Used KLA / TENCOR SP1-DLS #9016572 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9016572

Particle inspector

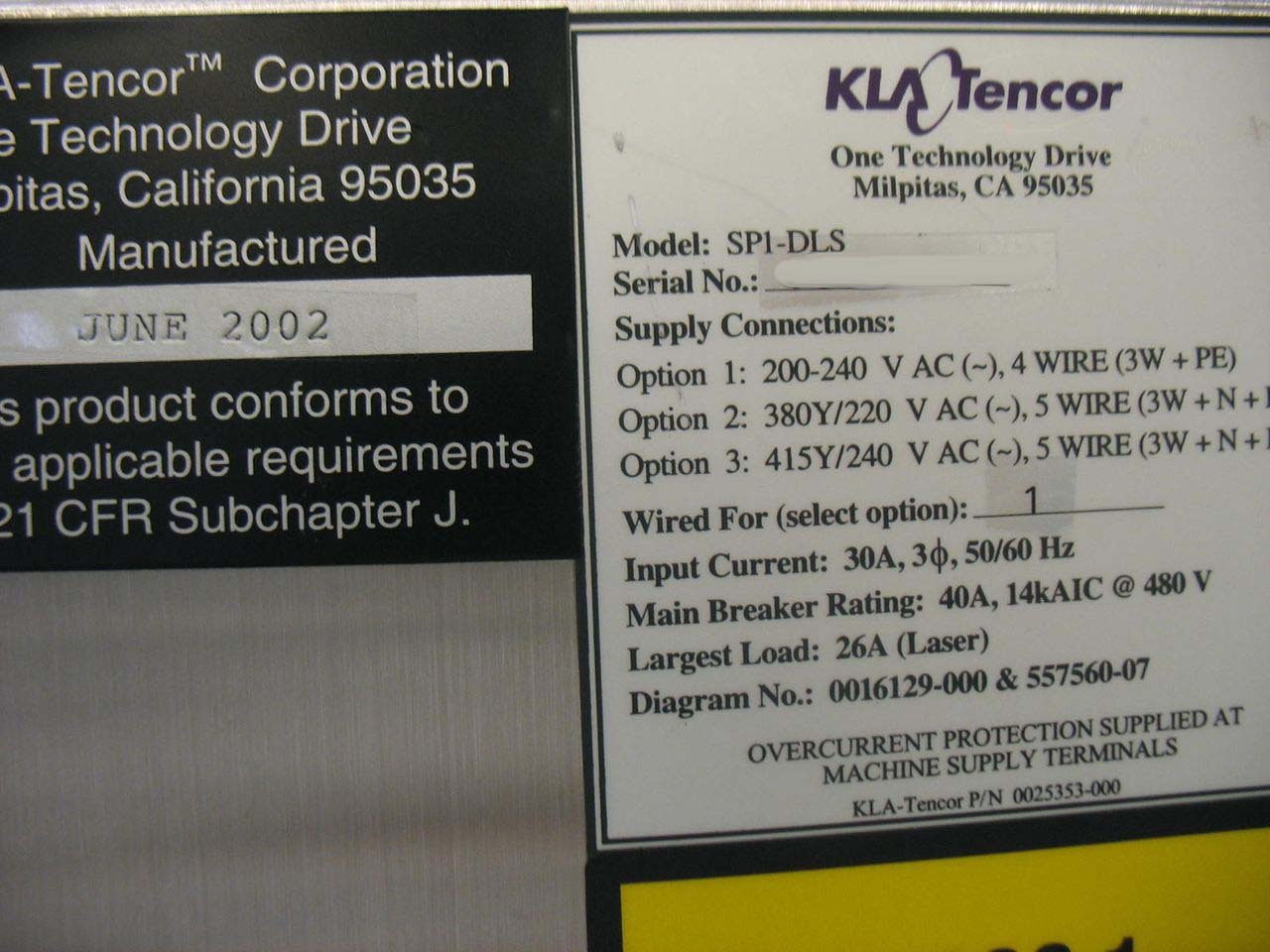

Supply connections: 200-240 VAC, 4 wire (3W+PE)

Input current: 30 A, 3 phase, 50/60 Hz

Main breaker rating: 40 A, 14k AIC @ 480 V

Largest load: 26 A (laser)

2002 vintage.

KLA / TENCOR SP1-DLS is an advanced mask and wafer inspection equipment designed to inspect for defects across multiple process steps and disciplines. It features the latest advanced imaging and inspection technologies to detect and identify various types of defects quickly and accurately. KLA SP1 DLS system is the industry standard in mask and wafer inspection for both production and laboratory environments and is used by many of the world's largest chipmakers and foundries. This automated unit is capable of inspecting a variety of masks and wafers on a single platform without the need to change tools or settings. It has a modular inspection area that can be customized for top, bottom, or in between viewing and achieves imaging resolution resolution up to ~2.5μm. TENCOR SP 1-DLS uses cutting-edge inspection algorithms and adaptive optical technologies designed to adapt to different product types and identify a number of defects including defects such as pattern-shift, line-edge roughness, and image contrast. Furthermore, the machine supports comprehensive product analysis with visualization tools such as false color 3D overlays, contour analysis, and cross-section graphic displays. With the software, users can review the defect results across multiple products or processes in the same dataset, to identify trends and yield impact. The high-precision vision assisted calibration feature on the tool ensures accurate repeatability over time by making live camera adjustments as needed. Additionally, KLA SEMVision automated machine learning toolkit further simplifies defect characterization by providing industry-leading classification accuracy with more rapid training times. The integrated reporting asset helps to easily keep track of defect information and the performance of the model on different products. Overall, SP 1-DLS equipment is the perfect choice for reliable and precise mask and wafer inspection. It is designed to help maintain the highest level of mask and wafer quality, while reducing inspection costs. It provides users with the ability to accurately identify a variety of defects, allowing for greater process control and visibility across the entire process.

There are no reviews yet