Used KLA / TENCOR SP3 SURFSCAN #9115616 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9115616

Vintage: 2012

Wafer inspection system

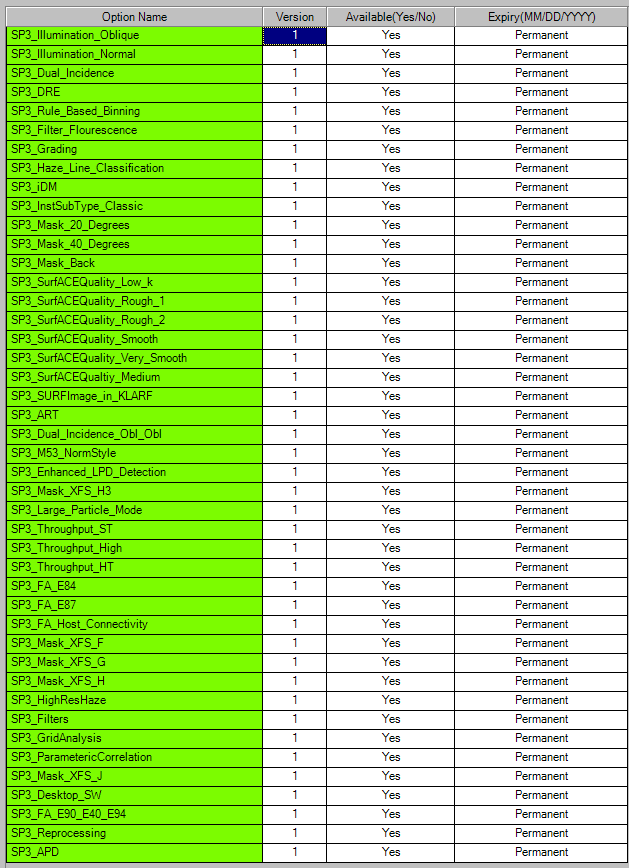

Specification:

Main laser: 500 - 550mW, 266nm DUV (deep ultra violet) diode laser, class 4

Edge scan laser: 7mW, 64 nm Diode Laser, Class 3B

2 PMTs

Software version NGS 6.10.6231

Software IMC version 2.20.6231

Optics modules:

Beam expander and attenuator (BEA) module

Beam steering and shaping (BSS) module

Spot size changer (SSC) module

Illumination module

Auto focus system (AFS)

Mask changer

IMC (Image computer): digital signal processing (DSP) by off system computers

Edge handling with 2 Shinko loadport & Yaskawa robot

KLARF compatibility

450mm extendibility

Optics purge N2

E84/OHT compatible

No bright field option

2012 vintage.

KLA / TENCOR SP3 SURFSCAN is a mask and wafer inspection equipment designed to quickly and accurately detect defects in integrated circuit fabrication. It offers high resolution, fast scanning, full automation, and easy integration with other systems. KLA SP3 SURFSCAN system offers automated surface inspection and micro surface metrology with high-performance, high-speed sampling and measuring capabilities in a single-unit solution. TENCOR SP3 SURFSCAN includes an automated and high-performance optical microscope, motorized stage, and powerful imaging and analysis machine. By coupling active removal and metrology technologies with high-resolution imaging, surfscan solutions take sampling to a level of accuracy and speed that has previously been impossible. SP3 SURFSCAN microscopes feature high-power objective lenses with working distances up to 200mm, offering exceptional accuracy and resolution. The powerful imaging and analysis tool speeds up detection and classification of physical, electrical, and chemical defects, enabling fast and accurate detection and repair of defects. KLA / TENCOR SP3 SURFSCAN asset also supports a wide range of wafer material types, including plated steel, plastic, and glass surfaces. Additionally, it supports a variety of pattern processes, including photoprocesses. It is also designed to support wet and dry processes, which are often used for nanoscale processes. KLA SP3 SURFSCAN also offers integrated optical test and metrology tools, which include resistivity mapping, CD and Roughness measurement, and 3D mapping. These tools enable fast characterization of devices, offering end users the ability to accurately measure changes in device characterizations during the process of fabricating ICs. The integrated optical test and metrology tools enable faster and more precise defects identification and process pattern recognition. Additionally, high-resolution image acquisition and defect classification allow users to accurately detect and repair any defects. This enables faster and more accurate processes with significantly reduced manufacturing costs. Finally, TENCOR SP3 SURFSCAN also provides enhanced user experience, with its intuitive graphical user interface, providing a clear view of what's going on. The model's advanced reporting and data analysis capabilities makes it easy to evaluate and compare processes and product results. The integrated workflow equipment enables users to effectively track and monitor progress and view quality metrics in real time.

There are no reviews yet