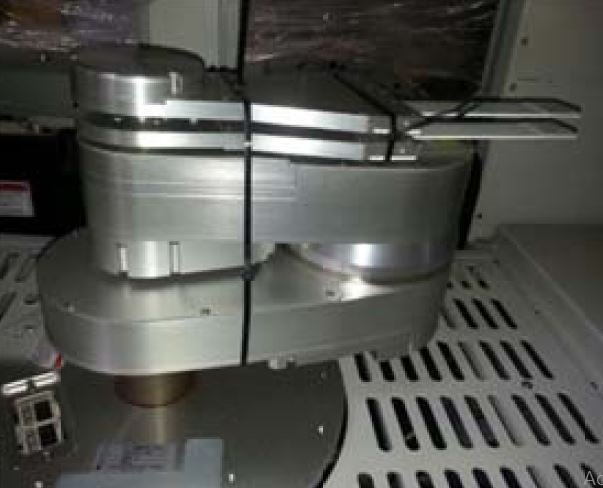

Used KLA / TENCOR SP2 XP #9250197 for sale

URL successfully copied!

Tap to zoom

KLA / TENCOR SP2 XP is an automated mask and wafer inspection equipment designed to enable manufacturers to identify and characterize defects on production wafers and photomasks. The system is equipped with four defect inspection modes including Critical Defect inspection (CDI), Wafer Scanning (WS), Defect Review (DR) and Complex Defect Review (CDR). The Critical Defect Inspection (CDI) mode is designed to rapidly and accurately identify critical lithography defects on photomasks and production wafers that could be missed by manual inspection. It utilizes advanced sensors and algorithms to detect and classify defects down to a minimum feature size as small as 1 micron. The powerful inspection engine can scan up to 500 wafers in a single job, ensuring high throughput and accuracy. The Wafer Scanning (WS) mode provides an efficient, cost effective approach to a full post-pattern inspection for production wafers. It utilizes advanced technology and powerful algorithms for accurate and reliable measurements and classification of defects. The unit can analyze up to 500 wafers per batch while considering a variety of geometries. The Defect Review (DR) mode can be used to inspect a single suspect die location. It utilizes multiple image magnification levels up to 1000X to aid in the manual analysis of a single die's defect characteristics. The powerful optical microscope and stitcher machine provides users with a sharp and detailed image of their wafer. The Complex Defect Review (CDR) mode is designed to provide detailed analysis of complex defects or "stacking effect" defects. It utilizes advanced image stitching capabilities to simulate a quadrant view of the defect or feature. This allows users to quickly and accurately identify a defect or feature's size, shape, and type. Overall, KLA SP2 XP is an advanced inspection tool designed to help manufacturers detect and characterize photomask and production wafer defects down to the most critical levels. It offers efficient workflow support, multiple inspection modes, and powerful automation technology to ensure high throughput and accuracy. The asset is an invaluable tool in manufacturing process control and defect reduction.

There are no reviews yet