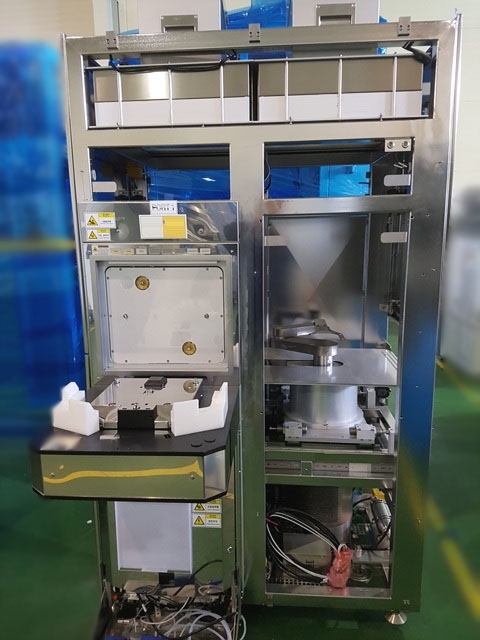

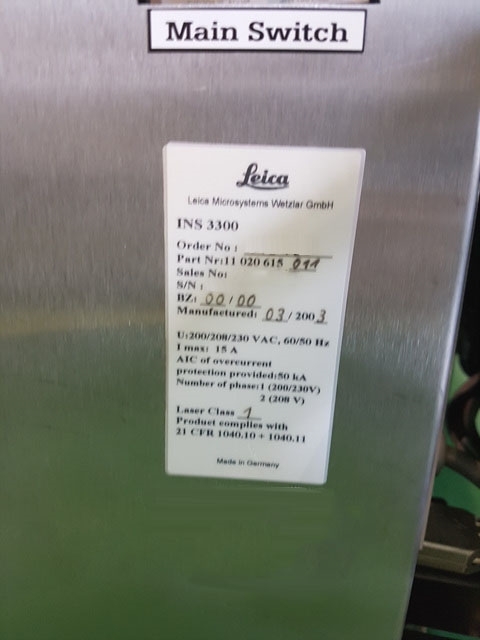

Used LEICA / VISTEC INS 3300 #9043674 for sale

URL successfully copied!

Tap to zoom

ID: 9043674

Wafer Size: 8"-12"

Vintage: 2003

Wafer inspection system, 8"-12"

2003 vintage.

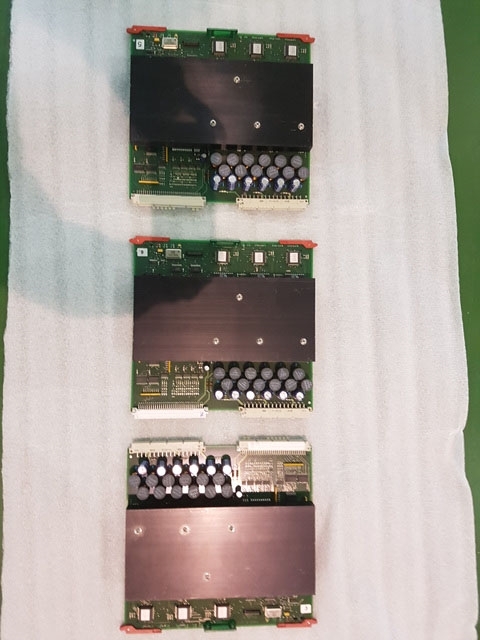

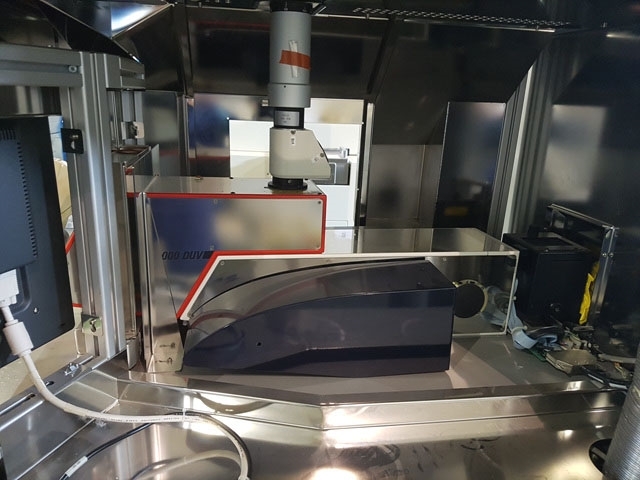

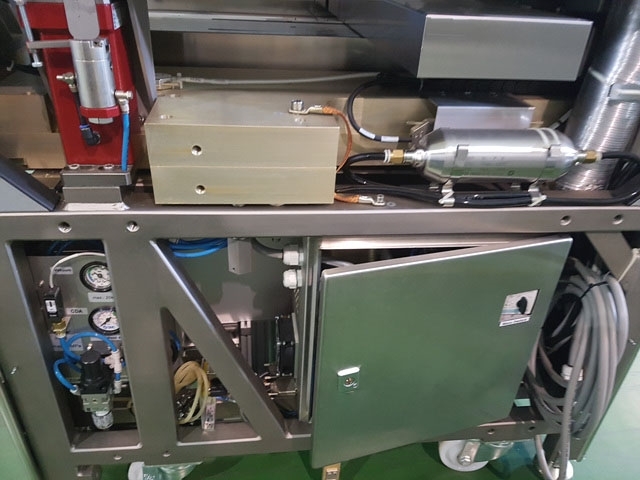

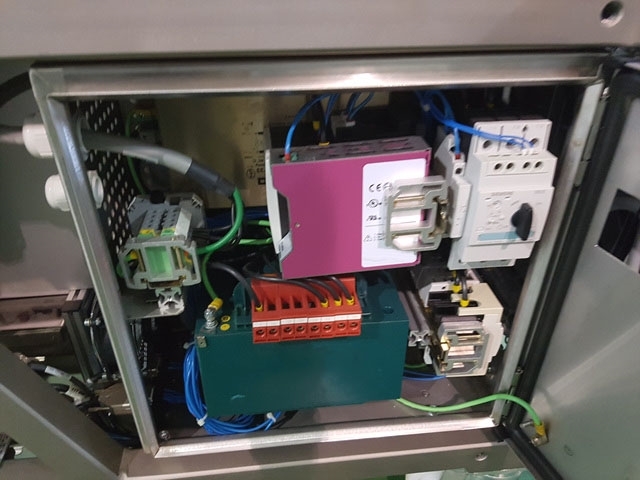

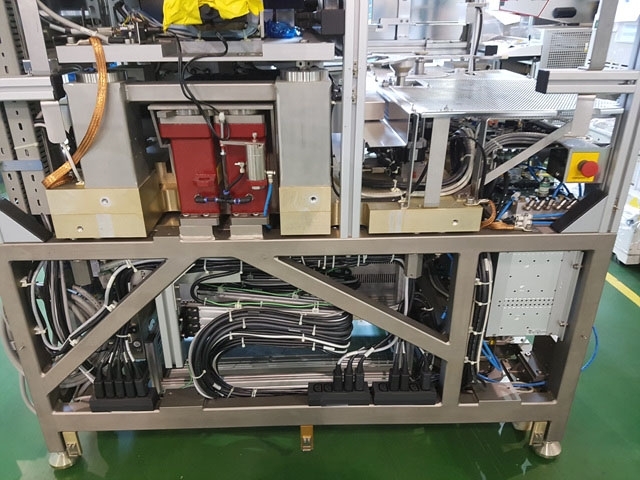

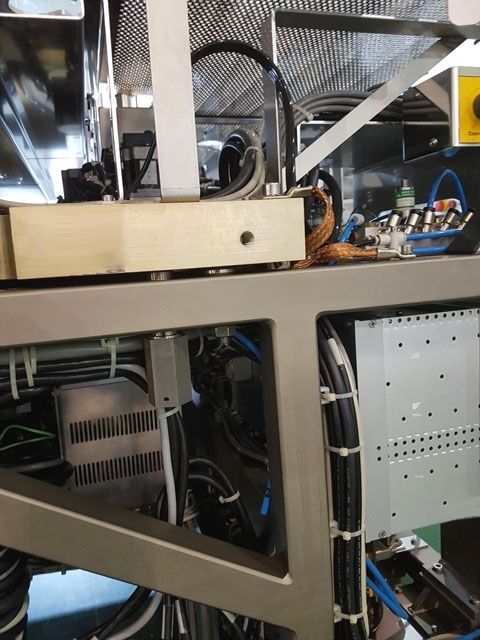

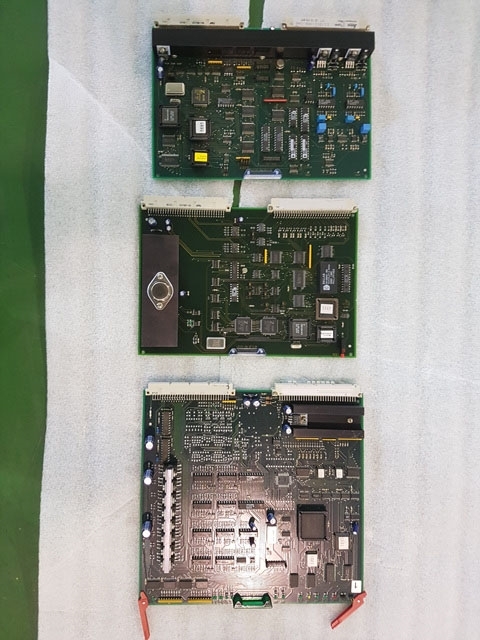

LEICA / VISTEC INS 3300 is a mask and wafer inspection equipment that is designed to analyze semiconductor masks and wafers for manufacturing yields, defect detection, and failure analysis. It is a fully automated, high speed imaging and inspection system that combines excellent resolution and high throughput while ensuring that all defects are correctly classified without false positives. The unit utilizes an automated, 13-megapixel CMOS sensor that quickly captures images of the mask/wafer at full 1x field-of-view magnification for in-depth inspection. It also provides multi-view detection to recognize and classify potential defects. By automatically adjusting light levels and exposure times, the machine ensures accurate and consistent image capture and inspection results. The tool is capable of inspecting a mask/wafer in both transillumination and backside irradiation. This automated illumination process provides consistent light intensity and illumination angle, thereby ensuring that all features on the mask/wafer are inspected with the same accuracy and resolution. The asset is equipped with Image Toolbox software that allows data analysis and programming. Based on this software, the model can be calibrated to detect various features, analyze images for defects, and report results. This software also supports data archiving, alpha particle mapping, and defect classification. The Inspect 3300's advanced technology makes it an ideal choice for manufacturers that require systematic, uniform inspection of their masks and wafers. It is equipped with precision optics, software, and hardware components designed to provide maximum accuracy and speed. Moreover, its advanced imaging and inspection capabilities make it a suitable choice for high-demand applications.

There are no reviews yet