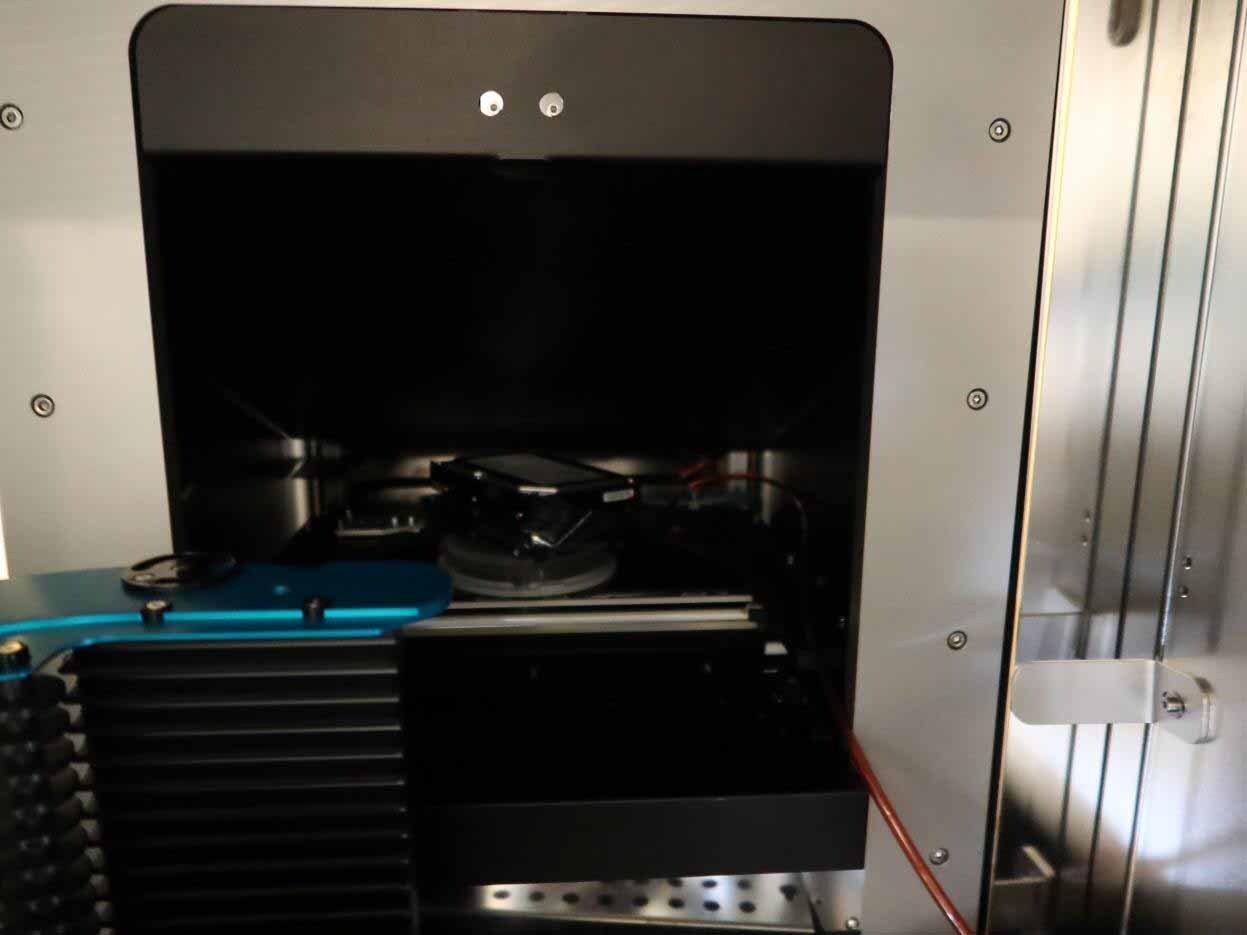

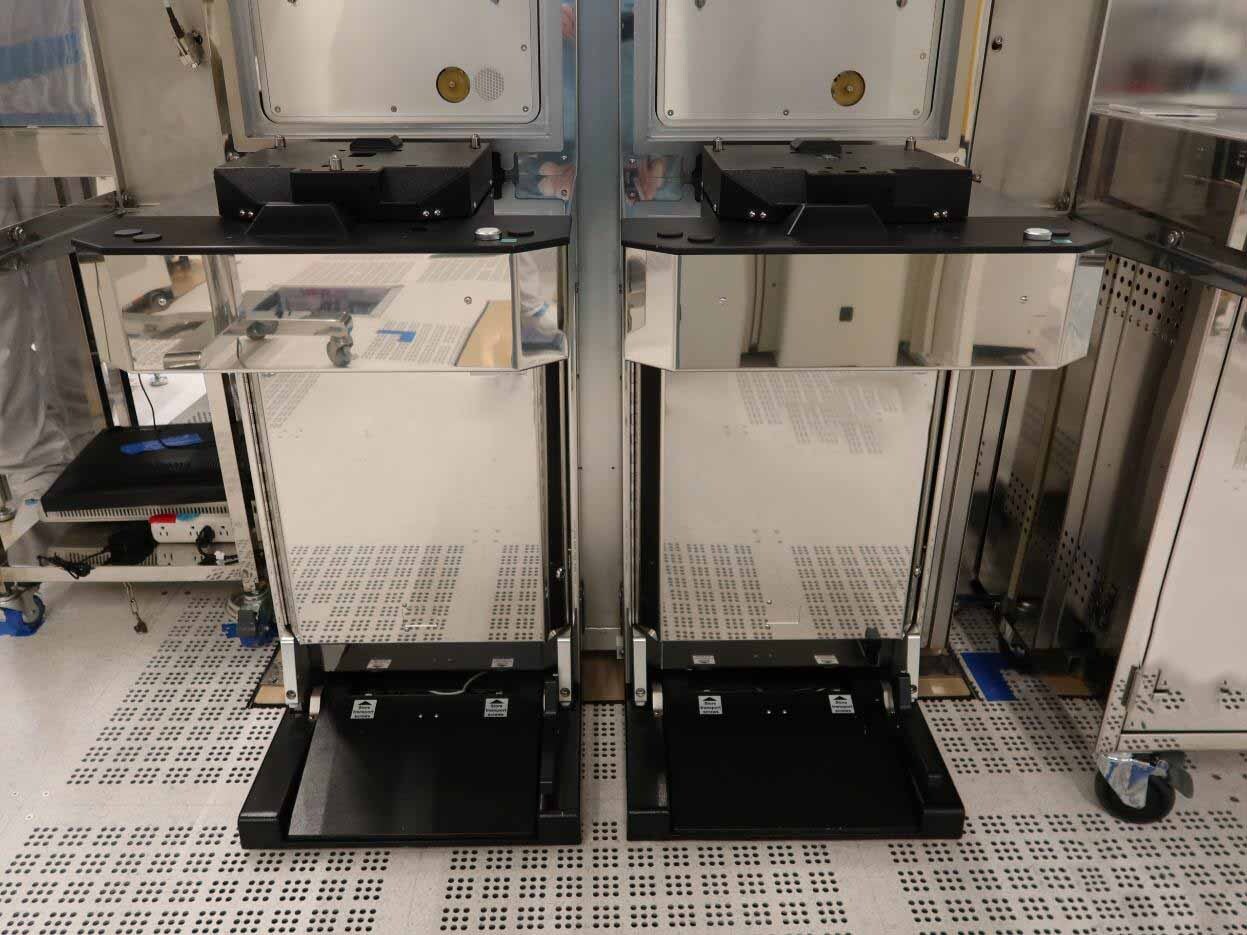

Used KLA / TENCOR / LEICA / VISTEC LDS 3300M #9127882 for sale

URL successfully copied!

Tap to zoom

ID: 9127882

Wafer Size: 8"-12"

Vintage: 2007

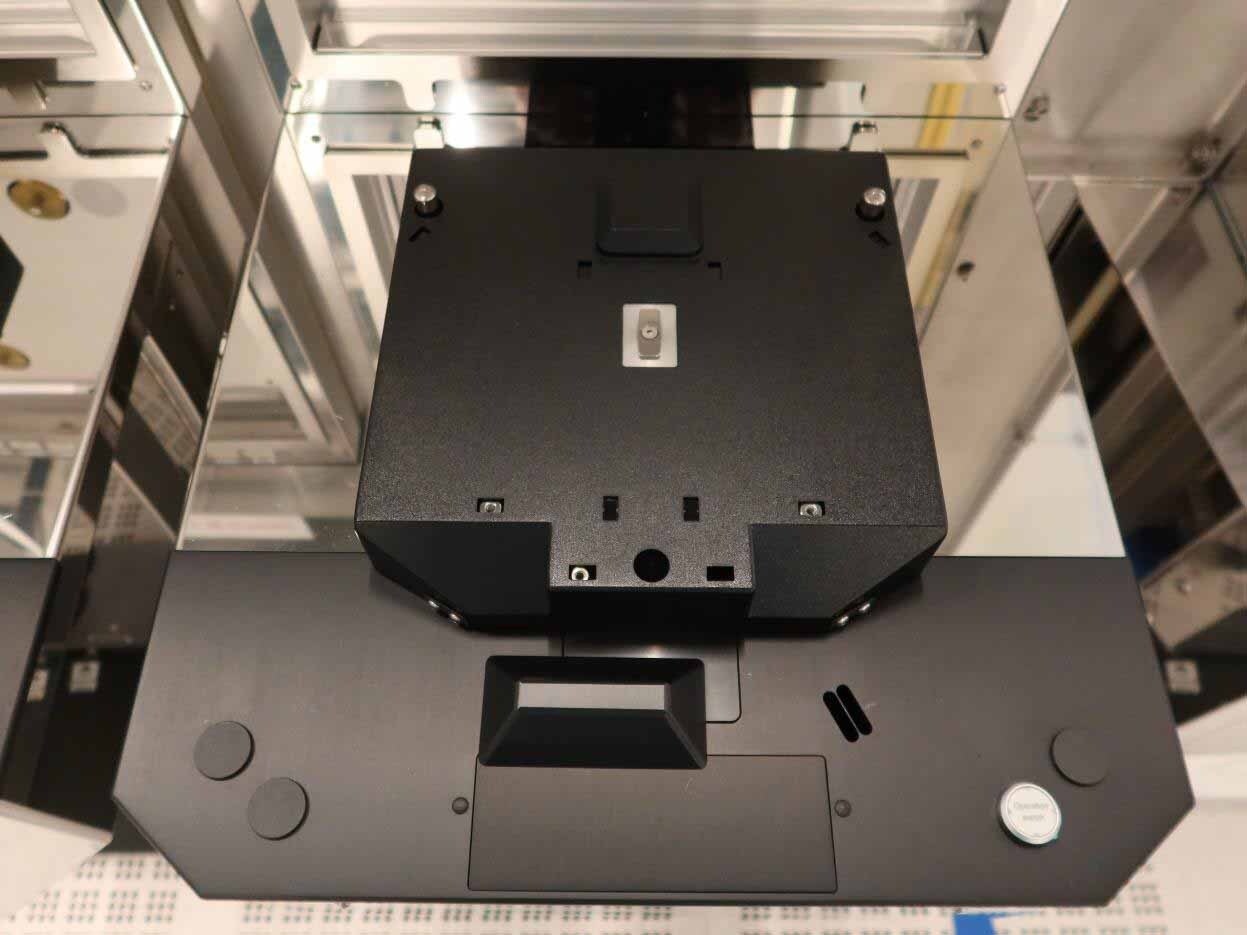

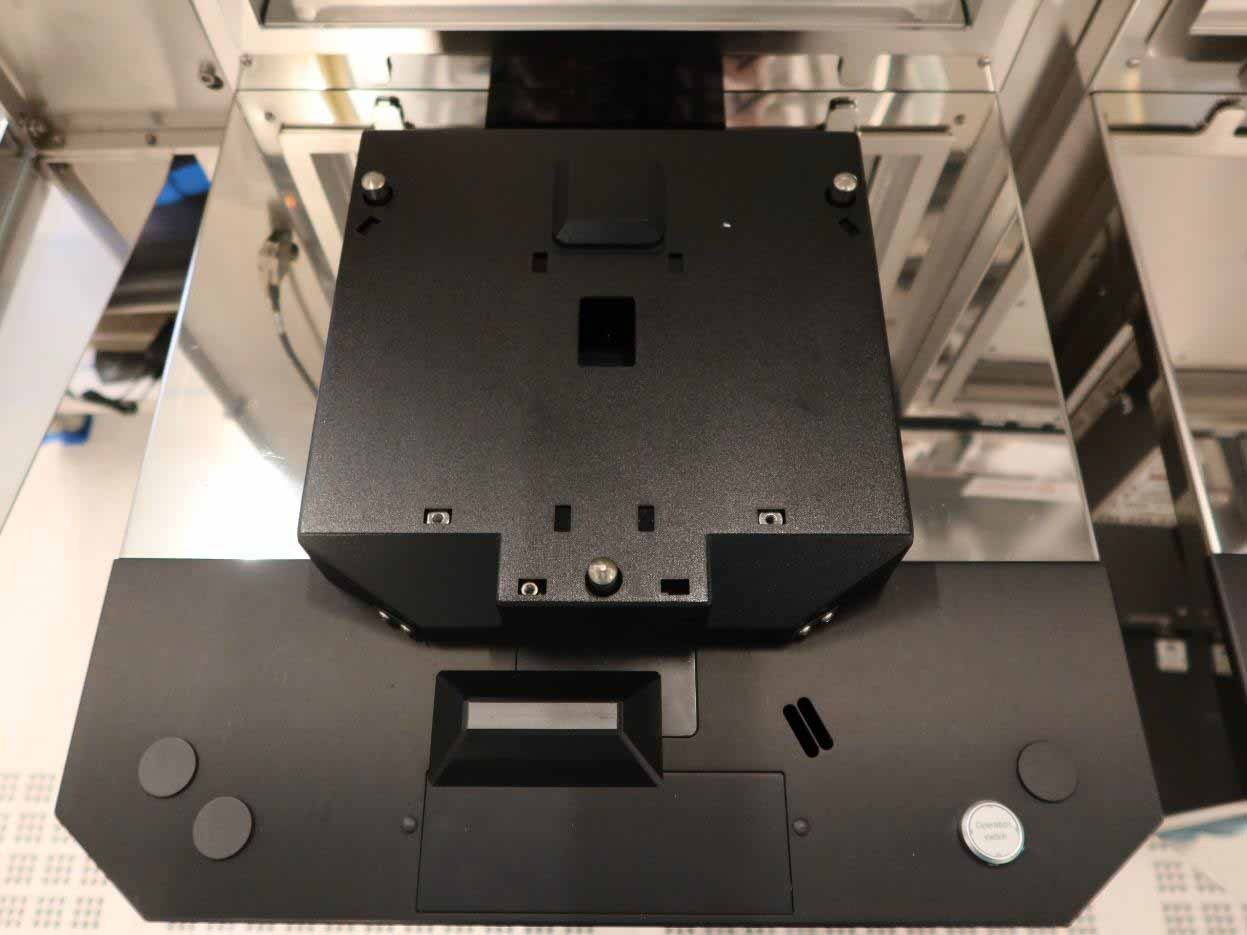

Macro defect inspection system, 8"-12"

Wafer type: Bare and pattern

Wafer surface inspection

Macro module: 30 µm Head

Sensitivity:

<10 µm For surface defects

30 µm For embedded defects

Throughput:

8" Wafer: 140 WPH

12" Wafer: 130 WPH

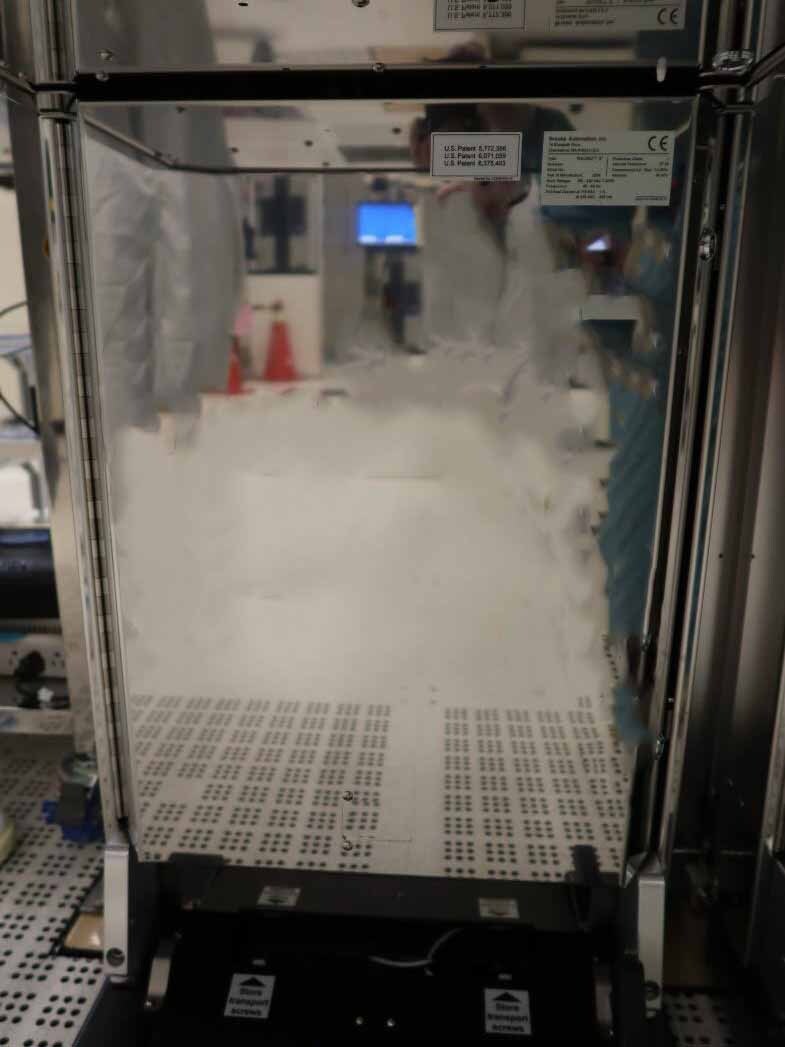

EFEM:

(2) Load ports

FOUP / Open cassette

BOLTS Interface, 12" / Load port, 8"

High throughput wafer handle with track

Wafer mapper: Cross / Double slot detection

Protrusion sensor

Automation interface: CID, AGV, OHT, Light curtain

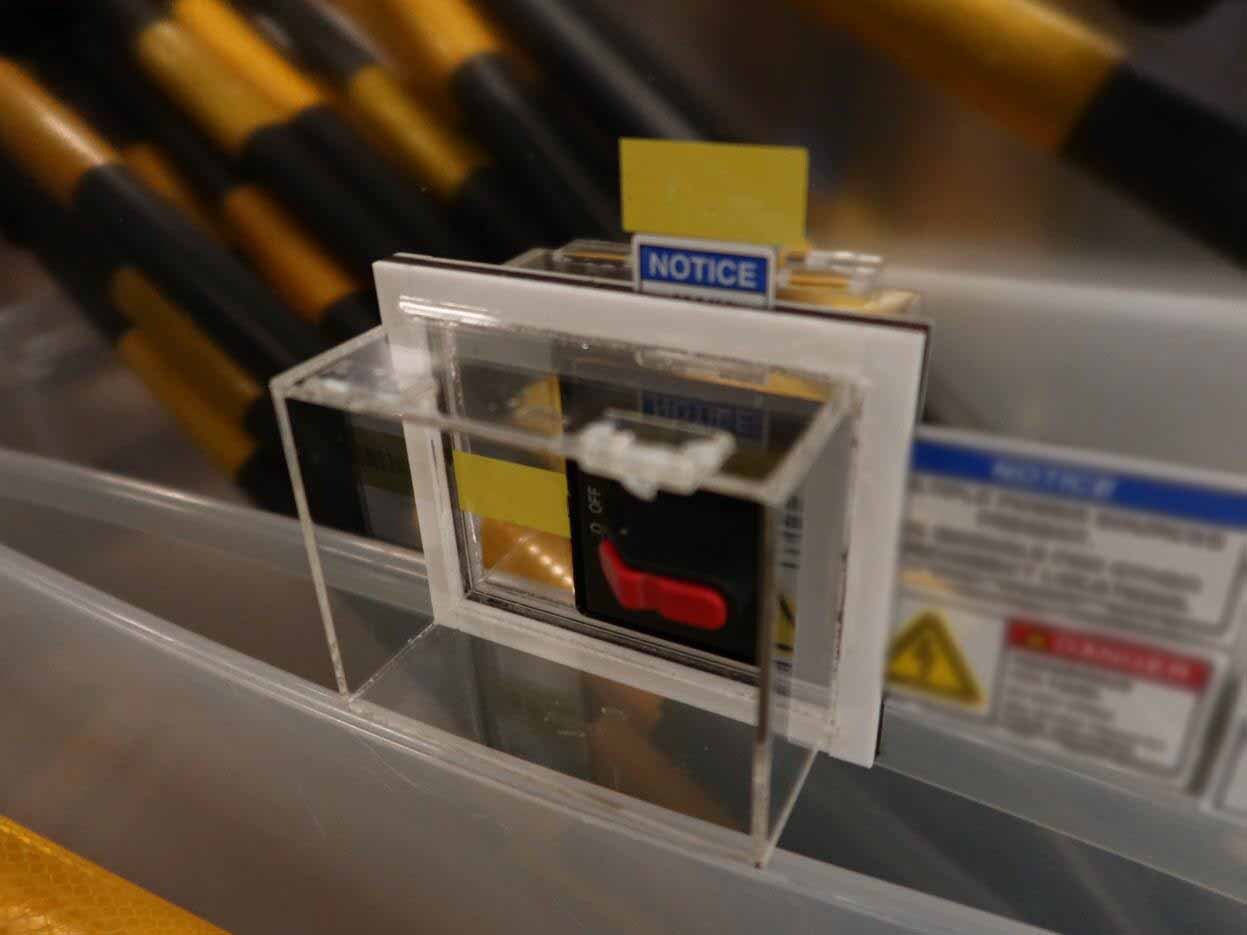

Stage air bearing damaged

2007 vintage.

KLA / TENCOR / LEICA / VISTEC LDS 3300M is a full-field, automated mask and wafer inspection equipment that helps ensure maximum yields during the fabrication of semiconductor device, components and systems. The system effectively inspects defects with a large field of view, and greatly reduces the process variation caused by multiple inspections. The bright-field optical library of KLA LDS 3300M is designed to scan a large work area (400mm x 600mm) with an extremely high resolution. This yields maximum defect detection and reduces the need for retouching. It employs an Object Flow Algorithm benchmark library that provides a comprehensive defect detection library for a wide range of features such as bridge defects, point defects, line defects and extraneous features. The automated maskless aligners of LEICA LDS 3300M provides the user with fast, accurate, and repeatable mask and wafer inspection. It can accommodate substrates up to 8 inches in diameter, and is designed to scan both bright-field and dark-field images to detect defects with higher sensitivity than ever before. With TENCOR LDS 3300M, users can also setup multiple aligners to inspect large work areas. LDS 3300M also incorporates advanced design versioning capabilities, which allow users to maintain a library of designs. This results in reducing inspection time, and helps in efficient defect detection for technologies such as flip-chip, ball bump and MEMS production. The cost-effective imaging components of VISTEC LDS 3300M ensure consistent, repeatable yield improvement and maximize throughput of the inspection tool. KLA / TENCOR / LEICA / VISTEC LDS 3300M is a highly reliable, user-friendly unit that is compatible with the most advanced wafer processing technologies. In summary, KLA LDS 3300M is an advanced mask & wafer inspection machine designed to ensure maximum yields during the fabrication of semiconductor devices, components, and systems. With a large field of view, automated maskless aligners, and versioning capabilities LEICA LDS 3300M offers the user an efficient, user-friendly and cost-effective solution for defect detection.

There are no reviews yet