Used LEICA / VISTEC DM5500B #9161873 for sale

URL successfully copied!

Tap to zoom

ID: 9161873

Vintage: 2008

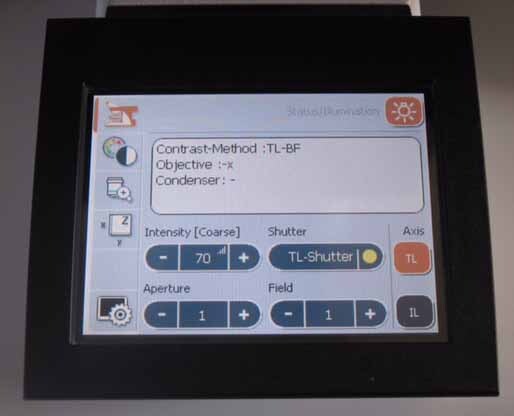

Microscope system

(2) HC Plans 10x/25 Eyepieces

(3) Objectives:

HCX PL Fluotar 40x/0.75

HCX PL Fluotar 20x/0.50

HCX PL Fluotar 10x/0.30

6-Place turret (manual)

Condenser (automated)

Trinocular head

100 W Lamp / Lamp housing

Prior H101A motorized stage

LEICA CTR5500 Electronics box

LEICA Smartmove stage joystick

Q-Imaging micropublisher MP5 5 MP CCD camera

DELL Optiplex 755 PC

17" DELL Flat panel monitor

Keyboard

Optical mouse

Objective imaging OASIS-4i controller

Objective imaging OI-SNP interface card

Objective imaging motion controller driver / Software

Oasis surveyor & turboscan mosaic imaging software

OS: Windows XP

Q-Imaging Q-capture image capturing software

2008 vintage.

LEICA / VISTEC DM5500B is a high-precision, comprehensive mask and wafer inspection equipment that provides a comprehensive analysis of the pattern and design of integrated circuit components. LEICA DM5500B accurately measures a wide range of devices, including thin dielectric films, submicron field structured elements, and photomasks. The system covers a wide range of wafer sizes up to 300 mm, at a multitude of magnifications. It features a powerful computer-controlled scan unit to ensure consistent and reliable data for quality analysis. The machine's automated scanning capabilities allow operators to quickly inspect and analyze the pattern geometry, measurements and defects of thin-film layers, isolated features, and alignment registration parameters. The built-in reporting function reports each scan automatically and can be shared electronically. VISTEC DM5500B provides advanced measurement and defect analysis capabilities, enabling users to qualitatively and quantitatively analyze parameter trends such as matching, overlay, contact hole shape, and line /space geometry. For complete characterisation and data correlation, the tool's array and wafer mapping options indicate the coordinates of potential defects with complete confidence. These results can be immediately monitored and analysed along with other test data. In addition, placement accuracy can be observed with the pre-characterised wafer template, which can be quickly loaded into the asset from a file and scanned on the segmented wafer. DM5500B inspects wafers with its high resolution digital optics and diffractive imaging technology, which enables an enhanced depth of focus and high image quality, while protecting the integrity of the exposed patterns. The model compliantly both reads and writes OPC (Optical Proximity Correction) in either a pseudo-stepper or a mirror-stepper platform, enabling detailed effectiveness checks of the OPC processes. The equipment is equipped with built-in productivity-enhancing features, such as the Start-up Screener and the integrated report manager. These functions can be tailored to the users' specific requirements, so that the system can be set up for optimum performance. The Start-up Screener can be used for quick mask quality control, and automated report generation. The optional advanced defect clustering function allows further characterisation of "peculiar" defects, while the automatic defect classification tool assists with improved quality control process. What's more, LEICA / VISTEC DM5500B supports remote inspection/analysis capabilities, allowing experienced operators to directly access and run the unit, and review data and analyses across many users. This enables users to quickly identify any required processes, or emerging trends, helping to continuously improve production yields. Coupled with its robust yet easy to use software, LEICA DM5500B is a powerful and comprehensive mask and wafer inspection machine. The tool provides users with the accuracy and precision needed for comprehensive pass/fail testing with confidence.

There are no reviews yet