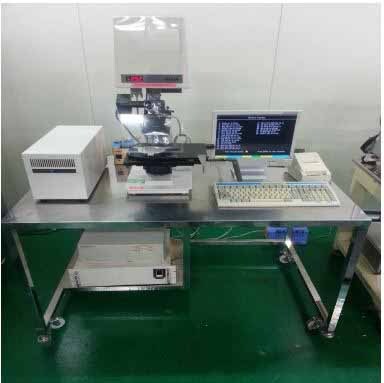

Used NANOMETRICS M-5000 #9159251 for sale

URL successfully copied!

Tap to zoom

ID: 9159251

Wafer Size: 6"

Thin film thickness measurement system, 6"

Operating system: DOS.

NANOMETRICS M-5000 is a mask and wafer inspection equipment designed for high-volume production environments. This automated system provides precise measurements of both defect topography and feature measurements for wafer geometries. The unit utilizes advanced imaging technology to capture detailed images of the wafer, and a fast laser scan head for mapping the defects over large areas. Utilizing an oscillating Y-axis mechanism, and a high speed X-axis stage/mirror, NANOMETRICS M5000 is capable of scanning a single wafer in a single pass, without disruption. This allows for decreased throughput times with superior accuracy. The highly integrated metrology machine offers both dark-field and bright-field imaging for both 2D and 3D image capture, enabling exceptional defect characterization and wafer metrology. M-5000 adopts sophisticated algorithms to analyze the images, and then calculates a variety of defect parameters. An integrated software tool supports the capacity to quickly and accurately measure dimensions, distances and angles of components, plus edge-plotting, scoring and layer-based color contrast. Data collected by the inspection asset is displayed in a comprehensive graphical user interface, providing significant improvement of defect visibility. With its high-resolution camera and integrated measurement tools, M5000 has been shown to enhance customers' manufacturing yield processes. In addition, NANOMETRICS M-5000 includes a range of automated calibration and validation procedures that can be configured for clean-room and non- clean-room shapes of wafers, as well as single and multi-zone contoured/not-contoured wafer surfaces. Furthermore, the advanced imaging capabilities of NANOMETRICS M5000 model enable it to monitor defects, such as flares and beveled defects, in smaller devices. Its intuitive navigation and control equipment helps reduce defect inspection time while increasing defect detection accuracy. This system also helps with defect reporting by generating PDF or tabular reports. Overall, M-5000 is an advanced metrology unit designed and manufactured for high-volume production in the semiconductor industry, providing detailed defect topography and feature measurement capabilities. The machine is highly advanced and provides significant throughput and accuracy benefits that are extremely valuable to production and manufacturing processes.

There are no reviews yet