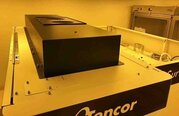

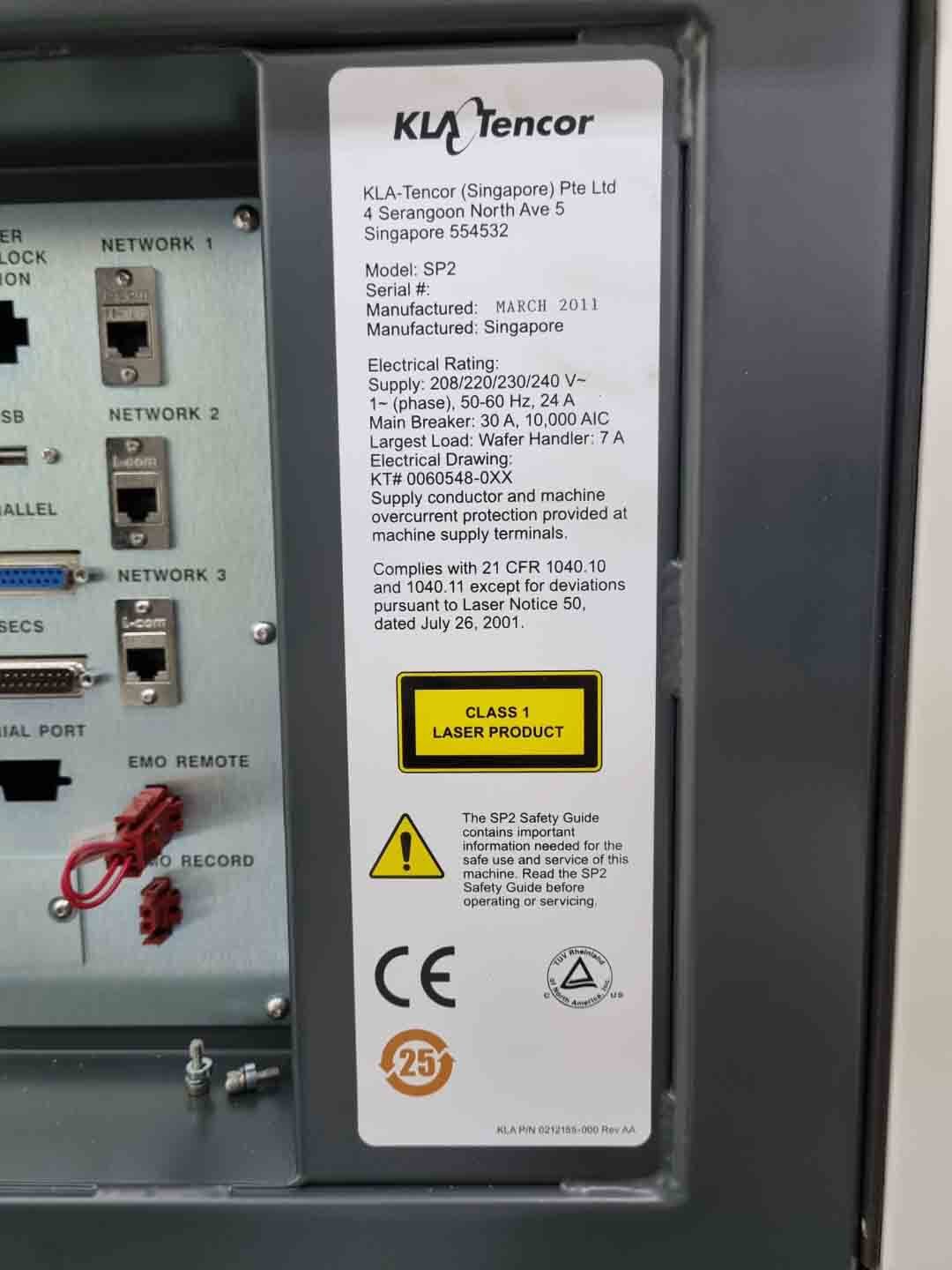

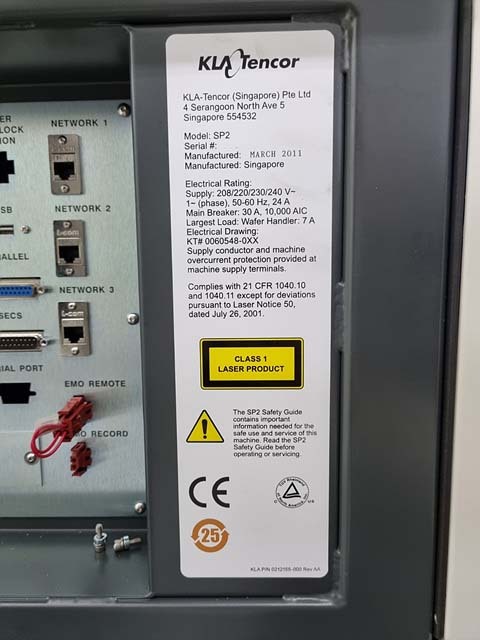

Used KLA / TENCOR Surfscan SP2 #9398740 for sale

URL successfully copied!

Tap to zoom

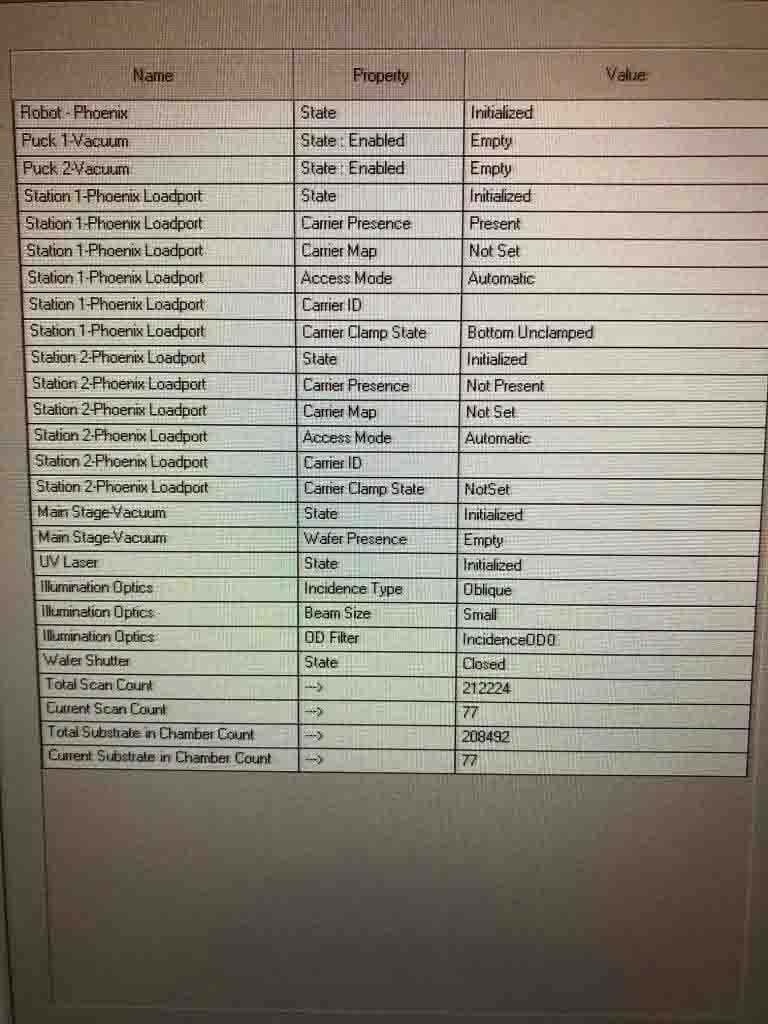

ID: 9398740

Vintage: 2011

Inspection system

Semi notch, 12"

Carrier:

(3) Load ports:

Phx

SHINKO

8-Configurable LED to display load ports

Load/unload button: Manual

Wafer cassette mapping: FOUP, 12"

Empty slots and cross slotted wafer

Vacuum load port: FIMS, 12"

Light tower (RBYGW)

Facilities:

CDA: > 28.3 NL/min, > 6.6791 kg/cm2

VAC: > 28.317 l/min, > -700 mm Hg

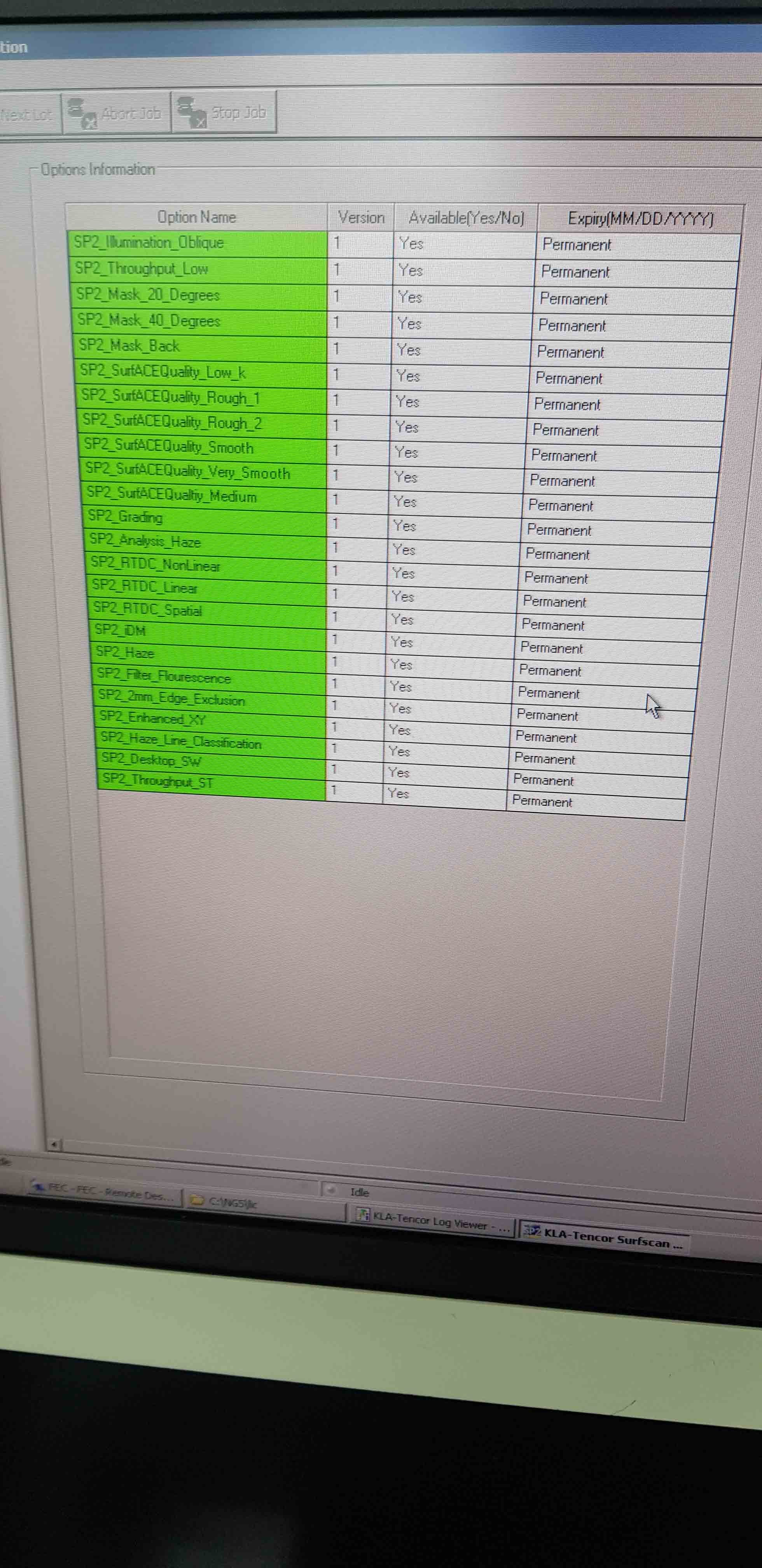

Edge exclusion, 2 mm

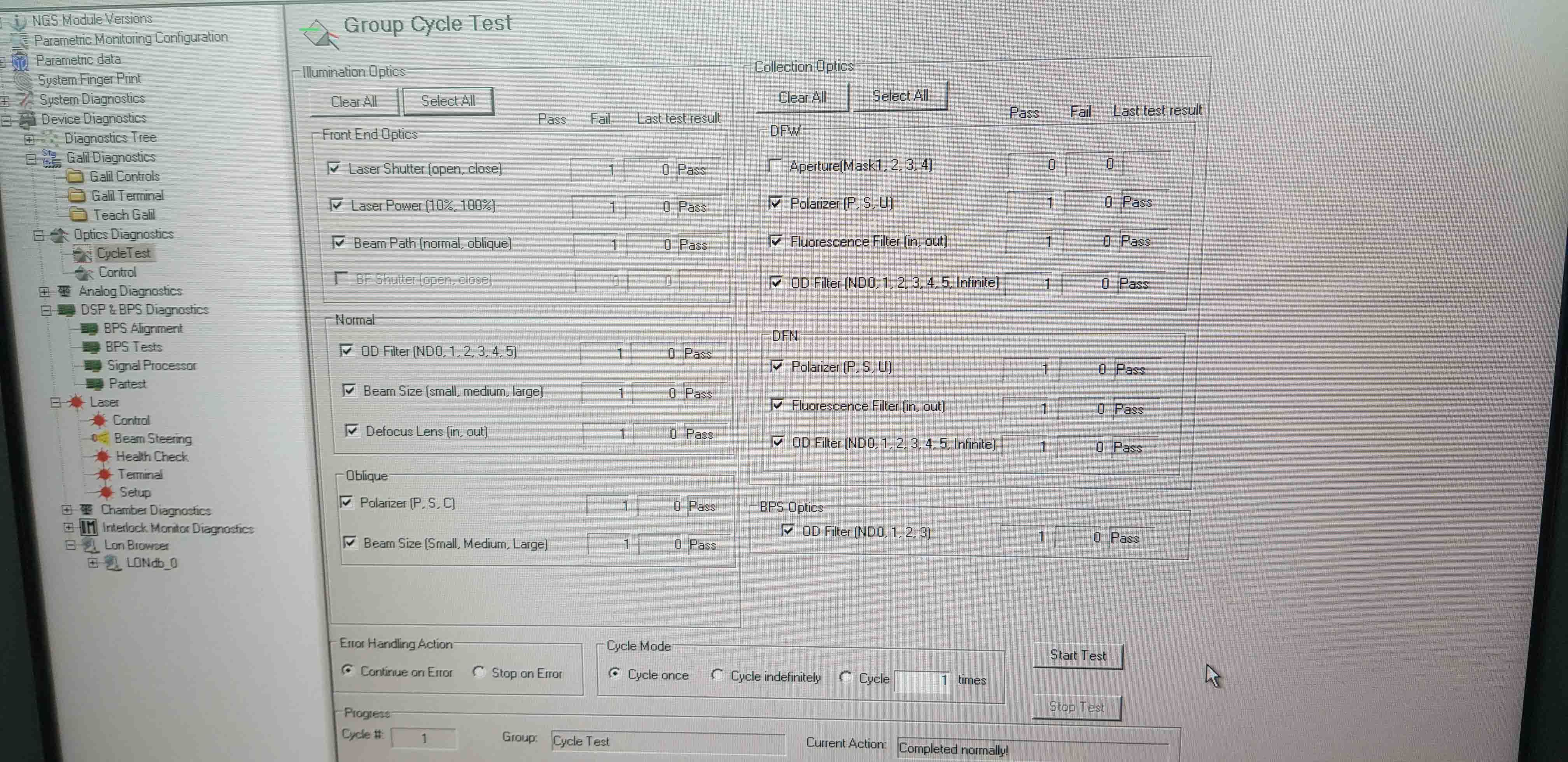

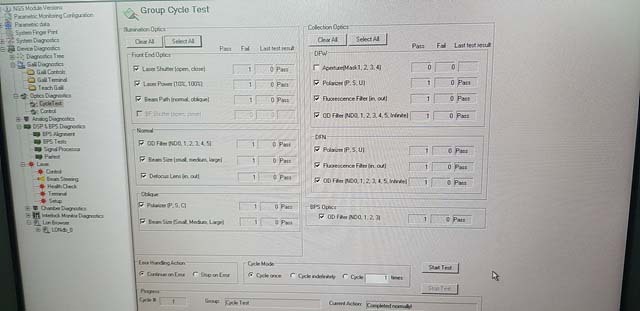

Oblique incidence illumination (High / Standard / Low)

Normal incidence illumination (Standard / Low)

XY Co-ordinates

IDM SP2

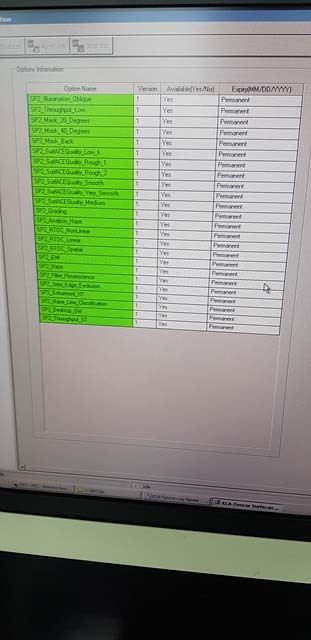

Standard classification package

LPD-N Classification

LPD-ES Classification

Grading and sorting

Spatial filter: 20°

Spatial filter: 40°

Spatial filter (Rough films)

Spatial filter (Back)

High sensitivity inspect mode

High throughput inspect mode

Haze

Haze normalization

Haze analysis

IC/OEM

Ethernet:

NFS Client

E84 enabled for OHT and AGV/RGV

E87 (Based on E39)

GEM/SECS and HSMS

E40 / E94 / E90 / E116

Main computer:

Intel Xeon CPU 3.20GHz

RAM: 3.5 GB

DVD-ROM

Mouse

Keyboard

Floppy Disk Drive (FDD), 3.5"

FEC Computer:

CPU: Intel Pentium 4

RAM: 512 MB

Operating system: Windows XP SP3

Power supply: 208 VAC, 3 W-N

2011 vintage.

KLA / TENCOR Surfscan SP2 is a most advanced mask and wafer inspection equipment, developed to provide the highest performance levels in automatic netlist pattern recognition and defect management applications. It offers comprehensive control of surface conditions and defect detection, with the ability to monitor overall presence of wafers and detect subtle changes in profile, including the presence and characteristics of microliths and particle interference. By combining advanced optical systems and innovative image processing technology, KLA Surfscan SP2 empowers users to inspect patterns, detect defects, identify nonuniformities, and classify anomalies to characterize surface conditions. TENCOR SURFSCAN SP 2 is an inspection system specifically designed to support demanding industrial semiconductor applications, as it supports high throughput and offers fast, accurate analysis of both single and multiple wafers. It comes equipped with a number of advanced features, such as multi-level imaging, binarization, shape analysis, and the ability to select custom optical filters for enhanced image clarity and character recognition. These filters work to detect very small patterns on the wafer, scanning for both defects and irregularities, and are adjustable for changing environments. The unit also offers advanced, top-level quality control capabilities, with the ability to selectively measure, detect, and correct any surface parameters to ensure proper deposition, masking, and resist profile of the wafer. The machine can scan and inspect wafers composed of a variety of materials, including glass, aluminum, silicon, and quartz. Its integrated 5-axis motion control tool is capable of accurately positioning the sample on the stage and scanning directly to the device, reducing alignment errors and the possibility of human errors that can lead to material or product defects. The asset also offers automated wafer mapping, storing detailed information on each wafer and offering various levels of analysis with built-in memory and buffers that enables other applications to retrieve the data quickly. Furthermore, the model's automated defect detection algorithms are able to detect faults that are too small for the human eye to see, making it an efficient and powerful tool for the rapid identification and removal of defects from a product before entering the market. This enables manufacturers to optimize their production processes, ensuring that their products meet the high standards of quality. In addition, its user-friendly interface and intuitive software offer complete control over inspection functions to quickly review, analyze and correct inspection data. In conclusion, TENCOR Surfscan SP2 is an advanced and comprehensive equipment for mask and wafer inspection and defect management. It offers fast scanning, accurate analysis and extensive control over surface conditions, enabling users to effectively detect and remove faults from products quickly and efficiently.

There are no reviews yet