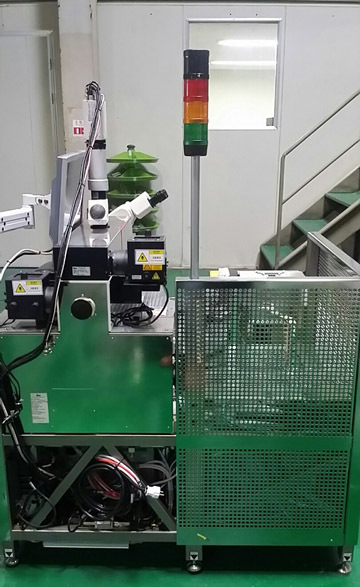

Used LEICA INS 3000 #9148695 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9148695

Wafer Size: 8"

Wafer defect inspection system, 8"

Open cassette

150x / 0.95 APO

100x / 0.90 APO

50x / 0.85 APO

10x / 0.30 HCPL

5x / 0.12 PL

5x / 0.90 PL.

LEICA INS 3000 is a powerful mask and wafer inspection equipment designed for both wafer and reticle fabrication. It uses both advanced imaging techniques and proactive mathematical algorithms to detect subtle defects in wafers and reticles. The system incorporates a highly sensitive, wide-gamut color imaging unit and a patented high frequency algorithm that detects the appearance of small particles, both on the wafer and reticle. The imaging machine captures a high-quality color, wide-gamut image of the wafer at every pixel on the wafer's surface. Through the use of sophisticated darkfield optics which allows the tool to detect amplitude and phase defects, any contaminants that may be present on the wafer are rendered more apparent. The imaging asset also features a patent pending active measurement structure which allows for accurate pixel registration and ensures that the image is free from distortion and blurring. Through this feature, the model ensures that the images it captures are of the highest resolution and clarity. LEICA INS-3000 is designed for efficiency and accuracy. It features several automated inspection cycles, which customize the inspection to the customer's specific needs. This ensures repeatable and accurate results, both in terms of the wafer and reticle inspection tasks. The equipment is also built with an Advanced Process Control (APC) capability, which allows the system to be configured to diagnose and correct detected defects with high accuracy and precision. INS 3000 also incorporates wafer edge control technology. This feature ensures that the wafer's perimeter is correctly and accurately aligned with the reticle pattern in question. Furthermore, the unit is designed with dual-step process control. This ensures that even the slightest anomaly is detected and isolated with greater speed and accuracy than ever before. The machine has a skilled, intuitive user interface to facilitate operation and ongoing support. Through a series of intuitive functions and features, operators are able to manage inspection tasks accurately and effectively, as well as analyse data and monitor progress in real-time. The tool also has built-in diagnostics to provide troubleshooting information in the event of an issue. In summary, INS-3000 is a powerful mask and wafer inspection asset designed for wafer and reticle fabrication. It is capable of accurately detecting and isolating subtle defects with industry leading precision. The model provides excellent features including automated inspection cycles, APC capabilities, wafer edge control technology, and dual-step process control. It also offers an intuitive user interface for ease and flexibility of use, as well as troubleshooting and diagnostics capabilities.

There are no reviews yet