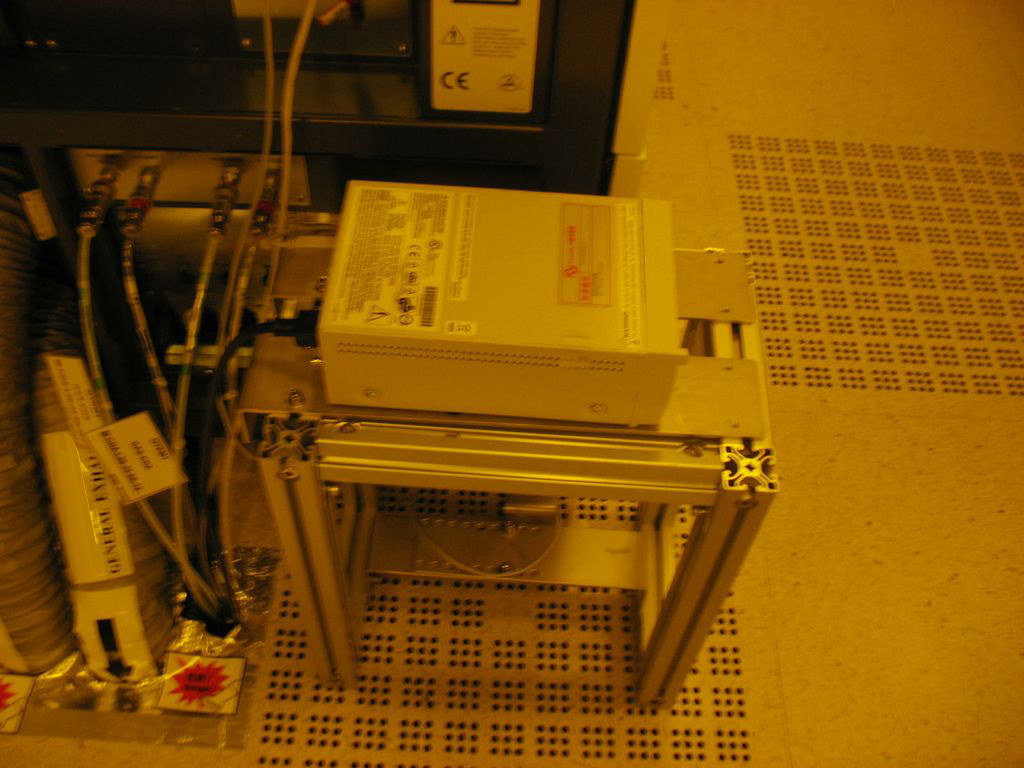

Used KLA / TENCOR SP2 #9023715 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9023715

Inspection system, edge handling

Bright field: no

Oblique mode: yes

Inspection mode: Normoul HT, ST, LT Obligue HT, ST, LT

Oil contamination kit: no

XP option: no

Software version: NGS 5.2 SR03B1153

Laser life: Spof 11, 1532 hrs

Currently installed in a cleanroom.

KLA / TENCOR SP2 is a automated mask and wafer inspection equipment used to inspect masks and wafers during integrated circuit production processes. The remarkable accuracy and speed of KLA SP-2 is a result of its advanced optical and measurement technologies, as well as its automated defect detection capabilities. TENCOR SP 2 measures all of the major OPC (optical proximity correction) parameters required for the successful inspection of masks and wafers, including CD (critical dimension) and MIS (micro-inspection system) measurements. It also includes OPC model-building capabilities and can measure CD-SEM, CD-FTIR (fourier transform infrared), CD-AFM (atomic force microscopy), AUBO-OCT (optical coherence tomography) and fringe projections. KLA SP 2's state-of-the-art, nanometer-level measurement technologies utilizes a five-dimensional alignment unit, providing enhanced flexibility and precision when adjusting camera lens positions and angles. SP2 employs specialized defect-detection algorithms and image-processing filters to detect, quantify and report its findings. Along with reading KLA and TENCOR-generated images, its large imaging library can also be used to compare test images to established patterns of good components or prepare for inspections or challenges. For example, its automated missing level detection can quickly identify appropriate levels that are missing from wafers, allowing users to quickly identify and address any issues with the production process. Finally, SP 2 includes a continuous automatic alignment machine that works in concert with the sensor's light field image. All the user has to do is enter the appropriate parameters, allowing the tool to quickly auto-calibrate to detect batches of unacceptable product. Further, the asset's automated defect recognition algorithms are over 90% reliable, meaning that the model can independently detect complex defects and classifications. In summary, TENCOR SP-2 is an advanced automated mask and wafer inspection equipment that is equipped with the latest optical and measurement technologies. Its ability to detect and quickly classify defects, measure OPC parameters and auto-align images make it an indispensable tool for integrated circuit production processes.

There are no reviews yet