Used MCBAIN SYSTEMS DDR-300 NIR #9169499 for sale

URL successfully copied!

Tap to zoom

ID: 9169499

Wafer Size: 8"-12"

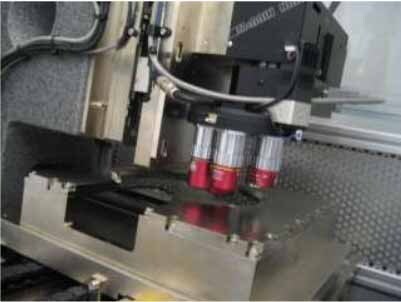

SWIR Inspection system, 8"-12"

Defect detection review for SWIR

Fully automated

Single cassette 8” wafer loader

Unloader with 4 axis robot

Pre-aligner

Wafer cassette mapping

Under / Over OCR cameras

Objectives: 5x, 10x, 20x, 50x

Camera sensor in-GaAs: 900nm - 1700nm sensitivity

Inspection applications:

For in-process, post-process and failure analysis

Bonded wafer alignment

Die alignment (flip-chip or hybridization)

Subsurface defect visualization, detection, characterization

MEMS Device inspection and metrology

3D Stacking process development and control

Integrated CD / dimensional metrology functions

Features:

Extensive defect detection features and capability

Integrated dimensional metrology features

Sub micron-precision optical measurements

High-accuracy staging to 20 nm linear encoder resolution

Highest resolution: 900-1700 nm in GaAs digital camera in class

High-speed linear servo motor staging

50-500 Defects / measurement / second per field of view

Multiple wafer / die / part handling systems

Application-specific customization software

Semi standard S2/S8 compliant.

MCBAIN SYSTEMS DDR-300 NIR is a mask & wafer inspection system that offers high-precision automated defect detection, classification, and mapping for all incident layers of a mask or wafer. Using Near Infrared (NIR) non-destructive techniques, it is capable of detecting defects at a sub-wavelength level of 0.13 microns. The NIR integrated technology works by illuminating samples with a range of NIR light, which is then analyzed by a specialized charge-coupled device (CCD) to detect and localize defect signatures. DDR-300 NIR system provides a complete set of wafer inspection capabilities, including automated detection and characterization for wafer defects, electromigration, process integration, and CD measurement. It also offers full software integration with MCBAIN's Focalpoint Suite, which provides wafer inspection, integration, and image processing capabilities for finer resolution imaging. Along with defect detection, MCBAIN SYSTEMS DDR-300 NIR also provides comprehensive metrology capabilities, such as surface analysis, overlay, BDQ (Bias Dependent Quantum-Leap) correction, and more. DDR-300 NIR offers flexible configuration options, such as a precision multi-axis stage, which provides the highest level of precision. It also comes with a range of detector and imaging options, including: pixel-pitch in-focus and off-focus detectors, multi-camera imaging options for increased defect coverage, and state-of-the-art software algorithms. It also features an area- and line-scanning stages for maximum defect coverage. MCBAIN SYSTEMS DDR-300 NIR also offers user-friendly operation. It integrates a QWERTY membrane touch-pad, and a 16-inch color LCD monitor provides clear visibility of defect analyses. The convenience of the user interface reduces user fatigue, enabling users to easily identify and locate defects, even on hard to reach areas of the surface. Overall, DDR-300 NIR is a reliable system that has complete and reliable non-destructive techniques to identify wafer defects with 0.13 micron resolution and comprehensive capability in defect detection, characterization, and mapping. It is ideal for producing high-quality and reliable products that meet customer requirements and industry standards.

There are no reviews yet