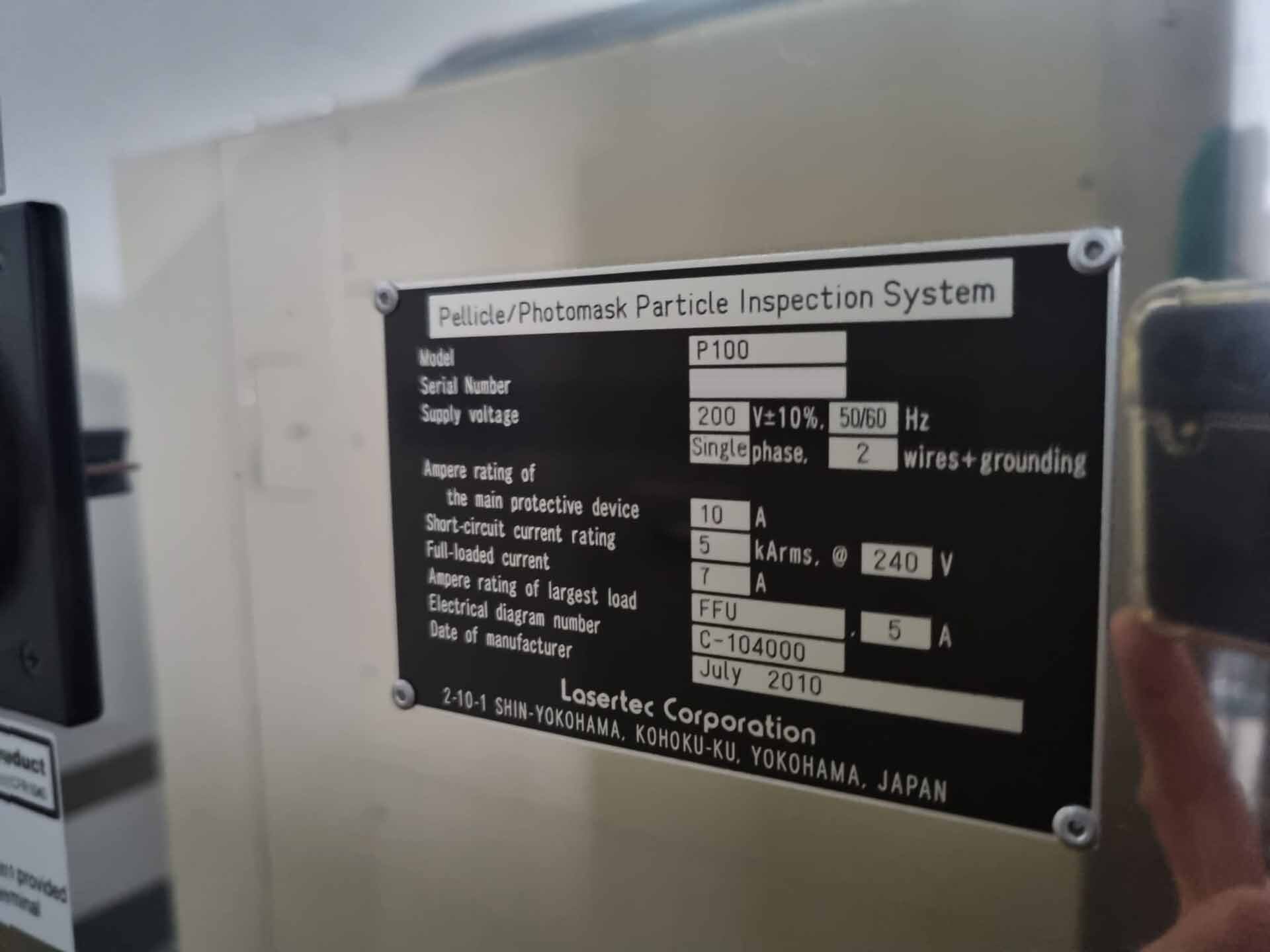

Used LASERTEC PEGSIS P100 #293625784 for sale

URL successfully copied!

Tap to zoom

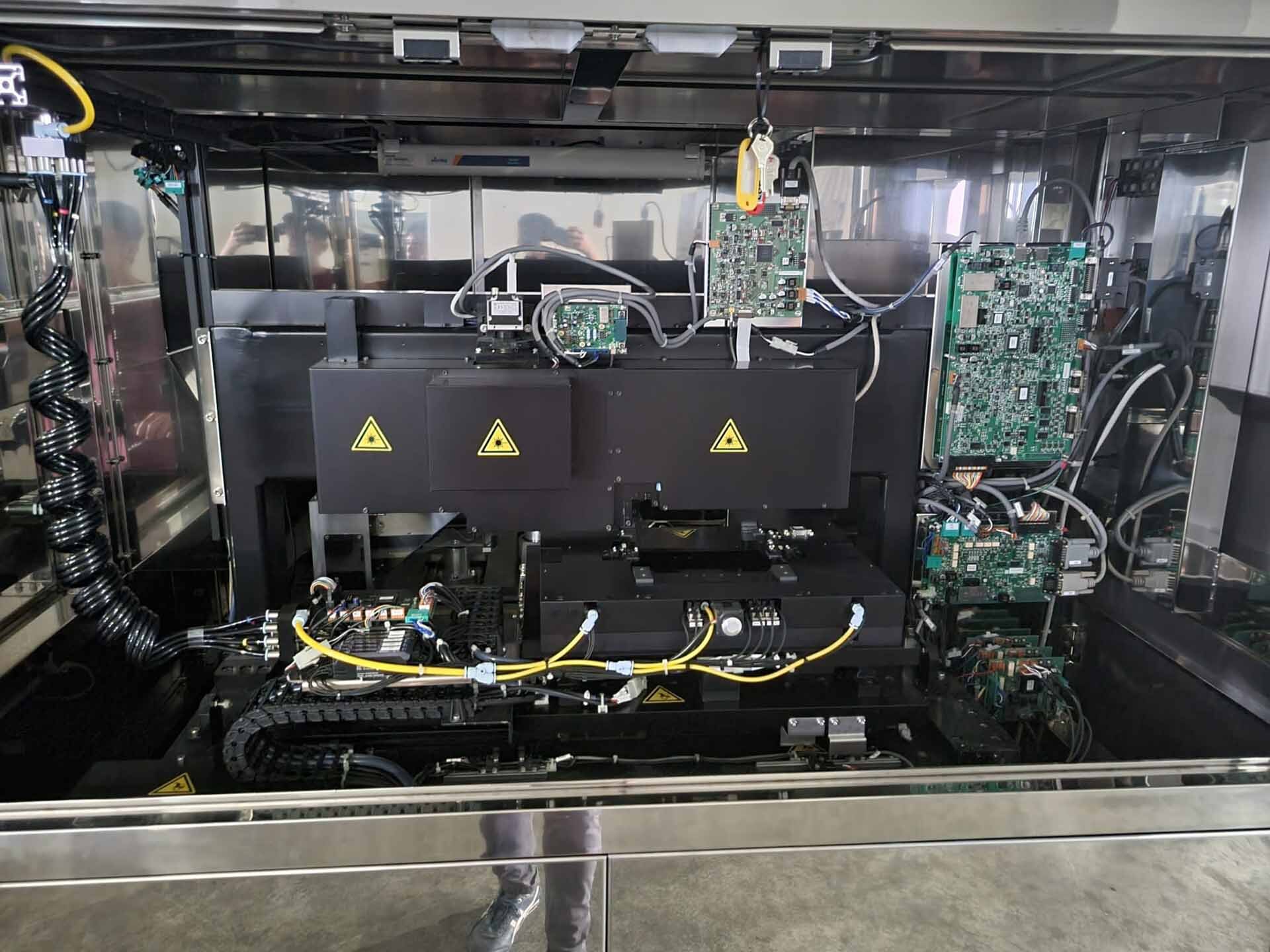

LASERTEC PEGSIS P100 Mask & Wafer Inspection Equipment is a high-end quality assurance tool designed to check and verify the integrity of masks and wafers during the fabrication process. It employs advanced laser scanning technology to accurately identify flaws, such as scratches, particles, and contamination, in the mask or wafer and then compares them to a reference layout. The system includes a pneumatically powered dual-source laser, which is comprised of both red and infrared lasers and uses their combined power to accurately identify and locate any contaminants. The laser beam scans the mask or wafer surface at 1,200 points per second and makes sure the reference layout is met. Once contaminants are identified and located, the unit can then verify their precise size, shape, and area coverage. The machine also offers an optional vision tool, which can be used to log and analyze defects, such as particles and other contaminants. The vision asset is equipped with advanced imaging and optics technology to provide high-resolution images and accurate sizing analysis. This allows it to identify even the smallest particles or contaminants that may escape the attention of the laser model. PEGSIS P100 is an incredibly powerful and versatile tool for detecting and correcting flaws, in both masks and wafers. With its combination of advanced laser, vision, and optics technologies, it can detect even the slightest flaws, providing you with invaluable insight into the integrity of the mask or wafer. Whether you are working on semiconductor fabrication or medical device fabrication, LASERTEC PEGSIS P100 is the perfect tool to help you maintain your quality standards.

There are no reviews yet