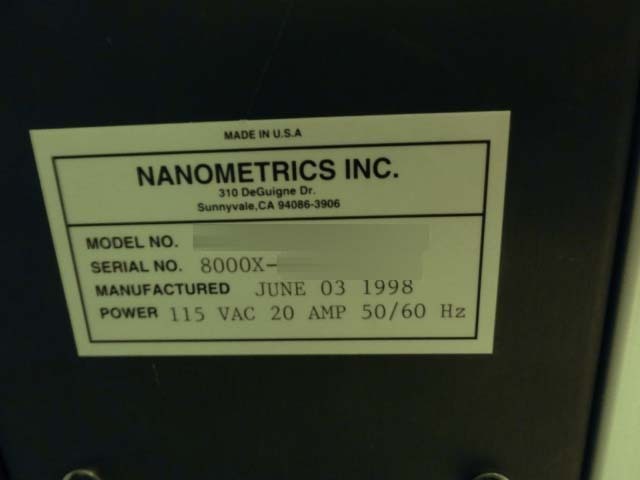

Used NANOMETRICS 8000X #9384489 for sale

URL successfully copied!

Tap to zoom

ID: 9384489

Wafer Size: 6"

Vintage: 1998

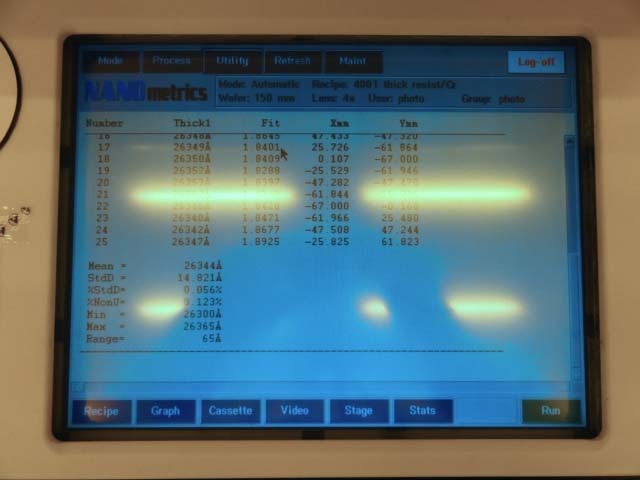

Film thickness measurement systems, 6"

1998 vintage.

NANOMETRICS 8000X is a powerful and efficient mask & wafer inspection equipment. It is designed to provide superior accuracy and measurement resolution, allowing users to detect even the smallest defects on wafers and masks. NANOMETRICS 8000 X, with its patented CCD-based Imaging system, is a powerful and versatile tool. Its advanced optical systems deliver extremely accurate measurement data, including detailed and comprehensive inspection results. The unit's high-accuracy, automated wafer mapping enables accurate alignment checks and defect detection. It is able to detect variations in lithography, particle contamination, foreign materials, and surface defects using nanometer-level resolution. 8000X is controlled by two powerful and integrated hardware controllers, which allow users to precisely control all the processing steps. The motorized reticle stage is designed for automated alignment and traverse mapping. The 8-position turret can accept up to 64 substrate wafers; these can be loaded directly in the turret without requiring any manual intervention. Multi-channel simultaneous metrology processes can be carried out owing to the machine's one-button automated functions. 8000 X also comes with sophisticated software for comprehensive analysis & reporting. This includes pattern recognition, signal filtering & classification, and fast pattern segmentation. It offers advanced data mining capabilities and defect localization features, which enable it to detect extremely small defects on wafers and masks. The tool's data management feature allows easy recall and validation of previous measurements and results. Overall, NANOMETRICS 8000X is an advanced mask & wafer inspection asset that helps users to detect and analyze small defects. It offers exceptional measurement accuracy, cutting-edge features, and a powerful hardware and software combination. Its simple user interface and automated processes enable quick and accurate analysis & reporting. Ultimately, it helps users to improve processing & yield performance across the entire electronics manufacturing process.

There are no reviews yet