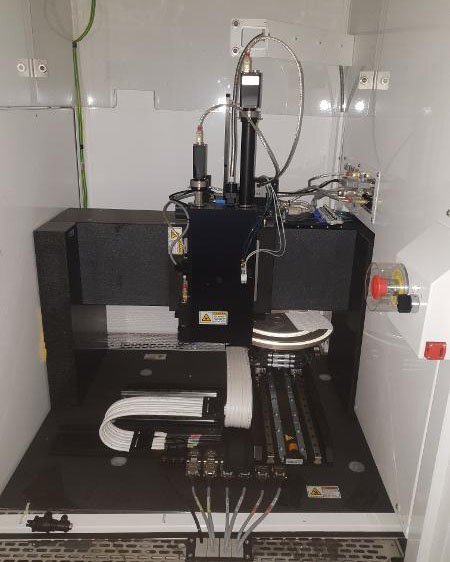

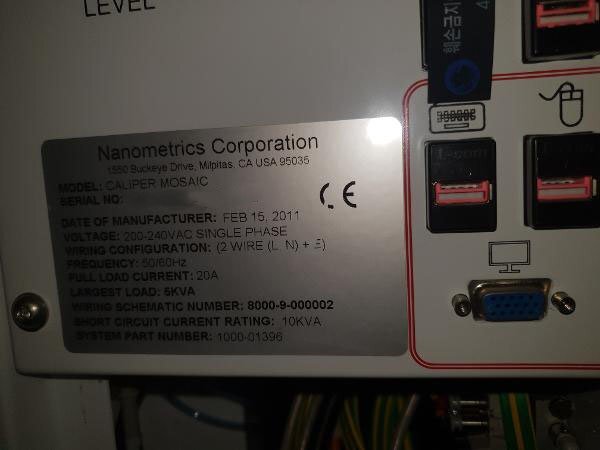

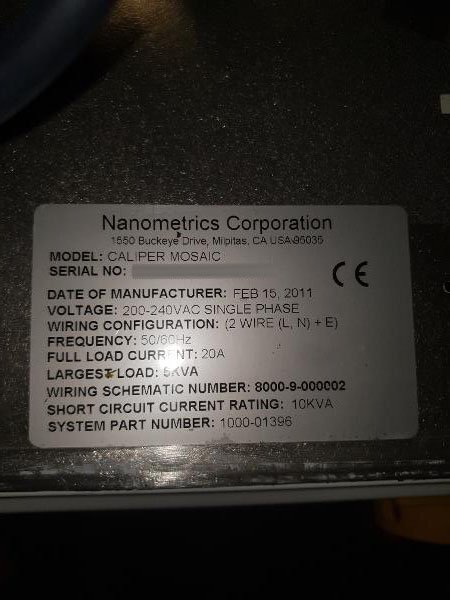

Used NANOMETRICS Caliper Mosaic #9281789 for sale

URL successfully copied!

Tap to zoom

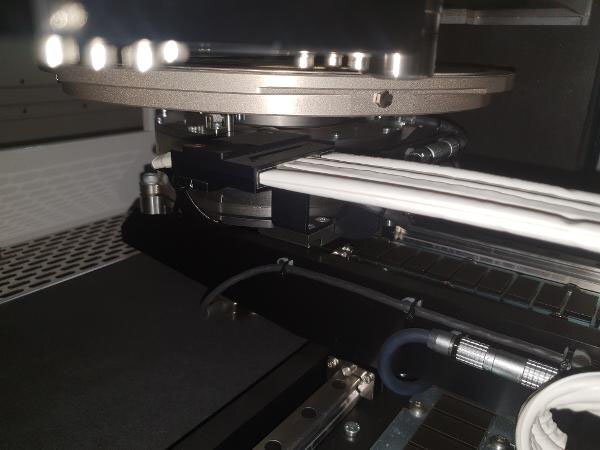

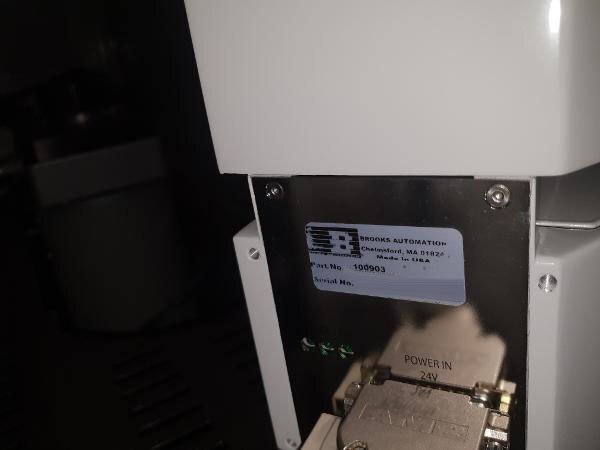

NANOMETRICS Caliper Mosaic is an automated mask and wafer inspection equipment designed to provide a comprehensive and accurate analysis of feature size, critical dimensions, profile, shape, and surface quality on a substructure down to 45 nm. The system includes both Optical Beam Induced Resistance (OBIR) and Optical Beam Induced Current (OBIC) measurement technologies to effectively measure both the critical dimensions (CD) and device topography of small, complex microstructures. The main goal of the unit is to provide fast, accurate and reliable data on semiconductor devices to improve production control and cost reduction. It is equipped with a unique turntable, which encompasses the entire wafer, that allows wafer mapping and deformation analysis. The machine operates on a highly automated scanner with an advanced optical imaging tool that grabs feature image data at high resolution on the mask and wafer. This yields lots of data points to analyze in a wide range of light conditions. The OBIR technology enables measurements on damascene, metal, isolations, and other reflective structures, and OBIC technology is designed to detect small geometries which might not be detectable using OBIR. This combination makes it virtually impossible to miss microstructure defects. Caliper Mosaic asset features an intuitive user interface as well as advanced software capabilities for defect analysis and data reporting. The user interface allows operators to easily set up a job directly from the data log, and to quickly review and confirm measurement results. The software provides the ability to measure across large layout frames without the requirement to measure point-by-point or to export data from measurement software. The model uses customized optics and filters to match the underlying semiconductor material, with the ability to work on asymmetric structures and hidden features. The equipment can also be used to perform multiple inspections concurrently, including sidewall, trench, NMOS, PMOS, and DF routing levels. Beneath the intuitive user interface and advanced software capabilities, NANOMETRICS Caliper Mosaic system features powerful hardware including an advanced optical imaging unit with high dynamic range and larger field of view, along with wettening machine, multiple lasers, and hardware automation to maximize throughput and reduce manual effort. Overall, Caliper Mosaic tool stands out as a reliable and comprehensive automated mask and wafer inspection asset for quick and accurate analysis of feature size, critical dimensions, profile, shape, and surface quality. The model is suitable for advanced semiconductor device fabrication, enabling effective process control and cost reduction.

There are no reviews yet