Used LEITZ Ergolux #60381 for sale

URL successfully copied!

Tap to zoom

ID: 60381

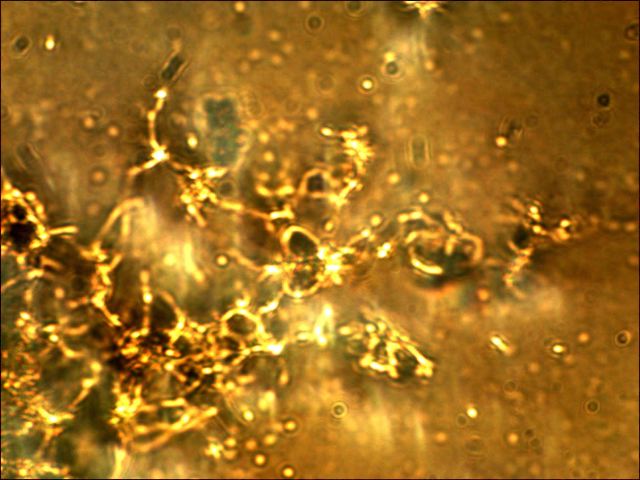

Trinocular with DF and BF

Motorized nosepieces

10x eyepieces

50x, 100x, 250x, 500x, 1000x NPL Plan

6" stage XYZ

5 mega pixel camera/video plus software

Can measure at less than micron level

Can measure exact distance between micron objects.

LEITZ Ergolux Mask & Wafer Inspection Equipment is a state-of-the-art machine that is used to inspect masks and wafers in manufacturing and scientific applications. The system employs advanced optical technologies to accurately and precisely measure the various characteristics of a wide range of mask and wafer types. The optical metrology unit provides unparalleled accuracy and rapid data analysis of the inspected surfaces. The fast and easy operation of the machine makes it ideal for use in high-volume production as well as research and development environments. Ergolux Mask & Wafer Inspection Tool is composed of a base unit with integrated optics and a spatial light modulator (SLM). The SLM contains the necessary components to measure and analyze the surface of the mask or wafer. This includes a laser light source, a polarizing beam splitter, and detection optics. The base unit contains the necessary CPUs, DSPs, and other hardware for operating the asset. The model is able to detect and measure surface features that are often too small for traditional methods, such as optical microscopes. It provides data on a wide range of parameters such as profile, out-of-plane displacement, surface roughness, reflectance, transmission, and structural characteristics. The equipment is equipped with advanced data analysis and visualization capabilities, allowing operators to quickly make meaningful interpretations of the results. LEITZ Ergolux Mask & Wafer Inspection System is capable of performing a variety of measurements. These include surface texture, film thickness, stress, sidewall angle, flatness rating, material composition, profile, out-of-plane displacement, and more. The optical unit is configured with an active focusing algorithm to ensure focused images from a range of heights. The ergonomic design of the machine is tailored to ensure operators can work comfortably for extended periods. Ergolux Mask & Wafer Inspection Tool is designed to provide detailed, accurate, and repeatable data analysis that is unbiased and reliable. The exceptional performance of the asset ensures reliable and repeatable results. The machine also comes with comprehensive software control options and comprehensive model documentation, making integration into automation systems easy and secure. LEITZ Ergolux Mask & Wafer Inspection Equipment is the perfect choice for any application needing reliable and accurate inspection of a variety of masks and wafers. With its advanced optical technologies, ease of operation, and ergonomic design, the system provides users with an efficient and powerful tool for producing accurate and repeatable results.

There are no reviews yet