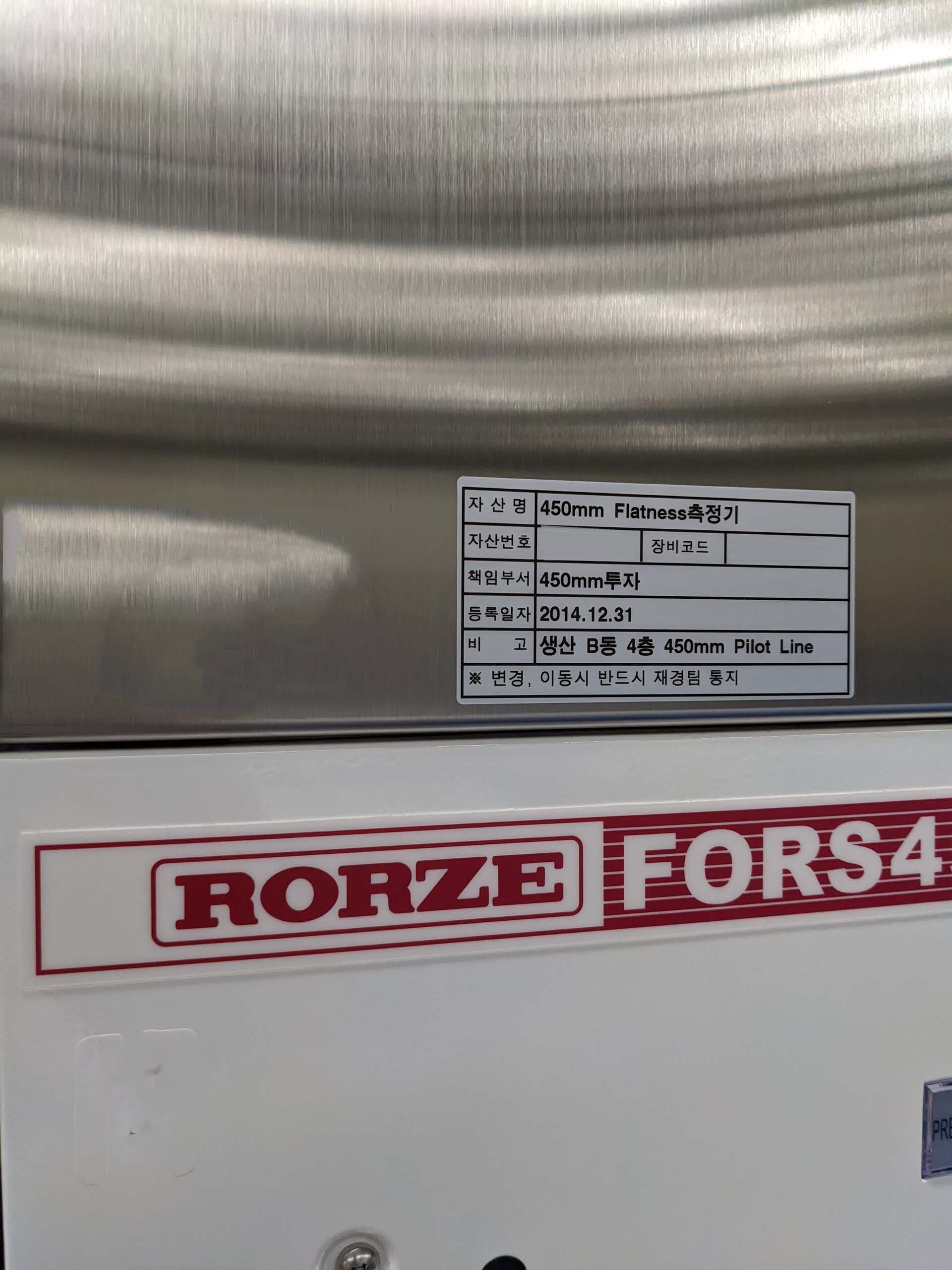

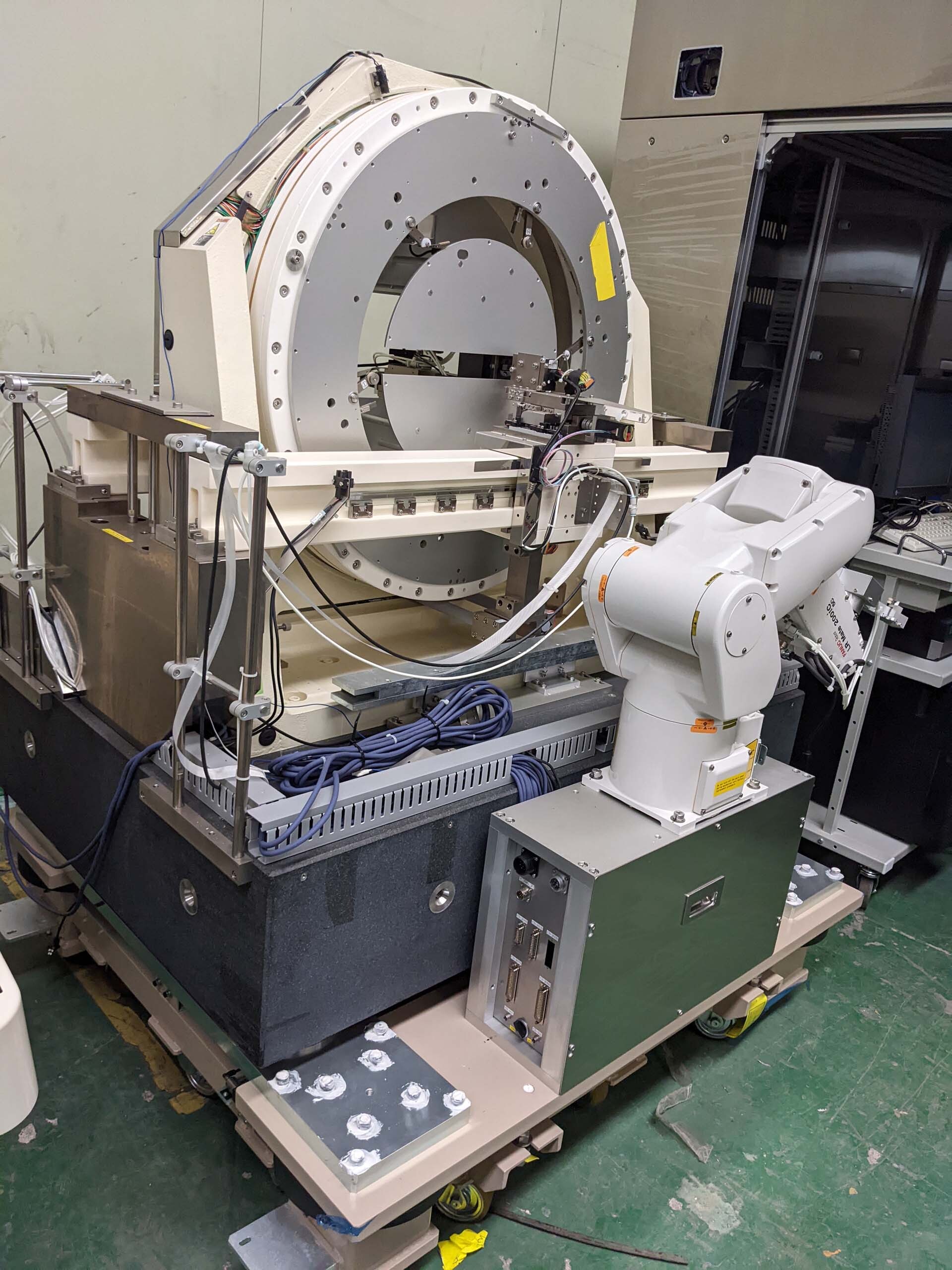

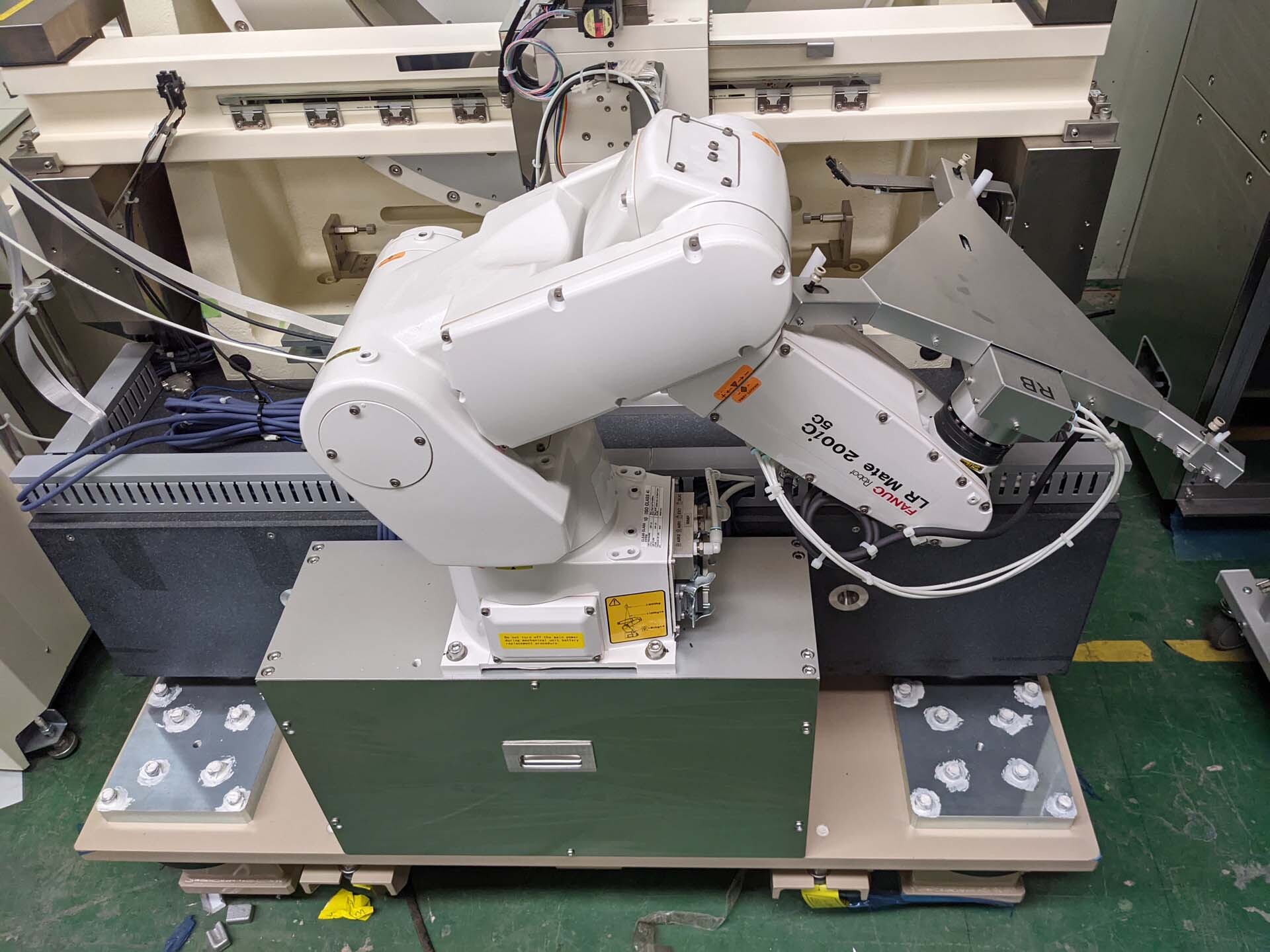

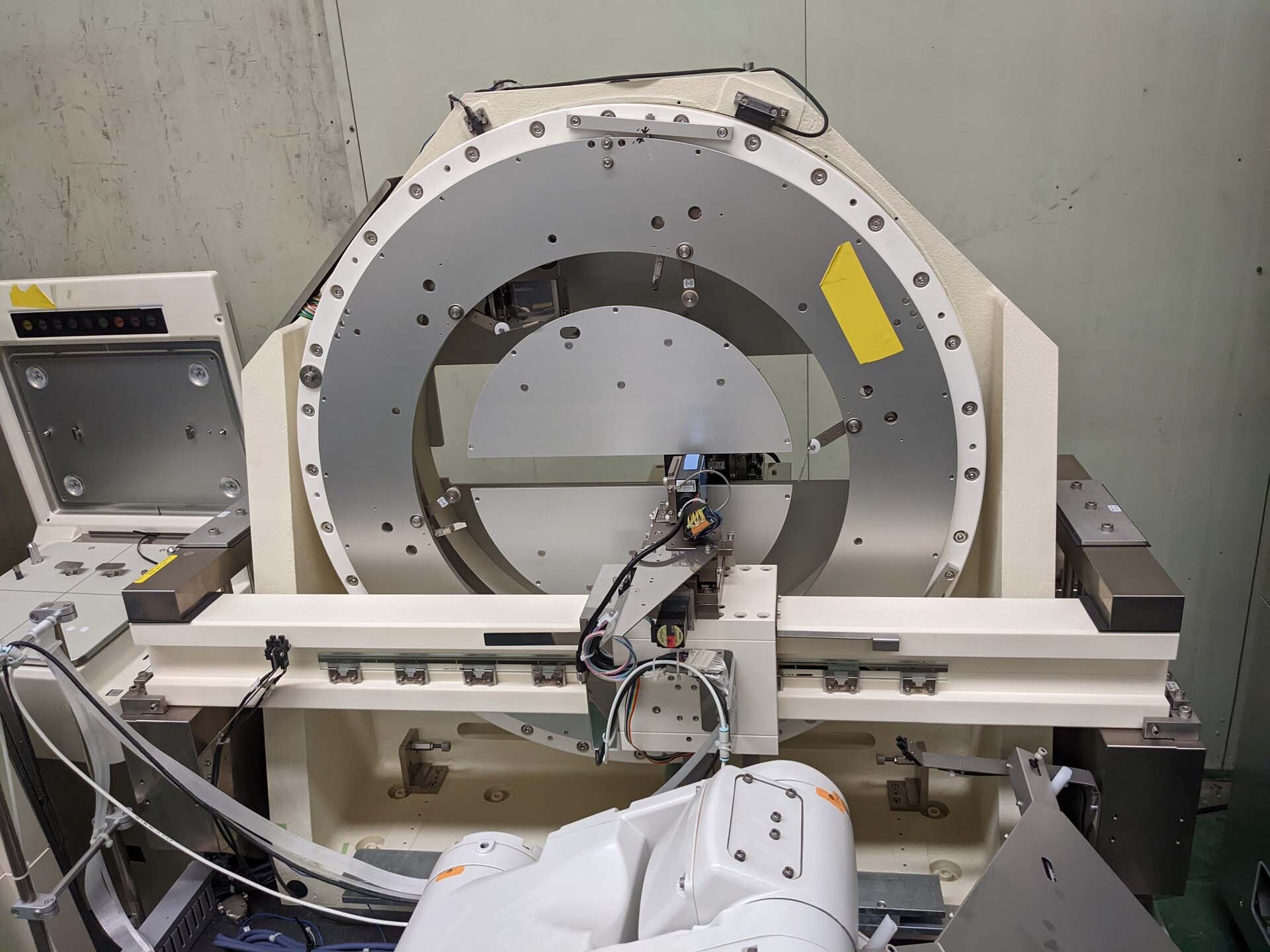

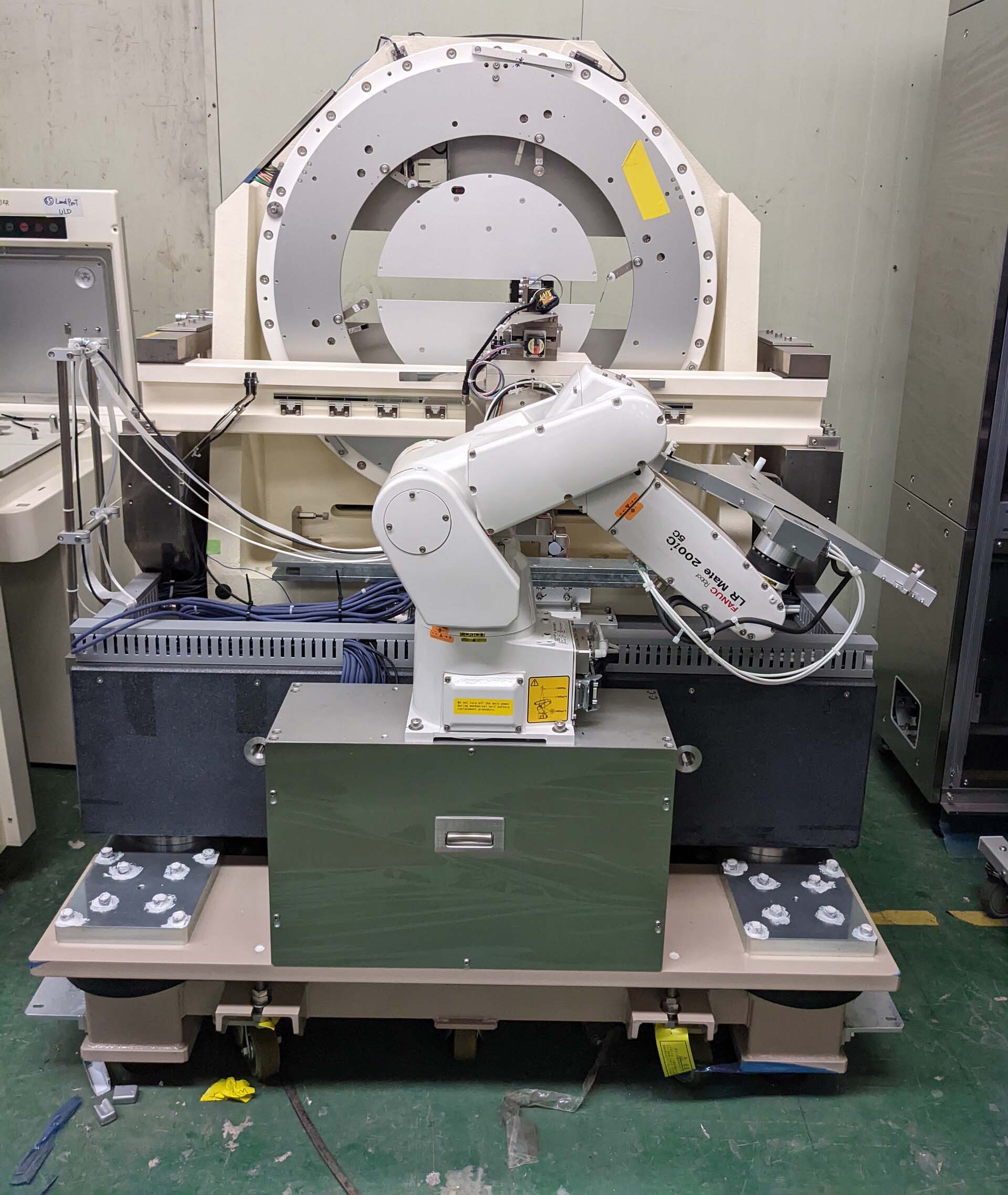

Used KURODA System #293665542 for sale

URL successfully copied!

Tap to zoom

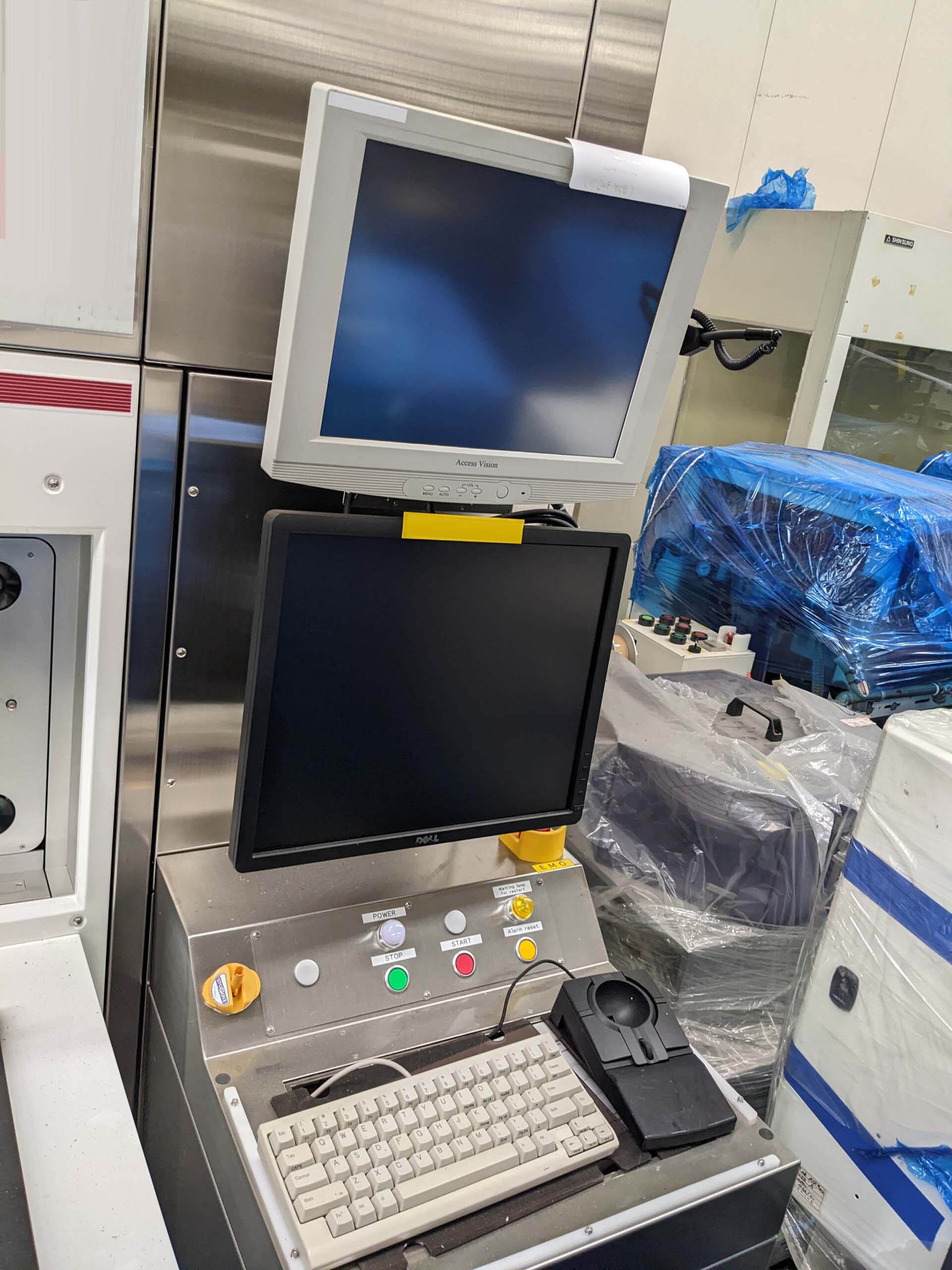

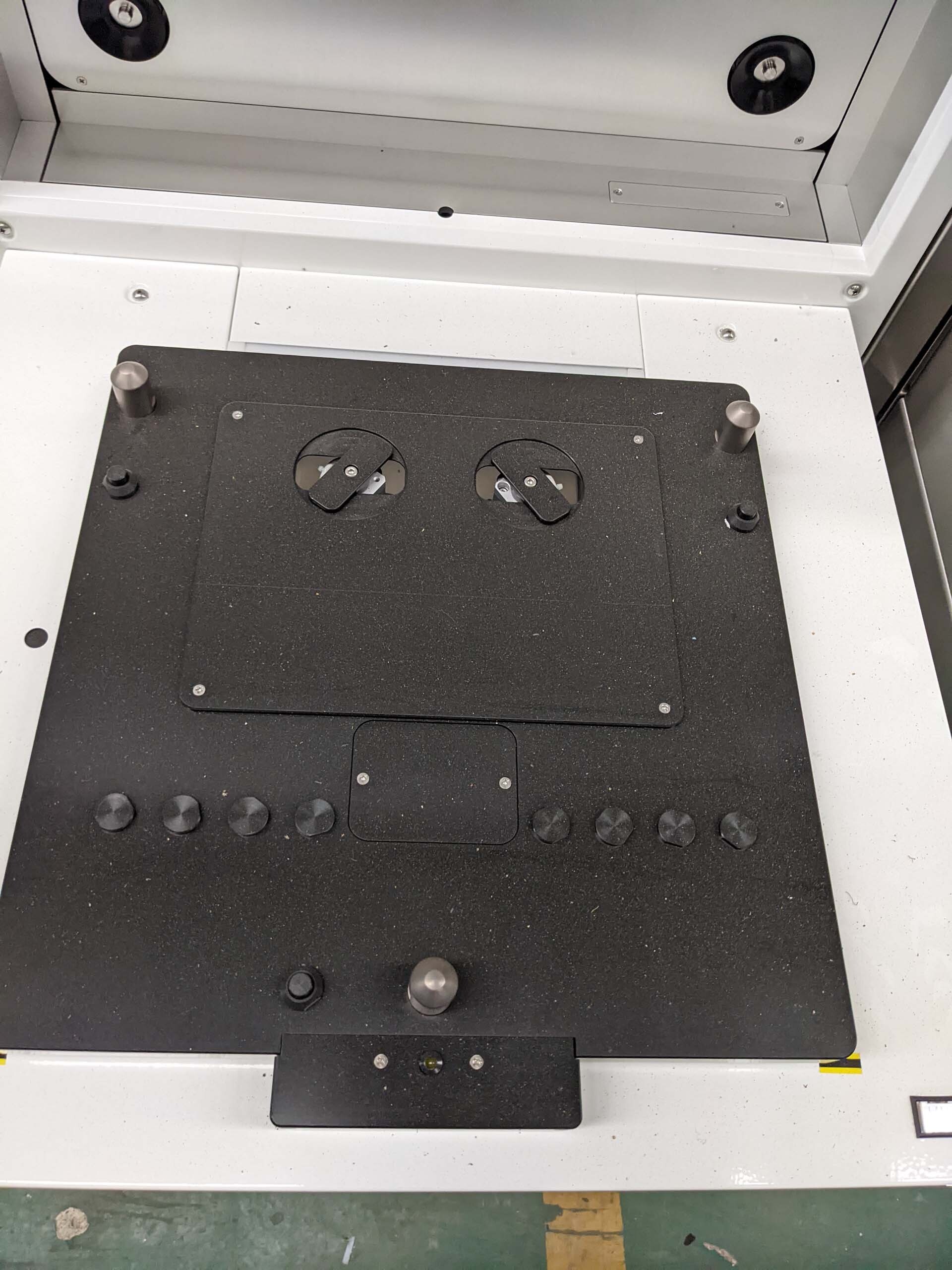

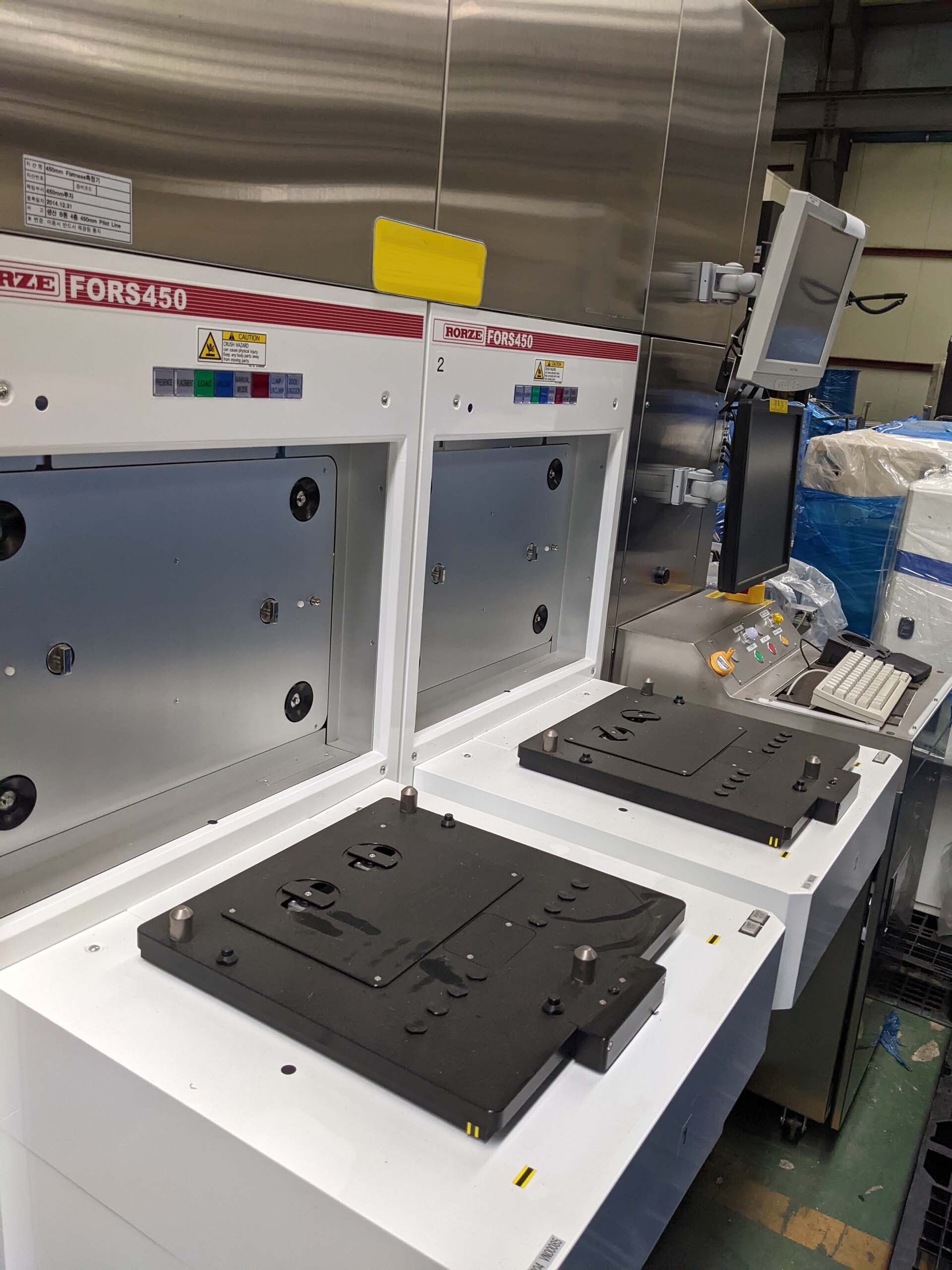

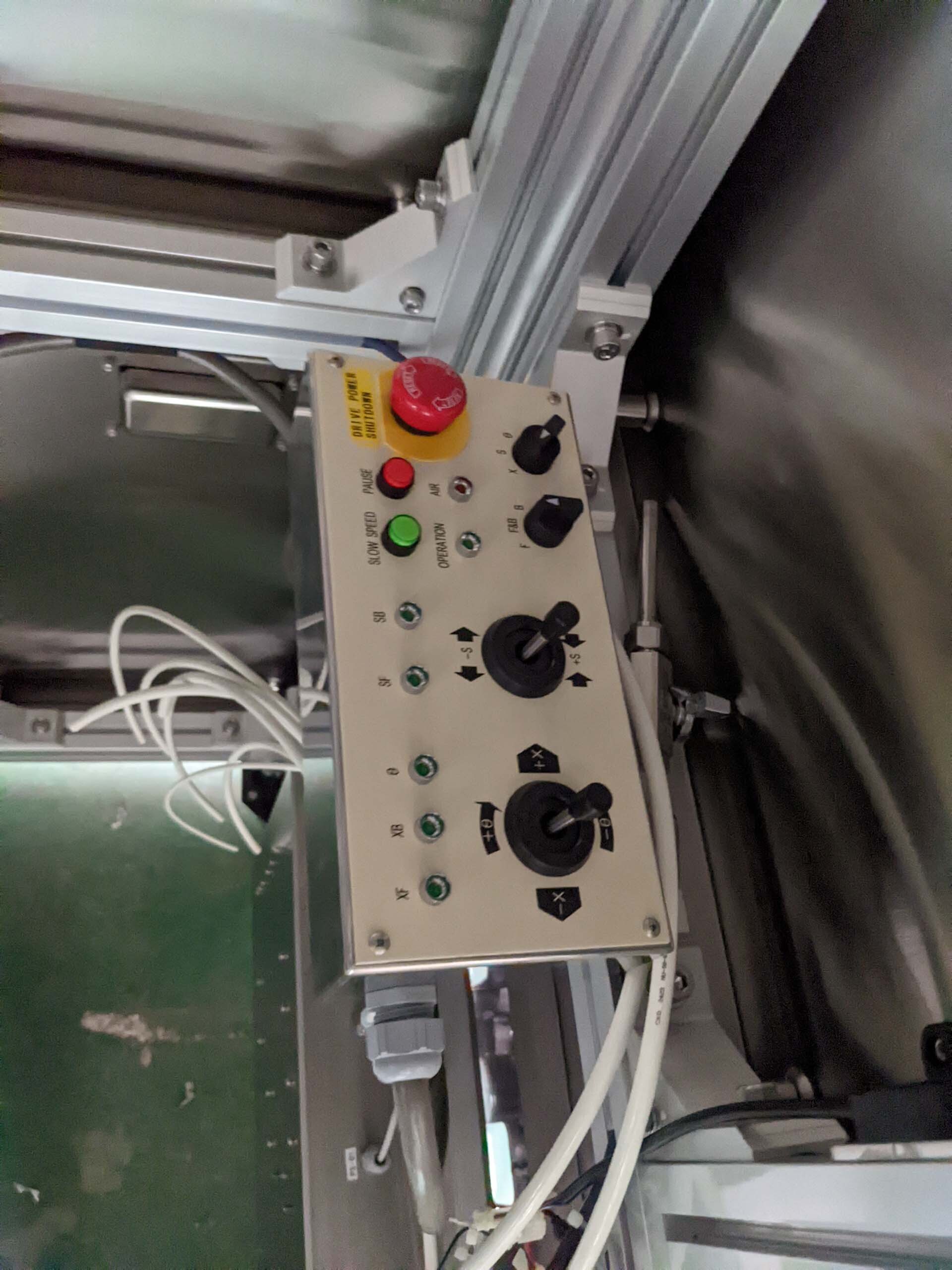

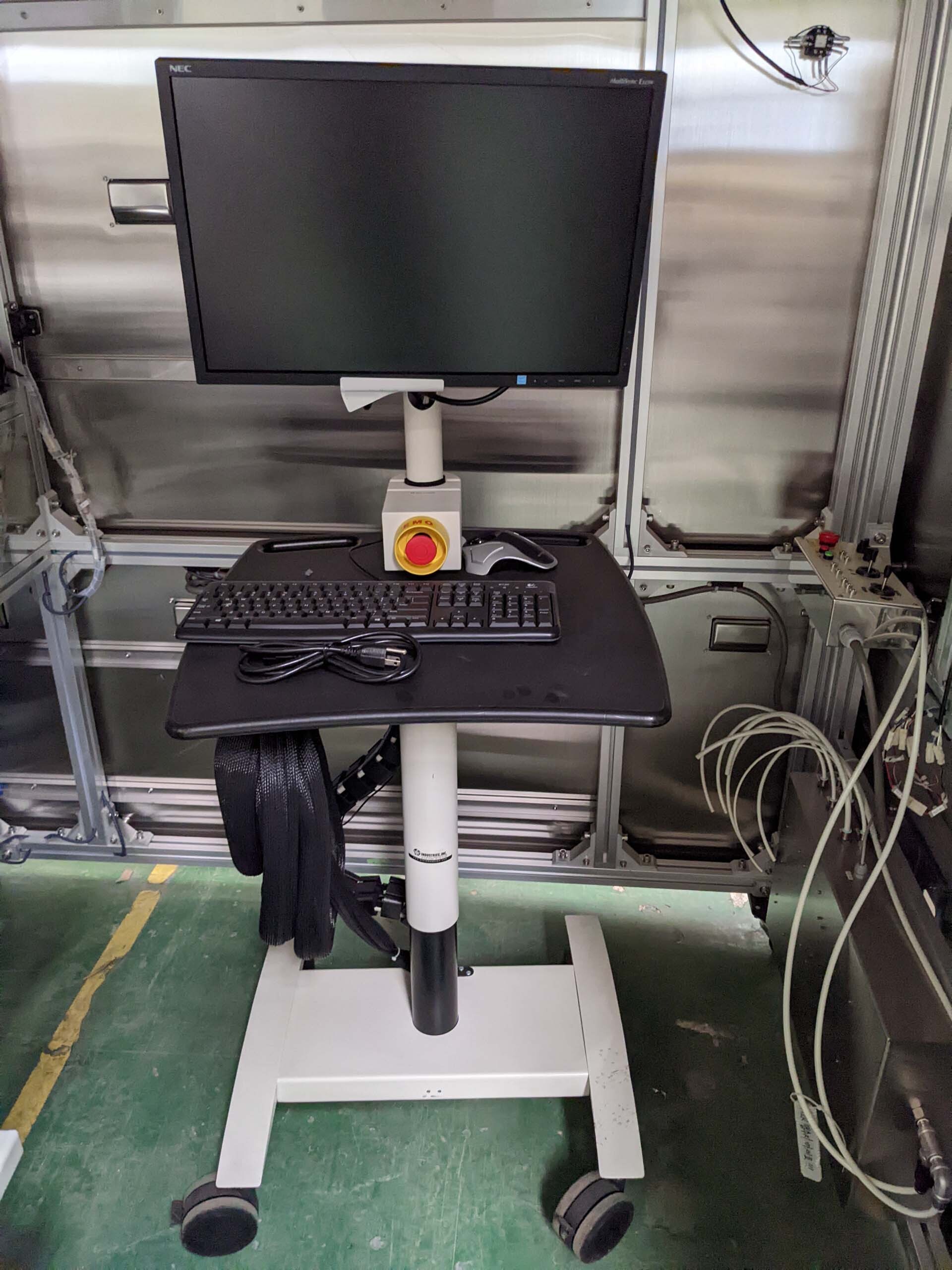

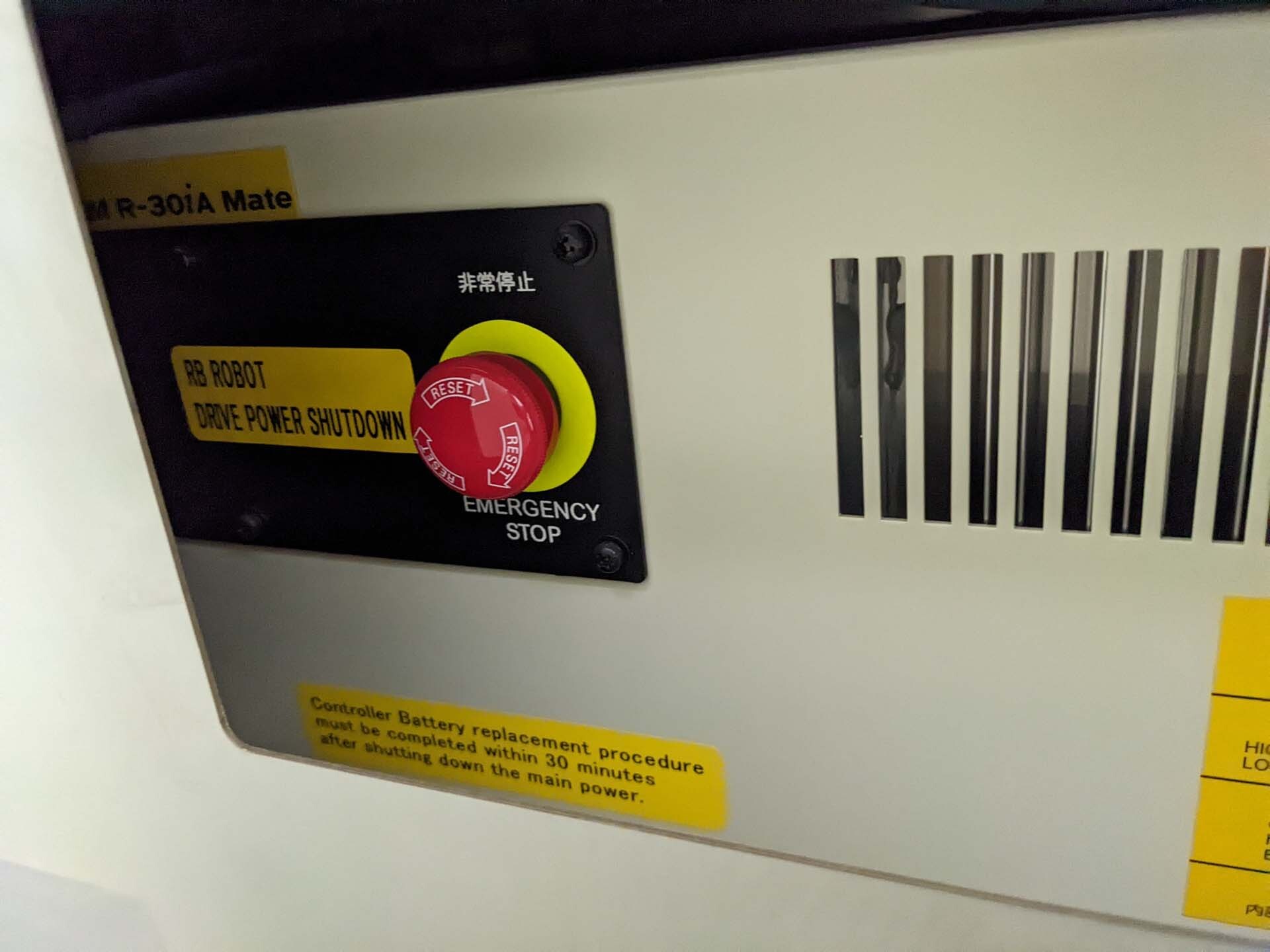

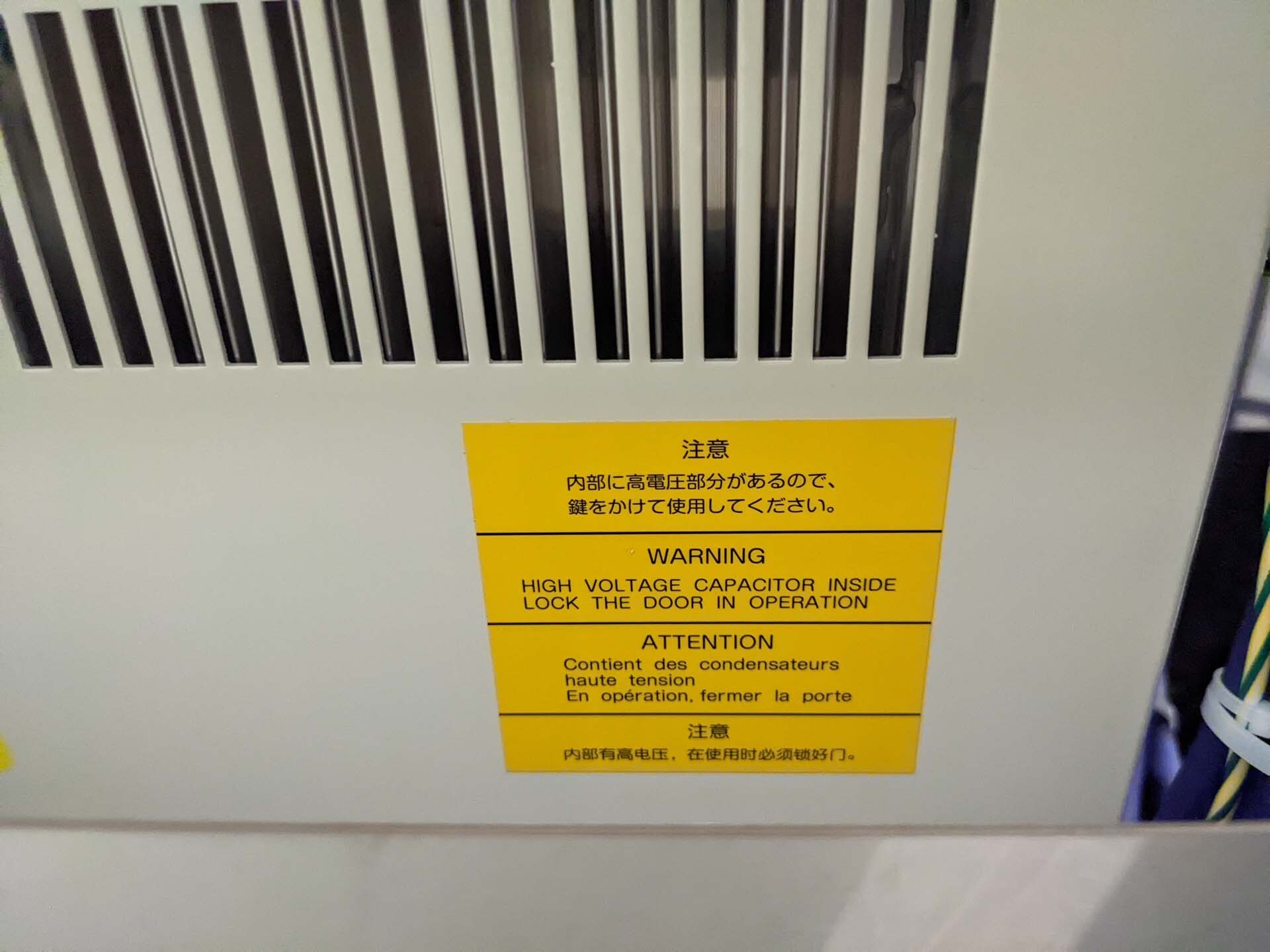

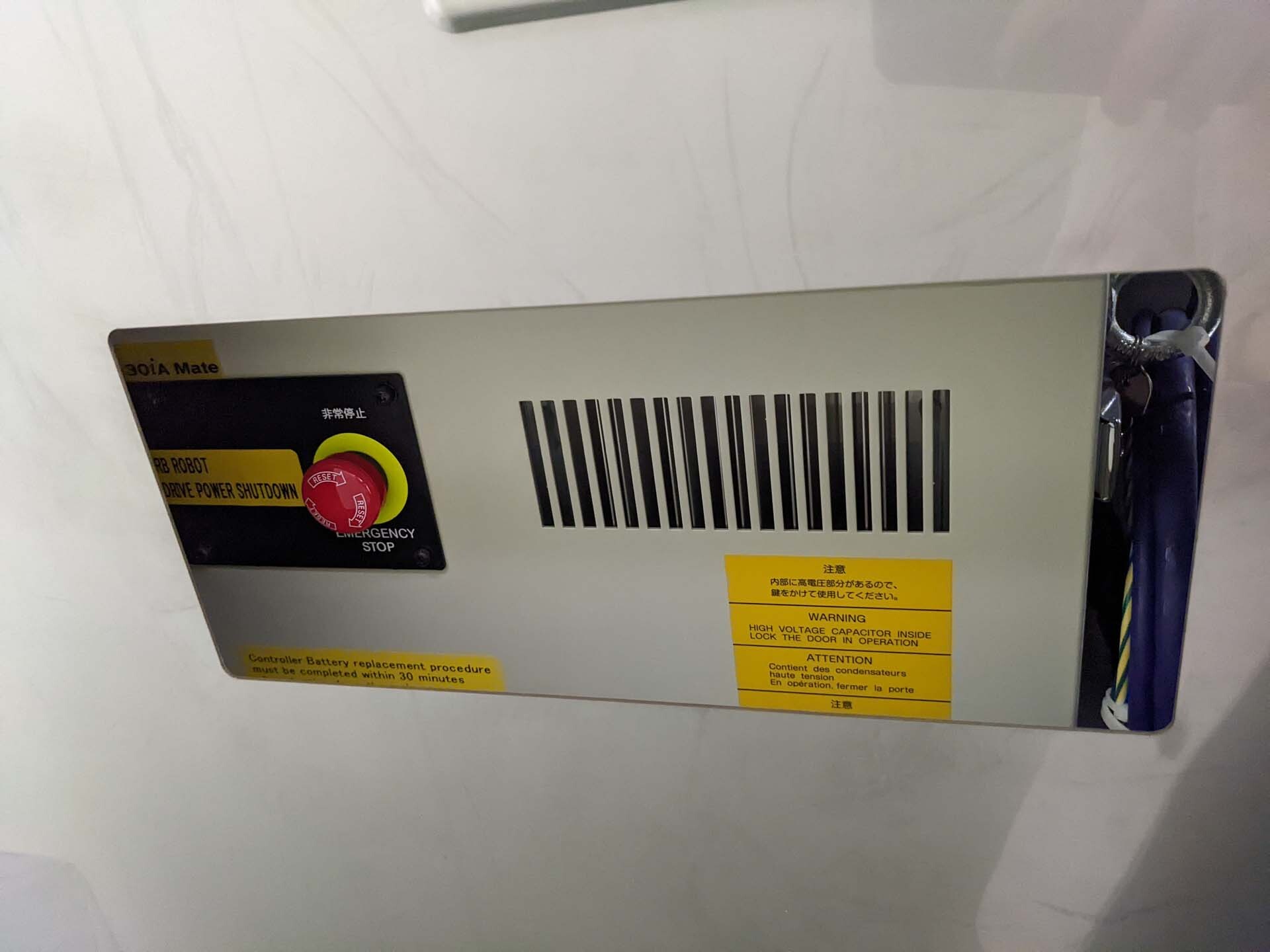

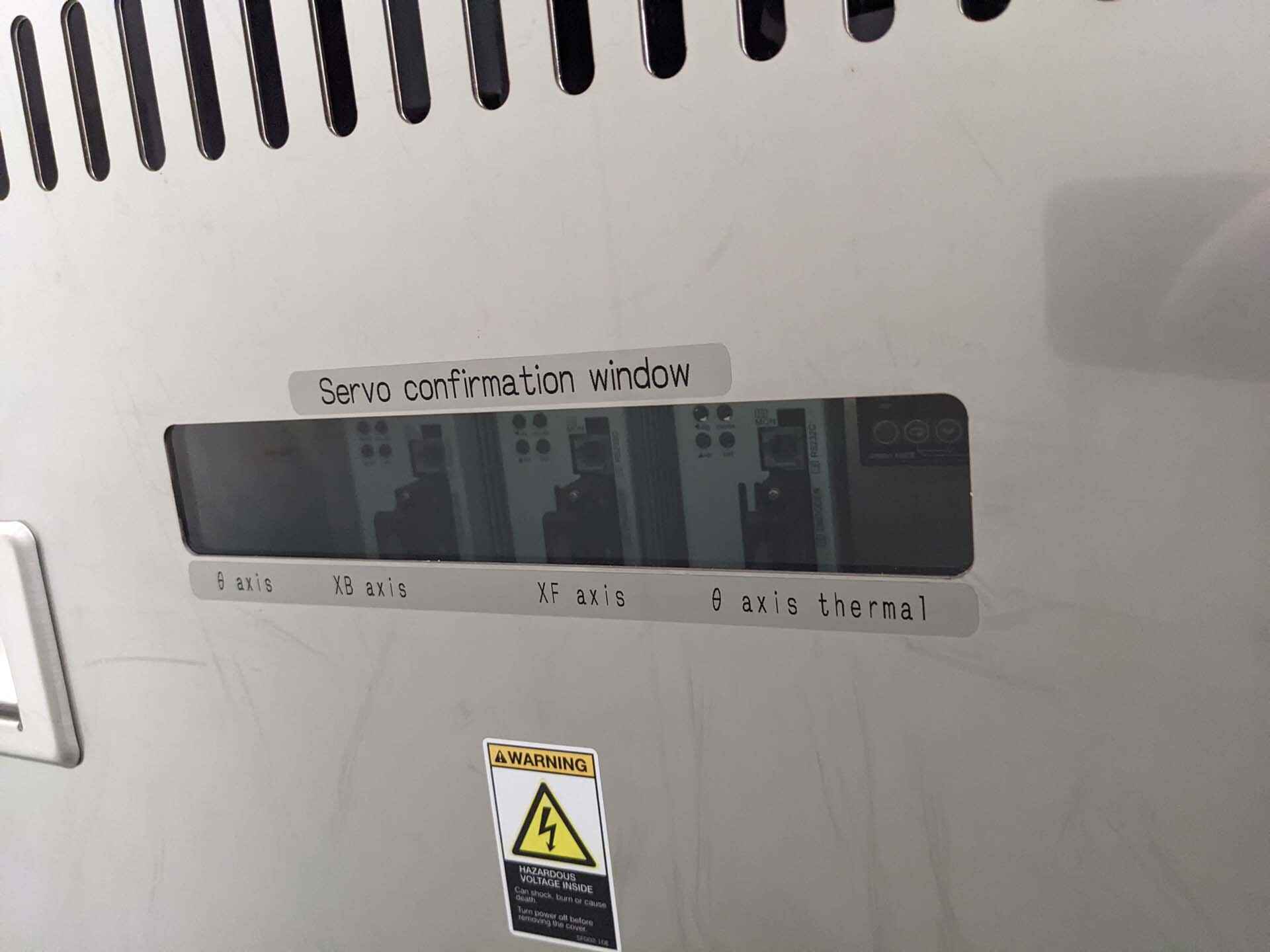

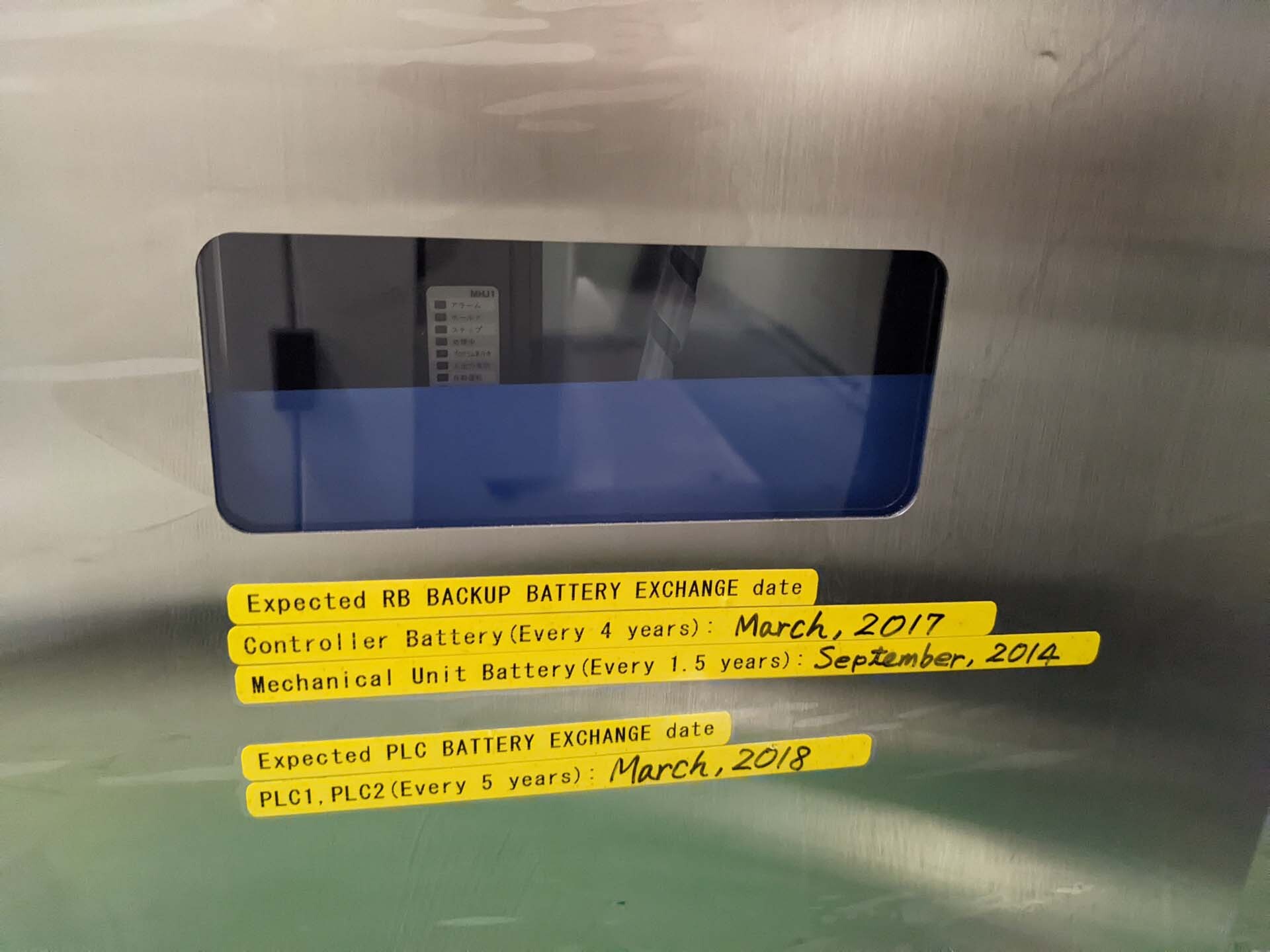

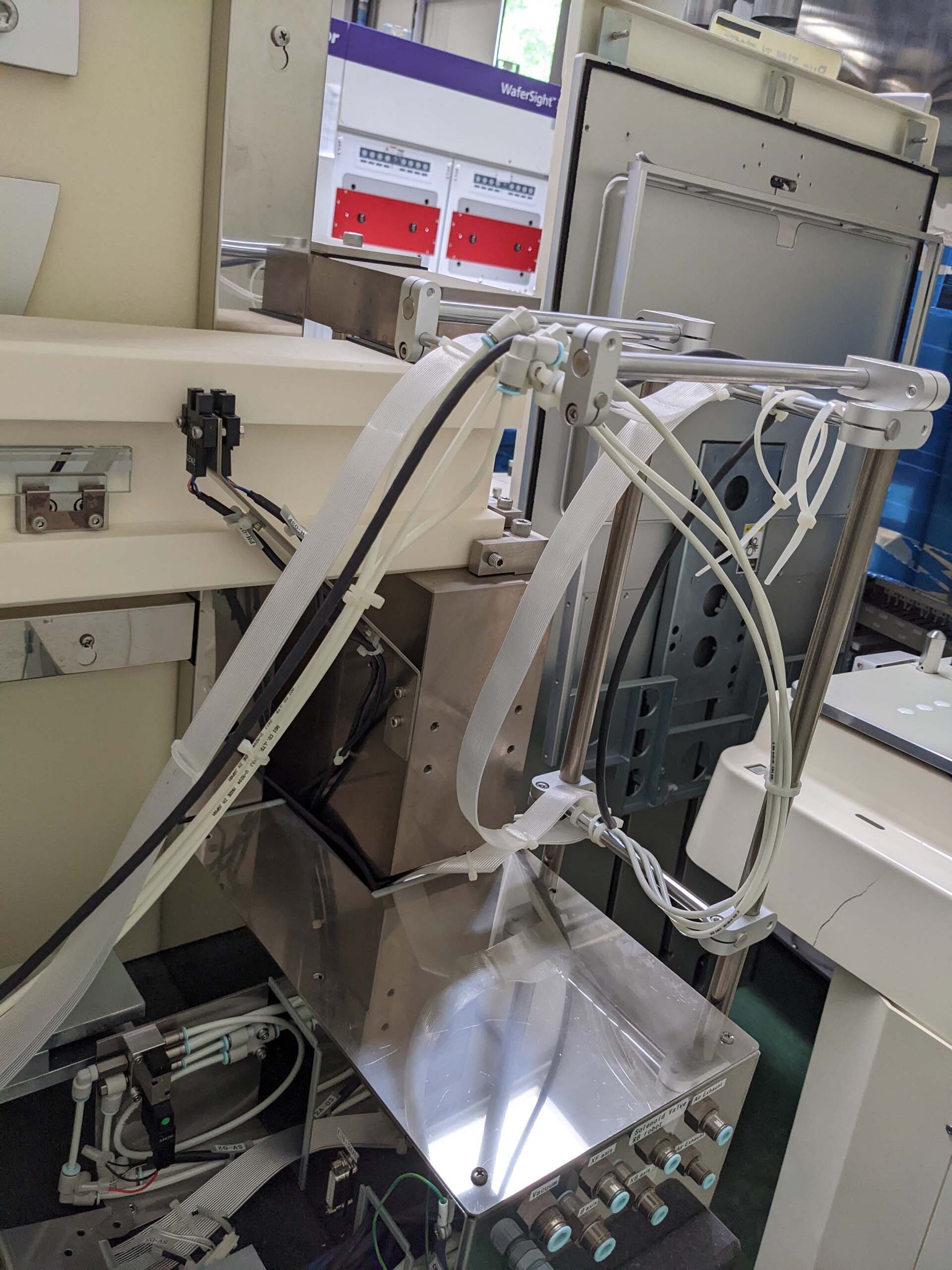

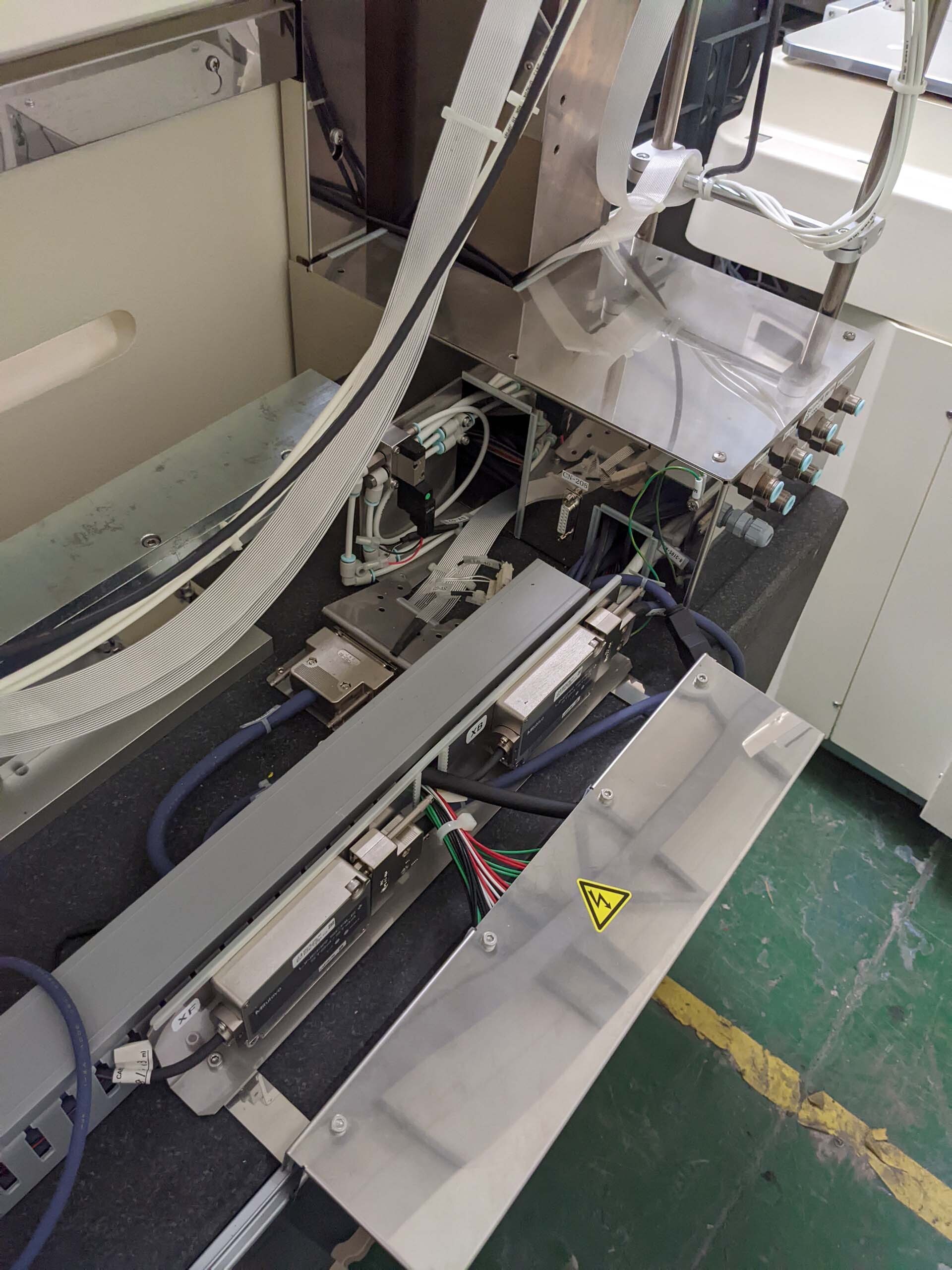

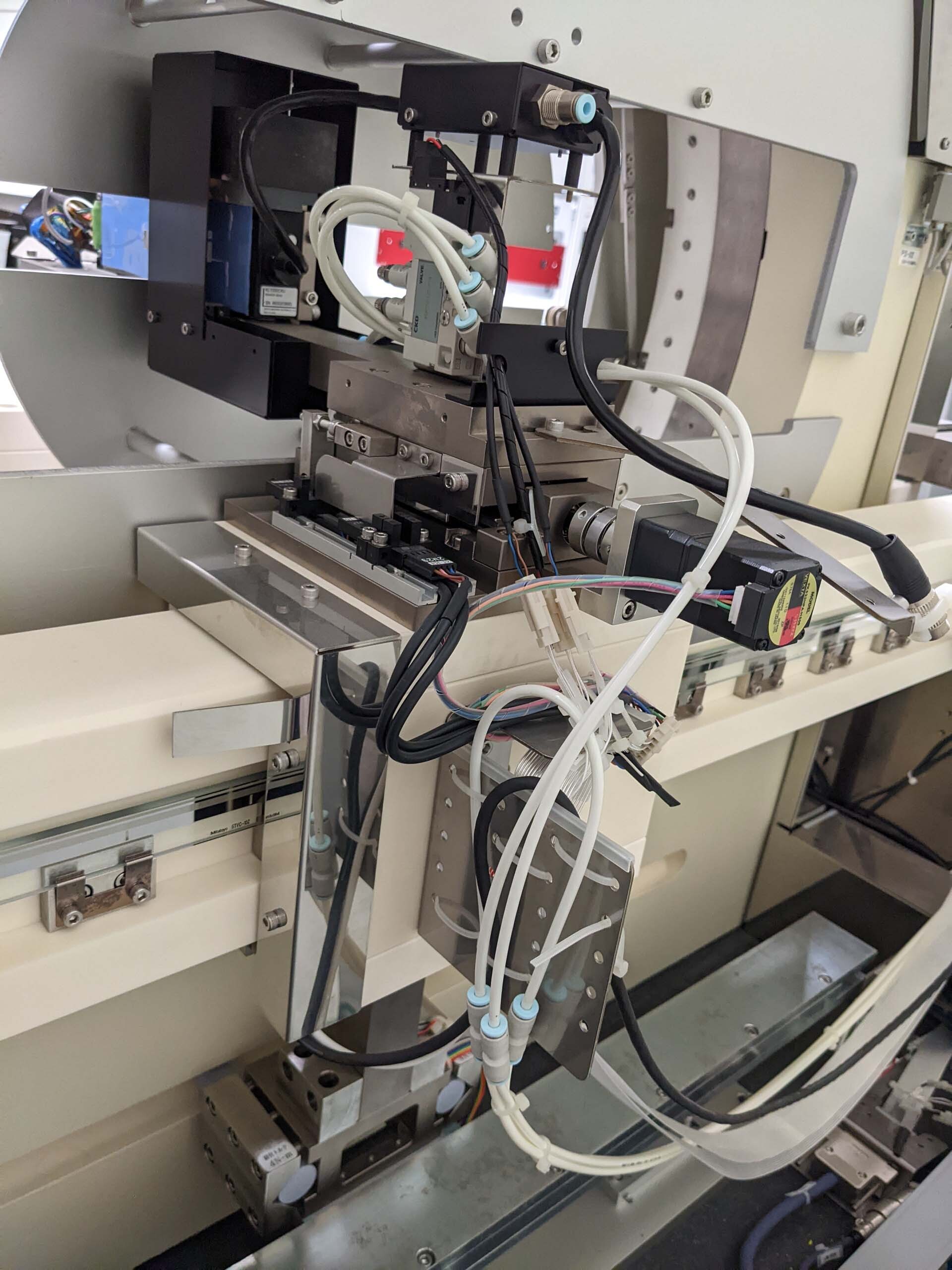

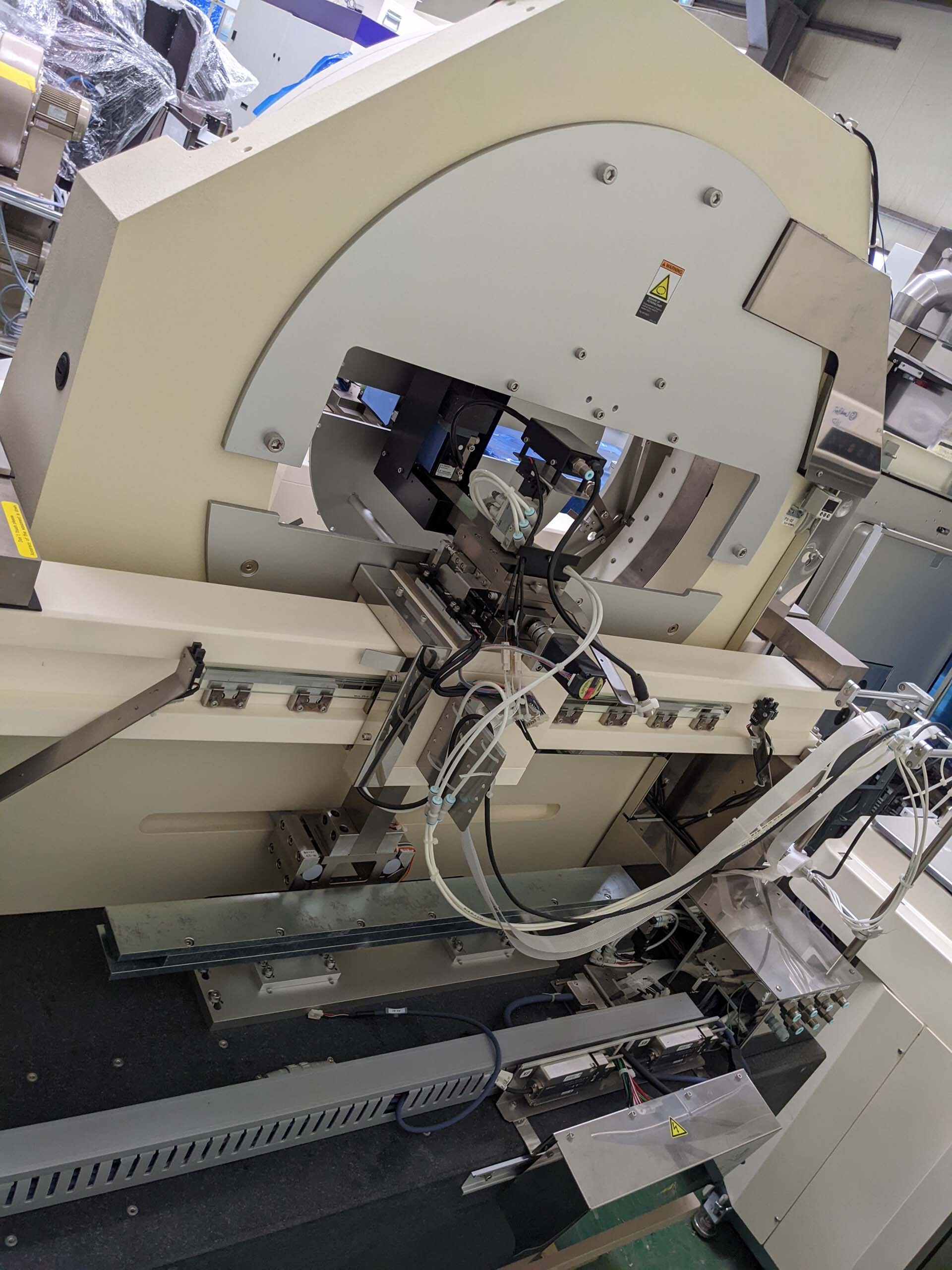

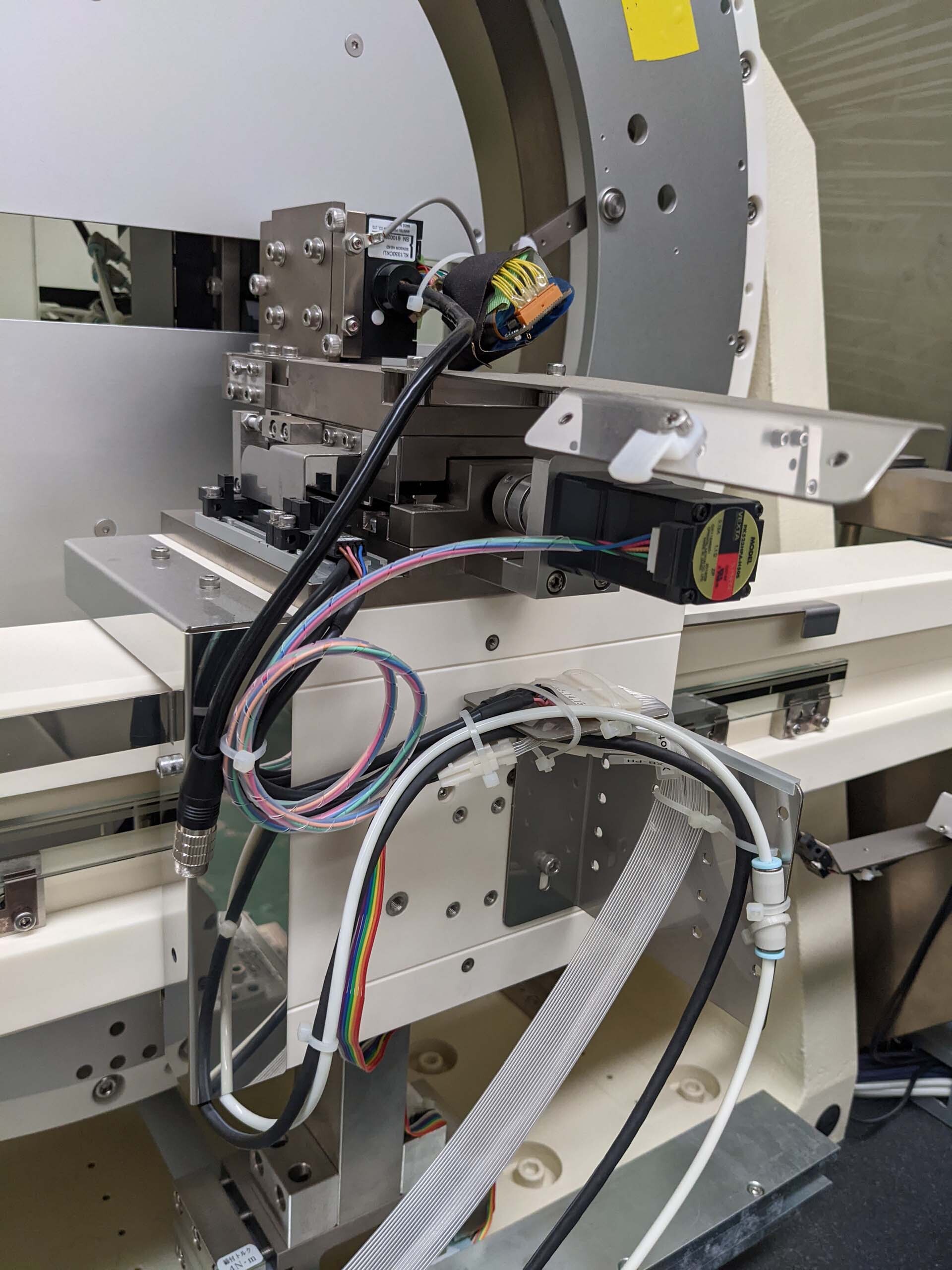

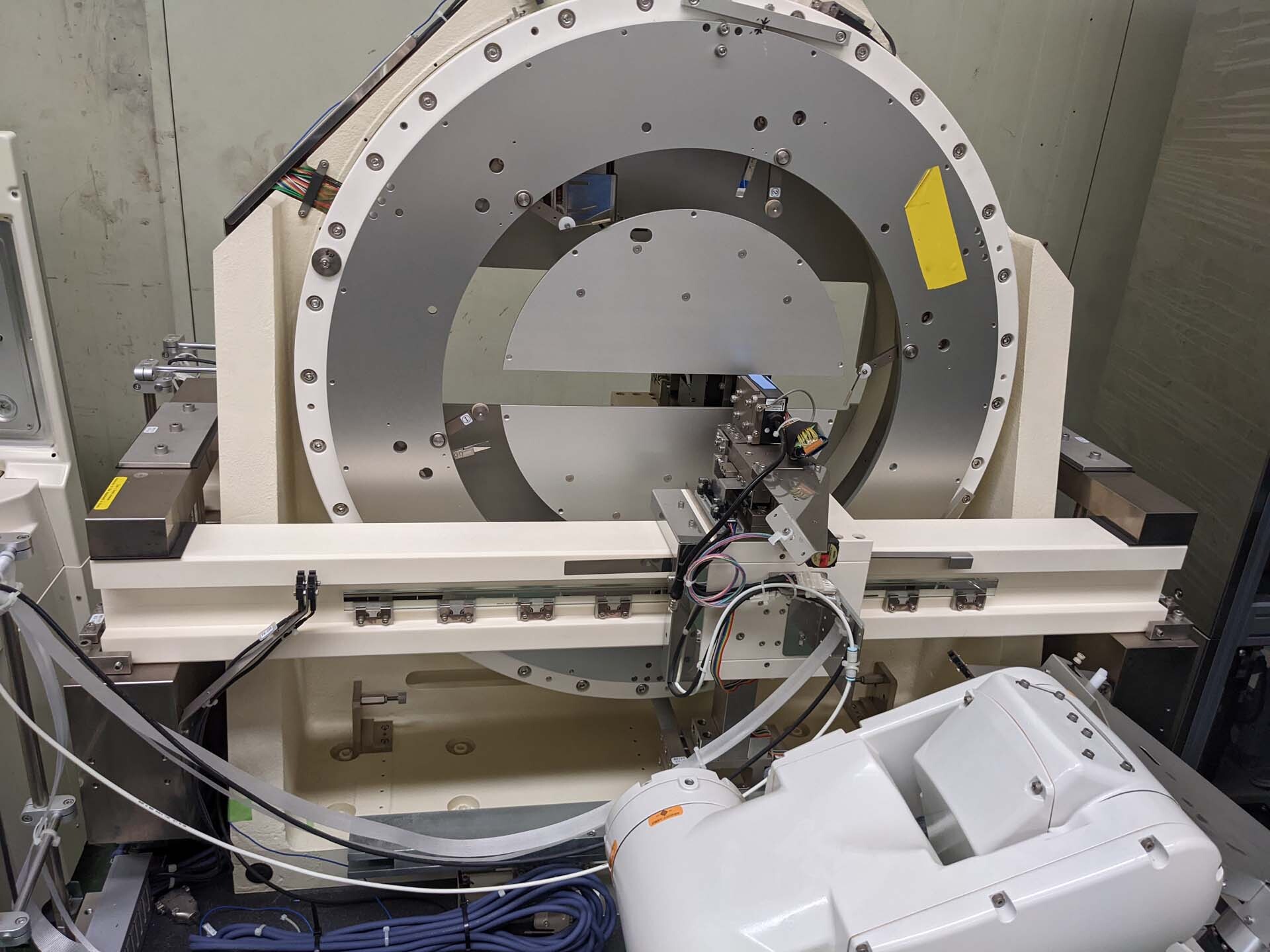

KURODA Equipment is a mask and wafer inspection System designed to help semiconductor manufacturers identify defects both on masks used for lithography and on the wafers themselves. This KURODA Unit is made up of two large modules: the Mask Inspector and the Wafer Inspector. The Mask Inspector is a highly accurate microscope that inspects pattern defects on photomasks before they are used in the lithography process. It uses advanced imaging technology such as optical diffraction, surface profilometry, and image modulation to check for faults. This Machine can detect minute pattern imperfections that would otherwise go unnoticed until after production. The Wafer Inspector inspects the planar surfaces of the wafer for any irregularities. It employs high-resolution optical imaging combined with high-precision reference measurements to detect any defects that might occur in the production process. By comparing the reference measurements to the image acquired, the Wafer Inspector can accurately determine if any issues exist. KURODA Tool has a number of advantages, including a comprehensive feature set that covers all aspects of mask and wafer inspection. It is also highly accurate and reliable, and its intuitive user interface makes it easy to use even for inexperienced operators. Additionally, Asset is highly customizable and can be tailored to fit the production needs of any semiconductor manufacturer. The cost-effectiveness of KURODA Model makes it a great choice for many semiconductor manufacturers. Its combination of features, accuracy, reliability, user-friendliness and affordability make it a great solution for quality assurance and defect identification. With its wide range of features and competitive pricing, Equipment is a great choice for a variety of mask and wafer inspection tasks.

There are no reviews yet