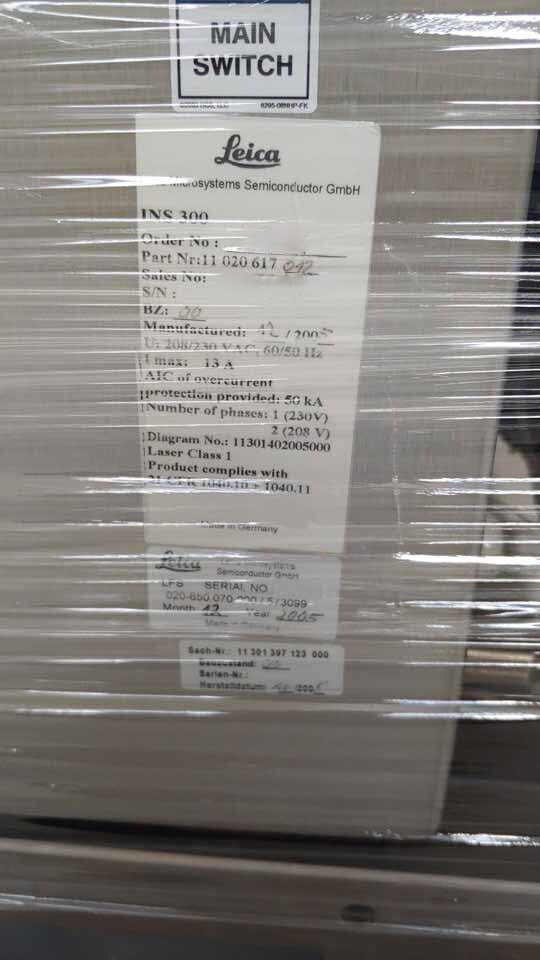

Used LEICA INS 300 #9298489 for sale

URL successfully copied!

Tap to zoom

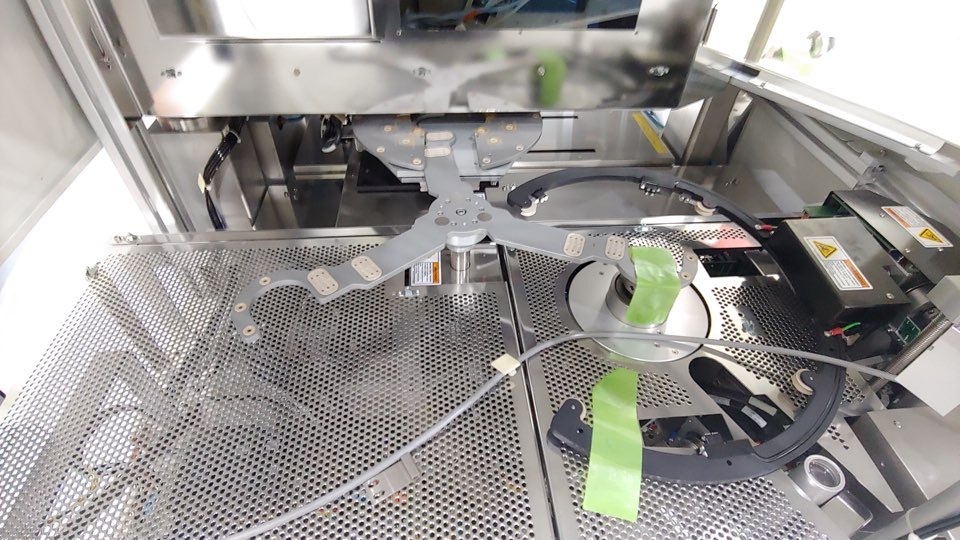

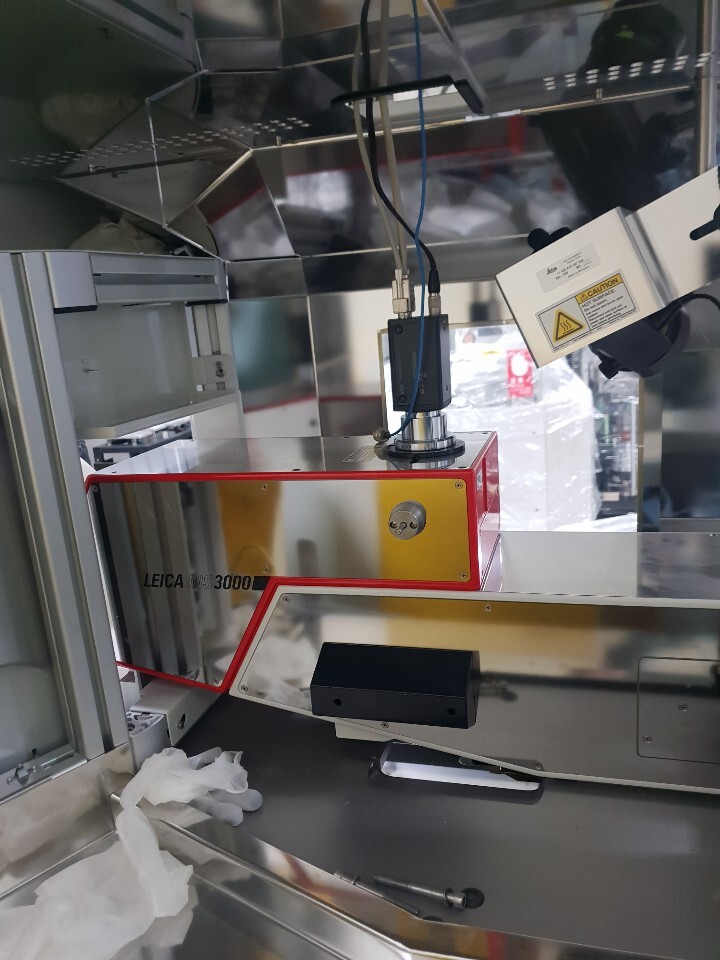

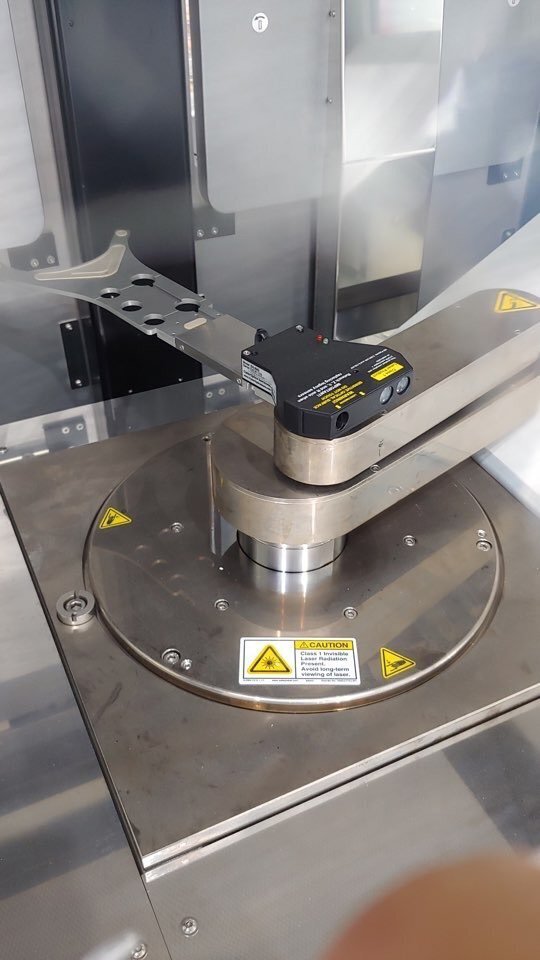

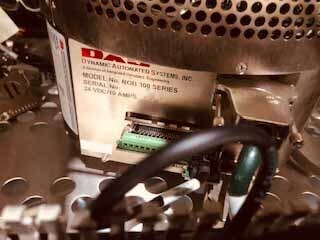

LEICA INS 300 is an state of the art, semiconductor metrology mask and wafer inspection equipment used in microelectronic fabrication. This highly specialized machine uses a combination of superior optics, high resolution imaging and precise motion controls to accurately evaluate the features needed for a wide range of mask and wafer applications. The machine features a vacuum-sealed, air-free environment that ensures optical clarity and a 30mm field of view. Its scanning laser assembly allows for a high degree of imaging accuracy, providing a resolution of up to 0.7 microns. In addition, the versatile digital imaging system can take up to 10 images per second, which ensures maximum fidelity of the images captured. INS 300 employs powerful custom software algorithms in order to optimize its imaging and analysis capabilities. Its sophisticated algorithms allow it to quickly identify and analyze patterns and defects through a variety of standard and proprietary techniques. These include Optical Resolution Imaging Measurement (ORIM), Fourier-transform Infrared (FTIR) spectroscopy, and Digital Cross Correlation (DCC) techniques. It also offers its users the ability to create their own custom algorithms to meet specific requirements. To further enhance its accuracy and reliability, LEICA INS 300 is equipped with various motion controllers, servo motors, and accelerometers. These components allow the unit to quickly and precisely adjust the sensitivities of different motions for different conditions. INS 300 guarantees overall performance, reliability, and accuracy. It is an ideal choice for a wide variety of inspection tasks, from basic optical testing to complex metrology applications. With its superior machine architecture and precise measurements, it can help ensure that masks used for fabrication have the highest possible level of functionality.

There are no reviews yet