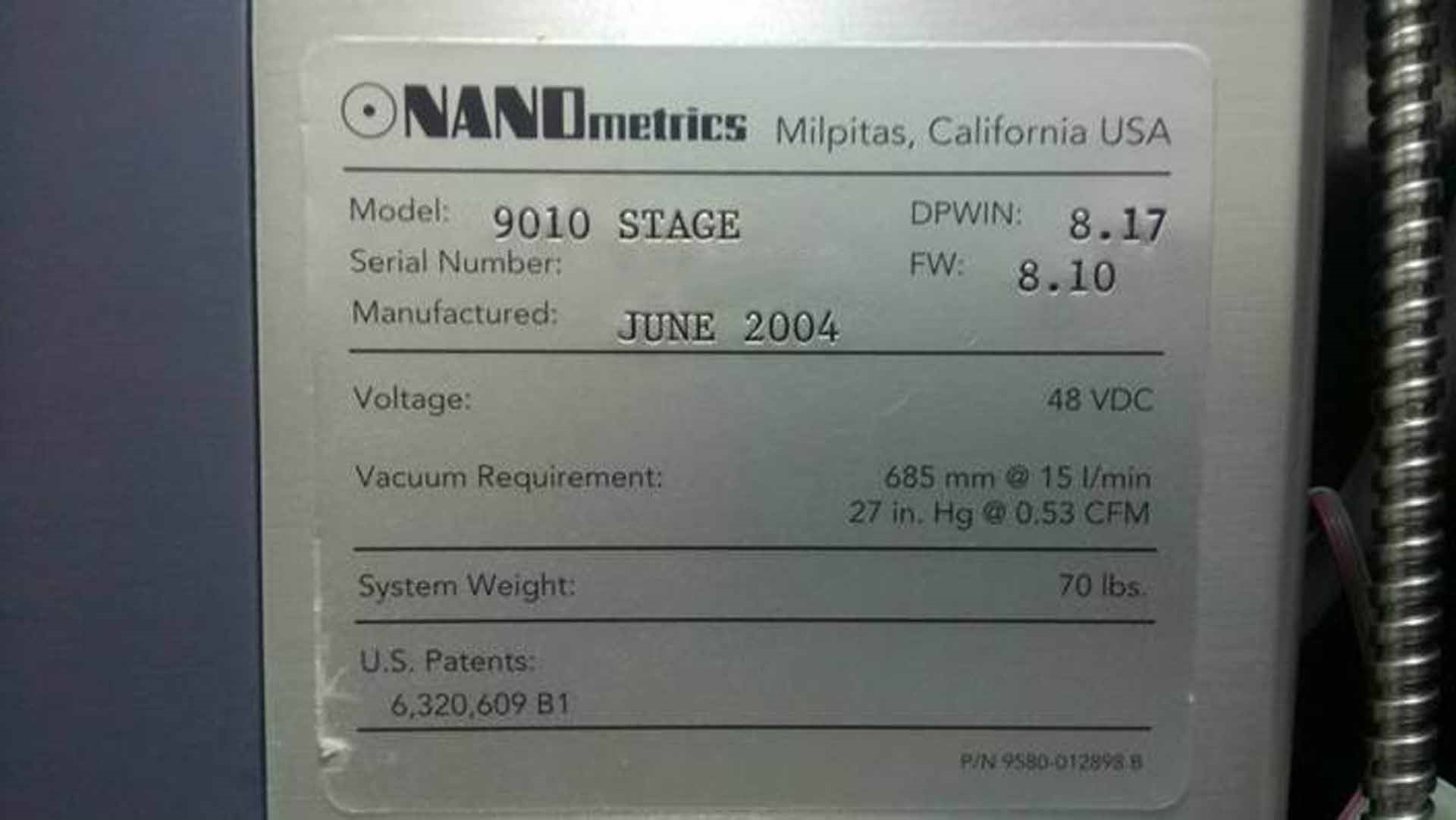

Used NANOMETRICS 9010 #9213384 for sale

URL successfully copied!

Tap to zoom

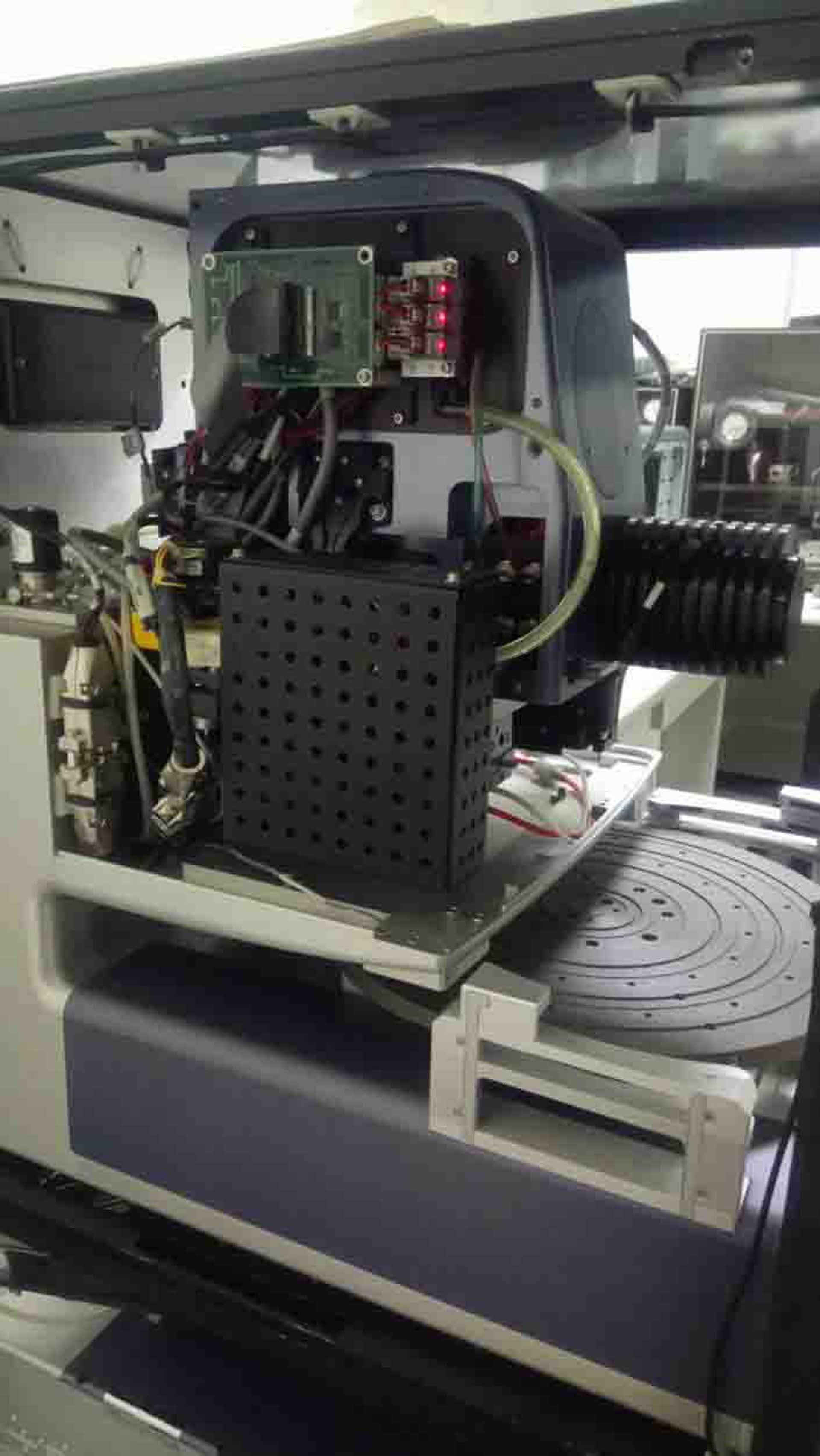

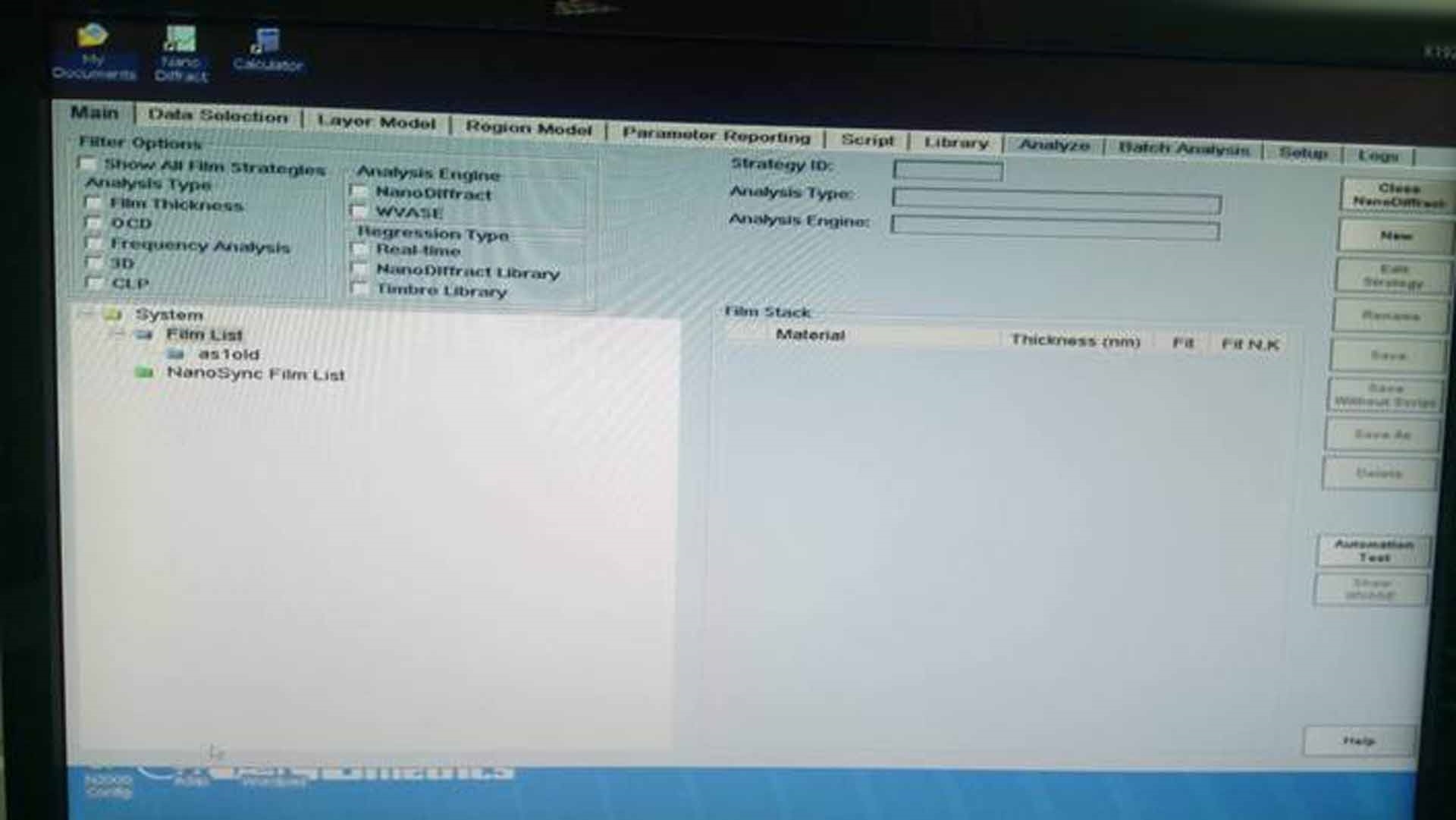

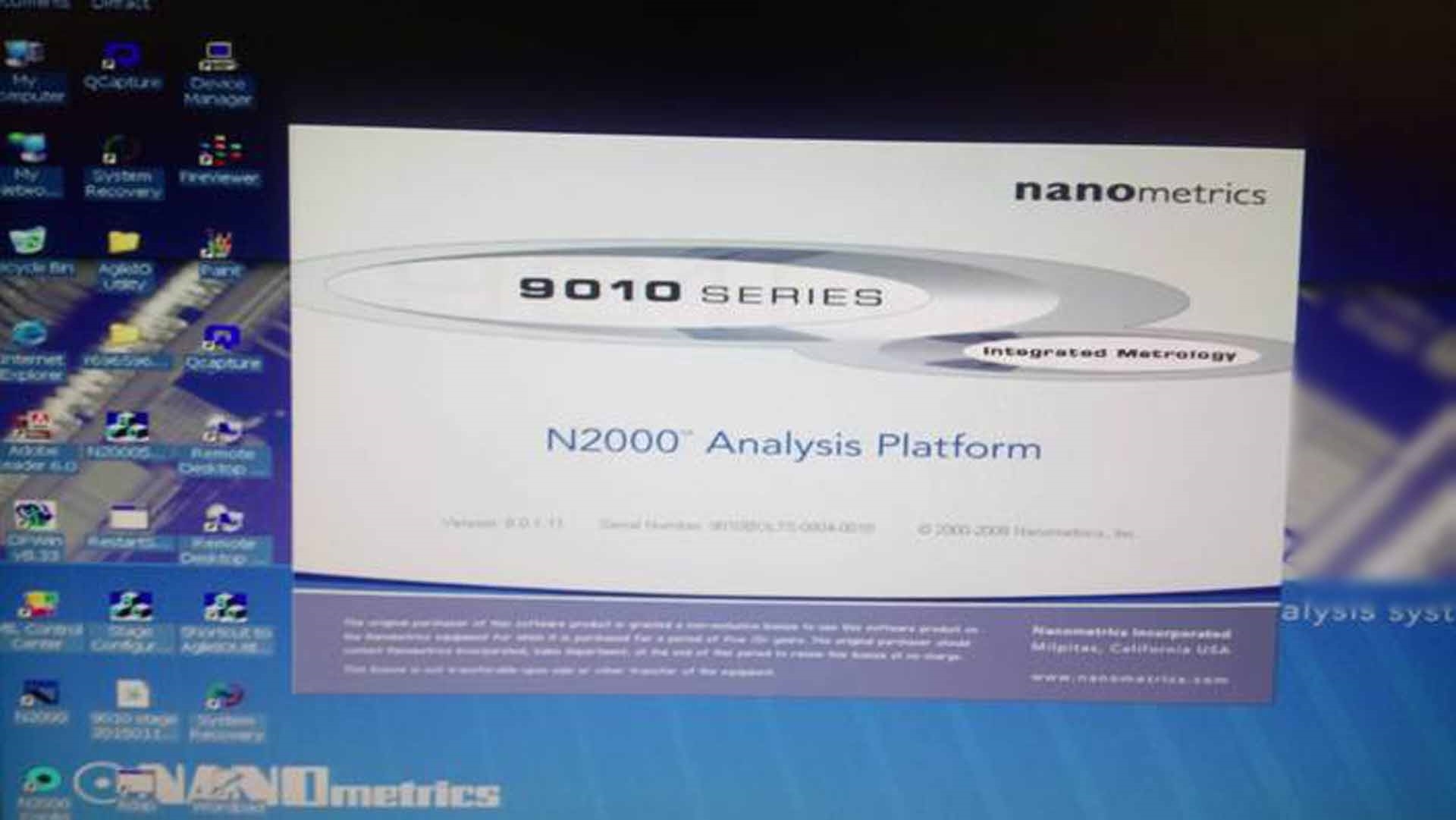

NANOMETRICS 9010 is a high-performance mask and wafer inspection equipment designed for rapid automatic recognition of defects in today's increasingly complex semiconductor manufacturing and research processes. This system utilizes an automated wafer inspection unit with automated software algorithms to scan and analyze production wafers quickly and accurately. 9010 is capable of recognizing various defects and anomalies such as scratches, through-holes, contaminants, and printing defects, improving cycle time, chip yield, and process control. The machine is highly efficient in terms of data acquisition speed and accuracy and features a user-friendly graphical user interface and a variety of automation tools. It is designed to meet the most demanding inspection requirements and combines advanced imaging capabilities with productive scanning technology. The tool comprises an array of digital cameras and sensors arranged in a parallel configuration. The cameras are connected to high-resolution optical filters to capture non-visible parameters such as infrared, ultraviolet, and electron emission at an accuracy greater than 1um. During the inspection process, the asset captures images of each wafer at multiple locations and angles, then compares them to inbuilt standard data. NANOMETRICS 9010 also features advanced pattern recognition technology that enables the detection of even extremely faint defects. This eliminates the need for manual supervision and ensures that errors are eliminated before further production steps are initiated. As a result, any defects detected are caught and resolved quickly and efficiently, optimizing yield and saving time and resources. In conclusion, 9010 mask and wafer inspection model offers a user-friendly interface and powerful imaging capabilities to automate defect detection for improved chip yield and cost savings

There are no reviews yet