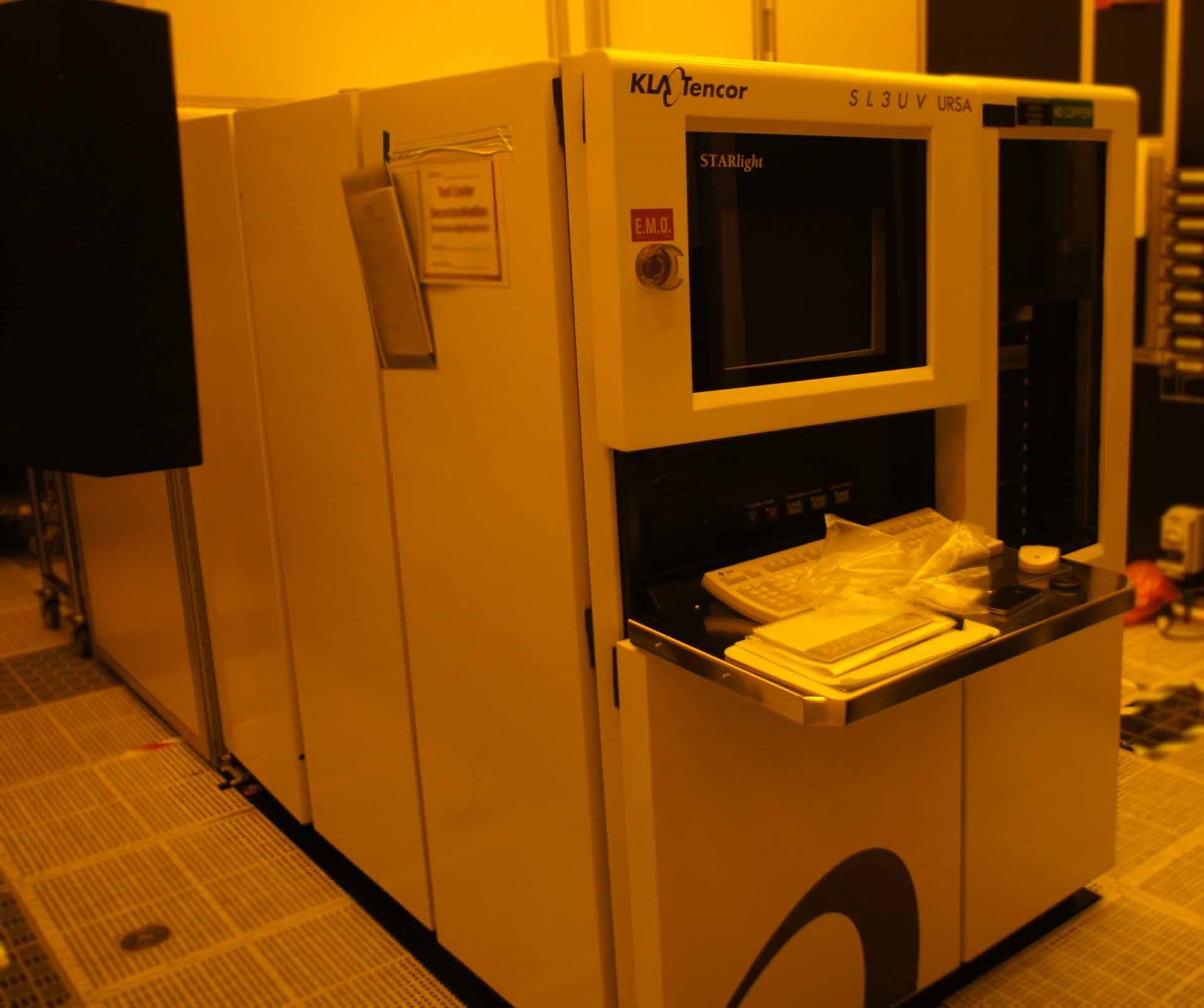

Used KLA / TENCOR STARlight SL3 UV URSA #9058370 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9058370

Inspection system, 6"

Automation:

KLA RF File format output

Klarity analysis

Automatic error recovery

System output:

Minimum output capability (Reticles per week):

0.25 um pixel size with 100 x 100 mm inspection area: 100

Minimum run rate (Reticles / Hour):

0.25 um pixel size for 100 x 100 mm inspection area: 0.7

0.375 um pixel size for 100 x 100 mm inspection area: 1.3

0.5 um pixel size for 100 x 100 mm inspection area: 1.9

Process capability:

Box handling

Manual load

NIKON Reticle, 6"

Upgraded to HR (High resolution)

Mask basic inspection capability:

OPC Inspection

APSM (DAP Design) Inspection

EPSM Inspection capability including EPSM and full ternary

Shifter transmission: ≤40% at 364 nm wavelength

Review capability:

Transmission review

Reflective review

On line review

Repeat review

Sizing capability

Offline view (Not classification)

Offline classification option

Show new defect capability

Recipe setup / Automation:

Auto setup capability

Light tower

Selectively inspect: Glass, pellicle or chrome surfaces

Maximum recipe setup time: 15 Minutes

Three level password protection capability: Operator, engineer & FSE

Continuous vs single-step operation capability

Auto loader cycling capability

Barcode reading capability

Networking capability

Auto operation capability with existing recipe

Minimum inspectable mask characteristics:

Minimum pitch larger than or equals to twice of the minimum line width:

Minimum inspectable main feature size (nm) at:

0.186 um pixel size (Option): 400

0.25 um pixel size: 500

0.375 um pixel size: 750

0.5 um pixel size: 1000

Minimum pitch larger than or equals to 2.5 times of the minimum chrome line width:

Minimum inspectable main feature size (nm) at:

0.186 um pixel size (Option): 220

0.25 um pixel size: 320

0.375 um pixel size: 560

OPC Features:

Minimum inspectable OPC serif / Inverse (nm): 200

Minimum inspectable OPC jog (nm): 14

Inspection characteristics:

Within tool matching: ≤5%

Tool to tool matching: ≤10%

False defect rate (Defects/cm²): 0.1

For inspection area > 10 cm²: 0.1

Sensitivity on pellicle @ 98% capture rate (nm): 4000

Sensitivity on glass @ 98% capture rate (nm):4000

Minimum pitch larger than/or equals to twice of the minimum line width:

Sensitivity on chrome @ 98% capture rate (nm) at 0.186um inspection pixel size

PSLs (Option) EPSM capture rate on shifter substrate @ 90.4%: 140

Sensitivity on chrome @ 98% capture rate (nm) at 0.25um

EPSM Capture rate on shifter substrate @ 90.4%: 180

Sensitivity on chrome @ 98% capture rate (nm) at 0.375um

Sensitivity on chrome @ 98% capture rate (nm) at 0.50um

Minimum pitch larger than or equals to 2.5 times of the minimum chrome line width:

Sensitivity on chrome @ 98% capture rate (nm) at 0.186um

Sensitivity on chrome @ 98% capture rate (nm) at 0.25um

Sensitivity on chrome @ 98% capture rate (nm) at 0.375 um

Inspection pixel size on reticle using PSLs: 350

Sensitivity on chrome @ 98% capture rate (nm) at 0.5 um

Inspection pixel size on a reticle using PSLs: 500

Exclusion zones:

Pelliclized plate:

Exclusion on chrome side (mm)

For 0.25um pixel or greater: 3.5

For 0.186um pixel: 5.5

Exclusion on pellicle (mm): 1

Exclusion on glass (mm): 3

Unpelliclized plate:

(3) Exclusion on 6" back glass

(3) Exclusion on 6" front side

1999 vintage.

KLA / TENCOR STARlight SL3 UV URSA is an advanced mask and wafer inspection equipment that uses patented dual-wavelength UV imaging technology. It eliminates the need for an external light source, enabling the wafer to be imaged directly, with maximum imaging accuracy and a high signal-to-noise ratio. KLA STARlight SL3 UV URSA is designed for automated, stand-alone inspection of mask and wafer applications, including wafer bump inspection, litho/etch inspection, photomask inspection, overlay inspection, and various defect detection and classification tasks. The system is built around a fully automated, mono- and dual-wavelength UV imaging engine with a large field-of-view of up to 17cm x 17cm. It provides the necessary UV illumination required for UV image acquisition. Its rigid construction, stable thermal environment and high-performance optics ensure accurate imaging over the entire field-of-view. The integrated noise-reduction unit helps reduce background noise and provides high-contrast images. The machine is equipped with a state-of-the-art image processing platform. It features fast, intuitive and highly accurate defect detection algorithms based on advanced pattern recognition technology. The adaptive signal enhancement feature automatically adjusts to changing conditions in order to detect even the smallest defects. The tool also offers integrated analysis and measurement capabilities that enable advanced process control and optimization. TENCOR STARlight SL3 UV URSA features a Windows-based user interface which provides a simple-to-use and efficient operation. It includes a comprehensive set of easy-to-use tools and allows for easy data acquisition and evaluation. The asset supports network connectivity and is compatible with popular manufacturing software packages, enabling flexible integration with existing production lines. STARlight SL3 UV URSA is a powerful and feature-rich model for inspecting mask and wafer applications. Its advanced dual-wavelength imaging technology and extensive image processing capabilities provide the utmost accuracy and reliability. Combined with its flexible integration capabilities, it is an ideal solution for automated mask and wafer inspection.

There are no reviews yet