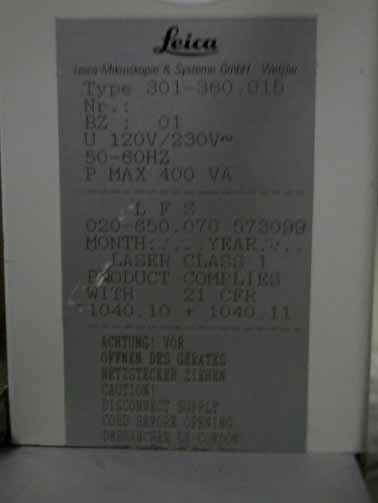

Used LEICA / VISTEC INS 1000i #9265479 for sale

URL successfully copied!

Tap to zoom

LEICA / VISTEC INS 1000i is a mask & wafer inspection equipment designed to enable high-precision surface and profile inspection for semiconductor manufacturing. The system can be used for a variety of QC and research applications, including die-bond, metalization, lithography, metrology, and defect inspection. LEICA INS 1000i utilizes a powerful combination of microscope optics, digital signal processing, and advanced algorithms to obtain high-resolution images and analysis. The unit features a 30-million-pixel camera that is optimized to capture clear images down to 1μm in size without blurring or distortion. This enables accurate, detailed imaging of a range of semiconductor materials, including oxide, metal, or dielectric materials. The machine is capable of surface inspection, wafer inspection, and profile measurement in one package. It is equipped with a 6-axis scanning stage capable of scanning at up to 100mm/second, allowing high-speed inspection and analysis. The tool also features a built-in SD and HD scan modes, allowing for fast inspection times and maximized throughput. VISTEC INS 1000i offers automated beat matching for wafer edge detection and analysis. This feature is designed to eliminate false-positives during wafer inspection. The asset also features automated measurement and analysis of wafer flatness and particle size. Its edge enhancement and contrast enhancement capabilities ensure that the differences between target material and non-target particles can be seen easily. INS 1000i is designed with user-friendly operation software that requires minimal training or expertise. It features fully automated set up routines for easy selection of parameters without manual adjustment or calibration. The user-friendly interface allows quick and easy operation with the model. In conclusion, LEICA / VISTEC INS 1000i is an advanced mask & wafer inspection equipment intended for semiconductor fabrication. Its 30-million-pixel camera, 6-axis scanning stage, and automated beat matching capabilities ensure high-resolution imaging and accurate inspection down to 1μm in size. It also features automated measurement and analysis, edge enhancement and contrast enhancement capabilities, and a user-friendly operation software with automated set up routines.

There are no reviews yet