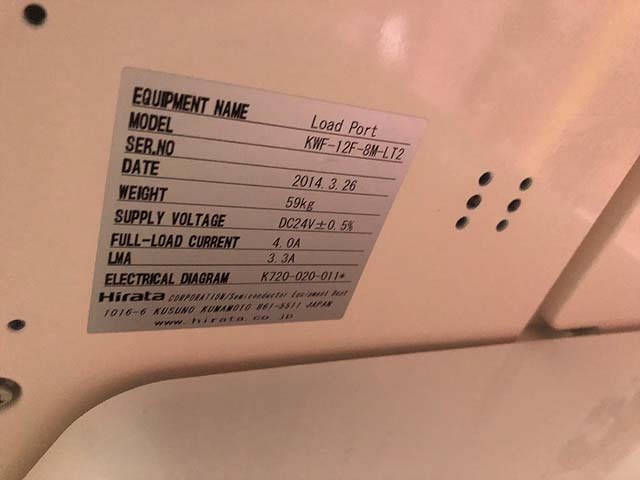

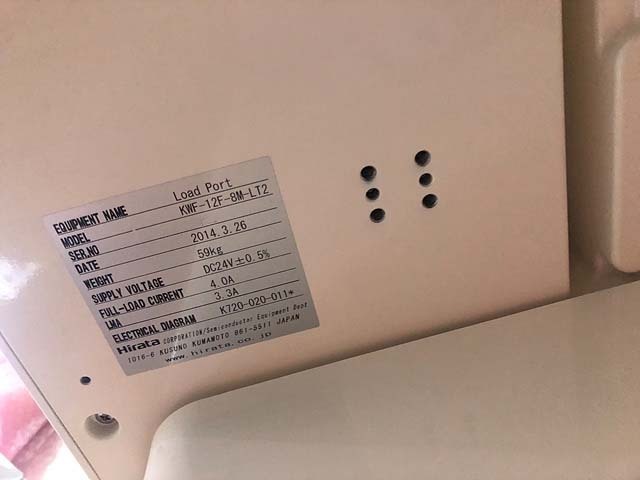

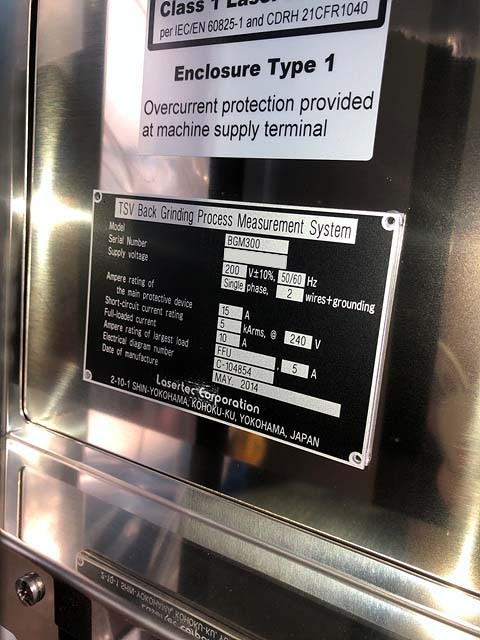

Used LASERTEC BGM 300 #293586631 for sale

URL successfully copied!

Tap to zoom

ID: 293586631

Wafer Size: 12"

Vintage: 2014

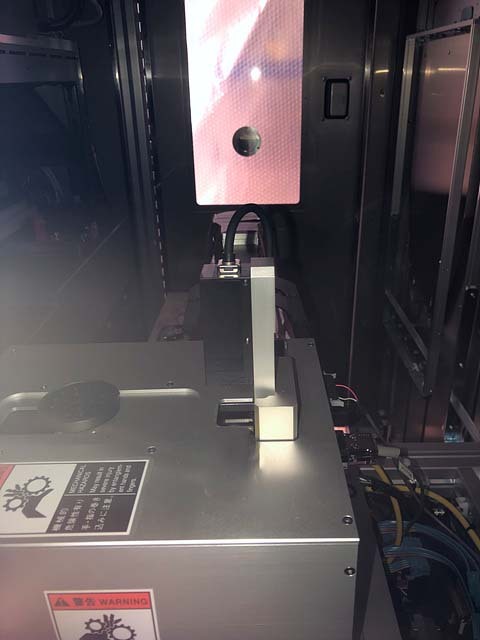

Wafer surface analyzing and visualization system, 12"

2014 vintage.

LASERTEC BGM 300 is a mask and wafer inspection equipment that uses photometric imaging and laser scanning techniques to measure and analyze thin layers of semiconductor materials. This system provides high-accuracy, precision performance, and is especially suited for mask and wafer process control in the production environment. The unit has a 2.5 inch scanner head, with a field of view that covers a whole mask or wafer in a single pass. This allows for fast and accurate real-time measurements. The laser light beam scans the entire surface of the workpiece, creating a digital two-dimensional image of the surface and recording its characteristics. The resulting image is then analyzed by advanced and powerful algorithms to check for features and process defects. When using BGM 300, high-precision accuracy is ensured with the help of a laser-marking machine. The laser-marking is integrated with the tool and provides a reliable reference point for inspecting the surface. This reference point then allows the asset to accurately measure and analyze the mask or wafer in real-time. The model can detect surface defects and faulted areas, allowing for easy process control and monitoring. LASERTEC BGM 300 equipment is designed for use in harsh environments like the production floor and offers a user-friendly and robust interface. It has built-in environmental sensors for environment monitoring and filtering, which optimizes the performance of the system and ensures a safe working environment. Additionally, the unit features an advanced ETL (Electronic Test Layer) feature that allows for efficient and accurate image captures and analysis. The machine is able to analyse the mask or wafer in different angles that include front, rear and side views, as well as stereo view. This allows operators to gain a complete picture of the geometry and surface of the mask or wafer. Furthermore, the tool's intelligent zoom capability enables accurate measurements of tiny objects and geometries. All the user control functions are accessible through a graphical user interface (GUI) as well as a serial port. In conclusion, BGM 300 is a mask and wafer inspection asset with technologically advanced features, offering accurate real-time measurements and high-precision accuracy. It is an ideal choice for process control and monitoring applications in the production environment.

There are no reviews yet