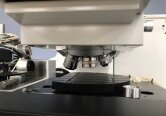

Used LEICA / VISTEC MIS 200 #9287263 for sale

URL successfully copied!

Tap to zoom

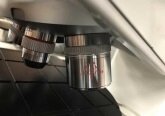

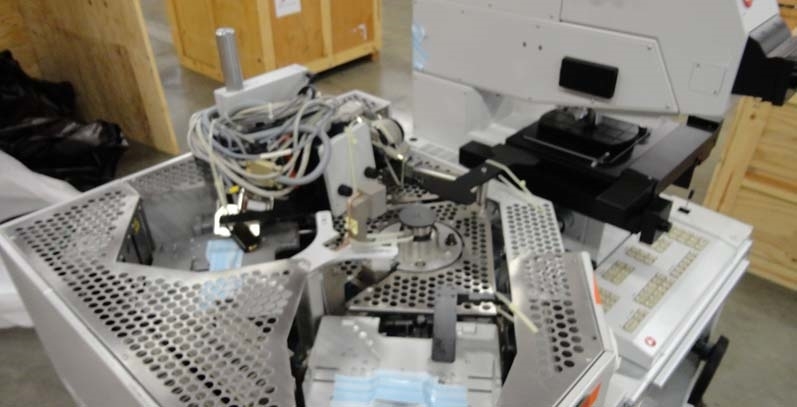

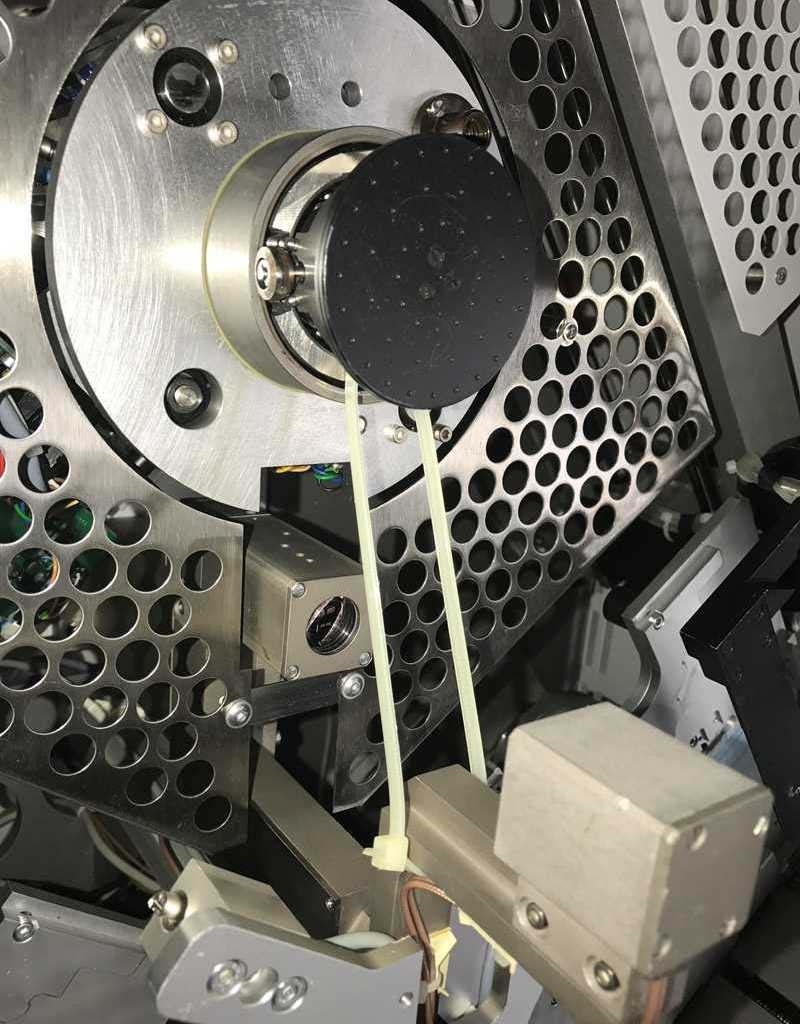

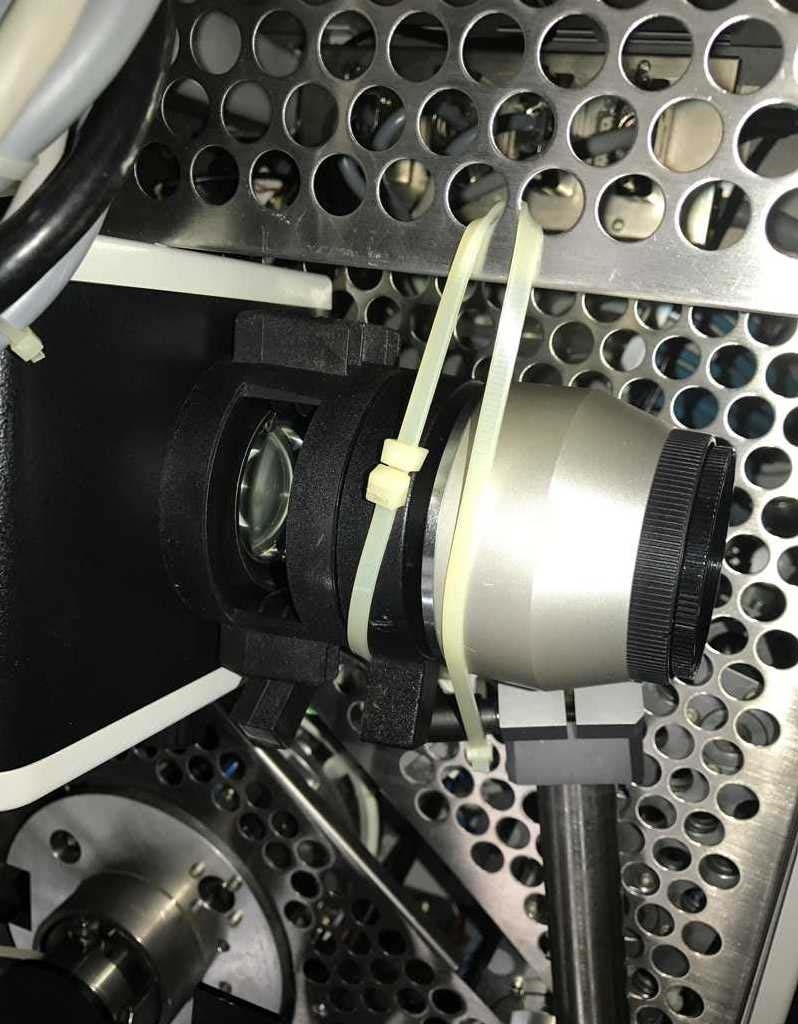

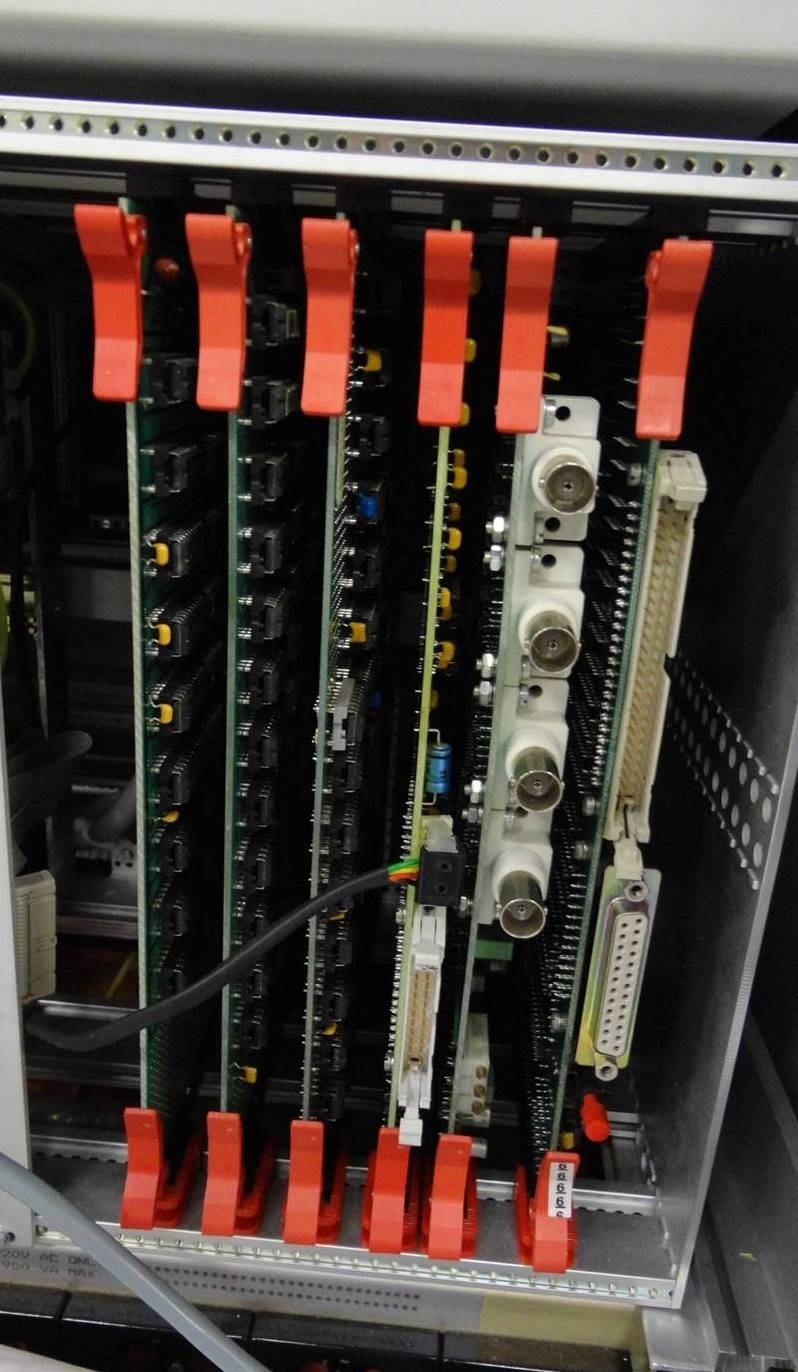

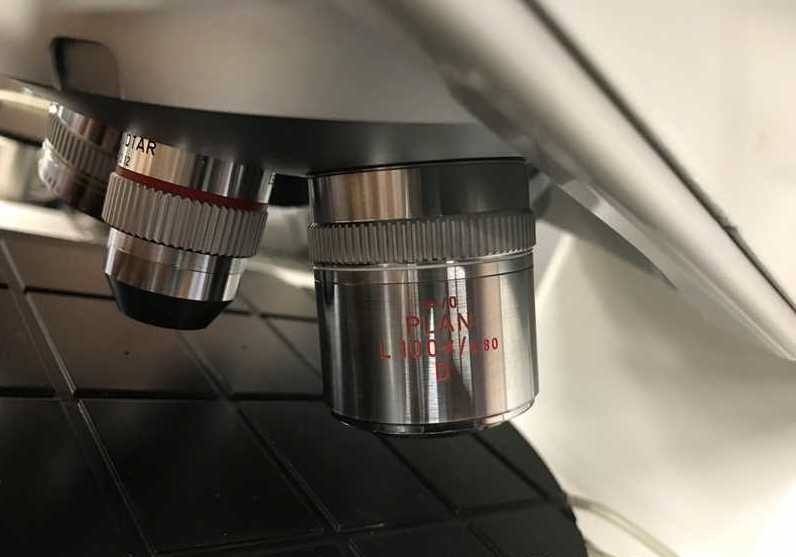

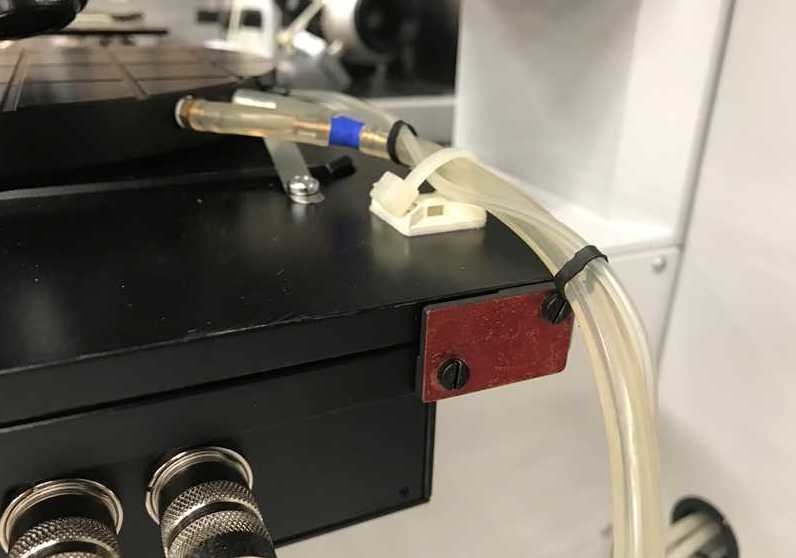

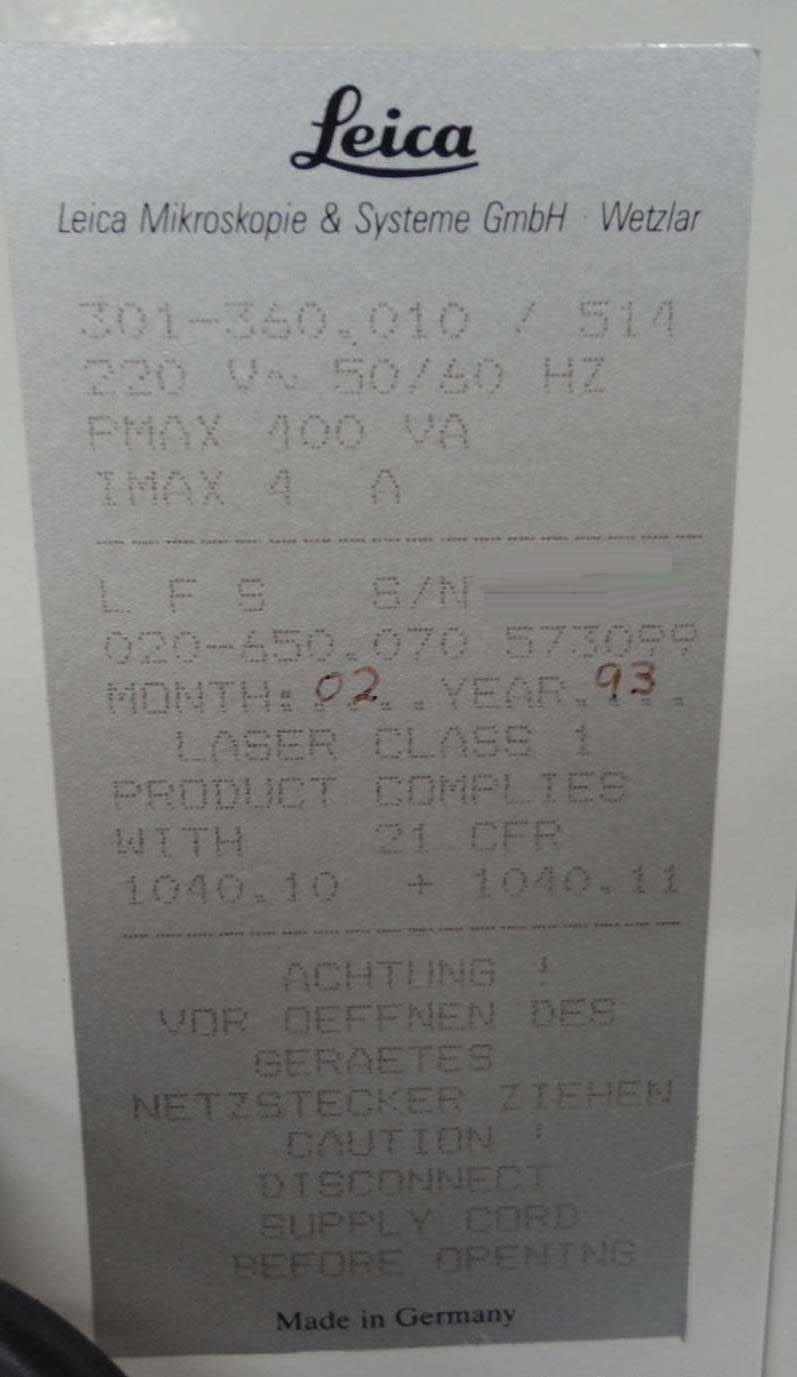

LEICA / VISTEC MIS 200 is a mask and wafer inspection equipment from LEICA series of inspection tools. The system provides a combination of automated inspection, optical variable micro imaging, and defect moving window inspection for rapidly identifying defects in both masks and wafers. The unit offers high resolution, multiple magnification levels, and fast reconstruction times which enable the user to accurately identify defects and potential problems quickly. The machine utilizes an incoherent strobe illumination with a unique light sheet design, which ensures a homogeneous illumination throughout the mask or wafer. This ensures that all points are uniform and equally illuminated and provides a high accuracy and precision of results. LEICA MIS 200 also allows for a wide variety of multi-dimensional and multi-level imaging modes such as real-time video inspection, line scan, and back side metrology. By making use of these features, the user can quickly analyze complex features on the mask or wafer, such as contact holes, line definitions, line widths, and the space between the lines. VISTEC MIS 200's automated analysis tools allow for automatic identification and classification of defects, from which the user can understand their probable cause. Additionally, the tool is able to automatically measure line widths and spaces, depth, and circularity of defects, allowing for more accurate results. Furthermore, the asset can allow for a detailed comparison of the mask and wafer to determine any differences between the two. Finally, the model also provides a powerful defect diagnostic application, which can detect and classify patterns and anomalies. This is an incredibly useful tool, as it can help the user identify structural defects and any other problems that could potentially interfere with the production process. Additionally, MIS 200 also provides a spectral optical metrology equipment, which can measure features such as line definition and fluctuations in the optical characteristics of the mask or wafer. Overall, LEICA / VISTEC MIS 200 is an incredibly powerful Mask and Wafer Inspection System that allows users to quickly and accurately analyze masks and wafers for defects. The unit offers a combination of automated inspection, optical variable micro imaging, and defect moving window inspection, as well as a range of multi-dimensional and multi-level imaging modes and a powerful defect diagnostic application. As such, the machine is extremely useful for quickly and accurately pinpointing defects and potential problems on masks and wafers.

There are no reviews yet