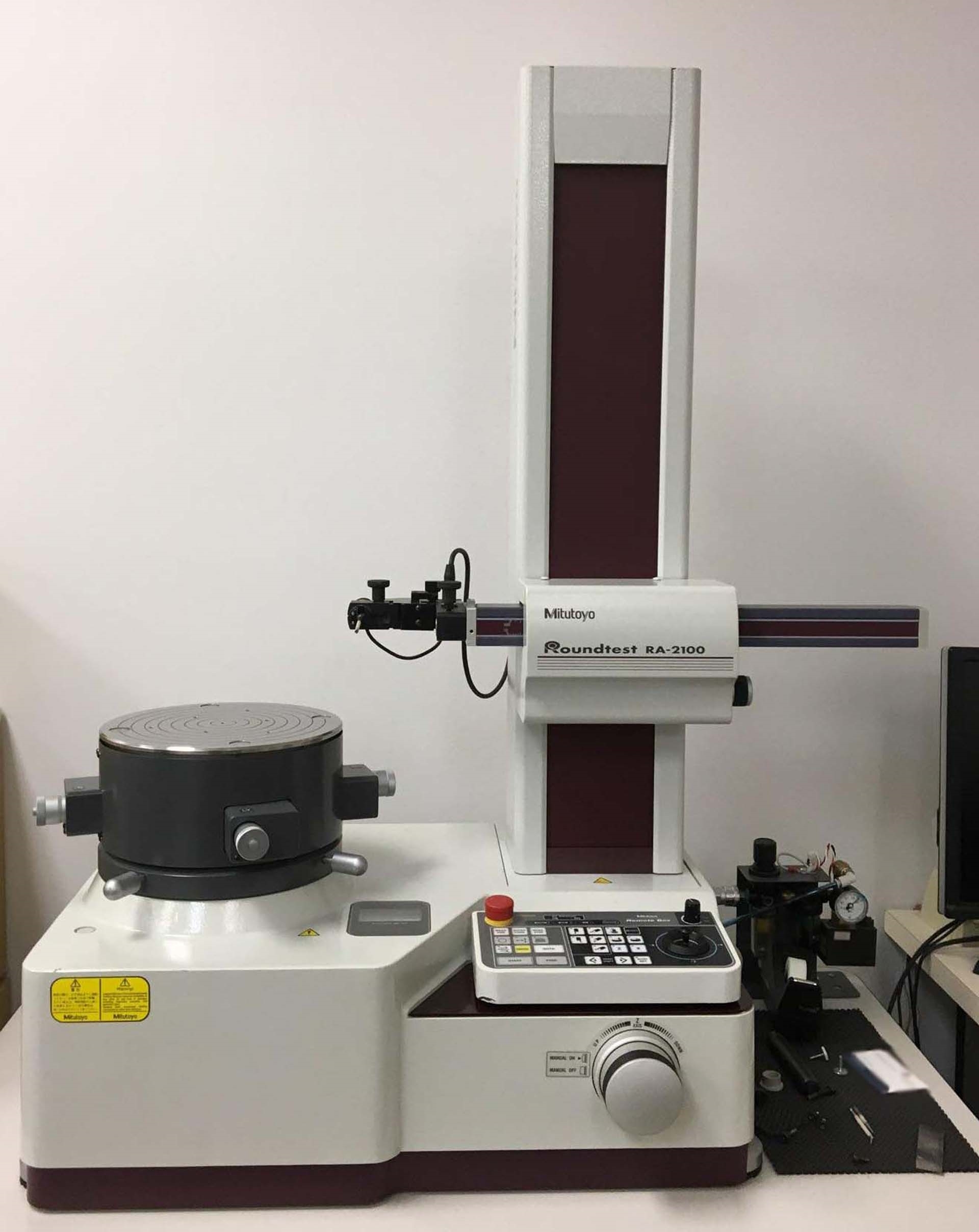

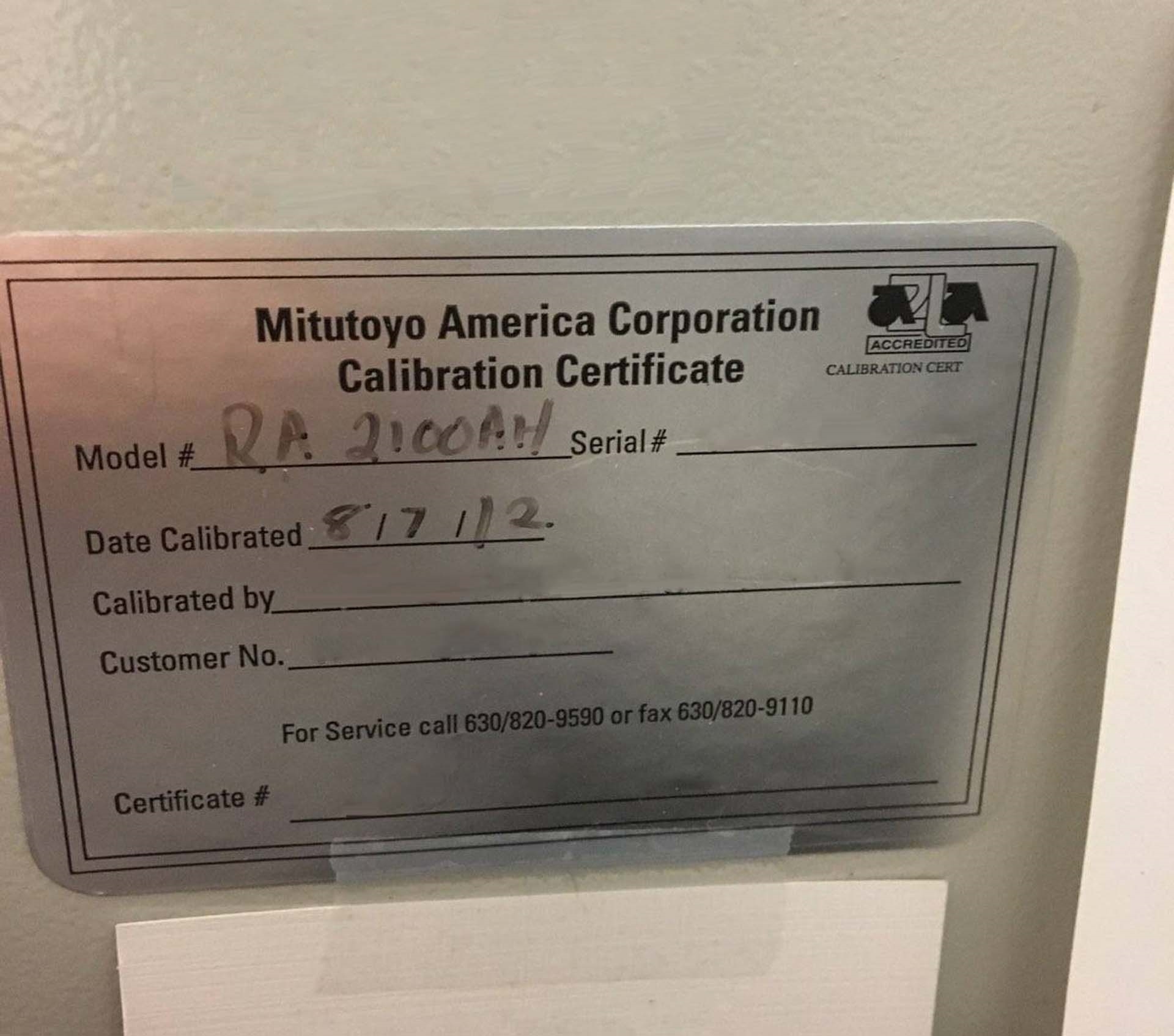

Used MITUTOYO RA 2100AH #9229616 for sale

URL successfully copied!

Tap to zoom

MITUTOYO RA 2100AH is an automated mask & wafer inspection equipment that provides unparalleled capabilities for defect detection. It features a multi-sensor architecture with a host of sophisticated optical and beam-based imaging techniques. This architecture enables the system to detect both surface and subsurface defects with exceptional sensitivity and accuracy. The unit is equipped with a Multi-Sensor Imaging Machine (MSIS) which includes color camera, backlight, a rear-illumination tool, autofocus, and an X-ray source. This imaging asset is used to capture both high-contrast defects and low-contrast imperfections. In addition, it is equipped with a pulsed beam model for automated defect selection. This equipment can be used to detect subtle surface contaminants such as pits, particles, scratches, and voids. Furthermore, the system utilizes a 3D printing module and an automated alignment unit to produce high-resolution masks and wafers. RA 2100AH is also equipped with an advanced defect tracking machine that is capable of tracking defect characteristics in real-time. This tracking tool allows for efficient identification and measurement of defects in order to identify areas of high concentrations and defects which need to be addressed. This asset also features advanced defect identification techniques such as pixel filtering and pattern recognition to distinguish between true and false defects. The model is integrated with advanced control software which is designed for control of the complete inspection process. This software provides a user-friendly graphical interface for easy equipment operation. It also allows users to adjust inspection parameters and measure and monitor the entire process. Finally, MITUTOYO RA 2100AH has advanced data analytics capabilities. This advanced data processing system is used to analyze and generate accurate and detailed statistical reports for each inspection task. The reporting unit is able to track performance and the current quality of the inspection process over time. This generates valuable feedback which can be used to improve process efficiency and defect detection accuracy.

There are no reviews yet